The Application of High-Pressure Fuel Systems in LS Engines

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Fuel System Evolution and Objectives

The evolution of fuel systems in LS engines represents a significant advancement in automotive technology, driven by the need for improved performance, efficiency, and emissions control. The journey began with the introduction of the LS1 engine in 1997, which featured a sequential fuel injection system operating at relatively low pressures of around 58 psi. This system, while advanced for its time, laid the foundation for future improvements.

As emissions regulations tightened and demand for higher performance increased, General Motors engineers focused on enhancing fuel delivery precision and atomization. The transition to higher pressure fuel systems became a key objective, aiming to achieve more complete combustion and reduced emissions. This evolution saw fuel pressures gradually increase, reaching up to 65 psi in later LS2 and LS3 engines.

The introduction of direct injection technology in the LS engine family marked a pivotal moment in fuel system development. This technology, first implemented in the LT1 engine (part of the Gen V LS family), dramatically increased fuel pressures to over 2,000 psi. The primary goal was to enable precise fuel delivery directly into the combustion chamber, allowing for better control over the air-fuel mixture and ignition timing.

Concurrent with pressure increases, fuel injector design underwent significant refinement. Engineers aimed to develop injectors capable of delivering finely atomized fuel spray patterns, even at higher pressures. This objective was crucial for optimizing fuel distribution within the combustion chamber, leading to more efficient burning and reduced emissions.

Another key objective in the evolution of LS engine fuel systems was the integration of advanced electronic control systems. These systems were designed to precisely manage fuel delivery based on real-time engine operating conditions, driver input, and environmental factors. The goal was to achieve optimal performance across all operating conditions while maintaining strict emissions compliance.

Durability and reliability remained paramount throughout this evolutionary process. As fuel pressures increased, so did the demands on system components. Engineers focused on developing robust fuel pumps, lines, and injectors capable of withstanding higher pressures and maintaining performance over extended periods.

The ongoing evolution of LS engine fuel systems continues to push boundaries, with current objectives including further refinement of direct injection technology, exploration of even higher fuel pressures, and integration with hybrid and electrification technologies. These advancements aim to meet increasingly stringent emissions standards while delivering the performance characteristics that have made LS engines renowned in the automotive world.

As emissions regulations tightened and demand for higher performance increased, General Motors engineers focused on enhancing fuel delivery precision and atomization. The transition to higher pressure fuel systems became a key objective, aiming to achieve more complete combustion and reduced emissions. This evolution saw fuel pressures gradually increase, reaching up to 65 psi in later LS2 and LS3 engines.

The introduction of direct injection technology in the LS engine family marked a pivotal moment in fuel system development. This technology, first implemented in the LT1 engine (part of the Gen V LS family), dramatically increased fuel pressures to over 2,000 psi. The primary goal was to enable precise fuel delivery directly into the combustion chamber, allowing for better control over the air-fuel mixture and ignition timing.

Concurrent with pressure increases, fuel injector design underwent significant refinement. Engineers aimed to develop injectors capable of delivering finely atomized fuel spray patterns, even at higher pressures. This objective was crucial for optimizing fuel distribution within the combustion chamber, leading to more efficient burning and reduced emissions.

Another key objective in the evolution of LS engine fuel systems was the integration of advanced electronic control systems. These systems were designed to precisely manage fuel delivery based on real-time engine operating conditions, driver input, and environmental factors. The goal was to achieve optimal performance across all operating conditions while maintaining strict emissions compliance.

Durability and reliability remained paramount throughout this evolutionary process. As fuel pressures increased, so did the demands on system components. Engineers focused on developing robust fuel pumps, lines, and injectors capable of withstanding higher pressures and maintaining performance over extended periods.

The ongoing evolution of LS engine fuel systems continues to push boundaries, with current objectives including further refinement of direct injection technology, exploration of even higher fuel pressures, and integration with hybrid and electrification technologies. These advancements aim to meet increasingly stringent emissions standards while delivering the performance characteristics that have made LS engines renowned in the automotive world.

