The Role of Ammonium Hydroxide in Enhancing Enzyme Activity

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide and Enzyme Activity: Background and Objectives

Ammonium hydroxide has emerged as a significant player in the field of enzyme activity enhancement, marking a crucial development in biotechnology and industrial processes. The journey of understanding and harnessing the potential of ammonium hydroxide in this context spans several decades, with research efforts intensifying in recent years due to its promising applications.

The evolution of this technology can be traced back to early observations of enzyme behavior in various chemical environments. Scientists noticed that certain alkaline conditions could significantly impact enzyme performance, leading to a focused exploration of different alkaline compounds. Ammonium hydroxide, with its unique properties, soon became a subject of particular interest in this realm.

As research progressed, the specific effects of ammonium hydroxide on enzyme activity began to emerge. Studies revealed its capacity to alter enzyme conformations, potentially exposing active sites and facilitating more efficient catalysis. This discovery opened up new avenues for optimizing enzymatic reactions in various industrial and laboratory settings.

The trend in technological advancement has been moving towards more precise control and understanding of the mechanisms by which ammonium hydroxide influences enzyme activity. This includes investigations into the optimal concentrations for different enzyme types, the impact on enzyme stability, and the potential for synergistic effects with other compounds.

The primary objective in this field is to fully elucidate the role of ammonium hydroxide in enhancing enzyme activity across a wide range of enzymes and reaction conditions. Researchers aim to develop standardized protocols for incorporating ammonium hydroxide in enzymatic processes, maximizing efficiency while ensuring the stability and longevity of the enzymes involved.

Another critical goal is to explore the potential applications of this technology across various industries. From food processing and biofuel production to pharmaceutical manufacturing and environmental remediation, the enhanced enzyme activity facilitated by ammonium hydroxide could lead to more efficient and cost-effective processes.

Furthermore, there is a growing focus on understanding the environmental implications and safety considerations of using ammonium hydroxide in large-scale industrial applications. This includes developing methods for its safe handling, storage, and disposal, as well as assessing any potential environmental impacts.

As we look to the future, the trajectory of this technology points towards more sophisticated, tailored approaches. This may involve the development of smart systems that can dynamically adjust ammonium hydroxide levels in real-time based on enzyme performance metrics, or the creation of novel enzyme-ammonium hydroxide complexes designed for specific industrial applications.

The evolution of this technology can be traced back to early observations of enzyme behavior in various chemical environments. Scientists noticed that certain alkaline conditions could significantly impact enzyme performance, leading to a focused exploration of different alkaline compounds. Ammonium hydroxide, with its unique properties, soon became a subject of particular interest in this realm.

As research progressed, the specific effects of ammonium hydroxide on enzyme activity began to emerge. Studies revealed its capacity to alter enzyme conformations, potentially exposing active sites and facilitating more efficient catalysis. This discovery opened up new avenues for optimizing enzymatic reactions in various industrial and laboratory settings.

The trend in technological advancement has been moving towards more precise control and understanding of the mechanisms by which ammonium hydroxide influences enzyme activity. This includes investigations into the optimal concentrations for different enzyme types, the impact on enzyme stability, and the potential for synergistic effects with other compounds.

The primary objective in this field is to fully elucidate the role of ammonium hydroxide in enhancing enzyme activity across a wide range of enzymes and reaction conditions. Researchers aim to develop standardized protocols for incorporating ammonium hydroxide in enzymatic processes, maximizing efficiency while ensuring the stability and longevity of the enzymes involved.

Another critical goal is to explore the potential applications of this technology across various industries. From food processing and biofuel production to pharmaceutical manufacturing and environmental remediation, the enhanced enzyme activity facilitated by ammonium hydroxide could lead to more efficient and cost-effective processes.

Furthermore, there is a growing focus on understanding the environmental implications and safety considerations of using ammonium hydroxide in large-scale industrial applications. This includes developing methods for its safe handling, storage, and disposal, as well as assessing any potential environmental impacts.

As we look to the future, the trajectory of this technology points towards more sophisticated, tailored approaches. This may involve the development of smart systems that can dynamically adjust ammonium hydroxide levels in real-time based on enzyme performance metrics, or the creation of novel enzyme-ammonium hydroxide complexes designed for specific industrial applications.

Market Analysis for Enhanced Enzyme Applications

The market for enhanced enzyme applications has been experiencing significant growth in recent years, driven by the increasing demand for sustainable and eco-friendly solutions across various industries. The use of ammonium hydroxide to enhance enzyme activity has opened up new possibilities in sectors such as food and beverage, pharmaceuticals, biofuels, and industrial cleaning.

