Testing Conformal Coating in Salt Fog Chambers: Protocols

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conformal Coating Testing Background and Objectives

Conformal coating technology has evolved significantly over the past five decades, transitioning from simple protective layers to sophisticated engineered materials designed to shield electronic components from harsh environmental conditions. Initially developed for military and aerospace applications in the 1960s, these coatings have become essential in numerous industries including automotive, consumer electronics, medical devices, and industrial control systems. The evolution of conformal coating materials has progressed from basic acrylic and silicone formulations to advanced hybrid polymers with specialized properties tailored to specific environmental challenges.

Salt fog testing represents one of the most critical evaluation protocols for conformal coatings, simulating accelerated corrosive conditions that electronic assemblies might encounter during their operational lifetime. This testing methodology originated from military standards but has since been adopted and refined by various international standardization bodies including IPC, IEC, and ASTM. The primary objective of salt fog testing is to evaluate the protective efficacy of conformal coatings against corrosion, electrical leakage, and physical degradation under extreme saline conditions.

Current technological objectives in conformal coating testing focus on developing standardized protocols that accurately predict real-world performance while accommodating the increasing miniaturization and complexity of modern electronic assemblies. There is growing emphasis on establishing correlations between accelerated testing results and actual field performance, particularly for emerging applications in harsh environments such as offshore wind farms, electric vehicles, and IoT devices deployed in coastal regions.

The industry is witnessing a paradigm shift from purely qualitative visual assessments toward quantitative measurement methodologies that incorporate advanced analytical techniques. These include impedance spectroscopy, 3D optical scanning, and chemical composition analysis to detect subtle degradation mechanisms that might not be apparent through traditional inspection methods. This evolution reflects the increasing reliability requirements for electronic systems in critical applications where failure is not an option.

Another significant objective is the harmonization of testing protocols across different industries and geographical regions to facilitate global supply chain integration and regulatory compliance. This includes efforts to align salt fog testing parameters, acceptance criteria, and reporting formats to enable meaningful comparisons between different coating technologies and formulations. The ultimate goal is to establish predictive models that can accurately forecast coating performance under various environmental conditions, reducing development cycles and improving product reliability.

Recent technological trends also indicate growing interest in developing environmentally sustainable testing methodologies that reduce water consumption and chemical waste while maintaining or improving the predictive value of the tests. This aligns with broader industry initiatives toward greener manufacturing practices and reduced environmental footprint throughout the product lifecycle.

Salt fog testing represents one of the most critical evaluation protocols for conformal coatings, simulating accelerated corrosive conditions that electronic assemblies might encounter during their operational lifetime. This testing methodology originated from military standards but has since been adopted and refined by various international standardization bodies including IPC, IEC, and ASTM. The primary objective of salt fog testing is to evaluate the protective efficacy of conformal coatings against corrosion, electrical leakage, and physical degradation under extreme saline conditions.

Current technological objectives in conformal coating testing focus on developing standardized protocols that accurately predict real-world performance while accommodating the increasing miniaturization and complexity of modern electronic assemblies. There is growing emphasis on establishing correlations between accelerated testing results and actual field performance, particularly for emerging applications in harsh environments such as offshore wind farms, electric vehicles, and IoT devices deployed in coastal regions.

The industry is witnessing a paradigm shift from purely qualitative visual assessments toward quantitative measurement methodologies that incorporate advanced analytical techniques. These include impedance spectroscopy, 3D optical scanning, and chemical composition analysis to detect subtle degradation mechanisms that might not be apparent through traditional inspection methods. This evolution reflects the increasing reliability requirements for electronic systems in critical applications where failure is not an option.

Another significant objective is the harmonization of testing protocols across different industries and geographical regions to facilitate global supply chain integration and regulatory compliance. This includes efforts to align salt fog testing parameters, acceptance criteria, and reporting formats to enable meaningful comparisons between different coating technologies and formulations. The ultimate goal is to establish predictive models that can accurately forecast coating performance under various environmental conditions, reducing development cycles and improving product reliability.

Recent technological trends also indicate growing interest in developing environmentally sustainable testing methodologies that reduce water consumption and chemical waste while maintaining or improving the predictive value of the tests. This aligns with broader industry initiatives toward greener manufacturing practices and reduced environmental footprint throughout the product lifecycle.