Market Demand for High-Pressure Fuel Systems

The market demand for high-pressure fuel systems in LS engines has been steadily increasing over the past decade, driven by the automotive industry's push for improved engine performance, fuel efficiency, and emissions reduction. This trend is particularly evident in the performance and racing sectors, where enthusiasts and professionals alike seek to maximize power output while adhering to increasingly stringent environmental regulations.

In the passenger vehicle market, there is a growing demand for high-pressure fuel systems as manufacturers strive to meet more stringent fuel economy standards without sacrificing performance. This has led to the widespread adoption of direct injection technology, which requires higher fuel pressures to operate effectively. The market for high-pressure fuel systems in this sector is expected to continue growing as automakers further optimize engine designs to meet future emissions targets.

The commercial vehicle segment has also shown significant interest in high-pressure fuel systems for LS engines. Fleet operators are increasingly looking for ways to reduce fuel consumption and operating costs, making high-pressure fuel systems an attractive option. The improved fuel atomization and combustion efficiency offered by these systems translate directly into cost savings and improved environmental performance for businesses operating large fleets of vehicles.

In the aftermarket and performance tuning sector, the demand for high-pressure fuel systems for LS engines has been particularly strong. Enthusiasts and professional tuners are constantly seeking ways to extract more power from these popular engines, and high-pressure fuel systems offer a reliable method to support increased horsepower and torque outputs. This has led to a thriving market for aftermarket high-pressure fuel pumps, injectors, and related components specifically designed for LS engine applications.

The racing industry has been a significant driver of demand for high-pressure fuel systems in LS engines. As race teams push the boundaries of engine performance, the need for fuel systems capable of delivering precise amounts of fuel at high pressures has become critical. This demand has spurred innovation in fuel system technology, with manufacturers developing specialized components to meet the extreme demands of motorsport applications.

Looking ahead, the market for high-pressure fuel systems in LS engines is expected to continue growing. Factors such as the ongoing electrification of vehicles and the development of hybrid powertrains may impact the trajectory of this growth, but the fundamental need for efficient fuel delivery in internal combustion engines is likely to persist for the foreseeable future. As such, manufacturers and suppliers in this space are likely to see continued opportunities for innovation and market expansion in the coming years.

In the passenger vehicle market, there is a growing demand for high-pressure fuel systems as manufacturers strive to meet more stringent fuel economy standards without sacrificing performance. This has led to the widespread adoption of direct injection technology, which requires higher fuel pressures to operate effectively. The market for high-pressure fuel systems in this sector is expected to continue growing as automakers further optimize engine designs to meet future emissions targets.

The commercial vehicle segment has also shown significant interest in high-pressure fuel systems for LS engines. Fleet operators are increasingly looking for ways to reduce fuel consumption and operating costs, making high-pressure fuel systems an attractive option. The improved fuel atomization and combustion efficiency offered by these systems translate directly into cost savings and improved environmental performance for businesses operating large fleets of vehicles.

In the aftermarket and performance tuning sector, the demand for high-pressure fuel systems for LS engines has been particularly strong. Enthusiasts and professional tuners are constantly seeking ways to extract more power from these popular engines, and high-pressure fuel systems offer a reliable method to support increased horsepower and torque outputs. This has led to a thriving market for aftermarket high-pressure fuel pumps, injectors, and related components specifically designed for LS engine applications.

The racing industry has been a significant driver of demand for high-pressure fuel systems in LS engines. As race teams push the boundaries of engine performance, the need for fuel systems capable of delivering precise amounts of fuel at high pressures has become critical. This demand has spurred innovation in fuel system technology, with manufacturers developing specialized components to meet the extreme demands of motorsport applications.