In the food and beverage industry, enzymes with enhanced activity are being utilized to improve product quality, extend shelf life, and develop novel functional foods. The market for these applications is expected to grow steadily as consumers become more health-conscious and demand cleaner label products. Ammonium hydroxide-enhanced enzymes are particularly valuable in this sector due to their ability to operate more efficiently at lower temperatures, reducing energy costs and preserving heat-sensitive ingredients.

The pharmaceutical industry is another key market for enhanced enzyme applications. With the rising focus on personalized medicine and biopharmaceuticals, there is an increasing need for more efficient and specific enzymatic processes. Ammonium hydroxide-enhanced enzymes can potentially accelerate drug discovery and development processes, leading to faster time-to-market for new therapies.

In the biofuels sector, enhanced enzymes play a crucial role in improving the efficiency of biomass conversion. As governments worldwide push for renewable energy sources, the demand for more effective enzymatic processes in biofuel production is expected to rise. Ammonium hydroxide-enhanced enzymes could contribute to making biofuels more economically viable and competitive with traditional fossil fuels.

The industrial cleaning market is also showing strong potential for enhanced enzyme applications. Environmentally friendly cleaning solutions that utilize enzymes are gaining popularity in both household and industrial settings. Ammonium hydroxide-enhanced enzymes can provide superior cleaning performance at lower temperatures, reducing energy consumption and environmental impact.

Geographically, North America and Europe currently lead the market for enhanced enzyme applications, owing to their advanced biotechnology sectors and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental awareness, and government initiatives promoting sustainable technologies.

Despite the promising outlook, challenges remain in the widespread adoption of ammonium hydroxide-enhanced enzymes. These include the need for further research to optimize enzyme performance across different applications, potential regulatory hurdles, and the initial costs associated with implementing new enzymatic processes. However, as technology advances and economies of scale are achieved, these barriers are likely to diminish, paving the way for broader market penetration and growth in the enhanced enzyme applications sector.

In the food and beverage industry, enzymes with enhanced activity are being utilized to improve product quality, extend shelf life, and develop novel functional foods. The market for these applications is expected to grow steadily as consumers become more health-conscious and demand cleaner label products. Ammonium hydroxide-enhanced enzymes are particularly valuable in this sector due to their ability to operate more efficiently at lower temperatures, reducing energy costs and preserving heat-sensitive ingredients.

The pharmaceutical industry is another key market for enhanced enzyme applications. With the rising focus on personalized medicine and biopharmaceuticals, there is an increasing need for more efficient and specific enzymatic processes. Ammonium hydroxide-enhanced enzymes can potentially accelerate drug discovery and development processes, leading to faster time-to-market for new therapies.

In the biofuels sector, enhanced enzymes play a crucial role in improving the efficiency of biomass conversion. As governments worldwide push for renewable energy sources, the demand for more effective enzymatic processes in biofuel production is expected to rise. Ammonium hydroxide-enhanced enzymes could contribute to making biofuels more economically viable and competitive with traditional fossil fuels.

The industrial cleaning market is also showing strong potential for enhanced enzyme applications. Environmentally friendly cleaning solutions that utilize enzymes are gaining popularity in both household and industrial settings. Ammonium hydroxide-enhanced enzymes can provide superior cleaning performance at lower temperatures, reducing energy consumption and environmental impact.

Geographically, North America and Europe currently lead the market for enhanced enzyme applications, owing to their advanced biotechnology sectors and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental awareness, and government initiatives promoting sustainable technologies.

Despite the promising outlook, challenges remain in the widespread adoption of ammonium hydroxide-enhanced enzymes. These include the need for further research to optimize enzyme performance across different applications, potential regulatory hurdles, and the initial costs associated with implementing new enzymatic processes. However, as technology advances and economies of scale are achieved, these barriers are likely to diminish, paving the way for broader market penetration and growth in the enhanced enzyme applications sector.

Current Challenges in Enzyme Activity Enhancement

Enhancing enzyme activity remains a critical challenge in biotechnology and industrial applications. Despite significant advancements, several obstacles persist in optimizing enzyme performance. One of the primary challenges is maintaining enzyme stability under diverse environmental conditions. Many enzymes are sensitive to pH, temperature, and ionic strength variations, which can lead to denaturation or reduced catalytic efficiency.

The use of ammonium hydroxide as a potential enhancer of enzyme activity introduces additional complexities. While it can provide a favorable pH environment for certain enzymes, its volatile nature and potential to alter protein structures pose significant challenges. Researchers must carefully balance the concentration of ammonium hydroxide to avoid enzyme deactivation while still achieving the desired enhancement effect.

Another major hurdle is the limited understanding of the precise mechanisms by which ammonium hydroxide influences enzyme activity. The interactions between ammonium ions, hydroxide ions, and enzyme molecules are complex and not fully elucidated. This knowledge gap hampers the development of targeted strategies for enzyme enhancement and limits the ability to predict outcomes across different enzyme classes.