Market Demand Analysis for Salt Fog Resistant Coatings

The global market for salt fog resistant conformal coatings has experienced significant growth in recent years, driven primarily by increasing demand from aerospace, automotive, marine, and electronics industries. These sectors require robust protection solutions for electronic components operating in harsh environments where salt exposure presents a critical risk factor.

Market research indicates that the conformal coating market was valued at approximately $2.1 billion in 2022, with salt fog resistant variants representing a substantial and growing segment. Industry analysts project a compound annual growth rate of 5.8% through 2028, with salt fog resistant formulations expected to outpace the broader market at nearly 7% annual growth.

The automotive electronics sector represents the largest consumer of these specialized coatings, accounting for roughly 32% of market demand. This is attributed to the increasing electronic content in vehicles and the need to protect these systems from environmental factors, particularly in coastal regions and areas where road salt is commonly used. The aerospace and defense sectors follow closely at 28% market share, where reliability requirements are exceptionally stringent.

Geographically, North America and Europe currently dominate the market, collectively representing over 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading regional growth at rates exceeding 9% annually. This shift reflects the expanding electronics manufacturing base and increasing automotive production in these regions.

Consumer trends indicate growing preference for environmentally friendly coating solutions with reduced volatile organic compounds (VOCs), creating a notable market segment for "green" salt fog resistant formulations. This eco-friendly segment is expected to grow at twice the rate of conventional solutions over the next five years.

Industry surveys reveal that manufacturers are increasingly seeking coatings that can demonstrate verified performance through standardized testing protocols, particularly those involving salt fog chamber testing. Over 75% of procurement specifications now explicitly require documented salt fog test results according to established standards such as ASTM B117 or IEC 60068-2-52.

The market is also witnessing increased demand for multi-functional coatings that offer salt fog resistance alongside other protective properties such as thermal stability, UV resistance, and flame retardancy. This trend toward consolidated protection solutions is expected to reshape product development roadmaps across the industry in the coming years.

Market research indicates that the conformal coating market was valued at approximately $2.1 billion in 2022, with salt fog resistant variants representing a substantial and growing segment. Industry analysts project a compound annual growth rate of 5.8% through 2028, with salt fog resistant formulations expected to outpace the broader market at nearly 7% annual growth.

The automotive electronics sector represents the largest consumer of these specialized coatings, accounting for roughly 32% of market demand. This is attributed to the increasing electronic content in vehicles and the need to protect these systems from environmental factors, particularly in coastal regions and areas where road salt is commonly used. The aerospace and defense sectors follow closely at 28% market share, where reliability requirements are exceptionally stringent.

Geographically, North America and Europe currently dominate the market, collectively representing over 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading regional growth at rates exceeding 9% annually. This shift reflects the expanding electronics manufacturing base and increasing automotive production in these regions.

Consumer trends indicate growing preference for environmentally friendly coating solutions with reduced volatile organic compounds (VOCs), creating a notable market segment for "green" salt fog resistant formulations. This eco-friendly segment is expected to grow at twice the rate of conventional solutions over the next five years.

Industry surveys reveal that manufacturers are increasingly seeking coatings that can demonstrate verified performance through standardized testing protocols, particularly those involving salt fog chamber testing. Over 75% of procurement specifications now explicitly require documented salt fog test results according to established standards such as ASTM B117 or IEC 60068-2-52.

The market is also witnessing increased demand for multi-functional coatings that offer salt fog resistance alongside other protective properties such as thermal stability, UV resistance, and flame retardancy. This trend toward consolidated protection solutions is expected to reshape product development roadmaps across the industry in the coming years.

Current Salt Fog Testing Challenges and Limitations

Despite the widespread adoption of salt fog testing for conformal coating evaluation, this methodology faces several significant challenges and limitations that impact test reliability and result interpretation. The current ASTM B117 standard, while established, lacks specificity for electronic applications, creating inconsistencies in how tests are conducted across different laboratories and industries.

One primary challenge is the poor correlation between accelerated salt fog testing and real-world performance. The aggressive, continuous salt spray environment often fails to accurately simulate the complex, cyclical exposure patterns that electronic devices encounter in actual field conditions. This discrepancy leads to either overly conservative designs or, more dangerously, false confidence in coating performance.

Standardization issues persist throughout the industry, with variations in test parameters such as temperature fluctuations, salt concentration consistency, and chamber humidity control. These variations can significantly alter test outcomes, making cross-laboratory comparisons difficult and undermining the reproducibility essential for scientific validity.

