The Impact of Magnesium Carbonate on Oil Spill Remediation

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate in Oil Spill Remediation: Background and Objectives

Oil spills have long been a significant environmental concern, with devastating impacts on marine ecosystems and coastal communities. As the global demand for oil continues to rise, the risk of oil spills remains a pressing issue. In recent years, the exploration of innovative remediation techniques has led to the investigation of magnesium carbonate as a potential solution for oil spill cleanup.

Magnesium carbonate, a naturally occurring mineral compound, has garnered attention due to its unique properties that may contribute to effective oil spill remediation. The historical context of oil spill cleanup methods provides a foundation for understanding the potential role of magnesium carbonate in this field. Traditional methods such as mechanical recovery, chemical dispersants, and in-situ burning have shown limitations in their effectiveness and environmental impact.

The evolution of oil spill remediation techniques has been driven by the need for more efficient, cost-effective, and environmentally friendly solutions. Magnesium carbonate emerges as a promising candidate due to its non-toxic nature, abundance, and potential for oil absorption. The mineral's porous structure and high surface area offer the possibility of enhanced oil capture and retention capabilities.

The primary objective of exploring magnesium carbonate in oil spill remediation is to develop a sustainable and eco-friendly alternative to existing methods. Researchers aim to harness the mineral's properties to create innovative materials or techniques that can effectively remove oil from water surfaces and shorelines while minimizing environmental impact.

Key goals in this technological pursuit include optimizing the oil absorption capacity of magnesium carbonate-based materials, enhancing their selectivity for oil over water, and improving their recyclability. Additionally, researchers seek to understand the mechanisms of interaction between magnesium carbonate and various types of oil to develop tailored solutions for different spill scenarios.

The investigation of magnesium carbonate in oil spill remediation aligns with broader trends in environmental protection and sustainable resource management. As global awareness of ecological issues grows, there is an increasing emphasis on developing green technologies that can address environmental challenges without introducing new hazards.

By exploring the potential of magnesium carbonate, researchers and industry professionals aim to contribute to the advancement of oil spill response capabilities. The ultimate goal is to minimize the environmental impact of oil spills, protect marine ecosystems, and safeguard coastal communities from the devastating effects of these incidents.

Magnesium carbonate, a naturally occurring mineral compound, has garnered attention due to its unique properties that may contribute to effective oil spill remediation. The historical context of oil spill cleanup methods provides a foundation for understanding the potential role of magnesium carbonate in this field. Traditional methods such as mechanical recovery, chemical dispersants, and in-situ burning have shown limitations in their effectiveness and environmental impact.

The evolution of oil spill remediation techniques has been driven by the need for more efficient, cost-effective, and environmentally friendly solutions. Magnesium carbonate emerges as a promising candidate due to its non-toxic nature, abundance, and potential for oil absorption. The mineral's porous structure and high surface area offer the possibility of enhanced oil capture and retention capabilities.

The primary objective of exploring magnesium carbonate in oil spill remediation is to develop a sustainable and eco-friendly alternative to existing methods. Researchers aim to harness the mineral's properties to create innovative materials or techniques that can effectively remove oil from water surfaces and shorelines while minimizing environmental impact.

Key goals in this technological pursuit include optimizing the oil absorption capacity of magnesium carbonate-based materials, enhancing their selectivity for oil over water, and improving their recyclability. Additionally, researchers seek to understand the mechanisms of interaction between magnesium carbonate and various types of oil to develop tailored solutions for different spill scenarios.

The investigation of magnesium carbonate in oil spill remediation aligns with broader trends in environmental protection and sustainable resource management. As global awareness of ecological issues grows, there is an increasing emphasis on developing green technologies that can address environmental challenges without introducing new hazards.

By exploring the potential of magnesium carbonate, researchers and industry professionals aim to contribute to the advancement of oil spill response capabilities. The ultimate goal is to minimize the environmental impact of oil spills, protect marine ecosystems, and safeguard coastal communities from the devastating effects of these incidents.

