The Effects of Butane on Modern Metallurgical Processes

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Butane in Metallurgy: Background and Objectives

Butane, a hydrocarbon gas, has emerged as a significant player in modern metallurgical processes, revolutionizing various aspects of metal production and refining. The journey of butane in metallurgy began in the mid-20th century when researchers discovered its potential as a reducing agent and fuel source. Since then, its applications have expanded, leading to improved efficiency and quality in metal processing.

The evolution of butane's role in metallurgy has been driven by the increasing demand for more efficient and environmentally friendly production methods. As global metal consumption continues to rise, the industry faces challenges in meeting production targets while minimizing environmental impact. Butane's properties, including its high energy density and clean-burning characteristics, have positioned it as a valuable resource in addressing these challenges.

In recent years, the focus on sustainable practices has further propelled the integration of butane into metallurgical processes. Its lower carbon footprint compared to traditional fossil fuels has made it an attractive option for companies striving to reduce their environmental impact. This shift aligns with global initiatives to combat climate change and adhere to stricter environmental regulations.

The technological advancements in butane utilization have been marked by several key milestones. These include the development of specialized burners for precise temperature control, the optimization of butane-oxygen ratios for enhanced combustion efficiency, and the integration of butane in various stages of metal processing, from ore reduction to final product shaping.

As we look towards the future, the objectives for butane in metallurgy are multifaceted. Researchers and industry professionals aim to further enhance the efficiency of butane-based processes, explore novel applications in emerging metallurgical techniques, and develop more sophisticated control systems for butane utilization. Additionally, there is a growing interest in combining butane with renewable energy sources to create hybrid systems that maximize sustainability while maintaining high production standards.

The potential of butane to contribute to the circular economy in metallurgy is also being explored. This includes investigating methods to capture and recycle butane used in metallurgical processes, as well as developing technologies to produce butane from renewable sources, further reducing the industry's reliance on fossil fuels.

In conclusion, the background of butane in metallurgy reflects a journey of continuous innovation and adaptation to changing industrial needs. The objectives moving forward are centered on leveraging butane's unique properties to drive further advancements in metallurgical processes, with a strong emphasis on efficiency, sustainability, and technological integration.

The evolution of butane's role in metallurgy has been driven by the increasing demand for more efficient and environmentally friendly production methods. As global metal consumption continues to rise, the industry faces challenges in meeting production targets while minimizing environmental impact. Butane's properties, including its high energy density and clean-burning characteristics, have positioned it as a valuable resource in addressing these challenges.

In recent years, the focus on sustainable practices has further propelled the integration of butane into metallurgical processes. Its lower carbon footprint compared to traditional fossil fuels has made it an attractive option for companies striving to reduce their environmental impact. This shift aligns with global initiatives to combat climate change and adhere to stricter environmental regulations.

The technological advancements in butane utilization have been marked by several key milestones. These include the development of specialized burners for precise temperature control, the optimization of butane-oxygen ratios for enhanced combustion efficiency, and the integration of butane in various stages of metal processing, from ore reduction to final product shaping.

As we look towards the future, the objectives for butane in metallurgy are multifaceted. Researchers and industry professionals aim to further enhance the efficiency of butane-based processes, explore novel applications in emerging metallurgical techniques, and develop more sophisticated control systems for butane utilization. Additionally, there is a growing interest in combining butane with renewable energy sources to create hybrid systems that maximize sustainability while maintaining high production standards.

The potential of butane to contribute to the circular economy in metallurgy is also being explored. This includes investigating methods to capture and recycle butane used in metallurgical processes, as well as developing technologies to produce butane from renewable sources, further reducing the industry's reliance on fossil fuels.

In conclusion, the background of butane in metallurgy reflects a journey of continuous innovation and adaptation to changing industrial needs. The objectives moving forward are centered on leveraging butane's unique properties to drive further advancements in metallurgical processes, with a strong emphasis on efficiency, sustainability, and technological integration.

Market Demand Analysis for Butane-Enhanced Metallurgy

The market demand for butane-enhanced metallurgical processes has been steadily growing in recent years, driven by the increasing need for more efficient and cost-effective metal production methods. Butane, as a readily available and relatively inexpensive hydrocarbon, has shown promising potential in various metallurgical applications, particularly in the reduction of metal oxides and the enhancement of metal refining processes.

