Role of quantum dot technology in AMOLED display improvements.

JUL 17, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QD-AMOLED Tech Evolution

The evolution of QD-AMOLED technology represents a significant milestone in display technology, combining the advantages of quantum dots (QDs) with Active-Matrix Organic Light-Emitting Diode (AMOLED) displays. This fusion has led to remarkable improvements in color gamut, brightness, and energy efficiency.

The journey began with the introduction of quantum dots in LCD displays, where they were used to enhance color performance. However, the real breakthrough came when researchers started exploring ways to integrate QDs into OLED structures. This integration aimed to overcome some of the limitations of traditional OLED displays, such as color accuracy and longevity issues with blue OLEDs.

Early attempts focused on using QDs as color converters in OLED displays. In this approach, blue OLEDs were used as the primary light source, with red and green QDs converting some of the blue light to their respective colors. This method showed promise in expanding the color gamut but faced challenges in efficiency and manufacturing complexity.

The next significant step was the development of electroluminescent quantum dot light-emitting diodes (QLED). This technology aimed to use QDs as the primary emissive material, potentially offering better efficiency and color purity compared to organic emitters. However, early QLEDs struggled with stability and efficiency, particularly for blue emission.

A major breakthrough came with the introduction of hybrid QD-OLED structures. This approach combines the stability and efficiency of OLED materials with the color purity of QDs. In these displays, blue OLED emitters are used in conjunction with red and green QD color converters, resulting in a display that offers the best of both technologies.

Recent advancements have focused on improving the efficiency and longevity of QD-AMOLED displays. This includes the development of more stable QD materials, better encapsulation techniques to protect QDs from degradation, and improved manufacturing processes to ensure uniform QD distribution and performance across large display areas.

The latest iterations of QD-AMOLED technology are exploring the use of QDs in all three primary colors, including blue. This all-QD approach promises even better color performance and efficiency but requires overcoming significant challenges in blue QD stability and efficiency.

The journey began with the introduction of quantum dots in LCD displays, where they were used to enhance color performance. However, the real breakthrough came when researchers started exploring ways to integrate QDs into OLED structures. This integration aimed to overcome some of the limitations of traditional OLED displays, such as color accuracy and longevity issues with blue OLEDs.

Early attempts focused on using QDs as color converters in OLED displays. In this approach, blue OLEDs were used as the primary light source, with red and green QDs converting some of the blue light to their respective colors. This method showed promise in expanding the color gamut but faced challenges in efficiency and manufacturing complexity.

The next significant step was the development of electroluminescent quantum dot light-emitting diodes (QLED). This technology aimed to use QDs as the primary emissive material, potentially offering better efficiency and color purity compared to organic emitters. However, early QLEDs struggled with stability and efficiency, particularly for blue emission.

A major breakthrough came with the introduction of hybrid QD-OLED structures. This approach combines the stability and efficiency of OLED materials with the color purity of QDs. In these displays, blue OLED emitters are used in conjunction with red and green QD color converters, resulting in a display that offers the best of both technologies.

Recent advancements have focused on improving the efficiency and longevity of QD-AMOLED displays. This includes the development of more stable QD materials, better encapsulation techniques to protect QDs from degradation, and improved manufacturing processes to ensure uniform QD distribution and performance across large display areas.

The latest iterations of QD-AMOLED technology are exploring the use of QDs in all three primary colors, including blue. This all-QD approach promises even better color performance and efficiency but requires overcoming significant challenges in blue QD stability and efficiency.

Market Demand Analysis

The market demand for AMOLED displays enhanced with quantum dot technology has been steadily increasing, driven by the growing consumer appetite for high-quality visual experiences across various devices. This technology offers significant improvements in color accuracy, brightness, and energy efficiency, making it particularly attractive for mobile devices, televisions, and emerging applications in automotive displays and virtual reality headsets.

In the smartphone sector, which represents a substantial portion of the AMOLED market, manufacturers are increasingly adopting quantum dot-enhanced displays to differentiate their premium models. Consumers are showing a strong preference for devices with vibrant, true-to-life colors and improved battery life, both of which are key benefits of quantum dot technology in AMOLED displays.