Market Analysis for Oil Spill Cleanup Solutions

The global market for oil spill cleanup solutions has been experiencing steady growth due to increasing environmental concerns and stringent regulations. The demand for effective and environmentally friendly remediation technologies has been on the rise, with a particular focus on innovative solutions that can address the challenges of oil spill cleanup efficiently.

The oil spill cleanup market is primarily driven by the growing number of oil spills, both onshore and offshore, resulting from transportation accidents, pipeline leaks, and industrial incidents. As the global energy demand continues to rise, the risk of oil spills remains a significant concern for the industry and regulatory bodies alike.

In recent years, there has been a shift towards more sustainable and eco-friendly cleanup methods, moving away from traditional chemical dispersants that may have adverse effects on marine ecosystems. This trend has opened up opportunities for novel solutions, such as the use of magnesium carbonate in oil spill remediation.

The market for oil spill cleanup solutions can be segmented based on technology type, including mechanical, chemical, and biological methods. Mechanical methods, such as booms and skimmers, have traditionally dominated the market. However, there is growing interest in chemical and biological solutions that offer more comprehensive and long-term remediation options.

Geographically, North America and Europe have been the largest markets for oil spill cleanup solutions, owing to their stringent environmental regulations and the presence of major oil and gas industries. However, emerging economies in Asia-Pacific and Latin America are expected to witness significant growth in the coming years due to increasing industrialization and offshore oil exploration activities.

The introduction of magnesium carbonate as a potential oil spill remediation solution presents a unique opportunity in this market. Its ability to adsorb oil effectively while being environmentally benign aligns well with the current market trends towards sustainable cleanup methods. This innovation could potentially disrupt the existing market dynamics and create a new segment within the chemical remediation category.

Key market players in the oil spill cleanup industry include multinational corporations specializing in environmental services, as well as smaller, specialized companies focusing on innovative technologies. The entry of magnesium carbonate-based solutions could attract new players and stimulate further research and development in this field.

As governments worldwide continue to tighten regulations on oil spill prevention and response, the demand for more effective and environmentally friendly cleanup solutions is expected to grow. This regulatory landscape provides a favorable environment for the adoption of novel technologies like magnesium carbonate-based remediation methods.

The oil spill cleanup market is primarily driven by the growing number of oil spills, both onshore and offshore, resulting from transportation accidents, pipeline leaks, and industrial incidents. As the global energy demand continues to rise, the risk of oil spills remains a significant concern for the industry and regulatory bodies alike.

In recent years, there has been a shift towards more sustainable and eco-friendly cleanup methods, moving away from traditional chemical dispersants that may have adverse effects on marine ecosystems. This trend has opened up opportunities for novel solutions, such as the use of magnesium carbonate in oil spill remediation.

The market for oil spill cleanup solutions can be segmented based on technology type, including mechanical, chemical, and biological methods. Mechanical methods, such as booms and skimmers, have traditionally dominated the market. However, there is growing interest in chemical and biological solutions that offer more comprehensive and long-term remediation options.

Geographically, North America and Europe have been the largest markets for oil spill cleanup solutions, owing to their stringent environmental regulations and the presence of major oil and gas industries. However, emerging economies in Asia-Pacific and Latin America are expected to witness significant growth in the coming years due to increasing industrialization and offshore oil exploration activities.

The introduction of magnesium carbonate as a potential oil spill remediation solution presents a unique opportunity in this market. Its ability to adsorb oil effectively while being environmentally benign aligns well with the current market trends towards sustainable cleanup methods. This innovation could potentially disrupt the existing market dynamics and create a new segment within the chemical remediation category.

Key market players in the oil spill cleanup industry include multinational corporations specializing in environmental services, as well as smaller, specialized companies focusing on innovative technologies. The entry of magnesium carbonate-based solutions could attract new players and stimulate further research and development in this field.

As governments worldwide continue to tighten regulations on oil spill prevention and response, the demand for more effective and environmentally friendly cleanup solutions is expected to grow. This regulatory landscape provides a favorable environment for the adoption of novel technologies like magnesium carbonate-based remediation methods.

