The Influence of Battery Acid on Separator Performance

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Impact Background and Objectives

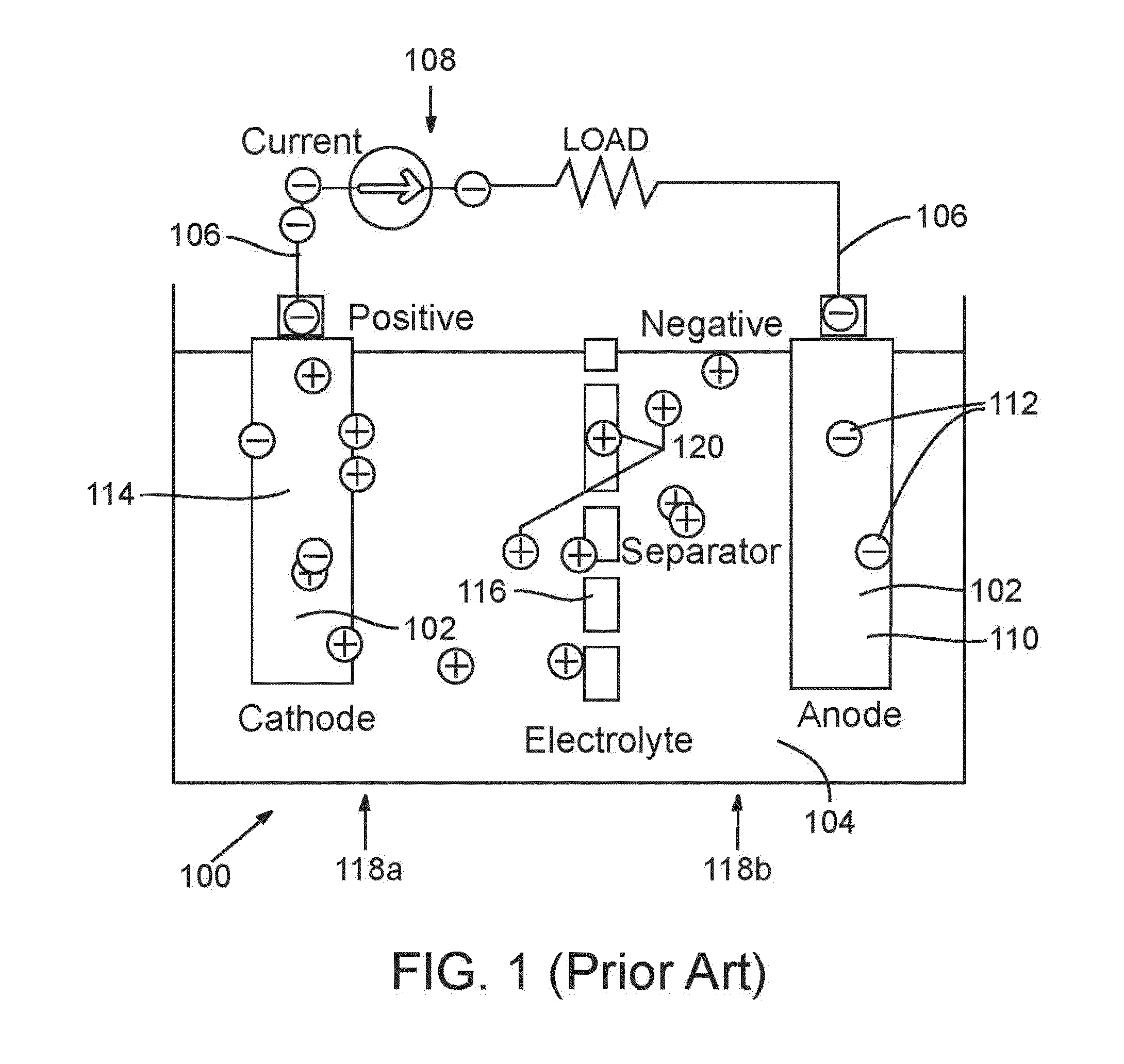

The development of battery technology has been a cornerstone of modern energy storage systems, with significant advancements in recent years. The interaction between battery acid and separator performance has emerged as a critical area of focus, given its profound impact on overall battery efficiency and longevity. This technical research aims to comprehensively examine the influence of battery acid on separator performance, tracing the evolution of this field and identifying key technological objectives.

Historically, lead-acid batteries have been the primary focus of acid-separator interactions. However, with the rise of lithium-ion and other advanced battery technologies, the scope of this research has expanded significantly. The acid-separator interface plays a crucial role in maintaining battery integrity, preventing short circuits, and facilitating ion transport. As such, understanding and optimizing this interaction has become paramount in advancing battery technology.