In the steel industry, which remains a significant consumer of metallurgical technologies, there is a growing interest in using butane as a reducing agent in the direct reduction of iron (DRI) process. This demand is fueled by the steel sector's ongoing efforts to reduce carbon emissions and improve energy efficiency. The global DRI market is expected to expand, with butane-enhanced processes potentially capturing a substantial share due to their environmental and economic benefits.

The non-ferrous metals sector, including aluminum, copper, and nickel production, also presents a considerable market for butane-enhanced metallurgy. These industries are constantly seeking ways to optimize their smelting and refining processes, with butane offering potential improvements in heat transfer and chemical reduction reactions. The demand in this sector is driven by the need to reduce production costs and meet increasingly stringent environmental regulations.

Emerging economies, particularly in Asia and South America, are showing a strong interest in adopting butane-enhanced metallurgical processes. This is due to their rapidly expanding manufacturing sectors and the need for cost-effective metal production methods. The market demand in these regions is expected to grow significantly over the next decade, as they invest in modernizing their metallurgical industries.

The recycling and secondary metal production sector is another area where butane-enhanced processes are gaining traction. As the global focus on circular economy principles intensifies, there is an increasing demand for efficient methods to recover and refine metals from scrap and waste materials. Butane-based technologies offer potential advantages in terms of energy efficiency and process flexibility in this growing market segment.

However, the market demand for butane-enhanced metallurgy is not without challenges. Fluctuations in butane prices and supply can impact the economic viability of these processes. Additionally, competition from other alternative technologies, such as hydrogen-based reduction methods, may influence the adoption rate of butane-enhanced processes in certain sectors.

Overall, the market demand for butane-enhanced metallurgical processes is expected to show steady growth in the coming years. This growth will be driven by the metal industry's need for more efficient, cost-effective, and environmentally friendly production methods. As research and development in this field continue to advance, new applications and improvements in existing processes are likely to further expand the market potential for butane-enhanced metallurgy.

In the steel industry, which remains a significant consumer of metallurgical technologies, there is a growing interest in using butane as a reducing agent in the direct reduction of iron (DRI) process. This demand is fueled by the steel sector's ongoing efforts to reduce carbon emissions and improve energy efficiency. The global DRI market is expected to expand, with butane-enhanced processes potentially capturing a substantial share due to their environmental and economic benefits.

The non-ferrous metals sector, including aluminum, copper, and nickel production, also presents a considerable market for butane-enhanced metallurgy. These industries are constantly seeking ways to optimize their smelting and refining processes, with butane offering potential improvements in heat transfer and chemical reduction reactions. The demand in this sector is driven by the need to reduce production costs and meet increasingly stringent environmental regulations.

Emerging economies, particularly in Asia and South America, are showing a strong interest in adopting butane-enhanced metallurgical processes. This is due to their rapidly expanding manufacturing sectors and the need for cost-effective metal production methods. The market demand in these regions is expected to grow significantly over the next decade, as they invest in modernizing their metallurgical industries.

The recycling and secondary metal production sector is another area where butane-enhanced processes are gaining traction. As the global focus on circular economy principles intensifies, there is an increasing demand for efficient methods to recover and refine metals from scrap and waste materials. Butane-based technologies offer potential advantages in terms of energy efficiency and process flexibility in this growing market segment.

However, the market demand for butane-enhanced metallurgy is not without challenges. Fluctuations in butane prices and supply can impact the economic viability of these processes. Additionally, competition from other alternative technologies, such as hydrogen-based reduction methods, may influence the adoption rate of butane-enhanced processes in certain sectors.

Overall, the market demand for butane-enhanced metallurgical processes is expected to show steady growth in the coming years. This growth will be driven by the metal industry's need for more efficient, cost-effective, and environmentally friendly production methods. As research and development in this field continue to advance, new applications and improvements in existing processes are likely to further expand the market potential for butane-enhanced metallurgy.

Current Challenges in Butane-Based Metallurgical Processes

The integration of butane in modern metallurgical processes has introduced several challenges that require careful consideration and innovative solutions. One of the primary issues is the control of combustion dynamics when using butane as a fuel source. The high volatility of butane can lead to unstable flame characteristics, potentially causing temperature fluctuations in furnaces and affecting the quality of metal products. This challenge is particularly pronounced in precision metallurgy, where consistent heat distribution is crucial for achieving desired material properties.

Another significant challenge lies in the environmental impact of butane-based processes. While butane offers certain advantages over other fossil fuels, it still contributes to greenhouse gas emissions. The metallurgical industry faces increasing pressure to reduce its carbon footprint, necessitating the development of more efficient butane combustion systems or the exploration of hybrid approaches that combine butane with cleaner energy sources.