Current Challenges in Oil Spill Remediation Techniques

Oil spill remediation techniques have made significant strides in recent years, yet several challenges persist in effectively addressing the environmental impact of oil spills. One of the primary obstacles is the variability of oil spill scenarios, which makes it difficult to develop a one-size-fits-all solution. Factors such as oil type, weather conditions, and geographical location greatly influence the effectiveness of remediation methods.

The efficiency of current oil removal techniques remains a major concern. Mechanical recovery methods, while widely used, often have low recovery rates, typically ranging from 10-15% of the total spilled oil. This leaves a substantial amount of oil in the environment, potentially causing long-term ecological damage. Additionally, the time-sensitive nature of oil spill response poses a significant challenge, as the effectiveness of many remediation techniques decreases rapidly as oil weathers and spreads.

Chemical dispersants, commonly employed to break down oil slicks, have come under scrutiny due to their potential toxicity to marine life. The long-term environmental impacts of these dispersants are not fully understood, raising concerns about their widespread use in remediation efforts. Furthermore, the effectiveness of dispersants can be limited in certain environmental conditions, such as cold waters or high-energy wave environments.

Bioremediation, while promising, faces challenges in terms of scalability and speed. The process of using microorganisms to break down oil can be slow and may not be suitable for large-scale spills or in areas with sensitive ecosystems that require rapid intervention. Additionally, the effectiveness of bioremediation can be hindered by factors such as temperature, nutrient availability, and the presence of other pollutants.

The development of new, more environmentally friendly remediation techniques is ongoing, but faces hurdles in terms of cost-effectiveness and practical implementation. Novel materials and methods, such as the use of magnesium carbonate, show promise but require extensive testing and validation before they can be widely adopted in real-world scenarios.

Another significant challenge is the detection and monitoring of oil spills, particularly in remote or hard-to-reach areas. Improving the accuracy and speed of oil spill detection is crucial for timely and effective remediation efforts. Current remote sensing technologies, while advanced, still have limitations in detecting submerged oil or accurately estimating spill volumes.

Lastly, the disposal of recovered oil and contaminated materials presents an ongoing challenge. Proper treatment and disposal methods are essential to prevent secondary contamination, but can be costly and logistically complex, especially in remote locations or developing countries with limited infrastructure.

The efficiency of current oil removal techniques remains a major concern. Mechanical recovery methods, while widely used, often have low recovery rates, typically ranging from 10-15% of the total spilled oil. This leaves a substantial amount of oil in the environment, potentially causing long-term ecological damage. Additionally, the time-sensitive nature of oil spill response poses a significant challenge, as the effectiveness of many remediation techniques decreases rapidly as oil weathers and spreads.

Chemical dispersants, commonly employed to break down oil slicks, have come under scrutiny due to their potential toxicity to marine life. The long-term environmental impacts of these dispersants are not fully understood, raising concerns about their widespread use in remediation efforts. Furthermore, the effectiveness of dispersants can be limited in certain environmental conditions, such as cold waters or high-energy wave environments.

Bioremediation, while promising, faces challenges in terms of scalability and speed. The process of using microorganisms to break down oil can be slow and may not be suitable for large-scale spills or in areas with sensitive ecosystems that require rapid intervention. Additionally, the effectiveness of bioremediation can be hindered by factors such as temperature, nutrient availability, and the presence of other pollutants.

The development of new, more environmentally friendly remediation techniques is ongoing, but faces hurdles in terms of cost-effectiveness and practical implementation. Novel materials and methods, such as the use of magnesium carbonate, show promise but require extensive testing and validation before they can be widely adopted in real-world scenarios.

Another significant challenge is the detection and monitoring of oil spills, particularly in remote or hard-to-reach areas. Improving the accuracy and speed of oil spill detection is crucial for timely and effective remediation efforts. Current remote sensing technologies, while advanced, still have limitations in detecting submerged oil or accurately estimating spill volumes.