The television market is another area where quantum dot-enhanced AMOLED displays are gaining traction. As consumers seek larger screens with higher resolutions, the demand for displays that can deliver superior color performance and energy efficiency is rising. This trend is particularly evident in the high-end segment, where picture quality is a crucial differentiator.

Emerging applications in automotive displays present a promising growth area for quantum dot-enhanced AMOLED technology. As vehicles become more technologically advanced and incorporate larger, more sophisticated display systems, the demand for high-performance screens that can maintain visibility in varying light conditions is increasing.

The virtual reality and augmented reality markets are also driving demand for quantum dot-enhanced AMOLED displays. These applications require high-resolution, low-latency displays with excellent color reproduction and energy efficiency to create immersive experiences while minimizing eye strain and extending device battery life.

From a geographical perspective, Asia-Pacific remains the largest market for AMOLED displays, with South Korea and China leading in production and adoption. However, North America and Europe are showing increasing demand, particularly in high-end consumer electronics and automotive applications.

The market for quantum dot-enhanced AMOLED displays is expected to grow significantly in the coming years, driven by technological advancements, decreasing production costs, and expanding applications. As manufacturers continue to invest in research and development, the performance improvements offered by this technology are likely to accelerate its adoption across various industries, further stimulating market demand.

In the smartphone sector, which represents a substantial portion of the AMOLED market, manufacturers are increasingly adopting quantum dot-enhanced displays to differentiate their premium models. Consumers are showing a strong preference for devices with vibrant, true-to-life colors and improved battery life, both of which are key benefits of quantum dot technology in AMOLED displays.

The television market is another area where quantum dot-enhanced AMOLED displays are gaining traction. As consumers seek larger screens with higher resolutions, the demand for displays that can deliver superior color performance and energy efficiency is rising. This trend is particularly evident in the high-end segment, where picture quality is a crucial differentiator.

Emerging applications in automotive displays present a promising growth area for quantum dot-enhanced AMOLED technology. As vehicles become more technologically advanced and incorporate larger, more sophisticated display systems, the demand for high-performance screens that can maintain visibility in varying light conditions is increasing.

The virtual reality and augmented reality markets are also driving demand for quantum dot-enhanced AMOLED displays. These applications require high-resolution, low-latency displays with excellent color reproduction and energy efficiency to create immersive experiences while minimizing eye strain and extending device battery life.

From a geographical perspective, Asia-Pacific remains the largest market for AMOLED displays, with South Korea and China leading in production and adoption. However, North America and Europe are showing increasing demand, particularly in high-end consumer electronics and automotive applications.

The market for quantum dot-enhanced AMOLED displays is expected to grow significantly in the coming years, driven by technological advancements, decreasing production costs, and expanding applications. As manufacturers continue to invest in research and development, the performance improvements offered by this technology are likely to accelerate its adoption across various industries, further stimulating market demand.

QD-AMOLED Challenges

Despite the promising potential of QD-AMOLED technology, several significant challenges hinder its widespread adoption and commercialization. These challenges span across technical, manufacturing, and economic domains, requiring concerted efforts from researchers, manufacturers, and industry stakeholders to overcome.

One of the primary technical challenges is the stability and longevity of quantum dots in AMOLED displays. Quantum dots are susceptible to degradation when exposed to oxygen, moisture, and high temperatures, which can lead to a decrease in luminescence efficiency and color shift over time. This degradation not only affects the display quality but also shortens the overall lifespan of the device, making it less attractive for consumers and manufacturers alike.

Another critical challenge lies in the precise control of quantum dot size and uniformity during the manufacturing process. The emission wavelength of quantum dots is directly related to their size, and even minor variations can result in significant color discrepancies across the display. Achieving consistent and uniform quantum dot sizes at scale remains a formidable task, requiring advanced manufacturing techniques and stringent quality control measures.

The integration of quantum dots into the existing AMOLED architecture presents its own set of challenges. Ensuring efficient energy transfer from the OLED emitters to the quantum dots while maintaining the thin-film structure of AMOLED displays is a complex engineering problem. This integration must be achieved without compromising the flexibility and form factor advantages that AMOLED technology offers.

From a manufacturing perspective, scaling up production of QD-AMOLED displays while maintaining cost-effectiveness is a significant hurdle. The current processes for synthesizing high-quality quantum dots and incorporating them into display panels are complex and expensive. Developing more efficient and economical manufacturing methods is crucial for making QD-AMOLED technology commercially viable and competitive with existing display technologies.

