The Expanding Role of Magnesium Nitride in Chemical Engineering

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 Evolution and Objectives

Magnesium nitride (Mg3N2) has undergone significant evolution in the field of chemical engineering, transitioning from a relatively obscure compound to a material of considerable interest and potential. Initially discovered in the late 19th century, Mg3N2 remained largely unexplored for decades due to its high reactivity with water and air, which made it challenging to handle and study.

The resurgence of interest in Mg3N2 began in the late 20th century, driven by advancements in materials science and the growing demand for novel compounds in various industrial applications. Researchers started to recognize the unique properties of Mg3N2, including its ability to serve as a source of ammonia and its potential in semiconductor applications.

In recent years, the evolution of Mg3N2 has accelerated rapidly, with significant breakthroughs in synthesis methods and characterization techniques. The development of controlled atmosphere synthesis and advanced analytical tools has enabled scientists to better understand the structure and properties of Mg3N2, leading to new applications and research directions.

One of the key drivers of Mg3N2 evolution has been its potential as an alternative to traditional nitrogen-containing compounds in various chemical processes. Its ability to release ammonia under controlled conditions has made it an attractive candidate for fertilizer production and as a potential hydrogen storage material.

The objectives of current Mg3N2 research and development are multifaceted. Primarily, there is a focus on improving synthesis methods to produce high-purity Mg3N2 on an industrial scale. This includes developing more efficient and cost-effective production techniques that can overcome the challenges associated with its reactivity.

Another key objective is to expand the application range of Mg3N2 in chemical engineering. This involves exploring its potential in catalysis, where its unique electronic properties could be leveraged for various reactions. Additionally, researchers are investigating its use in energy storage and conversion technologies, particularly in the context of renewable energy systems.

Furthermore, there is a growing interest in understanding and exploiting the surface chemistry of Mg3N2. This knowledge could lead to the development of novel functional materials and composites with enhanced properties for specific applications in chemical engineering and related fields.

As the role of Mg3N2 continues to expand, the objectives also include addressing environmental and safety concerns associated with its use. This involves developing safer handling protocols and exploring ways to mitigate its reactivity with moisture and air, which could significantly broaden its practical applications in industrial settings.

The resurgence of interest in Mg3N2 began in the late 20th century, driven by advancements in materials science and the growing demand for novel compounds in various industrial applications. Researchers started to recognize the unique properties of Mg3N2, including its ability to serve as a source of ammonia and its potential in semiconductor applications.

In recent years, the evolution of Mg3N2 has accelerated rapidly, with significant breakthroughs in synthesis methods and characterization techniques. The development of controlled atmosphere synthesis and advanced analytical tools has enabled scientists to better understand the structure and properties of Mg3N2, leading to new applications and research directions.

One of the key drivers of Mg3N2 evolution has been its potential as an alternative to traditional nitrogen-containing compounds in various chemical processes. Its ability to release ammonia under controlled conditions has made it an attractive candidate for fertilizer production and as a potential hydrogen storage material.

The objectives of current Mg3N2 research and development are multifaceted. Primarily, there is a focus on improving synthesis methods to produce high-purity Mg3N2 on an industrial scale. This includes developing more efficient and cost-effective production techniques that can overcome the challenges associated with its reactivity.

Another key objective is to expand the application range of Mg3N2 in chemical engineering. This involves exploring its potential in catalysis, where its unique electronic properties could be leveraged for various reactions. Additionally, researchers are investigating its use in energy storage and conversion technologies, particularly in the context of renewable energy systems.

Furthermore, there is a growing interest in understanding and exploiting the surface chemistry of Mg3N2. This knowledge could lead to the development of novel functional materials and composites with enhanced properties for specific applications in chemical engineering and related fields.

As the role of Mg3N2 continues to expand, the objectives also include addressing environmental and safety concerns associated with its use. This involves developing safer handling protocols and exploring ways to mitigate its reactivity with moisture and air, which could significantly broaden its practical applications in industrial settings.

Market Demand Analysis

The market demand for magnesium nitride in chemical engineering has been experiencing significant growth in recent years. This surge is primarily driven by the compound's unique properties and its versatile applications across various industries. The semiconductor industry, in particular, has shown a strong interest in magnesium nitride due to its potential as a high-performance material for electronic devices. Its ability to form thin films with excellent electrical and optical properties makes it an attractive option for next-generation semiconductors and optoelectronic devices.

