The potential of hybrid AMOLED display materials.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Evolution and Hybrid Materials Objectives

AMOLED (Active-Matrix Organic Light-Emitting Diode) technology has revolutionized the display industry since its inception in the late 1990s. The evolution of AMOLED displays has been marked by continuous improvements in efficiency, color accuracy, and longevity. As the technology matures, researchers and manufacturers are exploring hybrid materials to overcome existing limitations and unlock new possibilities.

The primary objective of hybrid AMOLED display materials is to combine the strengths of different material classes to create superior display performance. This approach aims to address key challenges such as power consumption, color gamut, and device lifetime. By integrating organic and inorganic components, hybrid materials offer the potential for enhanced electron mobility, improved thermal stability, and better light emission characteristics.

One of the main goals in developing hybrid AMOLED materials is to improve the efficiency of blue emitters. Blue OLEDs have traditionally lagged behind their red and green counterparts in terms of efficiency and longevity. Hybrid approaches, such as thermally activated delayed fluorescence (TADF) materials combined with phosphorescent dopants, show promise in achieving higher external quantum efficiencies for blue emission.

Another objective is to enhance the overall stability of AMOLED displays. Hybrid materials that incorporate inorganic nanoparticles or quantum dots into organic matrices are being investigated to improve resistance to degradation caused by heat and electrical stress. This could lead to displays with longer lifespans and more consistent performance over time.

Expanding the color gamut is also a key focus area for hybrid AMOLED materials. By combining narrow-band emitters with traditional organic materials, researchers aim to achieve a wider range of displayable colors, approaching or even exceeding the Rec. 2020 color space standard. This would result in more vibrant and lifelike images on AMOLED screens.

Flexibility and form factor innovation represent another frontier for hybrid materials in AMOLED technology. The goal is to develop materials that can maintain high performance while allowing for bendable, foldable, or even stretchable displays. This involves creating hybrid structures that can withstand mechanical stress without compromising electrical and optical properties.

As the AMOLED industry progresses, the objectives for hybrid materials also include improving manufacturing processes and reducing production costs. Researchers are exploring solution-processable hybrid materials that could enable more efficient and scalable manufacturing techniques, potentially lowering the barriers to entry for AMOLED production.

The primary objective of hybrid AMOLED display materials is to combine the strengths of different material classes to create superior display performance. This approach aims to address key challenges such as power consumption, color gamut, and device lifetime. By integrating organic and inorganic components, hybrid materials offer the potential for enhanced electron mobility, improved thermal stability, and better light emission characteristics.

One of the main goals in developing hybrid AMOLED materials is to improve the efficiency of blue emitters. Blue OLEDs have traditionally lagged behind their red and green counterparts in terms of efficiency and longevity. Hybrid approaches, such as thermally activated delayed fluorescence (TADF) materials combined with phosphorescent dopants, show promise in achieving higher external quantum efficiencies for blue emission.

Another objective is to enhance the overall stability of AMOLED displays. Hybrid materials that incorporate inorganic nanoparticles or quantum dots into organic matrices are being investigated to improve resistance to degradation caused by heat and electrical stress. This could lead to displays with longer lifespans and more consistent performance over time.

Expanding the color gamut is also a key focus area for hybrid AMOLED materials. By combining narrow-band emitters with traditional organic materials, researchers aim to achieve a wider range of displayable colors, approaching or even exceeding the Rec. 2020 color space standard. This would result in more vibrant and lifelike images on AMOLED screens.

Flexibility and form factor innovation represent another frontier for hybrid materials in AMOLED technology. The goal is to develop materials that can maintain high performance while allowing for bendable, foldable, or even stretchable displays. This involves creating hybrid structures that can withstand mechanical stress without compromising electrical and optical properties.

As the AMOLED industry progresses, the objectives for hybrid materials also include improving manufacturing processes and reducing production costs. Researchers are exploring solution-processable hybrid materials that could enable more efficient and scalable manufacturing techniques, potentially lowering the barriers to entry for AMOLED production.

