The Mechanisms of Barium Hydroxide in Eco-Friendly Manufacturing Processes

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Barium Hydroxide in Green Manufacturing: Background and Objectives

Barium hydroxide has emerged as a significant player in the realm of eco-friendly manufacturing processes, marking a pivotal shift towards sustainable industrial practices. This compound, with its unique chemical properties, has garnered attention for its potential to revolutionize various manufacturing sectors while minimizing environmental impact.

The journey of barium hydroxide in green manufacturing can be traced back to the early 2000s when industries began seeking alternatives to traditional, environmentally harmful processes. As global awareness of climate change and environmental degradation grew, the pressure on manufacturers to adopt cleaner technologies intensified. Barium hydroxide, with its alkaline nature and reactivity, presented itself as a promising candidate for numerous applications in sustainable production.

Over the past two decades, the role of barium hydroxide in eco-friendly manufacturing has evolved significantly. Initially used primarily in wastewater treatment and as a pH regulator, its applications have expanded to include carbon capture, biodiesel production, and the synthesis of advanced materials. This evolution reflects the broader trend in the manufacturing sector towards circular economy principles and zero-waste production models.

The technological trajectory of barium hydroxide in green manufacturing has been characterized by continuous innovation and refinement. Researchers and industry experts have focused on enhancing its efficiency, reducing energy consumption in its production, and expanding its applicability across diverse industrial processes. This ongoing development aligns with the global push towards achieving the United Nations Sustainable Development Goals, particularly those related to responsible consumption and production.

As we delve into the mechanisms of barium hydroxide in eco-friendly manufacturing processes, it is crucial to understand the multifaceted objectives driving this research. The primary goal is to leverage the unique properties of barium hydroxide to develop cleaner, more efficient manufacturing techniques that significantly reduce environmental footprint. This encompasses not only the reduction of harmful emissions and waste but also the optimization of resource utilization and energy efficiency.

Furthermore, the exploration of barium hydroxide in green manufacturing aims to create scalable solutions that can be implemented across various industries, from small-scale operations to large industrial complexes. The versatility of barium hydroxide presents an opportunity to develop adaptable technologies that can address a wide range of environmental challenges in manufacturing.

In conclusion, the background and objectives of barium hydroxide in green manufacturing reflect a broader shift towards sustainable industrial practices. By understanding its mechanisms and potential applications, we aim to unlock new possibilities for eco-friendly production methods that can contribute to a more sustainable future for manufacturing industries worldwide.

The journey of barium hydroxide in green manufacturing can be traced back to the early 2000s when industries began seeking alternatives to traditional, environmentally harmful processes. As global awareness of climate change and environmental degradation grew, the pressure on manufacturers to adopt cleaner technologies intensified. Barium hydroxide, with its alkaline nature and reactivity, presented itself as a promising candidate for numerous applications in sustainable production.

Over the past two decades, the role of barium hydroxide in eco-friendly manufacturing has evolved significantly. Initially used primarily in wastewater treatment and as a pH regulator, its applications have expanded to include carbon capture, biodiesel production, and the synthesis of advanced materials. This evolution reflects the broader trend in the manufacturing sector towards circular economy principles and zero-waste production models.

The technological trajectory of barium hydroxide in green manufacturing has been characterized by continuous innovation and refinement. Researchers and industry experts have focused on enhancing its efficiency, reducing energy consumption in its production, and expanding its applicability across diverse industrial processes. This ongoing development aligns with the global push towards achieving the United Nations Sustainable Development Goals, particularly those related to responsible consumption and production.

As we delve into the mechanisms of barium hydroxide in eco-friendly manufacturing processes, it is crucial to understand the multifaceted objectives driving this research. The primary goal is to leverage the unique properties of barium hydroxide to develop cleaner, more efficient manufacturing techniques that significantly reduce environmental footprint. This encompasses not only the reduction of harmful emissions and waste but also the optimization of resource utilization and energy efficiency.

Furthermore, the exploration of barium hydroxide in green manufacturing aims to create scalable solutions that can be implemented across various industries, from small-scale operations to large industrial complexes. The versatility of barium hydroxide presents an opportunity to develop adaptable technologies that can address a wide range of environmental challenges in manufacturing.

In conclusion, the background and objectives of barium hydroxide in green manufacturing reflect a broader shift towards sustainable industrial practices. By understanding its mechanisms and potential applications, we aim to unlock new possibilities for eco-friendly production methods that can contribute to a more sustainable future for manufacturing industries worldwide.