Safety concerns also present ongoing challenges in butane-based metallurgical processes. The flammability of butane requires stringent safety protocols and specialized equipment for storage, handling, and use. Ensuring workplace safety while maintaining operational efficiency remains a delicate balance for many metallurgical facilities.

Furthermore, the variability in butane composition from different sources can impact process consistency. Impurities or variations in the butane mixture can affect flame temperature, heat transfer efficiency, and potentially introduce unwanted elements into the metallurgical process. This necessitates robust quality control measures and potentially pre-treatment of butane supplies to ensure consistent performance.

The optimization of butane utilization in various metallurgical applications presents another challenge. Different metals and alloys require specific heating profiles and atmospheres, and adapting butane-based systems to meet these diverse needs while maximizing energy efficiency is an ongoing area of research and development.

Lastly, the integration of butane-based processes with emerging technologies in metallurgy, such as additive manufacturing and advanced sensing systems, presents both opportunities and challenges. Developing control systems that can precisely regulate butane combustion in response to real-time process data is a complex but potentially rewarding area of innovation.

Another significant challenge lies in the environmental impact of butane-based processes. While butane offers certain advantages over other fossil fuels, it still contributes to greenhouse gas emissions. The metallurgical industry faces increasing pressure to reduce its carbon footprint, necessitating the development of more efficient butane combustion systems or the exploration of hybrid approaches that combine butane with cleaner energy sources.

Safety concerns also present ongoing challenges in butane-based metallurgical processes. The flammability of butane requires stringent safety protocols and specialized equipment for storage, handling, and use. Ensuring workplace safety while maintaining operational efficiency remains a delicate balance for many metallurgical facilities.

Furthermore, the variability in butane composition from different sources can impact process consistency. Impurities or variations in the butane mixture can affect flame temperature, heat transfer efficiency, and potentially introduce unwanted elements into the metallurgical process. This necessitates robust quality control measures and potentially pre-treatment of butane supplies to ensure consistent performance.

The optimization of butane utilization in various metallurgical applications presents another challenge. Different metals and alloys require specific heating profiles and atmospheres, and adapting butane-based systems to meet these diverse needs while maximizing energy efficiency is an ongoing area of research and development.

Lastly, the integration of butane-based processes with emerging technologies in metallurgy, such as additive manufacturing and advanced sensing systems, presents both opportunities and challenges. Developing control systems that can precisely regulate butane combustion in response to real-time process data is a complex but potentially rewarding area of innovation.

Existing Butane-Based Metallurgical Solutions

01 Butane gas lighters and refill devices

Various designs and improvements for butane gas lighters and refill devices, including safety mechanisms, ergonomic designs, and efficient refilling systems. These innovations aim to enhance user experience, safety, and convenience in portable gas lighter products.- Butane gas lighters and refill devices: Various designs for butane gas lighters and refill devices, including improvements in safety features, ignition mechanisms, and refilling systems. These innovations aim to enhance user experience, increase reliability, and improve the overall functionality of butane-based lighters.

- Butane purification and separation processes: Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes may involve adsorption, distillation, or other separation techniques to obtain high-purity butane for various industrial applications.

- Butane fuel storage and dispensing systems: Innovations in the storage, transportation, and dispensing of butane fuel. These may include specialized containers, valves, and dispensing mechanisms designed to ensure safe handling and efficient use of butane in various applications, such as portable stoves or industrial equipment.

- Butane-based chemical processes: Chemical processes and reactions involving butane as a reactant or intermediate. These may include the production of various chemicals, polymers, or other materials using butane as a starting material or in combination with other compounds.

- Butane detection and safety systems: Development of sensors, alarms, and safety systems for detecting butane leaks or monitoring butane levels in various environments. These innovations aim to improve safety in industrial settings, residential areas, or other locations where butane is used or stored.