The primary objective of this research is to elucidate the mechanisms by which battery acid affects separator performance across various battery chemistries. This includes investigating the chemical and physical changes in separator materials exposed to different acid environments, as well as the long-term effects of acid exposure on separator durability and functionality. Additionally, we aim to identify potential innovations in separator materials and designs that can enhance resistance to acid degradation while maintaining optimal ion conductivity.

Another key goal is to explore the relationship between acid concentration, temperature, and separator performance. This involves analyzing how variations in these parameters impact the separator's ability to maintain its structural integrity and ion-selective properties. By understanding these dynamics, we can develop more robust and efficient battery systems capable of operating under a wider range of conditions.

Furthermore, this research seeks to address the environmental and safety concerns associated with battery acid-separator interactions. This includes investigating ways to minimize acid leakage and improve the overall safety profile of batteries, particularly in high-stress applications such as electric vehicles and grid-scale energy storage systems.

Lastly, we aim to establish standardized testing protocols for evaluating separator performance under various acid conditions. This will enable more accurate comparisons between different separator technologies and facilitate the development of industry-wide best practices for battery design and manufacturing.

By achieving these objectives, we anticipate significant advancements in battery technology, leading to improved energy density, longer cycle life, and enhanced safety across a wide range of applications. This research has the potential to drive innovation in the energy storage sector, supporting the global transition towards more sustainable and efficient power systems.

Historically, lead-acid batteries have been the primary focus of acid-separator interactions. However, with the rise of lithium-ion and other advanced battery technologies, the scope of this research has expanded significantly. The acid-separator interface plays a crucial role in maintaining battery integrity, preventing short circuits, and facilitating ion transport. As such, understanding and optimizing this interaction has become paramount in advancing battery technology.

The primary objective of this research is to elucidate the mechanisms by which battery acid affects separator performance across various battery chemistries. This includes investigating the chemical and physical changes in separator materials exposed to different acid environments, as well as the long-term effects of acid exposure on separator durability and functionality. Additionally, we aim to identify potential innovations in separator materials and designs that can enhance resistance to acid degradation while maintaining optimal ion conductivity.

Another key goal is to explore the relationship between acid concentration, temperature, and separator performance. This involves analyzing how variations in these parameters impact the separator's ability to maintain its structural integrity and ion-selective properties. By understanding these dynamics, we can develop more robust and efficient battery systems capable of operating under a wider range of conditions.

Furthermore, this research seeks to address the environmental and safety concerns associated with battery acid-separator interactions. This includes investigating ways to minimize acid leakage and improve the overall safety profile of batteries, particularly in high-stress applications such as electric vehicles and grid-scale energy storage systems.

Lastly, we aim to establish standardized testing protocols for evaluating separator performance under various acid conditions. This will enable more accurate comparisons between different separator technologies and facilitate the development of industry-wide best practices for battery design and manufacturing.

By achieving these objectives, we anticipate significant advancements in battery technology, leading to improved energy density, longer cycle life, and enhanced safety across a wide range of applications. This research has the potential to drive innovation in the energy storage sector, supporting the global transition towards more sustainable and efficient power systems.

Market Demand for Improved Separator Performance

The demand for improved battery separator performance has been steadily increasing in recent years, driven by the rapid growth of the electric vehicle (EV) market and the expanding energy storage sector. As batteries become more integral to various applications, the need for separators that can withstand harsh acidic environments while maintaining optimal functionality has become paramount.

In the automotive industry, the shift towards electrification has created a substantial market for high-performance separators. EV manufacturers are constantly seeking ways to enhance battery life, safety, and efficiency, with separator technology playing a crucial role in achieving these goals. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly influencing the demand for advanced separators.

The energy storage sector, including grid-scale applications and renewable energy systems, also contributes significantly to the market demand for improved separator performance. As countries worldwide invest in sustainable energy solutions, the need for reliable and long-lasting battery systems has intensified. Separators that can withstand the corrosive effects of battery acid while maintaining their integrity over extended periods are essential for these applications.

Consumer electronics represent another key market segment driving the demand for enhanced separator technology. With the increasing power requirements of smartphones, laptops, and wearable devices, manufacturers are looking for ways to improve battery performance and safety. Separators that can resist degradation from battery acid are crucial in preventing short circuits and extending the overall lifespan of these devices.

The industrial sector, particularly in areas such as uninterruptible power supplies (UPS) and material handling equipment, also contributes to the growing demand for improved separator performance. These applications often require batteries to operate in challenging environments, making acid-resistant separators a critical component for ensuring reliability and longevity.

Market research indicates that the global battery separator market is expected to experience substantial growth in the coming years. This growth is largely attributed to the increasing adoption of lithium-ion batteries across various industries and the ongoing research and development efforts to enhance separator technology.