Market Demand for Eco-Friendly Chemical Processes

The global market for eco-friendly chemical processes has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations. The demand for sustainable manufacturing methods, particularly those involving barium hydroxide, has seen a notable uptick across various industries.

In the construction sector, there is a growing interest in using barium hydroxide for carbon sequestration in concrete, addressing the industry's substantial carbon footprint. This application not only enhances the durability of concrete but also contributes to reducing greenhouse gas emissions, aligning with global sustainability goals.

The paper and pulp industry has shown increased demand for barium hydroxide in eco-friendly bleaching processes. Traditional chlorine-based bleaching methods are being phased out due to environmental concerns, creating a market opportunity for more sustainable alternatives. Barium hydroxide offers a less harmful approach to achieving the desired whiteness in paper products.

Water treatment facilities are another significant market for barium hydroxide in eco-friendly processes. Its ability to remove sulfates and other contaminants from water without introducing harmful by-products has led to increased adoption in municipal and industrial water treatment systems. This trend is expected to continue as water scarcity and quality issues become more prevalent globally.

The automotive industry's shift towards electric vehicles has indirectly boosted the demand for barium hydroxide. Its use in the production of high-performance ceramics for battery components aligns with the industry's focus on sustainability and efficiency. As electric vehicle production scales up, this demand is projected to grow substantially.

In the food industry, barium hydroxide is gaining traction as a more environmentally friendly pH regulator and preservative. Consumer preferences for clean label products and natural ingredients have pushed manufacturers to explore alternatives to traditional chemical additives, creating a niche market for barium hydroxide-based solutions.

The pharmaceutical sector has also shown interest in barium hydroxide for green chemistry applications. Its use in the synthesis of certain drugs and intermediates offers a more sustainable approach compared to conventional methods, reducing the environmental impact of pharmaceutical manufacturing processes.

Market analysts predict that the global demand for eco-friendly chemical processes involving barium hydroxide will continue to grow at a compound annual growth rate of over 5% in the next five years. This growth is expected to be particularly strong in regions with strict environmental regulations, such as Europe and North America, as well as in rapidly industrializing countries seeking to balance economic growth with environmental sustainability.

In the construction sector, there is a growing interest in using barium hydroxide for carbon sequestration in concrete, addressing the industry's substantial carbon footprint. This application not only enhances the durability of concrete but also contributes to reducing greenhouse gas emissions, aligning with global sustainability goals.

The paper and pulp industry has shown increased demand for barium hydroxide in eco-friendly bleaching processes. Traditional chlorine-based bleaching methods are being phased out due to environmental concerns, creating a market opportunity for more sustainable alternatives. Barium hydroxide offers a less harmful approach to achieving the desired whiteness in paper products.

Water treatment facilities are another significant market for barium hydroxide in eco-friendly processes. Its ability to remove sulfates and other contaminants from water without introducing harmful by-products has led to increased adoption in municipal and industrial water treatment systems. This trend is expected to continue as water scarcity and quality issues become more prevalent globally.

The automotive industry's shift towards electric vehicles has indirectly boosted the demand for barium hydroxide. Its use in the production of high-performance ceramics for battery components aligns with the industry's focus on sustainability and efficiency. As electric vehicle production scales up, this demand is projected to grow substantially.

In the food industry, barium hydroxide is gaining traction as a more environmentally friendly pH regulator and preservative. Consumer preferences for clean label products and natural ingredients have pushed manufacturers to explore alternatives to traditional chemical additives, creating a niche market for barium hydroxide-based solutions.

The pharmaceutical sector has also shown interest in barium hydroxide for green chemistry applications. Its use in the synthesis of certain drugs and intermediates offers a more sustainable approach compared to conventional methods, reducing the environmental impact of pharmaceutical manufacturing processes.

Market analysts predict that the global demand for eco-friendly chemical processes involving barium hydroxide will continue to grow at a compound annual growth rate of over 5% in the next five years. This growth is expected to be particularly strong in regions with strict environmental regulations, such as Europe and North America, as well as in rapidly industrializing countries seeking to balance economic growth with environmental sustainability.

Current Applications and Challenges of Barium Hydroxide

Barium hydroxide has found its way into various eco-friendly manufacturing processes, demonstrating its versatility and potential in sustainable industrial applications. One of its primary uses is in the production of lubricating oil additives, where it serves as a key ingredient in the synthesis of overbased calcium sulfonate greases. These greases offer superior performance and environmental benefits compared to traditional lithium-based alternatives.