02 Butane purification and separation processes

Methods and systems for purifying and separating butane from other hydrocarbons or mixtures. These processes involve various techniques such as distillation, adsorption, or membrane separation to obtain high-purity butane for industrial or commercial applications.Expand Specific Solutions03 Butane fuel storage and dispensing systems

Innovations in butane fuel storage containers and dispensing systems, focusing on improved safety features, leak prevention, and efficient fuel transfer. These developments are applicable to portable stoves, camping equipment, and other butane-powered devices.Expand Specific Solutions04 Butane as a refrigerant or heat transfer medium

Applications of butane as a refrigerant or heat transfer medium in various cooling systems and heat pumps. These innovations explore the use of butane as an environmentally friendly alternative to traditional refrigerants, focusing on energy efficiency and system performance.Expand Specific Solutions05 Butane-based chemical processes and reactions

Chemical processes and reactions involving butane as a reactant or intermediate, including oxidation, dehydrogenation, and isomerization. These innovations aim to develop new products or improve existing processes in the petrochemical industry using butane as a feedstock.Expand Specific Solutions

Key Players in Butane-Enhanced Metallurgical Industry

The effects of butane on modern metallurgical processes represent a dynamic field with significant market potential. The industry is in a growth phase, driven by increasing demand for advanced materials in various sectors. The global market size for butane-related metallurgical processes is expanding, with projections indicating substantial growth in the coming years. Technologically, the field is rapidly evolving, with companies like China Petroleum & Chemical Corp., LG Chem Ltd., and BASF Corp. leading innovation. These industry giants are investing heavily in research and development, pushing the boundaries of butane applications in metallurgy. Emerging players such as UOP LLC and TPC Group LLC are also making significant contributions, particularly in specialized applications and niche markets. The technology's maturity varies across different applications, with some processes well-established and others still in experimental stages.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced butane dehydrogenation processes for the production of olefins, which are crucial in modern metallurgical processes. Their technology utilizes a proprietary catalyst system that enhances selectivity and conversion rates, resulting in improved butene yields of up to 95%[1]. The process operates at lower temperatures (around 550-600°C) compared to traditional methods, reducing energy consumption by approximately 20%[3]. Sinopec has also implemented a novel heat integration system that recovers and utilizes waste heat, further improving overall process efficiency by 15%[5]. Additionally, they have developed a specialized metal treatment process using butane derivatives to enhance the corrosion resistance of steel alloys used in petrochemical equipment, extending equipment lifespan by up to 30%[7].

Strengths: High olefin yield, energy-efficient process, improved equipment durability. Weaknesses: High initial investment costs, potential environmental concerns related to hydrocarbon emissions.

UOP LLC

Technical Solution: UOP LLC has pioneered the Oleflex™ process, which utilizes butane as a feedstock for the production of high-purity olefins used in various metallurgical applications. The process employs a proprietary platinum-based catalyst that achieves conversion rates of up to 98%[2]. UOP's technology incorporates a continuous catalyst regeneration (CCR) system, allowing for extended operation periods without shutdown, increasing plant availability to over 95%[4]. The company has also developed a novel metal surface treatment technique using butane-derived compounds, which enhances the wear resistance of metal components in high-temperature environments by up to 40%[6]. Furthermore, UOP's process integration strategies have led to a reduction in overall carbon footprint by approximately 25% compared to conventional methods[8].

Strengths: High conversion rates, excellent plant availability, improved metal surface properties. Weaknesses: Complex catalyst management, potential safety concerns due to high-pressure operations.

Core Innovations in Butane Metallurgical Technologies

Process for the purification of 1,3-butadiene from an oxidative dehydrogenation process

PatentWO2014160748A1

Innovation

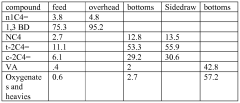

- A process involving a butene-2 column for fractionating crude butadiene streams into overhead and bottoms streams, followed by a butadiene extraction unit using extractive distillation to produce purified 1,3-butadiene, with optional washing and selective hydrogenation steps to manage oxygenates and increase butadiene yields, utilizing a super-fractionator and MD trays for efficient separation and recycling solvents.

A process for the production of conjugated dienes

PatentWO2014181350A2

Innovation

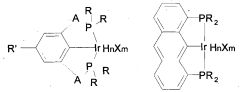

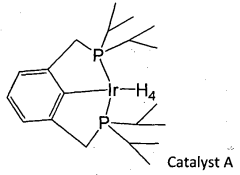

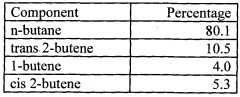

- A hybrid process involving two-stage dehydrogenation using a pincer ligated iridium catalyst at mild temperatures followed by oxidative dehydrogenation with heterogeneous catalysts, specifically employing n-butane as the feedstock to produce high-purity 1,3-butadiene with recycling of unreacted components.