Looking ahead, the market for high-pressure fuel systems in LS engines is expected to continue growing. Factors such as the ongoing electrification of vehicles and the development of hybrid powertrains may impact the trajectory of this growth, but the fundamental need for efficient fuel delivery in internal combustion engines is likely to persist for the foreseeable future. As such, manufacturers and suppliers in this space are likely to see continued opportunities for innovation and market expansion in the coming years.

Current State and Challenges of LS Engine Fuel Systems

The current state of LS engine fuel systems reflects a significant evolution in automotive technology, with high-pressure fuel systems becoming increasingly prevalent. Traditional LS engines typically utilized low-pressure fuel injection systems, operating at around 58-62 PSI. However, the industry has been steadily moving towards higher pressure systems to meet stringent emissions regulations and improve fuel efficiency.

Modern LS engines now commonly employ direct injection technology, which operates at much higher pressures, typically ranging from 2,000 to 3,000 PSI. This shift has led to substantial improvements in fuel atomization, resulting in more precise fuel delivery and combustion control. The enhanced atomization allows for better fuel-air mixture formation, leading to more complete combustion and reduced emissions.

Despite these advancements, the implementation of high-pressure fuel systems in LS engines faces several challenges. One primary concern is the increased complexity of the fuel delivery system. The higher operating pressures require more robust components, including high-pressure fuel pumps, reinforced fuel lines, and specialized injectors. This complexity not only increases manufacturing costs but also poses potential reliability issues over the long term.

Another significant challenge is the need for advanced engine management systems capable of precisely controlling fuel delivery at these elevated pressures. The electronic control units (ECUs) must be sophisticated enough to manage the intricate timing and duration of fuel injection events, which become more critical at higher pressures.

Heat management presents an additional hurdle. The high-pressure fuel systems generate more heat, which can potentially lead to fuel vaporization issues. Engineers must develop innovative cooling solutions to maintain fuel temperature within acceptable limits, ensuring consistent performance across various operating conditions.

Durability and longevity of components under high-pressure conditions remain ongoing concerns. The increased stress on fuel system parts, particularly injectors and seals, necessitates the use of advanced materials and manufacturing techniques to ensure long-term reliability.

Furthermore, the automotive industry faces the challenge of balancing the benefits of high-pressure fuel systems with the goal of reducing vehicle weight. The additional components required for these systems can contribute to increased overall vehicle mass, potentially offsetting some of the efficiency gains.

As the technology continues to mature, researchers and engineers are focusing on optimizing high-pressure fuel systems for LS engines. This includes exploring new materials for injector nozzles, developing more efficient high-pressure fuel pumps, and refining control algorithms to maximize the benefits of these advanced systems while addressing the associated challenges.

Modern LS engines now commonly employ direct injection technology, which operates at much higher pressures, typically ranging from 2,000 to 3,000 PSI. This shift has led to substantial improvements in fuel atomization, resulting in more precise fuel delivery and combustion control. The enhanced atomization allows for better fuel-air mixture formation, leading to more complete combustion and reduced emissions.

Despite these advancements, the implementation of high-pressure fuel systems in LS engines faces several challenges. One primary concern is the increased complexity of the fuel delivery system. The higher operating pressures require more robust components, including high-pressure fuel pumps, reinforced fuel lines, and specialized injectors. This complexity not only increases manufacturing costs but also poses potential reliability issues over the long term.

Another significant challenge is the need for advanced engine management systems capable of precisely controlling fuel delivery at these elevated pressures. The electronic control units (ECUs) must be sophisticated enough to manage the intricate timing and duration of fuel injection events, which become more critical at higher pressures.

Heat management presents an additional hurdle. The high-pressure fuel systems generate more heat, which can potentially lead to fuel vaporization issues. Engineers must develop innovative cooling solutions to maintain fuel temperature within acceptable limits, ensuring consistent performance across various operating conditions.

Durability and longevity of components under high-pressure conditions remain ongoing concerns. The increased stress on fuel system parts, particularly injectors and seals, necessitates the use of advanced materials and manufacturing techniques to ensure long-term reliability.