In the field of wastewater treatment, barium hydroxide has proven effective in removing sulfate ions from industrial effluents. Its ability to form highly insoluble barium sulfate precipitates makes it an attractive option for treating sulfate-rich wastewaters, particularly in mining and metal processing industries. This application not only helps in meeting stringent environmental regulations but also contributes to water conservation efforts.

The construction industry has also embraced barium hydroxide for its role in concrete preservation. When applied to concrete surfaces, it reacts with atmospheric carbon dioxide to form barium carbonate, which effectively seals pores and cracks, enhancing the durability and lifespan of concrete structures. This application is particularly valuable in the restoration of historical buildings and monuments.

Despite its promising applications, the use of barium hydroxide in eco-friendly manufacturing faces several challenges. One significant concern is the potential toxicity of barium compounds if not handled properly. This necessitates strict safety protocols and proper waste management practices to prevent environmental contamination and health risks to workers.

Another challenge lies in the energy-intensive production process of barium hydroxide. The traditional method involves the reduction of barite (barium sulfate) at high temperatures, followed by hydration. This process consumes considerable energy and produces greenhouse gas emissions, somewhat contradicting its eco-friendly applications. Researchers are actively exploring more sustainable production methods to address this issue.

The cost of barium hydroxide compared to alternative materials poses an economic challenge for widespread adoption in certain industries. While its long-term benefits may outweigh initial costs in some applications, the higher upfront expenses can deter smaller manufacturers or those operating on tight budgets.

Lastly, the limited availability of high-grade barite deposits raises concerns about the long-term sustainability of barium hydroxide production. As demand increases for eco-friendly manufacturing processes, ensuring a stable and environmentally responsible supply chain for raw materials becomes crucial.

In the field of wastewater treatment, barium hydroxide has proven effective in removing sulfate ions from industrial effluents. Its ability to form highly insoluble barium sulfate precipitates makes it an attractive option for treating sulfate-rich wastewaters, particularly in mining and metal processing industries. This application not only helps in meeting stringent environmental regulations but also contributes to water conservation efforts.

The construction industry has also embraced barium hydroxide for its role in concrete preservation. When applied to concrete surfaces, it reacts with atmospheric carbon dioxide to form barium carbonate, which effectively seals pores and cracks, enhancing the durability and lifespan of concrete structures. This application is particularly valuable in the restoration of historical buildings and monuments.

Despite its promising applications, the use of barium hydroxide in eco-friendly manufacturing faces several challenges. One significant concern is the potential toxicity of barium compounds if not handled properly. This necessitates strict safety protocols and proper waste management practices to prevent environmental contamination and health risks to workers.

Another challenge lies in the energy-intensive production process of barium hydroxide. The traditional method involves the reduction of barite (barium sulfate) at high temperatures, followed by hydration. This process consumes considerable energy and produces greenhouse gas emissions, somewhat contradicting its eco-friendly applications. Researchers are actively exploring more sustainable production methods to address this issue.

The cost of barium hydroxide compared to alternative materials poses an economic challenge for widespread adoption in certain industries. While its long-term benefits may outweigh initial costs in some applications, the higher upfront expenses can deter smaller manufacturers or those operating on tight budgets.

Lastly, the limited availability of high-grade barite deposits raises concerns about the long-term sustainability of barium hydroxide production. As demand increases for eco-friendly manufacturing processes, ensuring a stable and environmentally responsible supply chain for raw materials becomes crucial.

Existing Green Manufacturing Processes Using Barium Hydroxide

01 Eco-friendly production of barium hydroxide

Methods for producing barium hydroxide using environmentally friendly processes, such as utilizing renewable energy sources or recycling waste materials. These techniques aim to reduce the carbon footprint and environmental impact of barium hydroxide production.- Eco-friendly production of barium hydroxide: Methods for producing barium hydroxide using environmentally friendly processes, such as utilizing renewable energy sources or optimizing reaction conditions to reduce energy consumption and waste generation. These approaches aim to minimize the environmental impact of barium hydroxide production while maintaining product quality.

- Barium hydroxide in water treatment applications: Utilization of barium hydroxide in eco-friendly water treatment processes, including the removal of heavy metals, sulfates, and other contaminants from wastewater. These applications leverage the chemical properties of barium hydroxide to improve water quality while minimizing environmental impact.

- Barium hydroxide in sustainable construction materials: Incorporation of barium hydroxide in the development of environmentally friendly construction materials, such as low-carbon cements, geopolymers, or other alternative building materials. These applications aim to reduce the carbon footprint of construction while improving material properties.