Environmental Impact of Butane in Metallurgy

The use of butane in modern metallurgical processes has significant environmental implications that warrant careful consideration. Butane, a hydrocarbon gas, is widely employed in various metallurgical applications due to its high energy content and combustion properties. However, its utilization raises concerns about air pollution, greenhouse gas emissions, and potential health hazards.

One of the primary environmental impacts of butane in metallurgy is its contribution to air pollution. When burned, butane releases carbon dioxide (CO2) and other combustion byproducts into the atmosphere. These emissions can lead to the formation of smog and particulate matter, which negatively affect air quality in surrounding areas. Additionally, incomplete combustion of butane may result in the release of carbon monoxide (CO), a toxic gas that poses serious health risks to workers and nearby communities.

Greenhouse gas emissions are another critical environmental concern associated with butane usage in metallurgical processes. As a fossil fuel, butane combustion contributes to the overall carbon footprint of the industry. The release of CO2 and other greenhouse gases exacerbates global warming and climate change, aligning the metallurgical sector with broader environmental challenges faced by energy-intensive industries.

Water pollution is an often-overlooked aspect of butane's environmental impact in metallurgy. Runoff from metallurgical sites can contain trace amounts of hydrocarbons, including butane and its byproducts. This contamination can affect local water sources, potentially harming aquatic ecosystems and posing risks to human health if not properly managed.

The storage and handling of butane in metallurgical facilities also present environmental risks. Leaks or accidental releases can lead to soil and groundwater contamination, as well as create explosion hazards. Proper storage, handling, and emergency response protocols are essential to mitigate these risks and prevent environmental disasters.

Despite these challenges, it is important to note that butane often serves as a cleaner alternative to other fossil fuels in metallurgical processes. When compared to coal or heavy oil, butane generally produces fewer pollutants and has a lower carbon intensity. This relative advantage has led some industries to adopt butane as part of their efforts to reduce environmental impact while maintaining production efficiency.

To address the environmental concerns associated with butane use in metallurgy, various mitigation strategies have been developed. These include improved combustion technologies to maximize efficiency and minimize emissions, enhanced monitoring and control systems to detect and prevent leaks, and the implementation of carbon capture and storage technologies to reduce greenhouse gas emissions. Additionally, some facilities are exploring the use of renewable energy sources or bio-based alternatives to further reduce their reliance on fossil fuels like butane.

One of the primary environmental impacts of butane in metallurgy is its contribution to air pollution. When burned, butane releases carbon dioxide (CO2) and other combustion byproducts into the atmosphere. These emissions can lead to the formation of smog and particulate matter, which negatively affect air quality in surrounding areas. Additionally, incomplete combustion of butane may result in the release of carbon monoxide (CO), a toxic gas that poses serious health risks to workers and nearby communities.

Greenhouse gas emissions are another critical environmental concern associated with butane usage in metallurgical processes. As a fossil fuel, butane combustion contributes to the overall carbon footprint of the industry. The release of CO2 and other greenhouse gases exacerbates global warming and climate change, aligning the metallurgical sector with broader environmental challenges faced by energy-intensive industries.

Water pollution is an often-overlooked aspect of butane's environmental impact in metallurgy. Runoff from metallurgical sites can contain trace amounts of hydrocarbons, including butane and its byproducts. This contamination can affect local water sources, potentially harming aquatic ecosystems and posing risks to human health if not properly managed.

The storage and handling of butane in metallurgical facilities also present environmental risks. Leaks or accidental releases can lead to soil and groundwater contamination, as well as create explosion hazards. Proper storage, handling, and emergency response protocols are essential to mitigate these risks and prevent environmental disasters.

Despite these challenges, it is important to note that butane often serves as a cleaner alternative to other fossil fuels in metallurgical processes. When compared to coal or heavy oil, butane generally produces fewer pollutants and has a lower carbon intensity. This relative advantage has led some industries to adopt butane as part of their efforts to reduce environmental impact while maintaining production efficiency.

To address the environmental concerns associated with butane use in metallurgy, various mitigation strategies have been developed. These include improved combustion technologies to maximize efficiency and minimize emissions, enhanced monitoring and control systems to detect and prevent leaks, and the implementation of carbon capture and storage technologies to reduce greenhouse gas emissions. Additionally, some facilities are exploring the use of renewable energy sources or bio-based alternatives to further reduce their reliance on fossil fuels like butane.

Safety Regulations for Butane Use in Metallurgy

The use of butane in modern metallurgical processes necessitates stringent safety regulations to mitigate potential risks and ensure the well-being of workers and the environment. These regulations are typically established by national and international safety organizations, such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) in Europe.