Furthermore, the automotive industry faces the challenge of balancing the benefits of high-pressure fuel systems with the goal of reducing vehicle weight. The additional components required for these systems can contribute to increased overall vehicle mass, potentially offsetting some of the efficiency gains.

As the technology continues to mature, researchers and engineers are focusing on optimizing high-pressure fuel systems for LS engines. This includes exploring new materials for injector nozzles, developing more efficient high-pressure fuel pumps, and refining control algorithms to maximize the benefits of these advanced systems while addressing the associated challenges.

Existing High-Pressure Fuel Solutions for LS Engines

01 Fuel injection system design

High-pressure fuel systems often incorporate advanced fuel injection designs to improve engine performance and efficiency. These systems may include electronically controlled injectors, high-pressure pumps, and precision-engineered nozzles to optimize fuel delivery and atomization. Such designs can enhance combustion, reduce emissions, and increase power output across various engine types.- Fuel injection system design: High-pressure fuel systems often incorporate advanced fuel injection designs to improve engine performance and efficiency. These systems may include electronic control units, high-pressure pumps, and precision injectors to deliver fuel at optimal pressures and timings. Such designs can enhance fuel atomization, combustion efficiency, and overall engine output.

- Pressure regulation and control: Effective pressure regulation and control are crucial in high-pressure fuel systems. This may involve the use of pressure sensors, regulators, and relief valves to maintain optimal fuel pressure throughout the system. Advanced control algorithms and electronic components can be employed to adjust pressure based on engine load, speed, and other operating conditions.

- Fuel pump innovations: High-pressure fuel systems often rely on innovative fuel pump designs to achieve and maintain the required pressure levels. These pumps may incorporate advanced materials, precision manufacturing techniques, and optimized geometries to improve efficiency, durability, and performance. Some designs may also integrate cooling or lubrication systems to enhance reliability under high-pressure conditions.

- Fuel rail and distribution system: The fuel rail and distribution system play a critical role in high-pressure fuel systems. These components must be designed to withstand high pressures while ensuring even fuel distribution to all injectors. Advanced materials, precise manufacturing, and innovative geometries may be employed to optimize fuel flow, minimize pressure drops, and reduce system weight.

- Integration with engine management systems: High-pressure fuel systems are often closely integrated with advanced engine management systems. This integration allows for precise control of fuel delivery based on various engine parameters and operating conditions. It may involve sophisticated sensors, actuators, and control algorithms to optimize fuel efficiency, emissions, and performance across a wide range of operating conditions.

02 Pressure regulation and control

Effective pressure regulation and control are crucial in high-pressure fuel systems. This may involve the use of pressure sensors, electronic control units, and pressure relief valves to maintain optimal fuel pressure throughout the system. Advanced control algorithms can adjust fuel pressure based on engine load, speed, and other parameters to maximize efficiency and performance.Expand Specific Solutions03 Fuel pump technology

High-pressure fuel pumps are a key component in modern fuel systems. These pumps are designed to deliver fuel at extremely high pressures, often exceeding 2000 bar in some applications. Advanced pump designs may incorporate multiple plungers, precision-machined components, and durable materials to withstand the high pressures and ensure reliable operation over extended periods.Expand Specific Solutions04 Fuel rail and distribution systems

The fuel rail and distribution system in high-pressure setups are engineered to withstand extreme pressures while ensuring even fuel distribution to all injectors. This may involve the use of high-strength materials, specialized sealing technologies, and optimized flow paths to minimize pressure drops and maintain consistent fuel delivery across all cylinders.Expand Specific Solutions05 Integration with engine management systems

High-pressure fuel systems are often tightly integrated with advanced engine management systems. This integration allows for precise control of fuel delivery based on real-time engine data, enabling features such as multiple injection events per cycle, adaptive fuel pressure control, and advanced diagnostics. Such integration can lead to improved fuel efficiency, reduced emissions, and enhanced engine performance across various operating conditions.Expand Specific Solutions