Market Demand for Advanced Display Technologies

The demand for advanced display technologies has been steadily increasing across various sectors, driven by the growing consumer appetite for high-quality visual experiences and the expanding applications of displays in industries such as automotive, healthcare, and entertainment. Hybrid AMOLED (Active-Matrix Organic Light-Emitting Diode) display materials have emerged as a promising solution to meet these evolving market needs, offering a combination of superior performance characteristics and potential cost-effectiveness.

In the consumer electronics sector, smartphones and tablets continue to be the primary drivers of demand for advanced display technologies. The global smartphone market, in particular, has shown a strong preference for OLED displays, with AMOLED variants gaining traction due to their improved color accuracy, contrast ratios, and energy efficiency. This trend is expected to persist as consumers increasingly prioritize visual quality and battery life in their mobile devices.

The television market has also witnessed a shift towards OLED technology, with hybrid AMOLED materials presenting an opportunity to address the challenges of large-scale OLED production. As consumers seek larger screens with higher resolutions and better picture quality, hybrid AMOLED materials could potentially offer a more cost-effective solution for manufacturers to meet these demands while maintaining the superior visual characteristics associated with OLED technology.

In the automotive industry, the integration of advanced display technologies in vehicle interiors has become a key differentiator for manufacturers. The demand for larger, curved, and more interactive displays in dashboards and infotainment systems has created a new market opportunity for hybrid AMOLED materials. These materials can potentially provide the flexibility and durability required for automotive applications while delivering the high-quality visual output expected in premium vehicles.

The wearable technology market, encompassing smartwatches, fitness trackers, and augmented reality devices, represents another significant growth area for advanced display technologies. Hybrid AMOLED materials could address the unique requirements of these devices, such as low power consumption, high brightness for outdoor visibility, and the ability to conform to various form factors.

In the commercial and industrial sectors, there is an increasing demand for large-format displays with high resolution and color accuracy. Applications in digital signage, control rooms, and simulation environments could benefit from the advancements in hybrid AMOLED technology, particularly if it can offer improved longevity and reduced production costs compared to current OLED solutions.

The healthcare industry has also shown growing interest in advanced display technologies for medical imaging and diagnostic equipment. The superior contrast and color reproduction capabilities of hybrid AMOLED displays could potentially enhance the accuracy of medical imaging, leading to improved diagnostic outcomes.

As the market for advanced display technologies continues to expand, the potential of hybrid AMOLED materials to meet diverse industry needs while potentially offering cost advantages positions them as a key area of interest for both manufacturers and end-users. The ongoing research and development in this field are likely to further drive market demand as new applications and improvements in performance are realized.

In the consumer electronics sector, smartphones and tablets continue to be the primary drivers of demand for advanced display technologies. The global smartphone market, in particular, has shown a strong preference for OLED displays, with AMOLED variants gaining traction due to their improved color accuracy, contrast ratios, and energy efficiency. This trend is expected to persist as consumers increasingly prioritize visual quality and battery life in their mobile devices.

The television market has also witnessed a shift towards OLED technology, with hybrid AMOLED materials presenting an opportunity to address the challenges of large-scale OLED production. As consumers seek larger screens with higher resolutions and better picture quality, hybrid AMOLED materials could potentially offer a more cost-effective solution for manufacturers to meet these demands while maintaining the superior visual characteristics associated with OLED technology.

In the automotive industry, the integration of advanced display technologies in vehicle interiors has become a key differentiator for manufacturers. The demand for larger, curved, and more interactive displays in dashboards and infotainment systems has created a new market opportunity for hybrid AMOLED materials. These materials can potentially provide the flexibility and durability required for automotive applications while delivering the high-quality visual output expected in premium vehicles.

The wearable technology market, encompassing smartwatches, fitness trackers, and augmented reality devices, represents another significant growth area for advanced display technologies. Hybrid AMOLED materials could address the unique requirements of these devices, such as low power consumption, high brightness for outdoor visibility, and the ability to conform to various form factors.