Environmental and health concerns associated with certain types of quantum dots, particularly those containing heavy metals like cadmium, pose regulatory and consumer acceptance challenges. While efforts are being made to develop cadmium-free quantum dots, ensuring their performance matches that of cadmium-based alternatives remains an ongoing challenge.

Lastly, the economic viability of QD-AMOLED technology in the face of established and emerging display technologies presents a market challenge. Manufacturers must balance the improved color performance and energy efficiency of QD-AMOLED against its higher production costs and the need for significant investment in new manufacturing infrastructure. Convincing consumers of the value proposition of QD-AMOLED displays in a competitive market is crucial for its success.

One of the primary technical challenges is the stability and longevity of quantum dots in AMOLED displays. Quantum dots are susceptible to degradation when exposed to oxygen, moisture, and high temperatures, which can lead to a decrease in luminescence efficiency and color shift over time. This degradation not only affects the display quality but also shortens the overall lifespan of the device, making it less attractive for consumers and manufacturers alike.

Another critical challenge lies in the precise control of quantum dot size and uniformity during the manufacturing process. The emission wavelength of quantum dots is directly related to their size, and even minor variations can result in significant color discrepancies across the display. Achieving consistent and uniform quantum dot sizes at scale remains a formidable task, requiring advanced manufacturing techniques and stringent quality control measures.

The integration of quantum dots into the existing AMOLED architecture presents its own set of challenges. Ensuring efficient energy transfer from the OLED emitters to the quantum dots while maintaining the thin-film structure of AMOLED displays is a complex engineering problem. This integration must be achieved without compromising the flexibility and form factor advantages that AMOLED technology offers.

From a manufacturing perspective, scaling up production of QD-AMOLED displays while maintaining cost-effectiveness is a significant hurdle. The current processes for synthesizing high-quality quantum dots and incorporating them into display panels are complex and expensive. Developing more efficient and economical manufacturing methods is crucial for making QD-AMOLED technology commercially viable and competitive with existing display technologies.

Environmental and health concerns associated with certain types of quantum dots, particularly those containing heavy metals like cadmium, pose regulatory and consumer acceptance challenges. While efforts are being made to develop cadmium-free quantum dots, ensuring their performance matches that of cadmium-based alternatives remains an ongoing challenge.

Lastly, the economic viability of QD-AMOLED technology in the face of established and emerging display technologies presents a market challenge. Manufacturers must balance the improved color performance and energy efficiency of QD-AMOLED against its higher production costs and the need for significant investment in new manufacturing infrastructure. Convincing consumers of the value proposition of QD-AMOLED displays in a competitive market is crucial for its success.

Current QD Solutions

01 Improved quantum dot composition

Advancements in quantum dot composition, including novel materials and structures, lead to enhanced optical properties, improved stability, and increased efficiency in display applications. These improvements result in better color reproduction, brightness, and overall display performance.- Improved quantum dot composition: Advancements in quantum dot composition focus on enhancing the stability, efficiency, and color purity of displays. This includes developing new materials, optimizing the size and shape of quantum dots, and improving their surface properties to increase luminescence and reduce degradation over time.

- Enhanced quantum dot film structure: Innovations in quantum dot film structure aim to improve light extraction, color conversion efficiency, and overall display performance. This involves developing multi-layer structures, optimizing the arrangement of quantum dots within the film, and incorporating light-scattering elements to enhance brightness and viewing angles.

- Integration of quantum dots in display backlight systems: Advancements in integrating quantum dots into display backlight systems focus on improving color gamut, energy efficiency, and overall display quality. This includes developing new backlight unit designs, optimizing the placement of quantum dot layers, and enhancing light management techniques to maximize the benefits of quantum dot technology.

- Quantum dot-enhanced OLED displays: Combining quantum dots with OLED technology aims to create displays with improved color accuracy, brightness, and energy efficiency. This involves developing hybrid structures that leverage the strengths of both technologies, optimizing charge transfer between quantum dots and OLED materials, and enhancing overall device performance.

- Manufacturing and process improvements for quantum dot displays: Advancements in manufacturing processes and techniques for quantum dot displays focus on improving yield, reducing costs, and enhancing overall product quality. This includes developing new deposition methods, optimizing patterning techniques, and implementing quality control measures to ensure consistent performance across large-scale production.