The binary pass/fail evaluation criteria commonly employed in salt fog testing represents another substantial limitation. This approach fails to capture the progressive degradation of conformal coatings and provides little insight into failure mechanisms or performance thresholds. Without quantitative metrics, manufacturers struggle to optimize coating formulations or application processes effectively.

Modern electronic assemblies present unique testing challenges due to their increasingly complex geometries and miniaturization trends. Salt fog chambers often cannot adequately assess salt penetration in tight spaces, under components, or at the microscopic level where many critical failures originate. This limitation becomes more pronounced as electronic designs continue to evolve toward higher density configurations.

Environmental and health concerns associated with traditional salt fog testing are growing. The disposal of salt-laden waste and the energy consumption of continuous operation chambers raise sustainability questions that the industry has yet to fully address. Additionally, the extended test durations (often 500-1000 hours) create bottlenecks in product development cycles and delay time-to-market.

Perhaps most critically, current salt fog testing protocols struggle to account for the multifactorial nature of electronic failures. The isolated focus on salt corrosion neglects the combined effects of temperature cycling, humidity variations, mechanical stress, and electrical loading that typically occur simultaneously in operational environments. This single-variable approach significantly limits the predictive value of test results for real-world applications.

One primary challenge is the poor correlation between accelerated salt fog testing and real-world performance. The aggressive, continuous salt spray environment often fails to accurately simulate the complex, cyclical exposure patterns that electronic devices encounter in actual field conditions. This discrepancy leads to either overly conservative designs or, more dangerously, false confidence in coating performance.

Standardization issues persist throughout the industry, with variations in test parameters such as temperature fluctuations, salt concentration consistency, and chamber humidity control. These variations can significantly alter test outcomes, making cross-laboratory comparisons difficult and undermining the reproducibility essential for scientific validity.

The binary pass/fail evaluation criteria commonly employed in salt fog testing represents another substantial limitation. This approach fails to capture the progressive degradation of conformal coatings and provides little insight into failure mechanisms or performance thresholds. Without quantitative metrics, manufacturers struggle to optimize coating formulations or application processes effectively.

Modern electronic assemblies present unique testing challenges due to their increasingly complex geometries and miniaturization trends. Salt fog chambers often cannot adequately assess salt penetration in tight spaces, under components, or at the microscopic level where many critical failures originate. This limitation becomes more pronounced as electronic designs continue to evolve toward higher density configurations.

Environmental and health concerns associated with traditional salt fog testing are growing. The disposal of salt-laden waste and the energy consumption of continuous operation chambers raise sustainability questions that the industry has yet to fully address. Additionally, the extended test durations (often 500-1000 hours) create bottlenecks in product development cycles and delay time-to-market.

Perhaps most critically, current salt fog testing protocols struggle to account for the multifactorial nature of electronic failures. The isolated focus on salt corrosion neglects the combined effects of temperature cycling, humidity variations, mechanical stress, and electrical loading that typically occur simultaneously in operational environments. This single-variable approach significantly limits the predictive value of test results for real-world applications.

Standard Salt Fog Testing Protocols and Procedures

01 Salt fog test methods for conformal coatings

Various test methods are employed to evaluate the salt fog resistance of conformal coatings. These methods typically involve exposing coated samples to a controlled salt fog environment for specified periods to assess corrosion resistance. The tests may include different salt concentrations, exposure times, and environmental conditions to simulate various operational environments. These standardized testing procedures help determine the effectiveness of conformal coatings in protecting electronic components from salt-induced corrosion.- Salt fog test methods for conformal coatings: Various test methods are used to evaluate the salt fog resistance of conformal coatings. These methods typically involve exposing coated samples to a controlled salt fog environment for a specified period to assess corrosion resistance. The tests may include different salt concentrations, exposure times, and environmental conditions to simulate various operational environments. These standardized testing procedures help determine the effectiveness of conformal coatings in protecting electronic components from salt-induced corrosion.

- Conformal coating materials with enhanced salt fog resistance: Specialized conformal coating materials have been developed with enhanced resistance to salt fog environments. These materials include modified acrylics, polyurethanes, silicones, and epoxies with additives that improve their barrier properties against salt penetration. Some formulations incorporate hydrophobic components, corrosion inhibitors, or nanoparticles to enhance protection. These advanced materials provide superior protection for electronic components in harsh marine or coastal environments where salt exposure is a significant concern.