In the commercial and industrial sectors, there is an increasing demand for large-format displays with high resolution and color accuracy. Applications in digital signage, control rooms, and simulation environments could benefit from the advancements in hybrid AMOLED technology, particularly if it can offer improved longevity and reduced production costs compared to current OLED solutions.

The healthcare industry has also shown growing interest in advanced display technologies for medical imaging and diagnostic equipment. The superior contrast and color reproduction capabilities of hybrid AMOLED displays could potentially enhance the accuracy of medical imaging, leading to improved diagnostic outcomes.

As the market for advanced display technologies continues to expand, the potential of hybrid AMOLED materials to meet diverse industry needs while potentially offering cost advantages positions them as a key area of interest for both manufacturers and end-users. The ongoing research and development in this field are likely to further drive market demand as new applications and improvements in performance are realized.

Current Challenges in Hybrid AMOLED Materials

Hybrid AMOLED display materials face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the complexity of integrating organic and inorganic components seamlessly. The interface between these materials often suffers from poor compatibility, leading to reduced efficiency and shortened device lifespan.

Stability remains a critical concern for hybrid AMOLED materials. Organic components are particularly susceptible to degradation when exposed to oxygen, moisture, and high temperatures. This vulnerability compromises the overall durability of hybrid displays, necessitating advanced encapsulation techniques and protective layers to mitigate environmental factors.

Another challenge lies in achieving uniform performance across the entire display area. Hybrid materials often exhibit inconsistent electrical and optical properties, resulting in variations in brightness, color accuracy, and response time across different pixels. This non-uniformity can lead to visible artifacts and reduced display quality, especially in large-format applications.

The manufacturing process for hybrid AMOLED materials presents its own set of challenges. Precise deposition and patterning of both organic and inorganic layers require sophisticated equipment and tight process control. The need for high-temperature processing of inorganic components can potentially damage the more sensitive organic materials, necessitating careful thermal management during production.

Cost-effectiveness remains a significant hurdle for widespread adoption of hybrid AMOLED technology. The complex manufacturing processes and specialized materials contribute to higher production costs compared to conventional display technologies. Balancing performance improvements with economic viability is crucial for market acceptance and commercial success.

Energy efficiency is another area of concern for hybrid AMOLED materials. While AMOLEDs are generally known for their power-saving capabilities, the addition of inorganic components can potentially increase power consumption. Optimizing the energy efficiency of hybrid systems without compromising display quality is an ongoing challenge for researchers and engineers.

Lastly, the development of hybrid AMOLED materials faces challenges in terms of scalability and yield. As display sizes increase and resolution demands grow, maintaining consistent performance and minimizing defects across larger areas becomes increasingly difficult. Improving manufacturing yield and reducing production variability are essential for the commercial viability of hybrid AMOLED technology.

Stability remains a critical concern for hybrid AMOLED materials. Organic components are particularly susceptible to degradation when exposed to oxygen, moisture, and high temperatures. This vulnerability compromises the overall durability of hybrid displays, necessitating advanced encapsulation techniques and protective layers to mitigate environmental factors.

Another challenge lies in achieving uniform performance across the entire display area. Hybrid materials often exhibit inconsistent electrical and optical properties, resulting in variations in brightness, color accuracy, and response time across different pixels. This non-uniformity can lead to visible artifacts and reduced display quality, especially in large-format applications.

The manufacturing process for hybrid AMOLED materials presents its own set of challenges. Precise deposition and patterning of both organic and inorganic layers require sophisticated equipment and tight process control. The need for high-temperature processing of inorganic components can potentially damage the more sensitive organic materials, necessitating careful thermal management during production.

Cost-effectiveness remains a significant hurdle for widespread adoption of hybrid AMOLED technology. The complex manufacturing processes and specialized materials contribute to higher production costs compared to conventional display technologies. Balancing performance improvements with economic viability is crucial for market acceptance and commercial success.