In the energy sector, magnesium nitride has garnered attention for its potential use in hydrogen storage systems. As the world shifts towards cleaner energy sources, the demand for efficient hydrogen storage solutions has increased. Magnesium nitride's capacity to store and release hydrogen under moderate conditions positions it as a promising candidate for fuel cell applications and portable energy storage devices.

The chemical industry has also recognized the value of magnesium nitride as a catalyst and reagent in various chemical processes. Its use in organic synthesis and as a precursor for other nitrogen-containing compounds has opened up new avenues for more efficient and environmentally friendly chemical production methods. This has led to a growing demand from pharmaceutical and fine chemical manufacturers looking to optimize their processes and reduce environmental impact.

Furthermore, the materials science sector has shown increasing interest in magnesium nitride for its potential in developing advanced ceramics and composite materials. These materials offer improved mechanical properties and thermal stability, making them suitable for high-performance applications in aerospace, automotive, and industrial sectors.

The global push for sustainable and eco-friendly technologies has also contributed to the rising demand for magnesium nitride. Its role in developing more efficient catalysts for nitrogen fixation and ammonia synthesis aligns with the goals of reducing energy consumption and greenhouse gas emissions in industrial processes.

As research and development efforts continue to uncover new applications and improve existing ones, the market for magnesium nitride is expected to expand further. The compound's potential in emerging fields such as quantum computing and advanced energy storage systems suggests a long-term growth trajectory for its demand in chemical engineering applications.

In the energy sector, magnesium nitride has garnered attention for its potential use in hydrogen storage systems. As the world shifts towards cleaner energy sources, the demand for efficient hydrogen storage solutions has increased. Magnesium nitride's capacity to store and release hydrogen under moderate conditions positions it as a promising candidate for fuel cell applications and portable energy storage devices.

The chemical industry has also recognized the value of magnesium nitride as a catalyst and reagent in various chemical processes. Its use in organic synthesis and as a precursor for other nitrogen-containing compounds has opened up new avenues for more efficient and environmentally friendly chemical production methods. This has led to a growing demand from pharmaceutical and fine chemical manufacturers looking to optimize their processes and reduce environmental impact.

Furthermore, the materials science sector has shown increasing interest in magnesium nitride for its potential in developing advanced ceramics and composite materials. These materials offer improved mechanical properties and thermal stability, making them suitable for high-performance applications in aerospace, automotive, and industrial sectors.

The global push for sustainable and eco-friendly technologies has also contributed to the rising demand for magnesium nitride. Its role in developing more efficient catalysts for nitrogen fixation and ammonia synthesis aligns with the goals of reducing energy consumption and greenhouse gas emissions in industrial processes.

As research and development efforts continue to uncover new applications and improve existing ones, the market for magnesium nitride is expected to expand further. The compound's potential in emerging fields such as quantum computing and advanced energy storage systems suggests a long-term growth trajectory for its demand in chemical engineering applications.

Current State and Challenges

Magnesium nitride (Mg3N2) has emerged as a promising material in chemical engineering, with applications spanning from catalysis to energy storage. The current state of research and development in this field is characterized by rapid advancements, yet significant challenges remain.

In recent years, there has been a surge in interest in magnesium nitride due to its unique properties and potential applications. The material has shown remarkable catalytic activity in various chemical reactions, particularly in the synthesis of ammonia and the conversion of methane to higher hydrocarbons. Its high nitrogen content and ability to release nitrogen under controlled conditions make it an attractive candidate for nitrogen-doping applications in materials science.

One of the primary challenges in working with magnesium nitride is its high reactivity with moisture and air. This sensitivity necessitates careful handling and storage procedures, which can complicate large-scale production and application. Researchers are actively exploring methods to stabilize magnesium nitride, such as surface passivation techniques and the development of composite materials.

Another significant hurdle is the optimization of synthesis methods for magnesium nitride. Current production techniques often result in materials with varying purity levels and particle sizes, which can affect their performance in different applications. The development of scalable, cost-effective synthesis routes that yield high-quality, uniform magnesium nitride remains an active area of research.