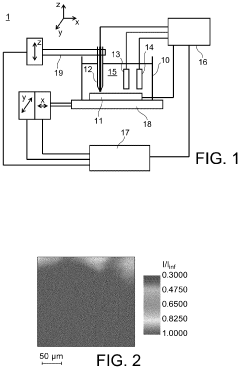

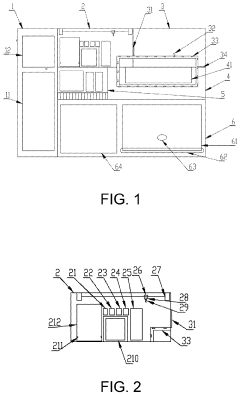

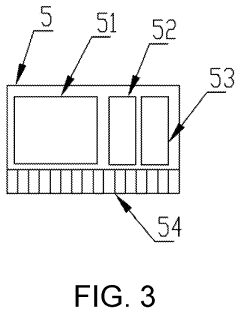

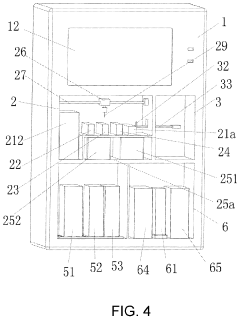

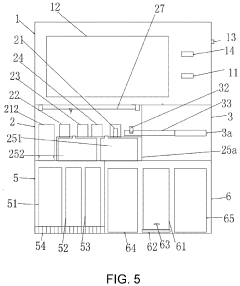

- Testing equipment and apparatus for salt fog resistance evaluation: Specialized equipment and apparatus have been designed for conducting salt fog resistance tests on conformal coatings. These include salt spray chambers, environmental test chambers with controlled temperature and humidity, and automated monitoring systems. The equipment may feature programmable test cycles, uniform salt fog distribution mechanisms, and precise control of environmental parameters. Some advanced systems incorporate real-time monitoring capabilities to track coating performance throughout the test duration.

- Performance evaluation criteria and standards for salt fog testing: Specific criteria and standards have been established to evaluate the performance of conformal coatings in salt fog environments. These include visual inspection for coating degradation, adhesion testing after salt exposure, electrical performance measurements, and corrosion assessment of the underlying substrate. Industry standards define test parameters such as salt concentration, exposure duration, temperature, and acceptance criteria. These standardized evaluation methods ensure consistent assessment of coating performance across different applications and environments.

- Application techniques for optimizing salt fog resistance: Various application techniques have been developed to optimize the salt fog resistance of conformal coatings. These include multi-layer coating systems, specialized pre-treatment processes, and controlled curing methods. Proper surface preparation, coating thickness control, and edge coverage are critical factors affecting salt fog resistance. Some techniques involve selective coating application to vulnerable areas or combining different coating types to achieve optimal protection. Advanced application methods ensure uniform coverage and minimize defects that could compromise salt fog resistance.

02 Conformal coating materials with enhanced salt fog resistance

Specialized conformal coating materials have been developed with improved resistance to salt fog environments. These materials include modified acrylics, polyurethanes, silicones, and epoxies with additives that enhance their barrier properties against salt penetration. Some formulations incorporate hydrophobic components, corrosion inhibitors, or nanoparticles to improve long-term protection. The selection of coating material depends on the specific application requirements, including the severity of the salt environment and the expected service life of the protected components.Expand Specific Solutions03 Testing equipment and apparatus for salt fog resistance evaluation

Specialized equipment and apparatus have been designed for conducting salt fog resistance tests on conformal coatings. These include salt spray chambers, environmental test chambers, and automated testing systems that can control temperature, humidity, and salt concentration. Some advanced systems incorporate real-time monitoring capabilities to track the degradation of coatings during testing. The equipment may also include fixtures for holding test specimens in specific orientations to ensure uniform exposure to the salt fog environment.Expand Specific Solutions04 Performance evaluation criteria and standards for salt fog testing

Specific criteria and standards have been established to evaluate the performance of conformal coatings in salt fog environments. These include visual inspection for signs of corrosion, adhesion testing after exposure, electrical property measurements, and surface analysis techniques. The evaluation may involve quantitative metrics such as corrosion rate, time to failure, or changes in electrical resistance. International standards and industry specifications provide guidelines for conducting these tests and interpreting the results to ensure consistency across different testing facilities.Expand Specific Solutions05 Application-specific salt fog resistance requirements for electronic components