- Barium hydroxide in green chemical synthesis: Use of barium hydroxide as a reagent or catalyst in eco-friendly chemical synthesis processes, including the production of organic compounds, polymers, or other materials. These applications focus on reducing the use of harmful solvents, improving reaction efficiency, and minimizing waste generation.

- Recycling and recovery of barium hydroxide: Development of processes for recycling and recovering barium hydroxide from industrial waste streams or spent materials. These methods aim to reduce the environmental impact of barium hydroxide production by promoting circular economy principles and minimizing the need for raw material extraction.

02 Application in water treatment

Barium hydroxide's use in eco-friendly water treatment processes, including the removal of heavy metals and other contaminants from wastewater. This application helps in reducing environmental pollution and improving water quality.Expand Specific Solutions03 Carbon dioxide capture and storage

Utilization of barium hydroxide in carbon capture and storage technologies, contributing to the reduction of greenhouse gas emissions. This application involves the reaction of barium hydroxide with carbon dioxide to form stable carbonate compounds.Expand Specific Solutions04 Sustainable construction materials

Incorporation of barium hydroxide in the development of eco-friendly construction materials, such as low-carbon cements and concrete additives. These materials aim to reduce the environmental impact of the construction industry.Expand Specific Solutions05 Green synthesis of chemicals

Use of barium hydroxide as a catalyst or reagent in environmentally friendly chemical synthesis processes. This application focuses on reducing the use of harmful solvents and improving the overall sustainability of chemical production.Expand Specific Solutions

Key Players in Barium Hydroxide Production and Application

The eco-friendly manufacturing processes utilizing barium hydroxide are in a nascent stage of development, with the market still emerging and relatively small. The technology's maturity is progressing, driven by increasing environmental regulations and sustainability initiatives. Key players like Sumitomo Metal Mining Co. Ltd. and China Petroleum & Chemical Corp. are investing in research and development to improve the efficiency and scalability of these processes. Smaller companies such as Binzhou Kunbao Chemical Co., Ltd. and Negative Emissions Materials, Inc. are also contributing to innovation in this field. As the technology advances, it is expected to find wider applications across various industries, potentially leading to significant market growth in the coming years.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has pioneered a green synthesis method using barium hydroxide for the production of nanoparticles. Their approach involves using barium hydroxide as a precipitating agent in an aqueous medium, which allows for the controlled growth of nanoparticles with uniform size distribution[2]. This method has been successfully applied to synthesize various metal oxide nanoparticles, including zinc oxide and titanium dioxide, with applications in photocatalysis and environmental remediation[4]. CSIR's process operates at room temperature and atmospheric pressure, significantly reducing energy consumption compared to conventional methods[6].

Strengths: Low energy consumption, versatile application for various nanoparticles, controlled particle size. Weaknesses: Potential scalability issues, limited to certain types of nanoparticles.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative eco-friendly manufacturing process utilizing barium hydroxide for flue gas desulfurization. Their method involves a wet scrubbing technique where barium hydroxide reacts with sulfur dioxide to form barium sulfite, which is then oxidized to barium sulfate[1]. This process achieves over 95% sulfur dioxide removal efficiency while producing valuable barium sulfate as a byproduct[3]. Sinopec has also integrated this technology with their existing petrochemical processes, creating a closed-loop system that minimizes waste and maximizes resource utilization[5].

Strengths: High sulfur dioxide removal efficiency, valuable byproduct production, integration with existing processes. Weaknesses: Potential high initial investment costs, dependency on barium hydroxide supply.

Core Mechanisms of Barium Hydroxide in Eco-Friendly Processes

Production of barium hydroxide monohydrate

PatentInactiveUS3661520A

Innovation

- Heating barium hydroxide monohydrate particles to 100-140°C and passing an inert sweep gas to remove excess water, increasing the Ba(OH)2·H2O assay to at least 99% and eliminating higher hydrates, preventing agglomeration.