Energy efficiency is another area of concern for hybrid AMOLED materials. While AMOLEDs are generally known for their power-saving capabilities, the addition of inorganic components can potentially increase power consumption. Optimizing the energy efficiency of hybrid systems without compromising display quality is an ongoing challenge for researchers and engineers.

Lastly, the development of hybrid AMOLED materials faces challenges in terms of scalability and yield. As display sizes increase and resolution demands grow, maintaining consistent performance and minimizing defects across larger areas becomes increasingly difficult. Improving manufacturing yield and reducing production variability are essential for the commercial viability of hybrid AMOLED technology.

Existing Hybrid AMOLED Material Solutions

01 Hybrid AMOLED display structures

Hybrid AMOLED displays combine organic and inorganic materials to improve performance. These structures often incorporate both OLED and LCD technologies, utilizing the benefits of each to enhance overall display quality, efficiency, and lifespan.- Hybrid AMOLED display structures: Hybrid AMOLED displays combine organic and inorganic materials to improve performance and efficiency. These structures often incorporate both OLED and LCD technologies, utilizing the benefits of each to create advanced display solutions. The hybrid approach can enhance brightness, color accuracy, and power efficiency compared to traditional OLED or LCD displays alone.

- Novel electrode materials for AMOLED displays: Advanced electrode materials are crucial for improving AMOLED display performance. These materials may include transparent conductive oxides, metal nanowires, or composite structures that offer better conductivity, transparency, and flexibility. Novel electrode designs can enhance current distribution, reduce power consumption, and improve overall display efficiency.

- Emissive layer materials for hybrid AMOLED displays: Innovative emissive layer materials are developed to enhance the performance of hybrid AMOLED displays. These materials may include new organic compounds, quantum dots, or hybrid organic-inorganic structures. The goal is to improve color gamut, efficiency, and lifetime of the display while maintaining compatibility with the hybrid structure.

- Backplane technologies for hybrid AMOLED displays: Advanced backplane technologies are essential for driving hybrid AMOLED displays. These may include low-temperature polysilicon (LTPS), oxide thin-film transistors (TFTs), or other novel semiconductor materials. The backplane design focuses on improving electron mobility, reducing power consumption, and enhancing overall display performance.

- Encapsulation and protection materials for hybrid AMOLED displays: Specialized encapsulation and protection materials are crucial for ensuring the longevity and reliability of hybrid AMOLED displays. These materials may include advanced barrier films, getter materials, or hybrid organic-inorganic encapsulation layers. The goal is to protect the sensitive organic components from moisture and oxygen while maintaining flexibility and optical transparency.

02 Novel electrode materials for AMOLED displays

Advanced electrode materials are crucial for hybrid AMOLED displays. These may include transparent conductive oxides, metal nanowires, or composite structures that offer improved conductivity, transparency, and flexibility compared to traditional electrode materials.Expand Specific Solutions03 Emissive layer materials for hybrid displays

Innovative emissive layer materials are developed for hybrid AMOLED displays, combining organic and inorganic components. These materials aim to enhance color gamut, efficiency, and stability of the display, often incorporating quantum dots or other nanostructures.Expand Specific Solutions04 Backplane technologies for hybrid AMOLED

Advanced backplane technologies are essential for hybrid AMOLED displays. These may include low-temperature polysilicon (LTPS), oxide thin-film transistors (TFTs), or other novel semiconductor materials that offer improved electron mobility and stability.Expand Specific Solutions05 Encapsulation and barrier materials

Specialized encapsulation and barrier materials are crucial for protecting hybrid AMOLED displays from moisture and oxygen. These may include multi-layer thin film encapsulation, hybrid organic-inorganic materials, or advanced glass substrates with enhanced barrier properties.Expand Specific Solutions