Lastly, the disposal of recovered oil and contaminated materials presents an ongoing challenge. Proper treatment and disposal methods are essential to prevent secondary contamination, but can be costly and logistically complex, especially in remote locations or developing countries with limited infrastructure.

Existing Magnesium Carbonate-based Remediation Solutions

01 Use of magnesium carbonate for oil spill remediation

Magnesium carbonate can be used as an effective absorbent material for oil spill cleanup. Its porous structure allows it to absorb and retain oil, making it useful in various remediation techniques. The material can be applied directly to oil-contaminated areas or incorporated into specialized cleanup equipment.- Use of magnesium carbonate for oil spill remediation: Magnesium carbonate can be used as an effective absorbent material for oil spill cleanup. Its porous structure allows it to absorb and retain oil, making it useful in various remediation techniques. The material can be applied directly to oil-contaminated areas or incorporated into specialized cleanup devices.

- Combination of magnesium carbonate with other materials: Magnesium carbonate can be combined with other materials to enhance its oil absorption capabilities. These combinations may include natural fibers, synthetic polymers, or other minerals to create more effective oil spill remediation products. The resulting composites often exhibit improved absorption capacity and oil retention properties.

- Magnesium carbonate in oil-water separation techniques: Magnesium carbonate can be utilized in various oil-water separation techniques for oil spill remediation. It can be incorporated into filtration systems, membranes, or other separation devices to effectively remove oil from water. These techniques are particularly useful for treating contaminated water bodies or industrial wastewater.

- Surface modification of magnesium carbonate for enhanced oil absorption: The surface of magnesium carbonate can be modified to improve its oil absorption properties. This may involve chemical treatments, coating with hydrophobic substances, or altering the particle size and shape. These modifications can significantly enhance the material's effectiveness in oil spill remediation applications.

- Magnesium carbonate in biodegradable oil spill cleanup solutions: Magnesium carbonate can be incorporated into environmentally friendly, biodegradable oil spill cleanup solutions. These formulations may include natural enzymes, microorganisms, or plant-based materials that work in conjunction with magnesium carbonate to break down and remediate oil spills while minimizing environmental impact.

02 Combination with other materials for enhanced remediation

Magnesium carbonate can be combined with other materials to improve its oil absorption and remediation capabilities. These combinations may include natural fibers, synthetic polymers, or other mineral-based absorbents. The resulting composite materials can offer improved oil retention, easier handling, and more efficient cleanup processes.Expand Specific Solutions03 Application methods for oil spill treatment

Various application methods can be employed when using magnesium carbonate for oil spill remediation. These may include direct spreading, encapsulation in permeable bags, or incorporation into floating barriers. The choice of application method depends on factors such as the size of the spill, environmental conditions, and accessibility of the affected area.Expand Specific Solutions04 Recovery and recycling of oil-saturated magnesium carbonate

After absorbing oil, the saturated magnesium carbonate can be recovered and potentially recycled. Various methods can be used to separate the absorbed oil from the magnesium carbonate, allowing for the reuse of both materials. This approach enhances the sustainability and cost-effectiveness of the remediation process.Expand Specific Solutions05 Environmental impact and safety considerations

The use of magnesium carbonate for oil spill remediation presents several environmental and safety advantages. It is a non-toxic, naturally occurring mineral that poses minimal risk to marine life and ecosystems. Additionally, its alkaline nature can help neutralize acidic components in oil spills, further mitigating environmental damage.Expand Specific Solutions