Key Players in LS Engine and Fuel System Industry

The application of high-pressure fuel systems in LS engines represents a mature technology in the automotive industry, with significant market penetration and ongoing development. The competitive landscape is characterized by established players and innovative newcomers, reflecting the industry's advanced stage. Major companies like Robert Bosch GmbH, Toyota Motor Corp., and Hyundai Motor Co., Ltd. are at the forefront, leveraging their extensive R&D capabilities and market presence. The market size is substantial, driven by the increasing demand for fuel-efficient and high-performance engines. Technological maturity is evident, with companies like Vitesco Technologies GmbH and Continental Automotive GmbH continually refining existing systems and exploring new advancements to maintain their competitive edge in this critical automotive component sector.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced high-pressure fuel systems for LS engines, focusing on direct injection technology. Their latest system operates at pressures up to 350 bar, significantly improving fuel atomization and combustion efficiency[1]. The system incorporates piezoelectric injectors capable of multiple injections per cycle, allowing for precise fuel metering and reduced emissions[2]. Bosch's system also features an integrated fuel rail with pressure sensors and a high-pressure fuel pump, optimized for LS engine applications. The company has implemented advanced control algorithms that adjust injection timing and duration based on real-time engine parameters, enhancing performance across various operating conditions[3].

Strengths: Industry-leading precision in fuel delivery, reduced emissions, and improved fuel economy. Weaknesses: Higher system complexity and cost compared to traditional fuel systems.

Toyota Motor Corp.

Technical Solution: Toyota has developed a high-pressure fuel system for LS engines that focuses on reliability and efficiency. Their system operates at pressures up to 300 bar and utilizes a unique injector design that improves fuel atomization while maintaining long-term durability[4]. Toyota's approach incorporates a dual-stage fuel pump system, which allows for more efficient pressure generation and better fuel economy[5]. The company has also implemented advanced materials in their injectors and fuel rails to withstand the high pressures while minimizing weight. Toyota's system includes adaptive pressure control that optimizes fuel delivery based on engine load and speed, resulting in improved performance and reduced emissions across a wide range of operating conditions[6].

Strengths: Excellent reliability and durability, good balance of performance and efficiency. Weaknesses: Slightly lower maximum pressure compared to some competitors, potentially limiting peak performance in high-output applications.

Core Innovations in High-Pressure Fuel Technology

High-pressure fuel pump for an internal combustion engine having direct injection

PatentPendingEP2635792A1

Innovation

- A high-pressure fuel pump design featuring a medium-pressure fuel supply chamber, a fuel switching valve, and a quantity control valve, along with a return line with hydraulic resistance, allows for selective connection of low-pressure and medium-pressure fuel supply chambers with the pump element, ensuring continuous fuel flow and cooling, while omitting the need for check valves and enabling operation with fuels at different pressure levels.

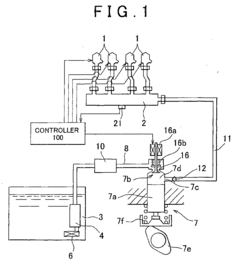

High-pressure fuel supply system of an internal combustion engine and control method thereof

PatentInactiveEP1321654A3

Innovation

- A high-pressure fuel supply system that includes a high-pressure pump and a low-pressure pump, where the fuel injection pressure is preset to be higher than the rated discharge pressure of the low-pressure pump, and the pressure drop is calculated to ensure sufficient fuel pressure for all cylinders, using a controller to manage the solenoid and valve operations to maximize fuel delivery and prevent backflow, ensuring reliable ignition.

Environmental Impact and Emissions Regulations

The application of high-pressure fuel systems in LS engines has significant implications for environmental impact and emissions regulations. These advanced fuel delivery systems have been developed in response to increasingly stringent emissions standards and the growing demand for more fuel-efficient vehicles.