The demand for improved separator performance is not limited to a specific geographic region. While Asia-Pacific currently leads in terms of market share, due to the concentration of battery manufacturing in countries like China, South Korea, and Japan, there is significant growth potential in North America and Europe as well. These regions are investing heavily in electric vehicle production and renewable energy infrastructure, driving the need for advanced battery technologies.

In conclusion, the market demand for improved separator performance, particularly in relation to acid resistance, is robust and multifaceted. It spans across various industries and geographical regions, with the automotive and energy storage sectors leading the charge. As battery technology continues to evolve, the importance of high-performance separators will only increase, creating opportunities for innovation and market growth in this critical component of modern energy storage systems.

In the automotive industry, the shift towards electrification has created a substantial market for high-performance separators. EV manufacturers are constantly seeking ways to enhance battery life, safety, and efficiency, with separator technology playing a crucial role in achieving these goals. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, directly influencing the demand for advanced separators.

The energy storage sector, including grid-scale applications and renewable energy systems, also contributes significantly to the market demand for improved separator performance. As countries worldwide invest in sustainable energy solutions, the need for reliable and long-lasting battery systems has intensified. Separators that can withstand the corrosive effects of battery acid while maintaining their integrity over extended periods are essential for these applications.

Consumer electronics represent another key market segment driving the demand for enhanced separator technology. With the increasing power requirements of smartphones, laptops, and wearable devices, manufacturers are looking for ways to improve battery performance and safety. Separators that can resist degradation from battery acid are crucial in preventing short circuits and extending the overall lifespan of these devices.

The industrial sector, particularly in areas such as uninterruptible power supplies (UPS) and material handling equipment, also contributes to the growing demand for improved separator performance. These applications often require batteries to operate in challenging environments, making acid-resistant separators a critical component for ensuring reliability and longevity.

Market research indicates that the global battery separator market is expected to experience substantial growth in the coming years. This growth is largely attributed to the increasing adoption of lithium-ion batteries across various industries and the ongoing research and development efforts to enhance separator technology.

The demand for improved separator performance is not limited to a specific geographic region. While Asia-Pacific currently leads in terms of market share, due to the concentration of battery manufacturing in countries like China, South Korea, and Japan, there is significant growth potential in North America and Europe as well. These regions are investing heavily in electric vehicle production and renewable energy infrastructure, driving the need for advanced battery technologies.

In conclusion, the market demand for improved separator performance, particularly in relation to acid resistance, is robust and multifaceted. It spans across various industries and geographical regions, with the automotive and energy storage sectors leading the charge. As battery technology continues to evolve, the importance of high-performance separators will only increase, creating opportunities for innovation and market growth in this critical component of modern energy storage systems.

Current Challenges in Separator-Acid Interactions

The interaction between battery acid and separators presents significant challenges in the field of battery technology. One of the primary issues is the chemical degradation of separator materials due to prolonged exposure to acidic environments. This degradation can lead to reduced mechanical strength and compromised integrity of the separator, potentially resulting in short circuits or battery failure.

Another critical challenge is the acid-induced swelling of separator materials, particularly in polymer-based separators. This swelling can alter the porosity and pore size distribution of the separator, affecting its ability to maintain proper ion transport while preventing electrode contact. The changes in separator dimensions can also lead to internal stress within the battery, potentially causing deformation or damage to other components.

The formation of dendrites is a persistent problem exacerbated by separator-acid interactions. As the separator's structure is compromised by acid exposure, its ability to prevent dendrite growth is diminished. This can lead to the penetration of the separator by metal dendrites, causing internal short circuits and safety hazards.

Acid-induced changes in the separator's wettability pose another significant challenge. The hydrophilic/hydrophobic balance of the separator surface can be altered by acid exposure, affecting its ability to maintain proper electrolyte distribution and ion transport. This can result in uneven current distribution and reduced battery performance.

The long-term stability of separators in acidic environments remains a major concern. Gradual degradation over time can lead to a reduction in the separator's effectiveness, potentially shortening the overall lifespan of the battery. This is particularly problematic for applications requiring long-term reliability, such as in electric vehicles or grid energy storage systems.

Furthermore, the acid-separator interaction can lead to the formation of unwanted byproducts or precipitates. These can clog the separator pores, reducing ion mobility and increasing internal resistance. In some cases, these byproducts may also be corrosive or reactive, further compromising battery integrity.

The challenge of maintaining consistent separator performance across a wide range of operating conditions is amplified by acid interactions. Temperature fluctuations, charge-discharge cycles, and mechanical stress can all exacerbate the effects of acid on the separator, making it difficult to ensure reliable performance over the battery's intended lifespan.