02 Enhanced quantum dot film structure

Innovations in quantum dot film structure, such as multi-layer designs and optimized arrangements, improve light extraction, reduce optical losses, and enhance color purity. These advancements contribute to better display quality and energy efficiency.Expand Specific Solutions03 Integration of quantum dots in display backlight systems

Novel approaches to integrating quantum dots into display backlight systems, including on-chip solutions and advanced light guide designs, lead to improved color gamut, reduced power consumption, and enhanced overall display performance.Expand Specific Solutions04 Quantum dot color conversion layers

Development of advanced quantum dot color conversion layers for displays, including patterning techniques and novel deposition methods, results in improved color accuracy, wider color gamut, and enhanced display brightness.Expand Specific Solutions05 Quantum dot-enhanced OLED displays

Integration of quantum dots with OLED technology leads to hybrid display solutions that combine the advantages of both technologies. This results in improved color purity, extended device lifetime, and enhanced energy efficiency in display applications.Expand Specific Solutions

Key Industry Players

The quantum dot technology in AMOLED displays is in a growth phase, with increasing market size and advancing technical maturity. Major players like Samsung Display, LG Display, and BOE Technology are driving innovation in this field. The market is expanding as quantum dots enhance color accuracy and energy efficiency in displays. While the technology is progressing rapidly, it is not yet fully mature, with ongoing research and development efforts by companies such as Apple and TCL China Star Optoelectronics. The competitive landscape is characterized by a mix of established display manufacturers and emerging tech firms, all vying to perfect and commercialize quantum dot-enhanced AMOLED displays for various applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has been actively developing quantum dot technology for AMOLED displays, focusing on large-scale applications such as TVs and monitors. Their approach involves using inkjet-printed quantum dots combined with blue OLED backplanes. This method allows for precise deposition of quantum dots, resulting in improved color uniformity across large panels. BOE's quantum dot AMOLED technology has demonstrated a color gamut coverage of up to 114% NTSC[6]. The company has also made progress in reducing the size of quantum dots, achieving an average particle size of less than 10 nm, which contributes to higher efficiency and longer lifespan of the displays[7].

Strengths: Expertise in large-scale display production; Advanced inkjet printing technology for quantum dots; High color gamut coverage. Weaknesses: Less experience in small form factor displays; Potential challenges in scaling down technology for mobile devices.

Apple, Inc.

Technical Solution: Apple has been exploring quantum dot technology to enhance its AMOLED displays in iPhones and other devices. Their approach focuses on using quantum dots as color conversion layers on top of blue OLED emitters. This allows for more precise color control and improved energy efficiency. Apple's research indicates potential for up to 20% reduction in power consumption while maintaining or improving color accuracy[4]. The company is also investigating hybrid quantum dot-OLED structures to create flexible and foldable displays with enhanced durability[5].

Strengths: Potential for significant power savings; Improved color accuracy in mobile displays; Compatibility with flexible display technology. Weaknesses: Still in research phase for many applications; Challenges in mass production for mobile devices.

QD-AMOLED Innovations

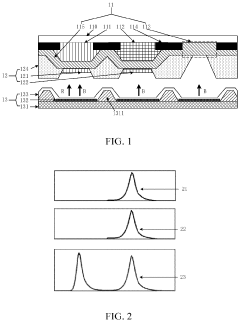

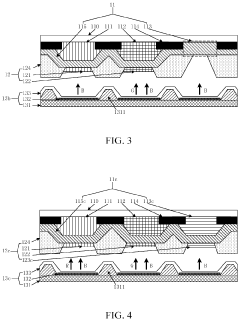

Quantum dot organic light emitting diode display panel

PatentActiveUS20210066629A1

Innovation

- The QD-OLED display panel incorporates a color filter with a color resist layer and an isolating layer, a quantum dot photo-transfer film with red and green quantum dot materials, and an OLED array substrate with a blue light source and a color-mixture light source. The color-mixture light source, comprising blue and red or green light, triggers the quantum dots to emit red and green light, respectively, improving brightness and efficiency while prolonging the panel's lifetime.