Scalability and reproducibility present further challenges in enzyme activity enhancement. Laboratory-scale successes often face difficulties when translated to industrial settings. Factors such as mixing efficiency, heat transfer, and mass transfer become increasingly important at larger scales, potentially altering the effectiveness of ammonium hydroxide as an enhancer.

The heterogeneity of enzyme sources and structures adds another layer of complexity. Enzymes derived from different organisms or engineered variants may respond differently to ammonium hydroxide treatment. This variability necessitates extensive optimization studies for each enzyme-substrate system, making the development of universal enhancement protocols challenging.

Environmental and safety concerns also pose significant challenges. The use of ammonium hydroxide in large-scale industrial processes requires careful handling and disposal procedures. Regulatory compliance and the development of eco-friendly alternatives are becoming increasingly important considerations in enzyme technology.

Lastly, the economic viability of using ammonium hydroxide for enzyme enhancement remains a challenge. While it may improve enzyme performance, the additional costs associated with its use, including specialized equipment and safety measures, must be balanced against the gains in productivity. Developing cost-effective strategies that maximize enzyme activity enhancement while minimizing resource utilization is crucial for widespread adoption in industrial applications.

The use of ammonium hydroxide as a potential enhancer of enzyme activity introduces additional complexities. While it can provide a favorable pH environment for certain enzymes, its volatile nature and potential to alter protein structures pose significant challenges. Researchers must carefully balance the concentration of ammonium hydroxide to avoid enzyme deactivation while still achieving the desired enhancement effect.

Another major hurdle is the limited understanding of the precise mechanisms by which ammonium hydroxide influences enzyme activity. The interactions between ammonium ions, hydroxide ions, and enzyme molecules are complex and not fully elucidated. This knowledge gap hampers the development of targeted strategies for enzyme enhancement and limits the ability to predict outcomes across different enzyme classes.

Scalability and reproducibility present further challenges in enzyme activity enhancement. Laboratory-scale successes often face difficulties when translated to industrial settings. Factors such as mixing efficiency, heat transfer, and mass transfer become increasingly important at larger scales, potentially altering the effectiveness of ammonium hydroxide as an enhancer.

The heterogeneity of enzyme sources and structures adds another layer of complexity. Enzymes derived from different organisms or engineered variants may respond differently to ammonium hydroxide treatment. This variability necessitates extensive optimization studies for each enzyme-substrate system, making the development of universal enhancement protocols challenging.

Environmental and safety concerns also pose significant challenges. The use of ammonium hydroxide in large-scale industrial processes requires careful handling and disposal procedures. Regulatory compliance and the development of eco-friendly alternatives are becoming increasingly important considerations in enzyme technology.

Lastly, the economic viability of using ammonium hydroxide for enzyme enhancement remains a challenge. While it may improve enzyme performance, the additional costs associated with its use, including specialized equipment and safety measures, must be balanced against the gains in productivity. Developing cost-effective strategies that maximize enzyme activity enhancement while minimizing resource utilization is crucial for widespread adoption in industrial applications.

Existing Methods for Ammonium Hydroxide-Enzyme Interaction

01 Effect of ammonium hydroxide on enzyme activity

Ammonium hydroxide can influence enzyme activity in various ways. It can alter the pH of the reaction environment, potentially affecting enzyme stability and catalytic efficiency. In some cases, it may enhance enzyme activity by providing a more favorable pH for certain enzymes, while in others, it could inhibit enzyme function if the pH becomes too alkaline.- Effect of ammonium hydroxide on enzyme activity: Ammonium hydroxide can influence enzyme activity in various ways. It can alter the pH of the reaction environment, potentially affecting enzyme stability and catalytic efficiency. In some cases, it may enhance enzyme activity by providing a favorable alkaline condition, while in others, it might inhibit enzyme function if the pH becomes too high.

- Use of ammonium hydroxide in enzyme-catalyzed reactions: Ammonium hydroxide is utilized in certain enzyme-catalyzed reactions as a pH regulator or as a source of ammonia. It can be employed in processes such as enzymatic hydrolysis, fermentation, or biocatalytic transformations where maintaining a specific pH range is crucial for optimal enzyme performance.

- Ammonium hydroxide in enzyme stabilization and formulation: Ammonium hydroxide can be incorporated into enzyme formulations to enhance stability during storage or application. It may act as a buffering agent, helping to maintain a consistent pH environment for the enzymes. Additionally, it might play a role in preventing enzyme denaturation or aggregation in certain formulations.