Another critical challenge is the acid-induced swelling of separator materials, particularly in polymer-based separators. This swelling can alter the porosity and pore size distribution of the separator, affecting its ability to maintain proper ion transport while preventing electrode contact. The changes in separator dimensions can also lead to internal stress within the battery, potentially causing deformation or damage to other components.

The formation of dendrites is a persistent problem exacerbated by separator-acid interactions. As the separator's structure is compromised by acid exposure, its ability to prevent dendrite growth is diminished. This can lead to the penetration of the separator by metal dendrites, causing internal short circuits and safety hazards.

Acid-induced changes in the separator's wettability pose another significant challenge. The hydrophilic/hydrophobic balance of the separator surface can be altered by acid exposure, affecting its ability to maintain proper electrolyte distribution and ion transport. This can result in uneven current distribution and reduced battery performance.

The long-term stability of separators in acidic environments remains a major concern. Gradual degradation over time can lead to a reduction in the separator's effectiveness, potentially shortening the overall lifespan of the battery. This is particularly problematic for applications requiring long-term reliability, such as in electric vehicles or grid energy storage systems.

Furthermore, the acid-separator interaction can lead to the formation of unwanted byproducts or precipitates. These can clog the separator pores, reducing ion mobility and increasing internal resistance. In some cases, these byproducts may also be corrosive or reactive, further compromising battery integrity.

The challenge of maintaining consistent separator performance across a wide range of operating conditions is amplified by acid interactions. Temperature fluctuations, charge-discharge cycles, and mechanical stress can all exacerbate the effects of acid on the separator, making it difficult to ensure reliable performance over the battery's intended lifespan.

Existing Solutions for Acid-Resistant Separators

01 Separator material composition

Battery separator performance can be enhanced through the use of specific materials and compositions. This includes the incorporation of ceramic particles, polymer blends, or composite structures to improve mechanical strength, thermal stability, and ion conductivity. The choice of materials can significantly impact the overall battery performance and safety.- Separator material composition: The performance of battery separators can be improved by optimizing the material composition. This includes using advanced polymers, ceramic coatings, or composite materials that enhance thermal stability, mechanical strength, and ion conductivity. These materials can also improve the separator's resistance to dendrite formation and electrolyte penetration.

- Separator structure and design: The structure and design of battery separators play a crucial role in their performance. This includes factors such as porosity, thickness, and surface modifications. Innovative designs like multi-layer structures or 3D architectures can enhance ion transport, mechanical strength, and overall battery efficiency.

- Separator coating technologies: Advanced coating technologies can significantly improve separator performance. These coatings can enhance thermal stability, wettability, and electrolyte retention. They may also provide additional functionalities such as flame retardancy or self-healing properties, contributing to improved battery safety and longevity.

- Separator performance testing and characterization: Developing and implementing advanced testing and characterization methods is crucial for evaluating and improving separator performance. This includes techniques for measuring mechanical properties, ion conductivity, thermal stability, and long-term durability under various operating conditions.

- Integration of smart functionalities: Incorporating smart functionalities into battery separators can enhance their performance and safety. This may include integrating sensors for real-time monitoring of battery conditions, self-healing mechanisms to address micro-damages, or responsive materials that can adapt to changing operating conditions.

02 Separator structure and design

The physical structure and design of the separator play a crucial role in its performance. This includes aspects such as porosity, thickness, and surface modifications. Advanced designs may incorporate multi-layer structures or patterned surfaces to optimize ion transport while maintaining mechanical integrity and preventing short circuits.Expand Specific Solutions03 Coating and surface treatments

Various coating techniques and surface treatments can be applied to battery separators to enhance their performance. These treatments can improve wettability, reduce internal resistance, and increase the separator's resistance to thermal shrinkage. Coatings may also provide additional functionality such as flame retardancy or improved adhesion to electrodes.Expand Specific Solutions04 Performance testing and characterization

Accurate testing and characterization of battery separator performance is essential for development and quality control. This includes methods for measuring physical properties such as porosity and permeability, as well as electrochemical performance metrics like ionic conductivity and cycling stability. Advanced testing techniques may involve in-situ monitoring or accelerated aging protocols.Expand Specific Solutions05 Integration with battery management systems

The performance of battery separators can be optimized through integration with advanced battery management systems. This may involve sensors embedded in the separator to monitor temperature, pressure, or chemical changes. Such integration allows for real-time performance monitoring and adaptive control strategies to enhance battery life and safety.Expand Specific Solutions

Key Players in Battery Separator Industry

The battery separator market is in a growth phase, driven by increasing demand for lithium-ion batteries in electric vehicles and energy storage systems. The global market size is projected to reach several billion dollars by 2025. Technologically, separators are evolving to improve battery performance and safety. Key players like Daramic, Asahi Kasei, and SK Innovation are investing heavily in R&D to develop advanced separator materials. Emerging companies such as Shenzhen Senior Technology and Sinoma Lithium Battery Separator are also making strides in innovative separator technologies. The industry is seeing a shift towards ceramic-coated and high-temperature resistant separators, with major manufacturers focusing on enhancing thermal stability and ion conductivity.