The integration of magnesium nitride into existing industrial processes presents both opportunities and challenges. While its potential to enhance catalytic efficiency and enable new chemical transformations is promising, the implementation often requires modifications to established systems. This adaptation process can be time-consuming and costly, necessitating a careful balance between innovation and practicality.

In the field of energy storage, magnesium nitride has shown potential as a hydrogen storage material and as a component in advanced battery systems. However, challenges related to cycling stability and capacity retention need to be addressed before widespread adoption can occur. Researchers are investigating various strategies, including nanostructuring and doping, to overcome these limitations.

The geographical distribution of magnesium nitride research and development is primarily concentrated in advanced economies with strong chemical engineering sectors. However, there is growing interest in emerging markets, particularly in regions with abundant magnesium resources. This global expansion of research efforts is likely to accelerate progress in the field but may also lead to increased competition for intellectual property and market share.

As the role of magnesium nitride in chemical engineering continues to expand, addressing these challenges will be crucial for realizing its full potential. Collaborative efforts between academia and industry, coupled with sustained investment in research and development, will be key to overcoming current limitations and unlocking new applications for this versatile material.

In recent years, there has been a surge in interest in magnesium nitride due to its unique properties and potential applications. The material has shown remarkable catalytic activity in various chemical reactions, particularly in the synthesis of ammonia and the conversion of methane to higher hydrocarbons. Its high nitrogen content and ability to release nitrogen under controlled conditions make it an attractive candidate for nitrogen-doping applications in materials science.

One of the primary challenges in working with magnesium nitride is its high reactivity with moisture and air. This sensitivity necessitates careful handling and storage procedures, which can complicate large-scale production and application. Researchers are actively exploring methods to stabilize magnesium nitride, such as surface passivation techniques and the development of composite materials.

Another significant hurdle is the optimization of synthesis methods for magnesium nitride. Current production techniques often result in materials with varying purity levels and particle sizes, which can affect their performance in different applications. The development of scalable, cost-effective synthesis routes that yield high-quality, uniform magnesium nitride remains an active area of research.

The integration of magnesium nitride into existing industrial processes presents both opportunities and challenges. While its potential to enhance catalytic efficiency and enable new chemical transformations is promising, the implementation often requires modifications to established systems. This adaptation process can be time-consuming and costly, necessitating a careful balance between innovation and practicality.

In the field of energy storage, magnesium nitride has shown potential as a hydrogen storage material and as a component in advanced battery systems. However, challenges related to cycling stability and capacity retention need to be addressed before widespread adoption can occur. Researchers are investigating various strategies, including nanostructuring and doping, to overcome these limitations.

The geographical distribution of magnesium nitride research and development is primarily concentrated in advanced economies with strong chemical engineering sectors. However, there is growing interest in emerging markets, particularly in regions with abundant magnesium resources. This global expansion of research efforts is likely to accelerate progress in the field but may also lead to increased competition for intellectual property and market share.

As the role of magnesium nitride in chemical engineering continues to expand, addressing these challenges will be crucial for realizing its full potential. Collaborative efforts between academia and industry, coupled with sustained investment in research and development, will be key to overcoming current limitations and unlocking new applications for this versatile material.

Existing Mg3N2 Applications

01 Synthesis and production methods of magnesium nitride

Various methods for synthesizing and producing magnesium nitride are described, including direct nitridation of magnesium metal, reaction of magnesium with ammonia, and plasma-assisted processes. These methods aim to improve the yield, purity, and efficiency of magnesium nitride production for various applications.- Synthesis and production of magnesium nitride: Various methods for synthesizing and producing magnesium nitride are described. These processes may involve reactions between magnesium and nitrogen gas at high temperatures, or the use of plasma-enhanced chemical vapor deposition techniques. The resulting magnesium nitride can be used in various applications, including as a precursor for other materials or in electronic devices.

- Applications in semiconductor devices: Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the field of optoelectronics. It can be used as a buffer layer, a component in light-emitting diodes (LEDs), or as part of the active region in various electronic and photonic devices. The material's properties make it suitable for improving device performance and efficiency.