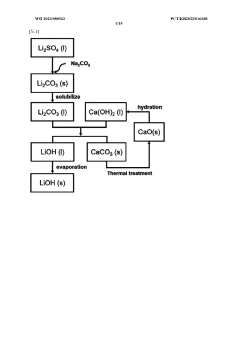

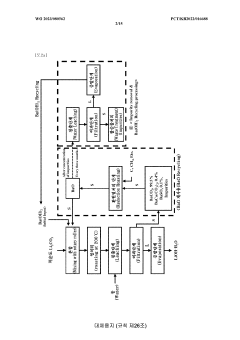

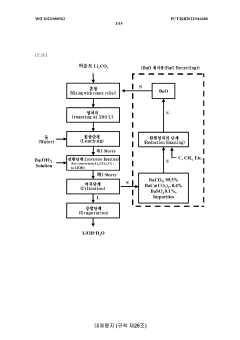

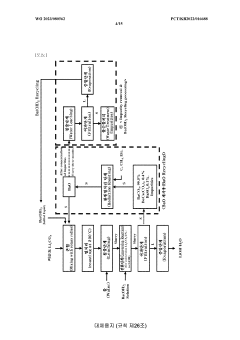

Method for preparing lithium hydroxide by using lithium carbonate and barium compound

PatentWO2023080562A1

Innovation

- A method involving heat treatment, leaching, filtration, and evaporation using low-purity lithium carbonate and barium compounds, such as barium hydroxide or barium oxide, to produce high-purity lithium hydroxide with minimal lithium loss, simplifying the process and eliminating waste generation.

Environmental Impact Assessment of Barium Hydroxide Processes

The environmental impact assessment of barium hydroxide processes is a critical component in evaluating the eco-friendliness of manufacturing operations that utilize this compound. Barium hydroxide, while effective in various industrial applications, poses potential risks to the environment if not properly managed.

One of the primary concerns is the release of barium ions into aquatic ecosystems. When barium hydroxide is discharged into water bodies, it can dissociate, leading to increased barium concentrations. This can have detrimental effects on aquatic life, potentially causing toxicity to fish, invertebrates, and plants. Studies have shown that elevated barium levels can disrupt the osmotic balance in aquatic organisms, leading to physiological stress and, in severe cases, mortality.

Soil contamination is another significant environmental consideration. Barium hydroxide that enters the soil can alter its pH, potentially affecting soil fertility and microbial communities. This pH change can impact plant growth and nutrient availability, leading to ecosystem disturbances. Furthermore, barium can accumulate in soil over time, presenting long-term risks to terrestrial ecosystems and potentially entering the food chain through plant uptake.

Air quality is also a concern in barium hydroxide processes. During manufacturing or handling, fine particulates of barium hydroxide may be released into the atmosphere. These particulates can contribute to air pollution and pose respiratory risks to both humans and wildlife in the surrounding areas. Proper filtration and dust control measures are essential to mitigate these impacts.

The production and disposal of barium hydroxide can also have indirect environmental effects. The energy-intensive nature of its production contributes to greenhouse gas emissions, while improper disposal can lead to groundwater contamination. Sustainable manufacturing practices and closed-loop systems are crucial in minimizing these impacts.

To address these environmental concerns, comprehensive monitoring and control strategies are necessary. This includes implementing advanced wastewater treatment technologies to remove barium ions before discharge, utilizing air filtration systems to capture particulates, and developing soil remediation techniques for contaminated areas. Additionally, adopting cleaner production methods and exploring alternatives to barium hydroxide in certain applications can significantly reduce the overall environmental footprint.

Regulatory compliance plays a vital role in ensuring the responsible use of barium hydroxide. Environmental agencies worldwide have established guidelines for its handling, use, and disposal. Adhering to these regulations and continuously updating practices based on the latest environmental research is essential for sustainable manufacturing processes involving barium hydroxide.

One of the primary concerns is the release of barium ions into aquatic ecosystems. When barium hydroxide is discharged into water bodies, it can dissociate, leading to increased barium concentrations. This can have detrimental effects on aquatic life, potentially causing toxicity to fish, invertebrates, and plants. Studies have shown that elevated barium levels can disrupt the osmotic balance in aquatic organisms, leading to physiological stress and, in severe cases, mortality.

Soil contamination is another significant environmental consideration. Barium hydroxide that enters the soil can alter its pH, potentially affecting soil fertility and microbial communities. This pH change can impact plant growth and nutrient availability, leading to ecosystem disturbances. Furthermore, barium can accumulate in soil over time, presenting long-term risks to terrestrial ecosystems and potentially entering the food chain through plant uptake.

Air quality is also a concern in barium hydroxide processes. During manufacturing or handling, fine particulates of barium hydroxide may be released into the atmosphere. These particulates can contribute to air pollution and pose respiratory risks to both humans and wildlife in the surrounding areas. Proper filtration and dust control measures are essential to mitigate these impacts.