Key Players in Hybrid AMOLED Material Industry

The hybrid AMOLED display materials market is in a growth phase, driven by increasing demand for high-quality displays in smartphones, TVs, and other electronic devices. The global market size is expanding rapidly, with major players like Samsung Electronics, LG Display, and BOE Technology Group leading the way. Technological maturity varies, with established companies like Universal Display Corp. and E Ink Corp. pushing innovation in OLED and e-paper technologies. Emerging players such as Guangzhou ChinaRay Optoelectronic Materials and Akron Polymer Systems are developing novel materials to enhance display performance. The competitive landscape is intensifying as more companies invest in R&D to capture market share in this promising sector.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology Group has been actively researching hybrid AMOLED materials to improve display performance and reduce production costs. Their approach includes the development of hybrid electron transport layers (ETLs) that combine solution-processed organic materials with vacuum-deposited inorganic compounds. This hybrid ETL structure has shown improved electron injection and transport properties, leading to lower driving voltages and increased device efficiency[10]. BOE has also explored hybrid emitter systems that utilize thermally activated delayed fluorescence (TADF) materials in combination with phosphorescent dopants, aiming to achieve 100% internal quantum efficiency while reducing reliance on expensive rare metal complexes[11]. Furthermore, the company has developed hybrid light outcoupling structures that incorporate both internal and external extraction layers to boost overall luminous efficacy[12].

Strengths: Cost-effective hybrid materials, improved device efficiency, and potential for simplified manufacturing processes. Weaknesses: Relatively new technology with less field-proven reliability compared to established OLED materials.

Universal Display Corp.

Technical Solution: Universal Display Corporation (UDC) is at the forefront of hybrid AMOLED display material development. Their phosphorescent OLED (PHOLED) technology combines organic and inorganic materials to enhance display performance. UDC's latest hybrid emitters incorporate platinum-based complexes into organic host materials, resulting in improved efficiency and color purity[1]. The company has also developed novel hybrid transport layers, utilizing metal oxide nanoparticles dispersed in organic matrices to enhance charge mobility and device stability[2]. UDC's hybrid approach extends to their barrier films, where they combine inorganic layers with flexible organic interlayers to achieve superior moisture protection for OLED devices[3].

Strengths: Industry-leading PHOLED technology, high efficiency, and extended device lifetimes. Weaknesses: Higher production costs compared to traditional OLED materials, potential supply chain dependencies for rare metal complexes.

Core Innovations in Hybrid AMOLED Materials

Organic light emitting diode display with color-correction component

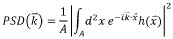

PatentWO2020212777A1

Innovation

- Incorporating a hybrid color correction component with a nanostructured interface and an angular transformation layer between the OLED stack and the nanostructured interface, which redirects light to improve color uniformity and brightness across different viewing angles.

Unit pixels and active matrix organic light emitting diode displays including the same

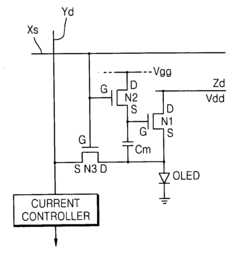

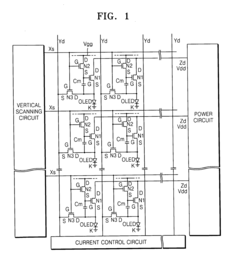

PatentInactiveUS20090201278A1

Innovation

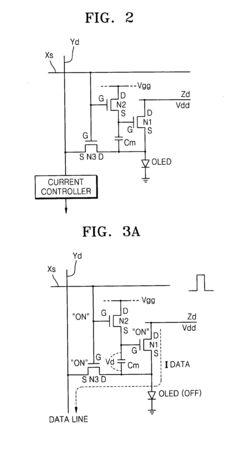

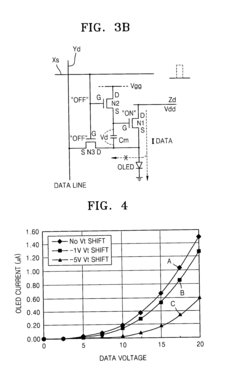

- The implementation of a current-programmable AMOLED display design using a simpler structure with fewer transistors, including a driving transistor, a programming transistor, and a switching transistor, where a memory capacitor is connected in parallel between the gate and one terminal of the driving transistor, and a current controller determines the current flowing through the transistors to maintain uniform brightness despite threshold voltage shifts.