Different electronic applications require specific levels of salt fog resistance based on their operating environments. Marine electronics, automotive systems, outdoor telecommunications equipment, and aerospace components each have unique requirements for conformal coating protection. Testing protocols may be customized to simulate the specific environmental conditions these components will face. The coating thickness, application method, and curing process may be optimized for particular components to ensure adequate protection while maintaining electrical performance and thermal management capabilities.Expand Specific Solutions

Key Industry Players in Conformal Coating Testing

The salt fog testing protocols for conformal coatings market is currently in a mature growth phase, with an estimated global market size of $1.5-2 billion annually. The technical landscape shows varying degrees of maturity across applications, with automotive and electronics sectors leading adoption. Key players demonstrate different specialization levels: BASF Coatings and PPG Industries dominate with comprehensive testing protocols, while Atotech and SDC Technologies offer specialized solutions for electronics applications. Kansai Paint and AkzoNobel have established strong positions in automotive-grade coatings with advanced salt fog resistance. Emerging players like Luna Labs USA are introducing innovative environmentally-friendly formulations, while research institutions such as CNRS and Fudan University are developing next-generation testing methodologies that promise to enhance reliability standards across the industry.

BASF Coatings GmbH

Technical Solution: BASF Coatings has developed a comprehensive protocol for testing conformal coatings in salt fog chambers that follows the ASTM B117 standard while incorporating proprietary enhancements. Their approach utilizes a multi-stage testing methodology that begins with sample preparation involving precise coating application techniques and controlled curing conditions. The testing protocol includes cyclic exposure patterns alternating between salt fog exposure (35°C with 5% NaCl solution) and controlled humidity/temperature conditions to simulate real-world environmental stresses. BASF employs advanced analytical techniques including 3D optical microscopy and electrochemical impedance spectroscopy to quantitatively assess coating performance beyond visual inspection. Their protocol specifically measures coating adhesion retention, dielectric strength maintenance, and corrosion creep resistance at predetermined intervals throughout the test duration, typically extending to 1,000+ hours for automotive and industrial applications.

Strengths: Industry-leading analytical capabilities with proprietary performance metrics that correlate well with field performance. Their cyclic testing approach more accurately simulates real-world conditions than standard constant exposure tests. Weaknesses: Testing protocols are highly specialized for automotive applications and may require significant modification for electronics or aerospace applications. Higher implementation costs compared to standard salt fog testing methods.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has pioneered an advanced salt fog testing protocol specifically designed for conformal coatings that incorporates electrochemical monitoring systems during exposure. Their methodology combines traditional ASTM B117 salt fog testing with modified IPC-CC-830B standards adapted specifically for electronic applications. The protocol features a multi-environmental approach where samples undergo programmed cycles between salt fog exposure (5% NaCl at 35°C), condensing humidity (40°C at 100% RH), and UV exposure to simulate outdoor aging effects comprehensively. PPG's testing includes specialized sample preparation techniques with standardized substrate cleaning procedures and controlled application methods ensuring coating thickness uniformity within ±5μm. Their evaluation metrics include quantitative adhesion measurements before and after exposure, surface resistivity monitoring throughout testing, and advanced optical analysis using fluorescent tracers incorporated into coatings to visualize microscopic penetration pathways that develop during exposure.

Strengths: Comprehensive multi-stress approach that correlates well with field performance across diverse environments. Their in-situ electrical property monitoring provides real-time performance data rather than just end-point results. Weaknesses: Complex testing protocol requires specialized equipment and expertise to implement correctly. The multi-factor approach makes it challenging to isolate specific failure mechanisms when problems occur.

Critical Technical Standards and Test Parameters

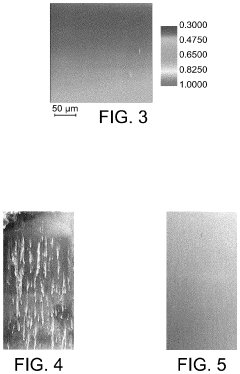

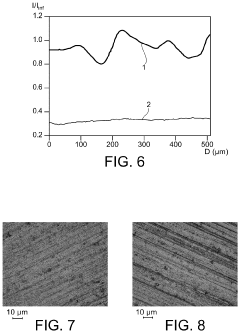

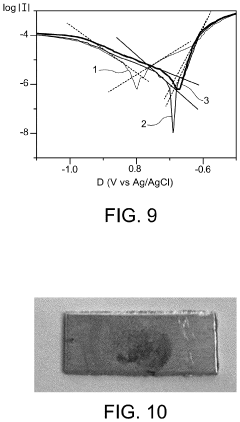

Use of scanning electrochemical microscopy as a predictive technique in a salt fog corrosion test

PatentActiveUS20240210444A1

Innovation

- Scanning electrochemical microscopy (SECM) is used as a predictive technique to analyze the corrosion resistance of surfaces treated with anticorrosion coatings, allowing for localized analysis and rapid prediction of salt fog test results by measuring current changes with a miniaturized electrode probe, enabling the identification of potential corrosion points and determining the likelihood of passing a salt fog test.