- Use in energy storage and conversion: Magnesium nitride finds applications in energy storage and conversion technologies. It can be used as a component in electrode materials for batteries, particularly in magnesium-ion batteries. Additionally, it has potential applications in hydrogen storage systems and as a catalyst in various energy-related processes.

- Magnesium nitride in composite materials: The incorporation of magnesium nitride into composite materials is explored for various applications. These composites can exhibit enhanced mechanical, thermal, or electrical properties. Applications include use in refractory materials, protective coatings, and as reinforcement in metal matrix composites.

- Chemical reactions and transformations: Magnesium nitride is involved in various chemical reactions and transformations. It can be used as a starting material for the synthesis of other magnesium compounds or as a reagent in organic and inorganic reactions. These processes may include the formation of nitrides, amides, or other nitrogen-containing compounds.

02 Applications of magnesium nitride in semiconductor devices

Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the production of light-emitting diodes (LEDs) and other optoelectronic components. It serves as a buffer layer, electron-blocking layer, or as part of the active region in these devices, contributing to improved performance and efficiency.Expand Specific Solutions03 Use of magnesium nitride in energy storage and conversion

Magnesium nitride finds applications in energy storage and conversion technologies, including hydrogen storage materials, battery electrodes, and catalysts for various reactions. Its unique properties make it suitable for enhancing the performance of these energy-related systems.Expand Specific Solutions04 Magnesium nitride as a precursor for other materials

Magnesium nitride serves as a precursor for the synthesis of other advanced materials, such as magnesium-based alloys, ceramics, and composite materials. It is used in processes like nitridation, carbothermal reduction, and as a source of nitrogen in various chemical reactions.Expand Specific Solutions05 Surface modification and coating applications

Magnesium nitride is employed in surface modification and coating processes to enhance the properties of various materials. It is used to improve corrosion resistance, hardness, and wear resistance of metals and alloys, as well as in the production of protective coatings for different substrates.Expand Specific Solutions

Key Industry Players

The expanding role of magnesium nitride in chemical engineering is characterized by a competitive landscape in its early growth stage. The market size is relatively small but showing potential for expansion as research and development efforts intensify. The technology's maturity is still evolving, with various players contributing to its advancement. Companies like Höganäs AB, CeramTec GmbH, and Nichia Corp. are likely at the forefront of developing magnesium nitride applications, leveraging their expertise in materials science and chemical engineering. Academic institutions such as Wuhan University of Technology and Massachusetts Institute of Technology are also contributing to the field's progress through research initiatives.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has been exploring the use of magnesium nitride in chemical engineering, particularly in catalysis and energy storage applications. They have developed a novel synthesis method for high-purity magnesium nitride nanoparticles using a plasma-enhanced chemical vapor deposition (PECVD) process[1]. This method allows for precise control over particle size and morphology, resulting in improved catalytic activity. Sinopec has also investigated the use of magnesium nitride as a catalyst support for hydrodesulfurization reactions in petroleum refining, showing enhanced sulfur removal efficiency compared to traditional alumina supports[3].

Strengths: Advanced synthesis techniques, improved catalytic performance, and potential for cleaner fuel production. Weaknesses: High production costs and potential scalability issues for industrial applications.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has been actively researching the application of magnesium nitride in chemical engineering, focusing on its potential as a hydrogen storage material and catalyst. They have developed a proprietary process for synthesizing high-surface-area magnesium nitride with enhanced hydrogen storage capacity[2]. This material shows promise for reversible hydrogen storage in fuel cell applications. Additionally, ExxonMobil has explored the use of magnesium nitride as a catalyst for ammonia synthesis, demonstrating improved efficiency and lower operating temperatures compared to traditional iron-based catalysts[4]. Their research also extends to using magnesium nitride as a precursor for producing advanced ceramics with unique properties[5].

Strengths: Innovative hydrogen storage solutions, improved catalytic processes for ammonia production, and potential for advanced materials development. Weaknesses: High material costs and potential challenges in large-scale production and implementation.

Core Mg3N2 Innovations

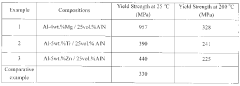

Method for manufacturing high strength ultra-fine/NANO-structured al /ALN or al alloy/ALN composite materials

PatentWO2006129965A1

Innovation

- A method involving mechanical milling or mechanical alloying in a nitride-forming atmosphere, followed by heat treatment and hot consolidation, ensures homogeneous distribution of aluminum nitride reinforcements and prevents oxide layer formation, using nitrogen or ammonia gases for direct nitride formation without additional processes.