Environmental Impact of Hybrid AMOLED Materials

The environmental impact of hybrid AMOLED materials is a critical consideration in the development and adoption of this display technology. These materials, which combine organic and inorganic components, offer potential benefits in terms of energy efficiency and display performance. However, their production, use, and disposal also present unique environmental challenges that must be carefully evaluated.

The manufacturing process of hybrid AMOLED materials involves the use of various chemicals and rare earth elements, which can have significant environmental implications. The extraction and processing of these raw materials often require intensive energy consumption and may lead to habitat disruption and pollution if not properly managed. Additionally, the production of hybrid AMOLED displays typically involves complex fabrication techniques that may generate hazardous waste and emissions.

During the use phase, hybrid AMOLED displays generally demonstrate improved energy efficiency compared to traditional display technologies. This can lead to reduced power consumption in devices, potentially lowering overall energy demand and associated carbon emissions. However, the longevity and repairability of these displays are important factors to consider, as shorter lifespans or difficulty in repair could lead to increased electronic waste.

End-of-life management for hybrid AMOLED displays presents both challenges and opportunities. The complex composition of these materials makes recycling more difficult than for conventional displays. Proper recycling techniques need to be developed to recover valuable materials and prevent the release of harmful substances into the environment. However, if effective recycling methods are implemented, there is potential for significant resource recovery and reduced environmental impact.

The use of organic materials in hybrid AMOLEDs raises concerns about biodegradability and potential ecological effects if not properly disposed of. While these materials may offer some advantages in terms of natural decomposition compared to fully inorganic displays, their impact on ecosystems and potential for bioaccumulation need to be thoroughly studied.

As the technology evolves, there is a growing focus on developing more environmentally friendly hybrid AMOLED materials. Research is being conducted to find alternatives to rare earth elements and toxic compounds, as well as to improve manufacturing processes to reduce waste and energy consumption. Additionally, efforts are being made to enhance the recyclability and overall lifecycle sustainability of hybrid AMOLED displays.

The manufacturing process of hybrid AMOLED materials involves the use of various chemicals and rare earth elements, which can have significant environmental implications. The extraction and processing of these raw materials often require intensive energy consumption and may lead to habitat disruption and pollution if not properly managed. Additionally, the production of hybrid AMOLED displays typically involves complex fabrication techniques that may generate hazardous waste and emissions.

During the use phase, hybrid AMOLED displays generally demonstrate improved energy efficiency compared to traditional display technologies. This can lead to reduced power consumption in devices, potentially lowering overall energy demand and associated carbon emissions. However, the longevity and repairability of these displays are important factors to consider, as shorter lifespans or difficulty in repair could lead to increased electronic waste.

End-of-life management for hybrid AMOLED displays presents both challenges and opportunities. The complex composition of these materials makes recycling more difficult than for conventional displays. Proper recycling techniques need to be developed to recover valuable materials and prevent the release of harmful substances into the environment. However, if effective recycling methods are implemented, there is potential for significant resource recovery and reduced environmental impact.

The use of organic materials in hybrid AMOLEDs raises concerns about biodegradability and potential ecological effects if not properly disposed of. While these materials may offer some advantages in terms of natural decomposition compared to fully inorganic displays, their impact on ecosystems and potential for bioaccumulation need to be thoroughly studied.

As the technology evolves, there is a growing focus on developing more environmentally friendly hybrid AMOLED materials. Research is being conducted to find alternatives to rare earth elements and toxic compounds, as well as to improve manufacturing processes to reduce waste and energy consumption. Additionally, efforts are being made to enhance the recyclability and overall lifecycle sustainability of hybrid AMOLED displays.