Daramic LLC

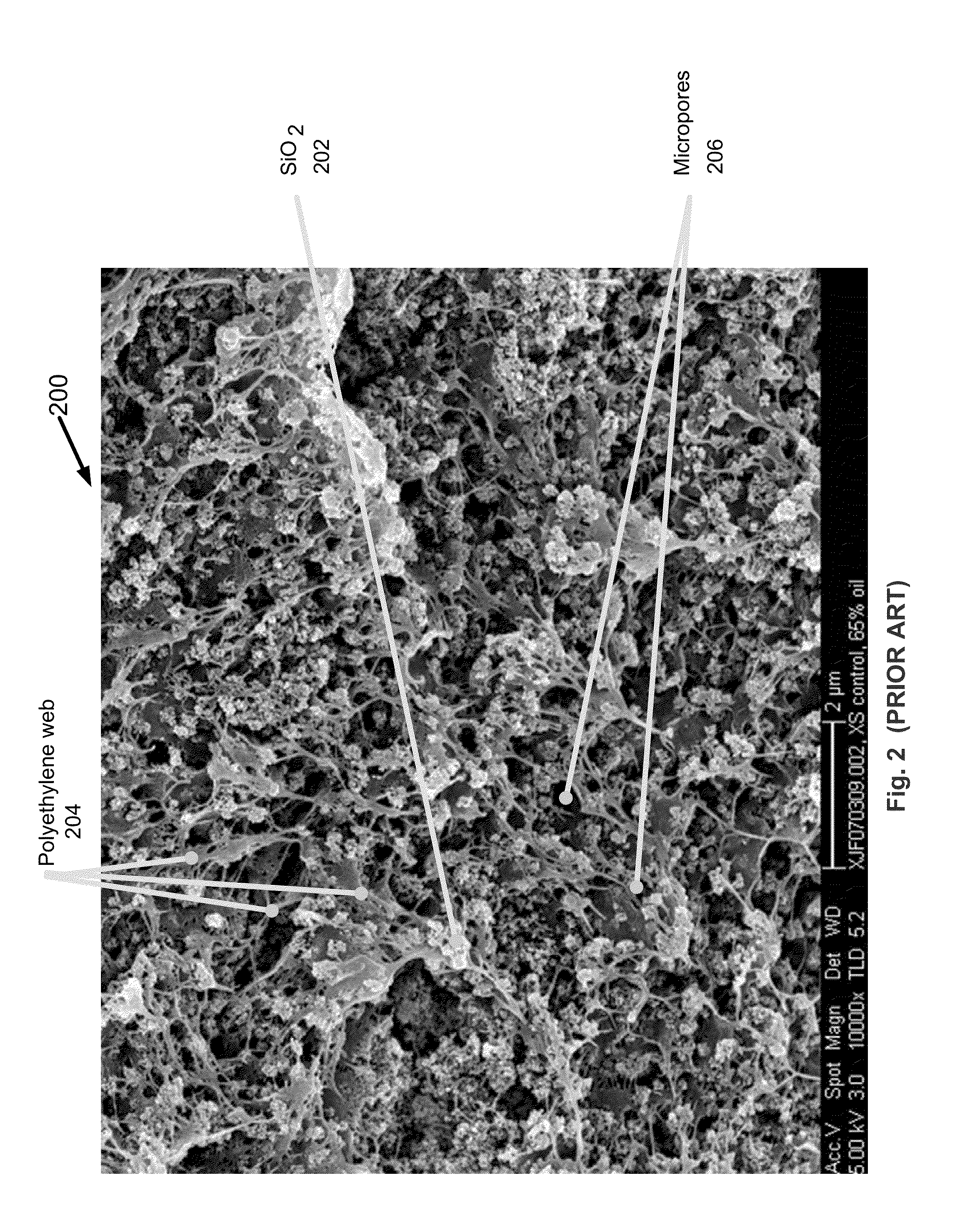

Technical Solution: Daramic LLC has developed advanced polyethylene (PE) separators with improved acid resistance and stability. Their DARAMIC XL technology incorporates a proprietary silica-based coating that enhances the separator's resistance to acid attack and oxidation[1]. This coating also improves the separator's wettability, allowing for better electrolyte absorption and distribution. Daramic's separators feature a unique microporous structure that balances ion conductivity with mechanical strength, crucial for long-term battery performance in acidic environments[2]. The company has also introduced nano-fiber reinforced separators that provide enhanced puncture resistance and thermal stability, further improving battery safety and lifespan in high-acid conditions[3].