The production and disposal of barium hydroxide can also have indirect environmental effects. The energy-intensive nature of its production contributes to greenhouse gas emissions, while improper disposal can lead to groundwater contamination. Sustainable manufacturing practices and closed-loop systems are crucial in minimizing these impacts.

To address these environmental concerns, comprehensive monitoring and control strategies are necessary. This includes implementing advanced wastewater treatment technologies to remove barium ions before discharge, utilizing air filtration systems to capture particulates, and developing soil remediation techniques for contaminated areas. Additionally, adopting cleaner production methods and exploring alternatives to barium hydroxide in certain applications can significantly reduce the overall environmental footprint.

Regulatory compliance plays a vital role in ensuring the responsible use of barium hydroxide. Environmental agencies worldwide have established guidelines for its handling, use, and disposal. Adhering to these regulations and continuously updating practices based on the latest environmental research is essential for sustainable manufacturing processes involving barium hydroxide.

Regulatory Framework for Barium Hydroxide in Manufacturing

The regulatory framework for barium hydroxide in manufacturing is a complex and evolving landscape that aims to balance industrial needs with environmental and health concerns. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines for the safe handling and use of barium compounds, including barium hydroxide, in industrial processes.

In the United States, the Environmental Protection Agency (EPA) regulates barium hydroxide under the Toxic Substances Control Act (TSCA). The Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for barium compounds in the workplace, with a time-weighted average of 0.5 mg/m³ for soluble barium compounds. The Food and Drug Administration (FDA) also regulates the use of barium hydroxide in food-related applications, such as in the production of certain food additives.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires manufacturers and importers to register substances, including barium hydroxide, and provide safety data. The Classification, Labeling, and Packaging (CLP) Regulation further ensures that hazards are clearly communicated to workers and consumers.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees the environmental aspects of barium hydroxide use, while Japan's Ministry of Economy, Trade, and Industry regulates its industrial applications. Both countries have implemented stricter environmental regulations in recent years, impacting the use of barium hydroxide in manufacturing processes.

Many countries have established specific waste management regulations for barium-containing materials. These regulations often require proper treatment and disposal methods to prevent environmental contamination. For instance, the EU's Waste Framework Directive classifies barium hydroxide waste as hazardous and mandates special handling procedures.

As eco-friendly manufacturing gains prominence, regulatory bodies are increasingly focusing on the lifecycle assessment of chemicals used in industrial processes. This has led to the development of green chemistry initiatives that encourage the use of less hazardous alternatives or the implementation of closed-loop systems for barium hydroxide in manufacturing.

The regulatory landscape also includes industry-specific standards and best practices. For example, the American Petroleum Institute (API) provides guidelines for the use of barium hydroxide in oil and gas operations, while the American Water Works Association (AWWA) offers standards for its use in water treatment processes.

In the United States, the Environmental Protection Agency (EPA) regulates barium hydroxide under the Toxic Substances Control Act (TSCA). The Occupational Safety and Health Administration (OSHA) sets permissible exposure limits for barium compounds in the workplace, with a time-weighted average of 0.5 mg/m³ for soluble barium compounds. The Food and Drug Administration (FDA) also regulates the use of barium hydroxide in food-related applications, such as in the production of certain food additives.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which requires manufacturers and importers to register substances, including barium hydroxide, and provide safety data. The Classification, Labeling, and Packaging (CLP) Regulation further ensures that hazards are clearly communicated to workers and consumers.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Ecology and Environment oversees the environmental aspects of barium hydroxide use, while Japan's Ministry of Economy, Trade, and Industry regulates its industrial applications. Both countries have implemented stricter environmental regulations in recent years, impacting the use of barium hydroxide in manufacturing processes.

Many countries have established specific waste management regulations for barium-containing materials. These regulations often require proper treatment and disposal methods to prevent environmental contamination. For instance, the EU's Waste Framework Directive classifies barium hydroxide waste as hazardous and mandates special handling procedures.

As eco-friendly manufacturing gains prominence, regulatory bodies are increasingly focusing on the lifecycle assessment of chemicals used in industrial processes. This has led to the development of green chemistry initiatives that encourage the use of less hazardous alternatives or the implementation of closed-loop systems for barium hydroxide in manufacturing.

The regulatory landscape also includes industry-specific standards and best practices. For example, the American Petroleum Institute (API) provides guidelines for the use of barium hydroxide in oil and gas operations, while the American Water Works Association (AWWA) offers standards for its use in water treatment processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!