Intellectual Property Landscape in AMOLED Technology

The intellectual property landscape in AMOLED technology is characterized by a complex web of patents and proprietary technologies held by major industry players. Key patent holders include Samsung Display, LG Display, and BOE Technology, who have invested heavily in research and development to secure their positions in the market. These companies have filed numerous patents covering various aspects of AMOLED technology, from pixel structures and driving methods to manufacturing processes and materials.

Samsung Display, as the market leader, holds a significant portion of AMOLED-related patents, particularly in areas such as pixel circuit designs, thin-film transistor (TFT) backplanes, and organic light-emitting materials. Their patent portfolio extends to flexible and foldable display technologies, which are becoming increasingly important in the mobile device market.

LG Display, another major player, has focused its patent efforts on large-scale OLED panels for televisions and innovative form factors like rollable displays. Their intellectual property covers areas such as panel design, manufacturing techniques, and color management systems.

Chinese companies, led by BOE Technology, have been rapidly expanding their patent portfolios in recent years. BOE's patents often focus on cost-effective manufacturing processes and improvements in display quality, aiming to challenge the dominance of Korean manufacturers.

The hybrid AMOLED display materials sector has seen a surge in patent activity, with companies exploring novel combinations of organic and inorganic materials to enhance display performance. Patents in this area often cover new emitter materials, electron transport layers, and hole injection layers that aim to improve efficiency, color gamut, and longevity of AMOLED displays.

Universities and research institutions also contribute significantly to the AMOLED patent landscape, often focusing on fundamental research into new materials and device architectures. Collaborations between academic institutions and industry leaders have resulted in numerous joint patents, bridging the gap between theoretical advancements and practical applications.

The global nature of the AMOLED market has led to a complex international patent landscape, with companies filing for protection in multiple jurisdictions. This has resulted in occasional patent disputes and cross-licensing agreements between major players, shaping the competitive dynamics of the industry.

As the technology continues to evolve, new patent trends are emerging in areas such as quantum dot-enhanced AMOLED displays, micro-LED integration, and advanced touch sensor technologies. These developments indicate the ongoing innovation in the field and the potential for further disruption in the display technology market.

Samsung Display, as the market leader, holds a significant portion of AMOLED-related patents, particularly in areas such as pixel circuit designs, thin-film transistor (TFT) backplanes, and organic light-emitting materials. Their patent portfolio extends to flexible and foldable display technologies, which are becoming increasingly important in the mobile device market.

LG Display, another major player, has focused its patent efforts on large-scale OLED panels for televisions and innovative form factors like rollable displays. Their intellectual property covers areas such as panel design, manufacturing techniques, and color management systems.

Chinese companies, led by BOE Technology, have been rapidly expanding their patent portfolios in recent years. BOE's patents often focus on cost-effective manufacturing processes and improvements in display quality, aiming to challenge the dominance of Korean manufacturers.

The hybrid AMOLED display materials sector has seen a surge in patent activity, with companies exploring novel combinations of organic and inorganic materials to enhance display performance. Patents in this area often cover new emitter materials, electron transport layers, and hole injection layers that aim to improve efficiency, color gamut, and longevity of AMOLED displays.

Universities and research institutions also contribute significantly to the AMOLED patent landscape, often focusing on fundamental research into new materials and device architectures. Collaborations between academic institutions and industry leaders have resulted in numerous joint patents, bridging the gap between theoretical advancements and practical applications.

The global nature of the AMOLED market has led to a complex international patent landscape, with companies filing for protection in multiple jurisdictions. This has resulted in occasional patent disputes and cross-licensing agreements between major players, shaping the competitive dynamics of the industry.

As the technology continues to evolve, new patent trends are emerging in areas such as quantum dot-enhanced AMOLED displays, micro-LED integration, and advanced touch sensor technologies. These developments indicate the ongoing innovation in the field and the potential for further disruption in the display technology market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!