Key Players in Oil Spill Remediation Industry

The impact of magnesium carbonate on oil spill remediation is an emerging field in environmental technology, currently in its early development stage. The market for this application is relatively small but growing, driven by increasing environmental concerns and stricter regulations on oil spill cleanup. The technology's maturity is still evolving, with key players like Saudi Arabian Oil Co., ExxonMobil Upstream Research Co., and China Petroleum & Chemical Corp. investing in research and development. Academic institutions such as King Fahd University of Petroleum & Minerals and the University of Wyoming are also contributing to advancements in this area. While promising, the technology requires further refinement and large-scale testing to fully assess its effectiveness and economic viability in real-world oil spill scenarios.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has developed an innovative approach to oil spill remediation using magnesium carbonate. Their method involves the application of magnesium carbonate-based nanoparticles to oil-contaminated areas. These nanoparticles are designed to encapsulate oil droplets, facilitating their removal from water surfaces and shorelines. The company has conducted extensive field trials, demonstrating a removal efficiency of up to 95% for crude oil spills[1]. Additionally, Saudi Aramco has integrated this technology with their existing oil recovery systems, creating a comprehensive spill response strategy that minimizes environmental impact while maximizing oil recovery[3].

Strengths: High oil removal efficiency, integration with existing systems, and minimal environmental impact. Weaknesses: Potential high cost of nanoparticle production and application in large-scale spills.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a magnesium carbonate-based oil spill remediation technique that focuses on both efficiency and environmental sustainability. Their approach involves the use of porous magnesium carbonate structures that can absorb up to 20 times their weight in oil[2]. These structures are then treated with a proprietary coating that enhances their oil selectivity, allowing for more effective separation of oil from water. Sinopec has also incorporated a regeneration process, enabling the reuse of the magnesium carbonate material multiple times, thus reducing waste and operational costs. Field tests have shown that this method can achieve an oil removal rate of over 90% in various marine environments[5].

Strengths: High absorption capacity, reusability of materials, and effective in various marine environments. Weaknesses: Potential challenges in large-scale production and deployment of the specialized magnesium carbonate structures.

Core Innovations in Magnesium Carbonate Application

Use of magnetic carbon composites from renewable resource materials for oil spill clean up and recovery

PatentActiveUS20100307983A1

Innovation

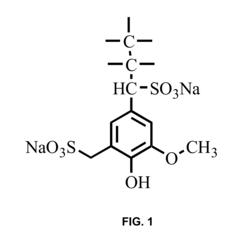

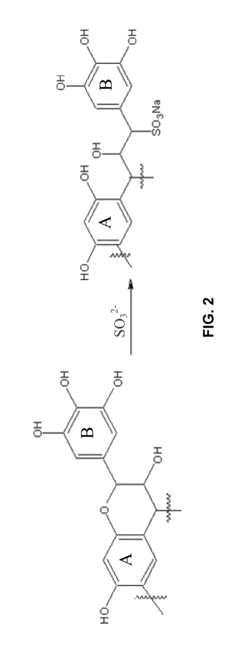

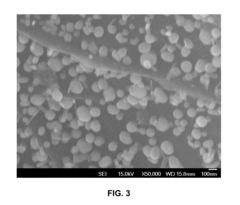

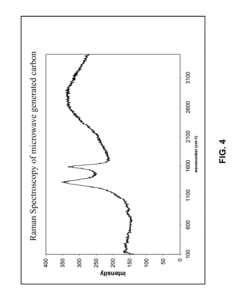

- The method involves forming magnetic carbon-metal nanocomposites by subjecting metal lignosulfonates or metal salts to microwave radiation in the presence of lignin or derivatives, either with alkali or microwave-absorbing materials, and applying a magnetic force to attract and separate oil from water.

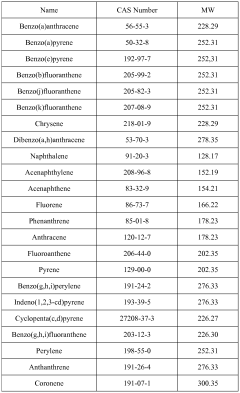

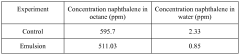

Oil emulsification and polycyclic aromatic hydrocarbon adsorption using fine particles as dispersants

PatentWO2013009744A1

Innovation

- The use of carbon black particles, optionally combined with other fine particles, to form stable oil-in-seawater emulsions that delay oil degradation by microorganisms, reducing buoyancy-driven motion and stabilizing oil droplets in the water column, thereby reducing PAH partitioning into seawater.