Strengths: Superior acid resistance, improved wettability, and enhanced mechanical properties. Weaknesses: Potentially higher production costs due to advanced materials and coating processes.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei Corp. has developed innovative separator technologies to address the challenges posed by battery acid. Their Hipore separator technology utilizes a unique wet process to create a microporous polyethylene membrane with excellent chemical stability in acidic environments[4]. The company has further enhanced this technology by incorporating ceramic coatings, which provide additional protection against acid-induced degradation and improve the separator's thermal stability[5]. Asahi Kasei's separators also feature a precisely controlled pore structure that optimizes ion transport while maintaining mechanical integrity under acidic conditions. Recent advancements include the development of multilayer separators that combine different materials to achieve a balance of acid resistance, mechanical strength, and electrochemical performance[6].

Strengths: High chemical stability, optimized pore structure for ion transport, and advanced multilayer designs. Weaknesses: Potential for increased manufacturing complexity and cost due to multilayer structures.

Core Innovations in Separator Materials

Separators for enhanced flooded batteries, batteries, and related methods

PatentActiveUS11843126B2

Innovation

- A microporous separator with decreased tortuosity, increased porosity, and improved fillers, such as silica with high silanol groups, is used to create a shish-kebab structure in the polyolefin microporous membrane, reducing electrical resistance and enhancing ion diffusion.