Device for online detection of atmospheric salt fog content and detection method thereof

PatentActiveUS20210268495A1

Innovation

- A device comprising a sampling module with a liquid absorbent and reagent system, and an analysis module using a spectrophotometer, which allows for continuous, directional-independent measurement of chloride ions in the air, reducing the impact of wind conditions and shortening the testing cycle.

Environmental Impact and Sustainability Considerations

The environmental impact of salt fog chamber testing for conformal coatings represents a significant consideration in modern electronics manufacturing sustainability efforts. Traditional salt fog testing protocols utilize substantial quantities of sodium chloride solutions, which after testing cycles must be properly treated before disposal. The discharge of untreated saline solutions can adversely affect freshwater ecosystems and agricultural lands, potentially causing soil salination and disrupting aquatic habitats. Furthermore, the energy consumption of salt fog chambers, which typically operate continuously for extended periods (often 168 hours or more), contributes significantly to the carbon footprint of the testing process.

Recent advancements in chamber design have focused on reducing water consumption through closed-loop recirculation systems that filter and reuse test solutions. These systems can reduce water usage by up to 60% compared to traditional open systems, while simultaneously decreasing the volume of waste requiring treatment. Additionally, energy-efficient chamber designs incorporating improved insulation, LED lighting, and smart control systems have demonstrated potential energy savings of 25-40% without compromising test integrity or results reliability.

The chemical composition of conformal coatings themselves presents another environmental consideration. Traditional solvent-based coatings release volatile organic compounds (VOCs) during application and curing, which can be exacerbated during accelerated testing. The industry trend toward water-based, UV-curable, and bio-based coating formulations has reduced these emissions substantially. When testing these environmentally friendly alternatives, modified protocols may be necessary to ensure comparable protection assessment while maintaining reduced environmental impact.

Life cycle assessment (LCA) methodologies are increasingly being applied to testing protocols to quantify their environmental footprint. Studies indicate that optimizing test duration and frequency based on statistical validation rather than arbitrary standards can reduce resource consumption by 15-30% without sacrificing data quality. Furthermore, implementing predictive modeling based on accumulated test data can potentially reduce the number of physical tests required, particularly for incremental product modifications.

Waste management strategies specific to salt fog testing have evolved to include neutralization processes for salt solutions, precipitation of heavy metals that may accumulate from tested components, and recovery of valuable materials when possible. Some facilities have implemented zero-discharge systems where all waste is either recycled or processed into non-hazardous byproducts, though these systems require significant initial investment and ongoing maintenance.

Recent advancements in chamber design have focused on reducing water consumption through closed-loop recirculation systems that filter and reuse test solutions. These systems can reduce water usage by up to 60% compared to traditional open systems, while simultaneously decreasing the volume of waste requiring treatment. Additionally, energy-efficient chamber designs incorporating improved insulation, LED lighting, and smart control systems have demonstrated potential energy savings of 25-40% without compromising test integrity or results reliability.

The chemical composition of conformal coatings themselves presents another environmental consideration. Traditional solvent-based coatings release volatile organic compounds (VOCs) during application and curing, which can be exacerbated during accelerated testing. The industry trend toward water-based, UV-curable, and bio-based coating formulations has reduced these emissions substantially. When testing these environmentally friendly alternatives, modified protocols may be necessary to ensure comparable protection assessment while maintaining reduced environmental impact.

Life cycle assessment (LCA) methodologies are increasingly being applied to testing protocols to quantify their environmental footprint. Studies indicate that optimizing test duration and frequency based on statistical validation rather than arbitrary standards can reduce resource consumption by 15-30% without sacrificing data quality. Furthermore, implementing predictive modeling based on accumulated test data can potentially reduce the number of physical tests required, particularly for incremental product modifications.