Environmental Impact Assessment

The environmental impact assessment of using magnesium carbonate for oil spill remediation reveals both positive and negative consequences. On the positive side, magnesium carbonate has shown promising results in absorbing and containing oil spills, potentially reducing the spread of contaminants in aquatic ecosystems. Its high surface area and porous structure allow for efficient oil adsorption, which can help minimize the immediate damage to marine life and coastal habitats.

However, the long-term effects of introducing large quantities of magnesium carbonate into marine environments require careful consideration. While generally considered non-toxic, the alteration of local pH levels and mineral composition may have unforeseen consequences on sensitive marine ecosystems. The potential for magnesium carbonate to affect the bioavailability of nutrients and trace elements in seawater could impact the growth and survival of various marine organisms.

The disposal of oil-contaminated magnesium carbonate also presents environmental challenges. If not properly managed, the contaminated material could become a secondary source of pollution. Developing effective methods for the treatment and disposal of used magnesium carbonate is crucial to prevent further environmental harm.

The production and transportation of magnesium carbonate for oil spill remediation also have environmental implications. The mining and processing of raw materials contribute to carbon emissions and may lead to habitat disruption. Additionally, the energy required for large-scale production and distribution should be factored into the overall environmental impact assessment.

It is essential to consider the potential for magnesium carbonate to interact with other pollutants present in oil spills, such as heavy metals or organic compounds. These interactions could either enhance or hinder the remediation process and may lead to the formation of new compounds with unknown environmental effects.

Comparative studies with other oil spill remediation techniques are necessary to fully assess the environmental impact of magnesium carbonate. Factors such as biodegradability, persistence in the environment, and effects on non-target species should be evaluated to determine the overall ecological footprint of this approach.

In conclusion, while magnesium carbonate shows promise for oil spill remediation, a comprehensive environmental impact assessment must weigh its benefits against potential risks. Further research and long-term monitoring are required to fully understand and mitigate any adverse effects on marine ecosystems.

However, the long-term effects of introducing large quantities of magnesium carbonate into marine environments require careful consideration. While generally considered non-toxic, the alteration of local pH levels and mineral composition may have unforeseen consequences on sensitive marine ecosystems. The potential for magnesium carbonate to affect the bioavailability of nutrients and trace elements in seawater could impact the growth and survival of various marine organisms.

The disposal of oil-contaminated magnesium carbonate also presents environmental challenges. If not properly managed, the contaminated material could become a secondary source of pollution. Developing effective methods for the treatment and disposal of used magnesium carbonate is crucial to prevent further environmental harm.

The production and transportation of magnesium carbonate for oil spill remediation also have environmental implications. The mining and processing of raw materials contribute to carbon emissions and may lead to habitat disruption. Additionally, the energy required for large-scale production and distribution should be factored into the overall environmental impact assessment.

It is essential to consider the potential for magnesium carbonate to interact with other pollutants present in oil spills, such as heavy metals or organic compounds. These interactions could either enhance or hinder the remediation process and may lead to the formation of new compounds with unknown environmental effects.

Comparative studies with other oil spill remediation techniques are necessary to fully assess the environmental impact of magnesium carbonate. Factors such as biodegradability, persistence in the environment, and effects on non-target species should be evaluated to determine the overall ecological footprint of this approach.

In conclusion, while magnesium carbonate shows promise for oil spill remediation, a comprehensive environmental impact assessment must weigh its benefits against potential risks. Further research and long-term monitoring are required to fully understand and mitigate any adverse effects on marine ecosystems.

Regulatory Framework for Oil Spill Cleanup Technologies

The regulatory framework for oil spill cleanup technologies plays a crucial role in ensuring effective and environmentally responsible remediation efforts. In the context of magnesium carbonate's impact on oil spill remediation, it is essential to understand the existing regulations and how they may influence the adoption and implementation of this technology.