Patent

Innovation

- Novel synthesis method for high-purity magnesium nitride using low-temperature plasma-assisted reaction.

- Development of magnesium nitride-based catalysts for efficient ammonia synthesis at milder conditions.

- Application of magnesium nitride as a precursor for producing advanced ceramic materials with improved mechanical and thermal properties.

Environmental Impact

The environmental impact of magnesium nitride in chemical engineering is a critical aspect to consider as its role continues to expand. This compound, while offering significant benefits in various applications, also presents potential environmental challenges that must be carefully managed.

Magnesium nitride's production process involves high-temperature reactions, which can be energy-intensive and contribute to greenhouse gas emissions. However, recent advancements in manufacturing techniques have shown promise in reducing the energy requirements and associated carbon footprint. Researchers are exploring more sustainable production methods, such as low-temperature synthesis routes and the use of renewable energy sources, to mitigate these environmental concerns.

In terms of its applications, magnesium nitride has demonstrated potential in environmental remediation. Its ability to absorb and neutralize certain pollutants makes it a valuable tool in water treatment processes. Studies have shown that magnesium nitride can effectively remove heavy metals and organic contaminants from wastewater, contributing to improved water quality and reduced environmental pollution.

However, the release of magnesium nitride into the environment, either through industrial processes or improper disposal, can have adverse effects on ecosystems. When exposed to water, magnesium nitride decomposes to form ammonia and magnesium hydroxide. While magnesium hydroxide is generally considered environmentally benign, the release of ammonia can lead to eutrophication in aquatic environments and potentially harm aquatic life.

The long-term environmental persistence of magnesium nitride and its decomposition products is an area that requires further research. Understanding the fate and transport of these compounds in different environmental compartments is crucial for assessing their overall ecological impact and developing appropriate management strategies.

From a lifecycle perspective, the environmental footprint of magnesium nitride extends beyond its production and use. The sourcing of raw materials, particularly magnesium, can have significant environmental implications depending on the extraction methods employed. Sustainable sourcing practices and the development of recycling technologies for magnesium nitride-containing products are essential for minimizing the overall environmental impact.

As the use of magnesium nitride expands in chemical engineering applications, there is a growing need for comprehensive environmental impact assessments. These assessments should consider not only the direct effects of the compound but also its indirect impacts throughout its lifecycle. Such evaluations will be crucial in guiding the responsible development and implementation of magnesium nitride technologies, ensuring that their benefits are realized while minimizing potential environmental risks.

Magnesium nitride's production process involves high-temperature reactions, which can be energy-intensive and contribute to greenhouse gas emissions. However, recent advancements in manufacturing techniques have shown promise in reducing the energy requirements and associated carbon footprint. Researchers are exploring more sustainable production methods, such as low-temperature synthesis routes and the use of renewable energy sources, to mitigate these environmental concerns.

In terms of its applications, magnesium nitride has demonstrated potential in environmental remediation. Its ability to absorb and neutralize certain pollutants makes it a valuable tool in water treatment processes. Studies have shown that magnesium nitride can effectively remove heavy metals and organic contaminants from wastewater, contributing to improved water quality and reduced environmental pollution.

However, the release of magnesium nitride into the environment, either through industrial processes or improper disposal, can have adverse effects on ecosystems. When exposed to water, magnesium nitride decomposes to form ammonia and magnesium hydroxide. While magnesium hydroxide is generally considered environmentally benign, the release of ammonia can lead to eutrophication in aquatic environments and potentially harm aquatic life.

The long-term environmental persistence of magnesium nitride and its decomposition products is an area that requires further research. Understanding the fate and transport of these compounds in different environmental compartments is crucial for assessing their overall ecological impact and developing appropriate management strategies.

From a lifecycle perspective, the environmental footprint of magnesium nitride extends beyond its production and use. The sourcing of raw materials, particularly magnesium, can have significant environmental implications depending on the extraction methods employed. Sustainable sourcing practices and the development of recycling technologies for magnesium nitride-containing products are essential for minimizing the overall environmental impact.