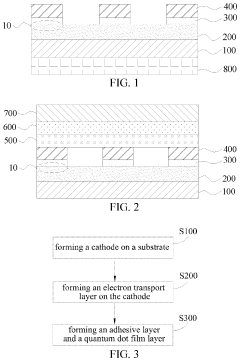

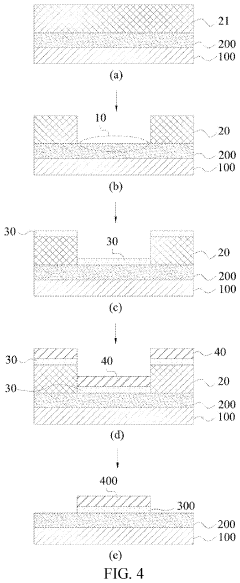

Quantum Dot Light-Emitting Device, Manufacturing Method and Display Device

PatentActiveUS20240065019A1

Innovation

- A quantum dot light-emitting device is designed with an adhesive layer connected to the electron transport layer through chemical bonding or physical entanglement, using materials like silane or avidin, which enhances the adhesion force between the quantum dot film and electron transport layers, preventing peeling and improving display quality.

QD Material Advances

Quantum dot (QD) technology has undergone significant advancements in recent years, particularly in its application to AMOLED displays. The development of new QD materials has been a key driver in improving display performance and efficiency.

One of the most notable advances in QD materials has been the refinement of cadmium-free quantum dots. These environmentally friendly alternatives have addressed concerns about toxicity while maintaining high color purity and efficiency. Indium phosphide-based quantum dots have emerged as a leading candidate, offering a wide color gamut and improved stability compared to their cadmium-based counterparts.

Another significant development has been the creation of quantum dots with enhanced thermal stability. Traditional QDs often suffered from degradation at high temperatures, limiting their longevity in display applications. New core-shell structures and surface treatments have been developed to mitigate this issue, allowing QDs to maintain their optical properties even under prolonged exposure to heat.

The size control of quantum dots has also seen remarkable progress. Researchers have developed methods to produce QDs with extremely narrow size distributions, resulting in more precise color emission and improved overall display quality. This level of control has been achieved through advancements in synthesis techniques, including hot-injection methods and continuous flow reactors.

Efforts to improve the quantum yield of QDs have led to materials with significantly higher efficiency. This has been accomplished through the optimization of surface ligands and the development of multi-shell structures that minimize non-radiative recombination processes. As a result, QD-enhanced displays can achieve higher brightness levels while consuming less power.

The integration of QDs into display manufacturing processes has also seen substantial improvements. New encapsulation techniques have been developed to protect QDs from moisture and oxygen, extending their operational lifetime. Additionally, advancements in patterning technologies have enabled more precise placement of QDs within display pixels, leading to enhanced color accuracy and resolution.

Perovskite quantum dots have emerged as a promising new class of materials for display applications. These QDs offer exceptional color purity and can be synthesized using low-cost solution processing methods. While stability remains a challenge, rapid progress is being made in addressing this issue through compositional engineering and surface passivation techniques.

One of the most notable advances in QD materials has been the refinement of cadmium-free quantum dots. These environmentally friendly alternatives have addressed concerns about toxicity while maintaining high color purity and efficiency. Indium phosphide-based quantum dots have emerged as a leading candidate, offering a wide color gamut and improved stability compared to their cadmium-based counterparts.

Another significant development has been the creation of quantum dots with enhanced thermal stability. Traditional QDs often suffered from degradation at high temperatures, limiting their longevity in display applications. New core-shell structures and surface treatments have been developed to mitigate this issue, allowing QDs to maintain their optical properties even under prolonged exposure to heat.

The size control of quantum dots has also seen remarkable progress. Researchers have developed methods to produce QDs with extremely narrow size distributions, resulting in more precise color emission and improved overall display quality. This level of control has been achieved through advancements in synthesis techniques, including hot-injection methods and continuous flow reactors.

Efforts to improve the quantum yield of QDs have led to materials with significantly higher efficiency. This has been accomplished through the optimization of surface ligands and the development of multi-shell structures that minimize non-radiative recombination processes. As a result, QD-enhanced displays can achieve higher brightness levels while consuming less power.