Waste management strategies specific to salt fog testing have evolved to include neutralization processes for salt solutions, precipitation of heavy metals that may accumulate from tested components, and recovery of valuable materials when possible. Some facilities have implemented zero-discharge systems where all waste is either recycled or processed into non-hazardous byproducts, though these systems require significant initial investment and ongoing maintenance.

Regulatory Compliance and Certification Requirements

Regulatory compliance for conformal coating testing in salt fog environments is governed by a comprehensive framework of international, regional, and industry-specific standards. The IPC-CC-830B standard serves as the primary reference for conformal coating qualification, establishing baseline requirements for salt fog testing protocols. This standard mandates specific exposure durations, concentration levels, and evaluation criteria to ensure consistent assessment across different coating technologies.

Military specifications, particularly MIL-I-46058C and MIL-STD-810G, impose more stringent requirements for conformal coatings used in defense applications. These standards require extended exposure periods of up to 96 hours in 5% salt solution environments, with detailed post-test analysis requirements for coating integrity and circuit functionality. Compliance with these military standards often serves as a benchmark for high-reliability commercial applications.

The automotive industry follows standards such as SAE J1211 and ISO 16750-4, which specify accelerated corrosion testing protocols specifically designed to simulate harsh vehicular operating environments. These standards require cyclical testing regimes that alternate between salt fog exposure and high-humidity conditions to replicate real-world stress scenarios.

For medical device applications, the IEC 60601 series includes specific requirements for conformal coating durability in corrosive environments, with emphasis on maintaining electrical safety and functional integrity. Compliance with these standards requires documented evidence of coating performance throughout the expected device lifecycle.

Certification processes typically involve third-party validation through accredited testing laboratories. These facilities must maintain calibration records for salt fog chambers and follow documented test procedures that ensure repeatability and reproducibility of results. The certification documentation must include detailed test parameters, photographic evidence of specimens before and after exposure, and quantitative measurements of coating degradation.

Emerging regulatory trends indicate a move toward harmonized global standards, with increasing emphasis on environmental considerations. Recent updates to RoHS and REACH regulations impact the chemical composition of conformal coatings, requiring manufacturers to balance corrosion protection performance with environmental compliance. Testing protocols are evolving to include assessment of coating performance without environmentally problematic compounds such as certain halogenated flame retardants.

Regional variations in regulatory requirements present challenges for global manufacturers. European standards often emphasize environmental aspects, while North American standards focus more on performance metrics. Asian markets frequently require compliance with both international standards and country-specific certification processes, creating a complex regulatory landscape that necessitates comprehensive testing strategies.

Military specifications, particularly MIL-I-46058C and MIL-STD-810G, impose more stringent requirements for conformal coatings used in defense applications. These standards require extended exposure periods of up to 96 hours in 5% salt solution environments, with detailed post-test analysis requirements for coating integrity and circuit functionality. Compliance with these military standards often serves as a benchmark for high-reliability commercial applications.

The automotive industry follows standards such as SAE J1211 and ISO 16750-4, which specify accelerated corrosion testing protocols specifically designed to simulate harsh vehicular operating environments. These standards require cyclical testing regimes that alternate between salt fog exposure and high-humidity conditions to replicate real-world stress scenarios.

For medical device applications, the IEC 60601 series includes specific requirements for conformal coating durability in corrosive environments, with emphasis on maintaining electrical safety and functional integrity. Compliance with these standards requires documented evidence of coating performance throughout the expected device lifecycle.

Certification processes typically involve third-party validation through accredited testing laboratories. These facilities must maintain calibration records for salt fog chambers and follow documented test procedures that ensure repeatability and reproducibility of results. The certification documentation must include detailed test parameters, photographic evidence of specimens before and after exposure, and quantitative measurements of coating degradation.

Emerging regulatory trends indicate a move toward harmonized global standards, with increasing emphasis on environmental considerations. Recent updates to RoHS and REACH regulations impact the chemical composition of conformal coatings, requiring manufacturers to balance corrosion protection performance with environmental compliance. Testing protocols are evolving to include assessment of coating performance without environmentally problematic compounds such as certain halogenated flame retardants.

Regional variations in regulatory requirements present challenges for global manufacturers. European standards often emphasize environmental aspects, while North American standards focus more on performance metrics. Asian markets frequently require compliance with both international standards and country-specific certification processes, creating a complex regulatory landscape that necessitates comprehensive testing strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!