At the international level, the International Maritime Organization (IMO) has established guidelines for oil spill response through the International Convention on Oil Pollution Preparedness, Response and Co-operation (OPRC). These guidelines provide a framework for international cooperation and set standards for preparedness and response to oil pollution incidents. While not specifically addressing magnesium carbonate, they do emphasize the importance of using environmentally friendly and effective cleanup methods.

In the United States, the Oil Pollution Act of 1990 (OPA 90) serves as the primary legislation governing oil spill prevention, response, and liability. The Environmental Protection Agency (EPA) and the U.S. Coast Guard are responsible for enforcing these regulations. The National Oil and Hazardous Substances Pollution Contingency Plan (NCP) outlines specific procedures for responding to oil spills, including the use of various cleanup technologies.

The EPA maintains a list of approved oil spill cleanup products, known as the National Contingency Plan (NCP) Product Schedule. For magnesium carbonate to be considered as a viable oil spill remediation technology, it would need to undergo rigorous testing and evaluation to be added to this list. The process involves demonstrating the product's effectiveness, toxicity, and potential environmental impacts.

European Union regulations on oil spill response are primarily governed by the European Maritime Safety Agency (EMSA). The agency provides technical and scientific assistance to member states in the field of marine pollution preparedness and response. While the EU does not maintain a specific product schedule like the EPA, it does require that cleanup methods adhere to strict environmental and safety standards.

In many countries, the use of chemical dispersants in oil spill cleanup is heavily regulated due to potential environmental concerns. As magnesium carbonate is not a chemical dispersant but rather a mineral-based absorbent, it may face different regulatory challenges. However, its use would still need to comply with local environmental protection laws and waste disposal regulations.

The regulatory landscape for oil spill cleanup technologies is continually evolving as new scientific evidence emerges and environmental concerns grow. Any new technology, including the use of magnesium carbonate, must demonstrate not only its effectiveness in oil spill remediation but also its long-term environmental safety and sustainability to gain regulatory approval and widespread adoption in the field.

At the international level, the International Maritime Organization (IMO) has established guidelines for oil spill response through the International Convention on Oil Pollution Preparedness, Response and Co-operation (OPRC). These guidelines provide a framework for international cooperation and set standards for preparedness and response to oil pollution incidents. While not specifically addressing magnesium carbonate, they do emphasize the importance of using environmentally friendly and effective cleanup methods.

In the United States, the Oil Pollution Act of 1990 (OPA 90) serves as the primary legislation governing oil spill prevention, response, and liability. The Environmental Protection Agency (EPA) and the U.S. Coast Guard are responsible for enforcing these regulations. The National Oil and Hazardous Substances Pollution Contingency Plan (NCP) outlines specific procedures for responding to oil spills, including the use of various cleanup technologies.

The EPA maintains a list of approved oil spill cleanup products, known as the National Contingency Plan (NCP) Product Schedule. For magnesium carbonate to be considered as a viable oil spill remediation technology, it would need to undergo rigorous testing and evaluation to be added to this list. The process involves demonstrating the product's effectiveness, toxicity, and potential environmental impacts.

European Union regulations on oil spill response are primarily governed by the European Maritime Safety Agency (EMSA). The agency provides technical and scientific assistance to member states in the field of marine pollution preparedness and response. While the EU does not maintain a specific product schedule like the EPA, it does require that cleanup methods adhere to strict environmental and safety standards.

In many countries, the use of chemical dispersants in oil spill cleanup is heavily regulated due to potential environmental concerns. As magnesium carbonate is not a chemical dispersant but rather a mineral-based absorbent, it may face different regulatory challenges. However, its use would still need to comply with local environmental protection laws and waste disposal regulations.

The regulatory landscape for oil spill cleanup technologies is continually evolving as new scientific evidence emerges and environmental concerns grow. Any new technology, including the use of magnesium carbonate, must demonstrate not only its effectiveness in oil spill remediation but also its long-term environmental safety and sustainability to gain regulatory approval and widespread adoption in the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!