The integration of QDs into display manufacturing processes has also seen substantial improvements. New encapsulation techniques have been developed to protect QDs from moisture and oxygen, extending their operational lifetime. Additionally, advancements in patterning technologies have enabled more precise placement of QDs within display pixels, leading to enhanced color accuracy and resolution.

Perovskite quantum dots have emerged as a promising new class of materials for display applications. These QDs offer exceptional color purity and can be synthesized using low-cost solution processing methods. While stability remains a challenge, rapid progress is being made in addressing this issue through compositional engineering and surface passivation techniques.

QD Manufacturing Process

The manufacturing process of quantum dots (QDs) for AMOLED displays involves several sophisticated steps, each crucial for producing high-quality, uniform nanocrystals. The process typically begins with the synthesis of QDs through colloidal chemistry methods. Precursor materials, such as cadmium selenide or indium phosphide, are combined in a high-temperature reaction vessel under controlled conditions. The size and composition of the QDs are carefully regulated by adjusting parameters like temperature, reaction time, and precursor ratios.

Following synthesis, the QDs undergo a purification process to remove excess reactants and byproducts. This often involves centrifugation and washing steps with organic solvents. The purified QDs are then subjected to a surface modification process, where ligands are attached to the nanocrystal surface. These ligands play a vital role in stabilizing the QDs and enhancing their compatibility with the host matrix in AMOLED displays.

The next critical step is the encapsulation of QDs. This process involves embedding the nanocrystals in a protective matrix, typically a polymer or inorganic material. Encapsulation serves multiple purposes: it shields the QDs from environmental factors like oxygen and moisture, prevents aggregation, and facilitates integration into display devices. Advanced techniques such as microencapsulation or on-chip fabrication may be employed to achieve precise control over QD distribution and alignment.

Quality control is an integral part of the manufacturing process. Sophisticated characterization techniques, including spectroscopy and electron microscopy, are used to assess the optical properties, size distribution, and structural integrity of the QDs. Stringent quality standards are enforced to ensure consistency and performance in AMOLED applications.

The final stages of QD manufacturing for AMOLED displays involve integration into the display structure. This may include incorporating the QDs into color conversion layers or directly into the emissive layers of the OLED stack. Advanced deposition techniques, such as inkjet printing or photolithography, are often employed to achieve precise patterning and placement of QDs within the display architecture.

Throughout the manufacturing process, maintaining a clean, controlled environment is paramount. Many steps are conducted in cleanroom facilities to minimize contamination and ensure the highest quality of QDs for AMOLED display applications. The entire process requires a delicate balance of chemical precision, advanced engineering, and rigorous quality control to produce QDs that can significantly enhance the color performance and efficiency of AMOLED displays.

Following synthesis, the QDs undergo a purification process to remove excess reactants and byproducts. This often involves centrifugation and washing steps with organic solvents. The purified QDs are then subjected to a surface modification process, where ligands are attached to the nanocrystal surface. These ligands play a vital role in stabilizing the QDs and enhancing their compatibility with the host matrix in AMOLED displays.

The next critical step is the encapsulation of QDs. This process involves embedding the nanocrystals in a protective matrix, typically a polymer or inorganic material. Encapsulation serves multiple purposes: it shields the QDs from environmental factors like oxygen and moisture, prevents aggregation, and facilitates integration into display devices. Advanced techniques such as microencapsulation or on-chip fabrication may be employed to achieve precise control over QD distribution and alignment.

Quality control is an integral part of the manufacturing process. Sophisticated characterization techniques, including spectroscopy and electron microscopy, are used to assess the optical properties, size distribution, and structural integrity of the QDs. Stringent quality standards are enforced to ensure consistency and performance in AMOLED applications.

The final stages of QD manufacturing for AMOLED displays involve integration into the display structure. This may include incorporating the QDs into color conversion layers or directly into the emissive layers of the OLED stack. Advanced deposition techniques, such as inkjet printing or photolithography, are often employed to achieve precise patterning and placement of QDs within the display architecture.

Throughout the manufacturing process, maintaining a clean, controlled environment is paramount. Many steps are conducted in cleanroom facilities to minimize contamination and ensure the highest quality of QDs for AMOLED display applications. The entire process requires a delicate balance of chemical precision, advanced engineering, and rigorous quality control to produce QDs that can significantly enhance the color performance and efficiency of AMOLED displays.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!