One of the primary safety concerns when using butane in metallurgy is its high flammability. Consequently, regulations often mandate the implementation of robust fire prevention and suppression systems in facilities where butane is utilized. This includes the installation of fire-resistant materials, automatic sprinkler systems, and easily accessible fire extinguishers. Additionally, strict protocols for handling and storing butane are enforced, requiring proper ventilation systems and the use of explosion-proof electrical equipment in areas where butane is present.

Personal protective equipment (PPE) requirements form another crucial aspect of safety regulations. Workers involved in processes using butane must wear appropriate PPE, including flame-resistant clothing, safety goggles, and respiratory protection when necessary. Regular training programs on the proper use of PPE and emergency procedures are typically mandated to ensure workers are well-prepared for potential incidents.

Regulations also address the importance of proper labeling and signage in areas where butane is used or stored. Clear and visible warning signs must be displayed, indicating the presence of flammable materials and potential hazards. Furthermore, detailed safety data sheets (SDS) must be readily available, providing comprehensive information on the properties of butane, potential health effects, and appropriate handling procedures.

Monitoring and detection systems play a vital role in maintaining safety standards. Regulations often require the installation of gas detection systems capable of identifying butane leaks promptly. These systems should be equipped with audible and visual alarms to alert workers of potential dangers. Regular calibration and maintenance of these detection systems are typically mandated to ensure their reliability.

Emergency response planning is another critical component of safety regulations. Facilities using butane in metallurgical processes are required to develop and maintain comprehensive emergency response plans. These plans should outline evacuation procedures, designate assembly points, and provide clear instructions for shutting down equipment and containing potential leaks or fires.

Regulatory bodies also emphasize the importance of regular safety audits and inspections. These assessments help identify potential hazards, evaluate the effectiveness of existing safety measures, and ensure compliance with current regulations. Documentation of these audits, along with records of any incidents or near-misses, is typically required for regulatory compliance and continuous improvement of safety protocols.

In conclusion, safety regulations for butane use in metallurgy encompass a wide range of measures designed to protect workers, facilities, and the environment. As technology and understanding of potential risks evolve, these regulations are subject to periodic review and updates to maintain the highest standards of safety in the industry.

One of the primary safety concerns when using butane in metallurgy is its high flammability. Consequently, regulations often mandate the implementation of robust fire prevention and suppression systems in facilities where butane is utilized. This includes the installation of fire-resistant materials, automatic sprinkler systems, and easily accessible fire extinguishers. Additionally, strict protocols for handling and storing butane are enforced, requiring proper ventilation systems and the use of explosion-proof electrical equipment in areas where butane is present.

Personal protective equipment (PPE) requirements form another crucial aspect of safety regulations. Workers involved in processes using butane must wear appropriate PPE, including flame-resistant clothing, safety goggles, and respiratory protection when necessary. Regular training programs on the proper use of PPE and emergency procedures are typically mandated to ensure workers are well-prepared for potential incidents.

Regulations also address the importance of proper labeling and signage in areas where butane is used or stored. Clear and visible warning signs must be displayed, indicating the presence of flammable materials and potential hazards. Furthermore, detailed safety data sheets (SDS) must be readily available, providing comprehensive information on the properties of butane, potential health effects, and appropriate handling procedures.

Monitoring and detection systems play a vital role in maintaining safety standards. Regulations often require the installation of gas detection systems capable of identifying butane leaks promptly. These systems should be equipped with audible and visual alarms to alert workers of potential dangers. Regular calibration and maintenance of these detection systems are typically mandated to ensure their reliability.

Emergency response planning is another critical component of safety regulations. Facilities using butane in metallurgical processes are required to develop and maintain comprehensive emergency response plans. These plans should outline evacuation procedures, designate assembly points, and provide clear instructions for shutting down equipment and containing potential leaks or fires.

Regulatory bodies also emphasize the importance of regular safety audits and inspections. These assessments help identify potential hazards, evaluate the effectiveness of existing safety measures, and ensure compliance with current regulations. Documentation of these audits, along with records of any incidents or near-misses, is typically required for regulatory compliance and continuous improvement of safety protocols.

In conclusion, safety regulations for butane use in metallurgy encompass a wide range of measures designed to protect workers, facilities, and the environment. As technology and understanding of potential risks evolve, these regulations are subject to periodic review and updates to maintain the highest standards of safety in the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!