High-pressure fuel systems in LS engines contribute to improved fuel atomization and more precise fuel delivery, resulting in more complete combustion. This enhanced combustion process leads to reduced emissions of harmful pollutants such as carbon monoxide (CO), unburned hydrocarbons (HC), and nitrogen oxides (NOx). As a result, vehicles equipped with these systems are better positioned to meet current and future emissions regulations.

The Environmental Protection Agency (EPA) and other regulatory bodies worldwide have been progressively tightening emissions standards for vehicles. In the United States, the Corporate Average Fuel Economy (CAFE) standards have pushed automakers to develop more efficient engines, including those with high-pressure fuel systems. These regulations aim to reduce greenhouse gas emissions and improve air quality, making the adoption of advanced fuel systems crucial for compliance.

Furthermore, the implementation of high-pressure fuel systems in LS engines aligns with the global effort to combat climate change. By improving fuel efficiency and reducing emissions, these systems contribute to lowering the overall carbon footprint of vehicles. This is particularly important as many countries set ambitious targets for reducing greenhouse gas emissions in the transportation sector.

The impact of high-pressure fuel systems extends beyond tailpipe emissions. These systems also enable the use of alternative fuels, such as ethanol blends and biodiesel, which can further reduce the environmental impact of LS engines. The ability to efficiently utilize these cleaner-burning fuels helps manufacturers meet renewable fuel standards and supports the transition towards more sustainable transportation options.

However, the environmental benefits of high-pressure fuel systems must be balanced against potential drawbacks. The production and disposal of these more complex systems may have their own environmental implications, including increased energy consumption during manufacturing and the need for specialized recycling processes at the end of the vehicle's life cycle.

As emissions regulations continue to evolve, high-pressure fuel systems in LS engines will likely play an increasingly important role in meeting these standards. Future regulations may focus on lifecycle emissions, considering not only the vehicle's operational emissions but also those associated with its production and disposal. This holistic approach to environmental impact assessment may drive further innovations in fuel system design and materials selection.

High-pressure fuel systems in LS engines contribute to improved fuel atomization and more precise fuel delivery, resulting in more complete combustion. This enhanced combustion process leads to reduced emissions of harmful pollutants such as carbon monoxide (CO), unburned hydrocarbons (HC), and nitrogen oxides (NOx). As a result, vehicles equipped with these systems are better positioned to meet current and future emissions regulations.

The Environmental Protection Agency (EPA) and other regulatory bodies worldwide have been progressively tightening emissions standards for vehicles. In the United States, the Corporate Average Fuel Economy (CAFE) standards have pushed automakers to develop more efficient engines, including those with high-pressure fuel systems. These regulations aim to reduce greenhouse gas emissions and improve air quality, making the adoption of advanced fuel systems crucial for compliance.

Furthermore, the implementation of high-pressure fuel systems in LS engines aligns with the global effort to combat climate change. By improving fuel efficiency and reducing emissions, these systems contribute to lowering the overall carbon footprint of vehicles. This is particularly important as many countries set ambitious targets for reducing greenhouse gas emissions in the transportation sector.

The impact of high-pressure fuel systems extends beyond tailpipe emissions. These systems also enable the use of alternative fuels, such as ethanol blends and biodiesel, which can further reduce the environmental impact of LS engines. The ability to efficiently utilize these cleaner-burning fuels helps manufacturers meet renewable fuel standards and supports the transition towards more sustainable transportation options.

However, the environmental benefits of high-pressure fuel systems must be balanced against potential drawbacks. The production and disposal of these more complex systems may have their own environmental implications, including increased energy consumption during manufacturing and the need for specialized recycling processes at the end of the vehicle's life cycle.

As emissions regulations continue to evolve, high-pressure fuel systems in LS engines will likely play an increasingly important role in meeting these standards. Future regulations may focus on lifecycle emissions, considering not only the vehicle's operational emissions but also those associated with its production and disposal. This holistic approach to environmental impact assessment may drive further innovations in fuel system design and materials selection.