As the use of magnesium nitride expands in chemical engineering applications, there is a growing need for comprehensive environmental impact assessments. These assessments should consider not only the direct effects of the compound but also its indirect impacts throughout its lifecycle. Such evaluations will be crucial in guiding the responsible development and implementation of magnesium nitride technologies, ensuring that their benefits are realized while minimizing potential environmental risks.

Safety Considerations

The use of magnesium nitride in chemical engineering applications necessitates careful consideration of safety protocols due to its reactive nature. Magnesium nitride is highly sensitive to moisture and can react vigorously with water, producing ammonia gas and magnesium hydroxide. This reaction can be exothermic and potentially hazardous if not properly controlled. Therefore, handling and storage of magnesium nitride require stringent moisture-free conditions to prevent unintended reactions.

In laboratory and industrial settings, proper personal protective equipment (PPE) is essential when working with magnesium nitride. This includes chemical-resistant gloves, safety goggles, and appropriate respiratory protection to guard against potential dust or gas exposure. Adequate ventilation systems must be in place to manage any ammonia gas that may be generated during accidental exposure to moisture or during intentional reactions.

Fire safety is another critical aspect when dealing with magnesium nitride. While not inherently flammable, the compound can contribute to the intensity of fires by releasing nitrogen, which can support combustion. Fire suppression systems in areas where magnesium nitride is used or stored should be designed with this in mind, avoiding water-based systems that could exacerbate the situation.

Proper waste management and disposal procedures are crucial for magnesium nitride and its byproducts. Unreacted material and reaction residues must be carefully neutralized and disposed of in accordance with local environmental regulations. This often involves specialized chemical waste treatment processes to ensure safe and compliant disposal.

Training and education of personnel working with magnesium nitride are paramount. Comprehensive safety protocols should be established and regularly reviewed, including emergency response procedures for spills, fires, or accidental exposures. Regular safety drills and updates on handling procedures help maintain a culture of safety awareness among staff.

In the context of expanding applications in chemical engineering, risk assessments should be conducted for each new use case of magnesium nitride. This includes evaluating potential interactions with other chemicals in the process, assessing the scalability of safety measures, and considering the long-term stability of magnesium nitride in various engineered systems.

As research continues to explore novel applications for magnesium nitride, ongoing safety studies are necessary to address any emerging risks associated with its use in new chemical processes or products. This proactive approach to safety will be crucial in supporting the responsible expansion of magnesium nitride's role in chemical engineering while minimizing potential hazards to personnel, equipment, and the environment.

In laboratory and industrial settings, proper personal protective equipment (PPE) is essential when working with magnesium nitride. This includes chemical-resistant gloves, safety goggles, and appropriate respiratory protection to guard against potential dust or gas exposure. Adequate ventilation systems must be in place to manage any ammonia gas that may be generated during accidental exposure to moisture or during intentional reactions.

Fire safety is another critical aspect when dealing with magnesium nitride. While not inherently flammable, the compound can contribute to the intensity of fires by releasing nitrogen, which can support combustion. Fire suppression systems in areas where magnesium nitride is used or stored should be designed with this in mind, avoiding water-based systems that could exacerbate the situation.

Proper waste management and disposal procedures are crucial for magnesium nitride and its byproducts. Unreacted material and reaction residues must be carefully neutralized and disposed of in accordance with local environmental regulations. This often involves specialized chemical waste treatment processes to ensure safe and compliant disposal.

Training and education of personnel working with magnesium nitride are paramount. Comprehensive safety protocols should be established and regularly reviewed, including emergency response procedures for spills, fires, or accidental exposures. Regular safety drills and updates on handling procedures help maintain a culture of safety awareness among staff.

In the context of expanding applications in chemical engineering, risk assessments should be conducted for each new use case of magnesium nitride. This includes evaluating potential interactions with other chemicals in the process, assessing the scalability of safety measures, and considering the long-term stability of magnesium nitride in various engineered systems.

As research continues to explore novel applications for magnesium nitride, ongoing safety studies are necessary to address any emerging risks associated with its use in new chemical processes or products. This proactive approach to safety will be crucial in supporting the responsible expansion of magnesium nitride's role in chemical engineering while minimizing potential hazards to personnel, equipment, and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!