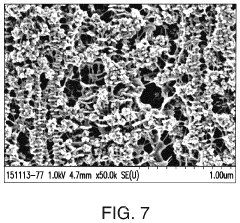

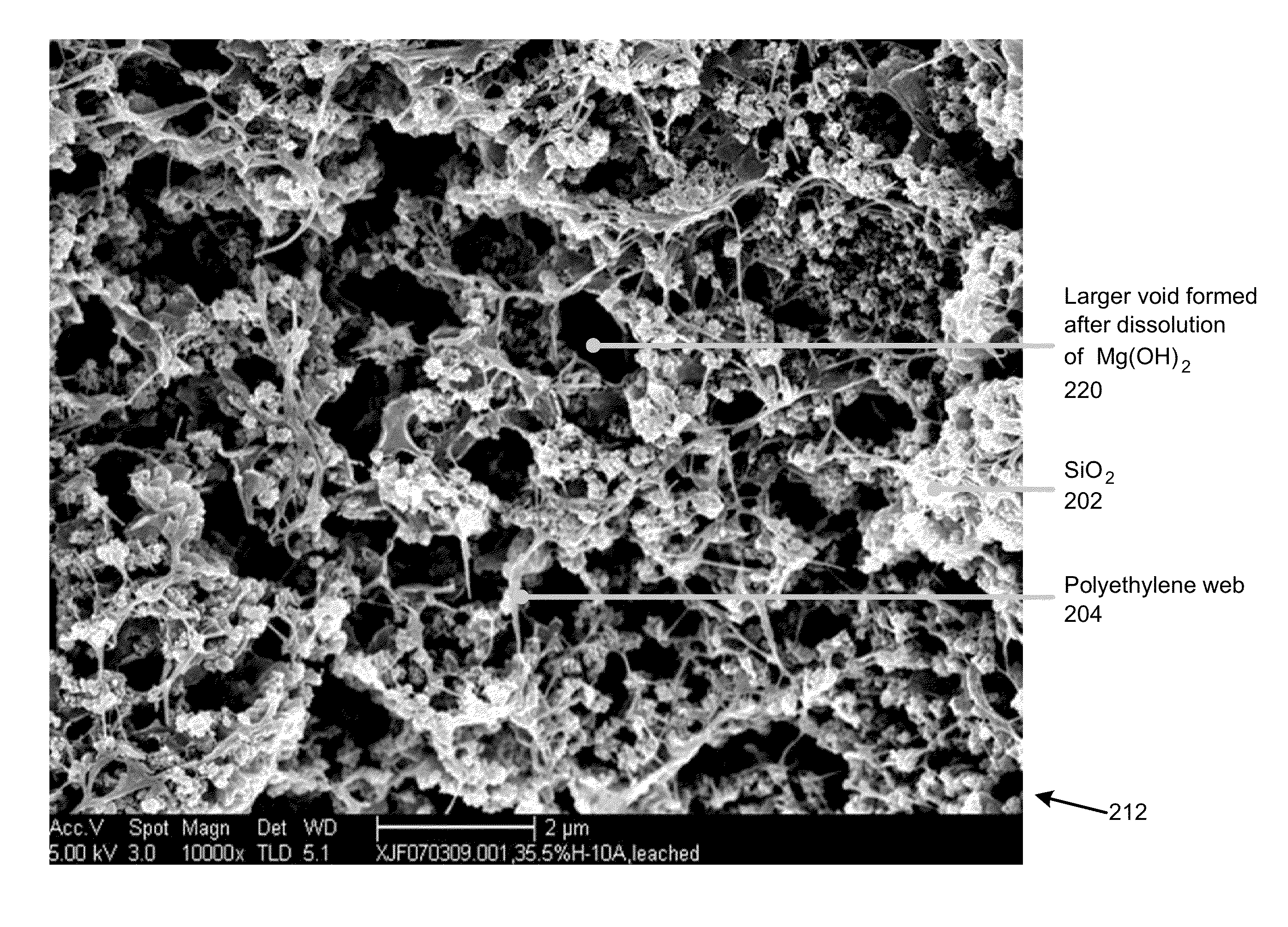

In-situ pore generation in lead-acid battery separator using electrolyte-soluble pore former

PatentActiveUS8592089B2

Innovation

- A microporous polymer web composed of ultrahigh molecular weight polyethylene (UHMWPE), precipitated silica, and a sacrificial pore former like magnesium hydroxide (Mg(OH)2) that dissolves in sulfuric acid, increasing porosity and modifying pore size distribution, thereby enhancing wettability and reducing electrical resistance.

Environmental Impact of Battery Acid Management

The environmental impact of battery acid management is a critical concern in the battery industry, particularly in relation to separator performance. Battery acid, primarily composed of sulfuric acid, poses significant risks to ecosystems and human health if not properly managed. The production, use, and disposal of batteries contribute to the release of acid into the environment, necessitating stringent control measures.

Improper handling of battery acid can lead to soil contamination, affecting plant growth and soil microorganisms. When acid seeps into the ground, it alters soil pH, potentially rendering large areas infertile and disrupting local ecosystems. Furthermore, acid runoff can contaminate water sources, harming aquatic life and compromising water quality for both wildlife and human consumption.

Air pollution is another consequence of inadequate battery acid management. During battery manufacturing and recycling processes, acid mists can be released, contributing to air quality degradation and potentially causing respiratory issues in nearby populations. These emissions may also contribute to acid rain formation, exacerbating the environmental impact on a broader scale.

The recycling of batteries presents both challenges and opportunities for environmental protection. While recycling helps recover valuable materials and reduces the need for raw resource extraction, the process itself can be environmentally hazardous if not properly controlled. Advanced recycling technologies and strict regulations are essential to minimize the release of acid and other harmful substances during the recycling process.

To mitigate these environmental risks, the battery industry has implemented various strategies. These include the development of sealed battery designs to reduce acid leakage, the use of acid-resistant materials in battery construction, and the implementation of advanced wastewater treatment systems in manufacturing facilities. Additionally, the industry is exploring alternative electrolyte materials that are less environmentally harmful than traditional sulfuric acid.

The regulatory landscape surrounding battery acid management continues to evolve, with increasingly stringent environmental protection standards being implemented worldwide. These regulations often mandate proper storage, transportation, and disposal procedures for batteries and battery acid, as well as set limits on emissions from manufacturing and recycling facilities.

Research into more environmentally friendly battery technologies is ongoing, with a focus on developing batteries that use less toxic materials or have improved containment systems. This includes advancements in solid-state batteries and the exploration of bio-based electrolytes, which could significantly reduce the environmental risks associated with traditional battery acid.

Improper handling of battery acid can lead to soil contamination, affecting plant growth and soil microorganisms. When acid seeps into the ground, it alters soil pH, potentially rendering large areas infertile and disrupting local ecosystems. Furthermore, acid runoff can contaminate water sources, harming aquatic life and compromising water quality for both wildlife and human consumption.

Air pollution is another consequence of inadequate battery acid management. During battery manufacturing and recycling processes, acid mists can be released, contributing to air quality degradation and potentially causing respiratory issues in nearby populations. These emissions may also contribute to acid rain formation, exacerbating the environmental impact on a broader scale.

The recycling of batteries presents both challenges and opportunities for environmental protection. While recycling helps recover valuable materials and reduces the need for raw resource extraction, the process itself can be environmentally hazardous if not properly controlled. Advanced recycling technologies and strict regulations are essential to minimize the release of acid and other harmful substances during the recycling process.