Cost-Benefit Analysis of High-Pressure Fuel Systems

The implementation of high-pressure fuel systems in LS engines presents a complex cost-benefit scenario that requires careful analysis. On the cost side, these systems typically involve higher initial investment due to the need for specialized components such as high-pressure fuel pumps, reinforced fuel lines, and more robust injectors. The installation process may also be more intricate, potentially increasing labor costs during engine assembly or retrofitting.

However, the benefits of high-pressure fuel systems can be substantial. One of the primary advantages is improved fuel atomization, which leads to more efficient combustion. This efficiency gain can result in increased engine power output and improved fuel economy. In performance applications, the ability to deliver precise amounts of fuel at high pressures allows for better control over the air-fuel mixture, especially at high engine speeds and loads.

The long-term cost implications should also be considered. While initial costs are higher, the improved efficiency and potential for increased power output may lead to reduced fuel consumption over time, particularly in high-performance or heavy-duty applications. This could result in significant savings over the lifespan of the engine, especially for commercial or industrial users where fuel costs are a major operational expense.

Maintenance costs are another factor to weigh. High-pressure systems may require more frequent servicing and potentially more expensive replacement parts. However, the improved fuel delivery and combustion characteristics could lead to reduced carbon buildup and wear on engine components, potentially extending the overall engine life and reducing long-term maintenance needs.

From a performance perspective, the benefits of high-pressure fuel systems can translate into tangible competitive advantages in motorsports or other high-performance applications. The ability to extract more power from an engine without significant modifications to other components can provide a cost-effective path to improved performance.

Environmental considerations also play a role in the cost-benefit analysis. The improved fuel efficiency and more complete combustion associated with high-pressure fuel systems can lead to reduced emissions. This may help manufacturers meet increasingly stringent environmental regulations without resorting to more costly emission control technologies.

In conclusion, while high-pressure fuel systems for LS engines come with increased upfront costs, the potential benefits in terms of performance, efficiency, and long-term savings can outweigh these initial expenses in many applications. The specific cost-benefit ratio will depend on factors such as the intended use of the engine, fuel prices, and regulatory environment.

However, the benefits of high-pressure fuel systems can be substantial. One of the primary advantages is improved fuel atomization, which leads to more efficient combustion. This efficiency gain can result in increased engine power output and improved fuel economy. In performance applications, the ability to deliver precise amounts of fuel at high pressures allows for better control over the air-fuel mixture, especially at high engine speeds and loads.

The long-term cost implications should also be considered. While initial costs are higher, the improved efficiency and potential for increased power output may lead to reduced fuel consumption over time, particularly in high-performance or heavy-duty applications. This could result in significant savings over the lifespan of the engine, especially for commercial or industrial users where fuel costs are a major operational expense.

Maintenance costs are another factor to weigh. High-pressure systems may require more frequent servicing and potentially more expensive replacement parts. However, the improved fuel delivery and combustion characteristics could lead to reduced carbon buildup and wear on engine components, potentially extending the overall engine life and reducing long-term maintenance needs.

From a performance perspective, the benefits of high-pressure fuel systems can translate into tangible competitive advantages in motorsports or other high-performance applications. The ability to extract more power from an engine without significant modifications to other components can provide a cost-effective path to improved performance.

Environmental considerations also play a role in the cost-benefit analysis. The improved fuel efficiency and more complete combustion associated with high-pressure fuel systems can lead to reduced emissions. This may help manufacturers meet increasingly stringent environmental regulations without resorting to more costly emission control technologies.

In conclusion, while high-pressure fuel systems for LS engines come with increased upfront costs, the potential benefits in terms of performance, efficiency, and long-term savings can outweigh these initial expenses in many applications. The specific cost-benefit ratio will depend on factors such as the intended use of the engine, fuel prices, and regulatory environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!