To mitigate these environmental risks, the battery industry has implemented various strategies. These include the development of sealed battery designs to reduce acid leakage, the use of acid-resistant materials in battery construction, and the implementation of advanced wastewater treatment systems in manufacturing facilities. Additionally, the industry is exploring alternative electrolyte materials that are less environmentally harmful than traditional sulfuric acid.

The regulatory landscape surrounding battery acid management continues to evolve, with increasingly stringent environmental protection standards being implemented worldwide. These regulations often mandate proper storage, transportation, and disposal procedures for batteries and battery acid, as well as set limits on emissions from manufacturing and recycling facilities.

Research into more environmentally friendly battery technologies is ongoing, with a focus on developing batteries that use less toxic materials or have improved containment systems. This includes advancements in solid-state batteries and the exploration of bio-based electrolytes, which could significantly reduce the environmental risks associated with traditional battery acid.

Safety Regulations for Battery Separators

Safety regulations for battery separators play a crucial role in ensuring the reliability and safety of battery systems. These regulations are designed to address the potential risks associated with battery acid and its impact on separator performance. The primary focus is on preventing acid leakage, maintaining separator integrity, and minimizing the risk of short circuits and thermal runaway.

Regulatory bodies, such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), have established specific standards for battery separators. These standards outline the minimum requirements for chemical resistance, mechanical strength, and thermal stability of separator materials. For instance, IEC 62133 specifies safety requirements for portable sealed secondary cells and batteries, including separator performance under various conditions.

One key aspect of safety regulations is the requirement for acid resistance testing. Separators must demonstrate the ability to withstand prolonged exposure to battery acid without significant degradation. This typically involves immersion tests in simulated electrolyte solutions, followed by assessments of mechanical properties and dimensional stability.

Mechanical strength requirements are another critical component of safety regulations. Separators must maintain their structural integrity under normal operating conditions and during potential abuse scenarios. This includes resistance to puncture, tear, and compression forces. Standards often specify minimum tensile strength and elongation values to ensure adequate mechanical performance.

Thermal stability is a paramount concern in battery safety. Regulations mandate that separators maintain their dimensional stability and barrier properties at elevated temperatures. This is typically evaluated through hot oven tests and thermal shrinkage measurements. Some standards also require separators to demonstrate shutdown capabilities, where the material melts and closes its pores at a specific temperature to prevent further ion transport and potential thermal runaway.

Regulations also address the chemical composition of separators, particularly concerning the presence of harmful substances. Restrictions on the use of certain additives or processing aids may be in place to prevent the release of toxic compounds during battery operation or in the event of a failure.

Manufacturing quality control is an integral part of safety regulations. Manufacturers are required to implement rigorous quality assurance processes to ensure consistent separator performance. This includes in-process testing, batch sampling, and documentation of production parameters.

As battery technology continues to evolve, safety regulations are regularly updated to address new challenges and incorporate emerging best practices. This ongoing process involves collaboration between industry stakeholders, research institutions, and regulatory bodies to enhance the overall safety and reliability of battery systems.

Regulatory bodies, such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL), have established specific standards for battery separators. These standards outline the minimum requirements for chemical resistance, mechanical strength, and thermal stability of separator materials. For instance, IEC 62133 specifies safety requirements for portable sealed secondary cells and batteries, including separator performance under various conditions.

One key aspect of safety regulations is the requirement for acid resistance testing. Separators must demonstrate the ability to withstand prolonged exposure to battery acid without significant degradation. This typically involves immersion tests in simulated electrolyte solutions, followed by assessments of mechanical properties and dimensional stability.

Mechanical strength requirements are another critical component of safety regulations. Separators must maintain their structural integrity under normal operating conditions and during potential abuse scenarios. This includes resistance to puncture, tear, and compression forces. Standards often specify minimum tensile strength and elongation values to ensure adequate mechanical performance.

Thermal stability is a paramount concern in battery safety. Regulations mandate that separators maintain their dimensional stability and barrier properties at elevated temperatures. This is typically evaluated through hot oven tests and thermal shrinkage measurements. Some standards also require separators to demonstrate shutdown capabilities, where the material melts and closes its pores at a specific temperature to prevent further ion transport and potential thermal runaway.

Regulations also address the chemical composition of separators, particularly concerning the presence of harmful substances. Restrictions on the use of certain additives or processing aids may be in place to prevent the release of toxic compounds during battery operation or in the event of a failure.

Manufacturing quality control is an integral part of safety regulations. Manufacturers are required to implement rigorous quality assurance processes to ensure consistent separator performance. This includes in-process testing, batch sampling, and documentation of production parameters.

As battery technology continues to evolve, safety regulations are regularly updated to address new challenges and incorporate emerging best practices. This ongoing process involves collaboration between industry stakeholders, research institutions, and regulatory bodies to enhance the overall safety and reliability of battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!