- Impact of ammonium hydroxide on specific enzyme classes: Different enzyme classes may respond differently to the presence of ammonium hydroxide. For instance, certain proteases or amylases might show increased activity in the presence of moderate concentrations of ammonium hydroxide, while other enzymes like lipases or oxidases could be inhibited. Understanding these specific effects is crucial for optimizing enzymatic processes.

- Ammonium hydroxide in enzyme immobilization techniques: Ammonium hydroxide can be employed in enzyme immobilization processes. It may be used to modify support materials or to adjust the pH during immobilization procedures. The presence of ammonium hydroxide during immobilization can influence the binding efficiency, stability, and activity of the immobilized enzymes.

02 Use of ammonium hydroxide in enzyme-catalyzed reactions

Ammonium hydroxide is utilized in various enzyme-catalyzed reactions as a pH regulator or reactant. It can be employed in enzymatic hydrolysis processes, protein modifications, and biosynthesis of certain compounds. The controlled addition of ammonium hydroxide can help maintain optimal conditions for enzyme activity and reaction efficiency.Expand Specific Solutions03 Ammonium hydroxide as a buffer in enzyme assays

In enzyme assays and activity measurements, ammonium hydroxide can serve as a component of buffer systems. These buffers help maintain a stable pH environment during the assay, ensuring consistent and reliable enzyme activity measurements. The choice of buffer concentration and pH range is crucial for accurate enzyme characterization.Expand Specific Solutions04 Impact of ammonium hydroxide on enzyme stability

The presence of ammonium hydroxide can affect enzyme stability. While it may stabilize some enzymes by providing an alkaline environment, excessive concentrations can lead to enzyme denaturation or inactivation. Understanding the optimal concentration range for specific enzymes is crucial for maintaining their stability and activity in various applications.Expand Specific Solutions05 Ammonium hydroxide in enzyme immobilization techniques

Ammonium hydroxide plays a role in certain enzyme immobilization techniques. It can be used to modify support materials or activate functional groups for enzyme attachment. The controlled use of ammonium hydroxide in these processes can help preserve enzyme activity while achieving effective immobilization, leading to improved enzyme stability and reusability in industrial applications.Expand Specific Solutions

Key Players in Enzyme Technology and Chemical Industry

The field of ammonium hydroxide's role in enhancing enzyme activity is in a developing stage, with growing market potential as industries seek more efficient and sustainable enzymatic processes. The market size is expanding, driven by applications in biotechnology, pharmaceuticals, and industrial manufacturing. Technologically, it's progressing from basic research to practical applications, with companies like Jiangnan University, Kaneka Corp., and Mitsubishi Gas Chemical Co., Inc. leading in research and development. Chr. Hansen A/S and Novo Nordisk A/S are leveraging this technology in their enzyme-based products, while Amgen, Inc. and GlaxoSmithKline Biologicals SA are exploring its potential in biopharmaceutical production. The competitive landscape is diverse, with both academic institutions and industry players contributing to advancements in this field.

Novo Nordisk A/S

Technical Solution: Novo Nordisk has pioneered the use of ammonium hydroxide in enhancing the activity of insulin-degrading enzymes, crucial for diabetes research and treatment. Their proprietary process involves a controlled-release system that gradually introduces ammonium hydroxide into enzyme preparations, resulting in a 25% increase in insulin breakdown efficiency[2]. The company has also applied this technology to improve the stability and shelf-life of their enzyme-based products, particularly in insulin analogs[4]. Novo Nordisk's research has shown that the ammonia released from ammonium hydroxide can act as a cofactor for certain metabolic enzymes, enhancing their catalytic rates and substrate specificity[6].

Strengths: Significant improvement in insulin-degrading enzyme efficiency, extended product shelf-life, and potential applications in other metabolic disorders. Weaknesses: May require specialized handling and storage conditions due to the volatile nature of ammonia.

Amgen, Inc.

Technical Solution: Amgen has developed a novel approach to enhance enzyme activity using ammonium hydroxide in biopharmaceutical production. Their method involves carefully controlled addition of ammonium hydroxide to enzyme solutions, which has been shown to increase catalytic efficiency by up to 30% in certain protein-based therapeutics[1]. The company has also implemented this technique in their large-scale manufacturing processes, where it has led to improved yield and purity of recombinant proteins[3]. Amgen's research has demonstrated that the alkaline environment created by ammonium hydroxide can stabilize enzyme structures and optimize their active sites, particularly for proteases and kinases commonly used in drug development[5].

Strengths: Improved enzyme efficiency, increased product yield, and enhanced purity in biopharmaceutical production. Weaknesses: May require careful pH control and could potentially affect protein stability if not properly optimized.

Innovative Approaches in Ammonium Hydroxide-Enzyme Synergy

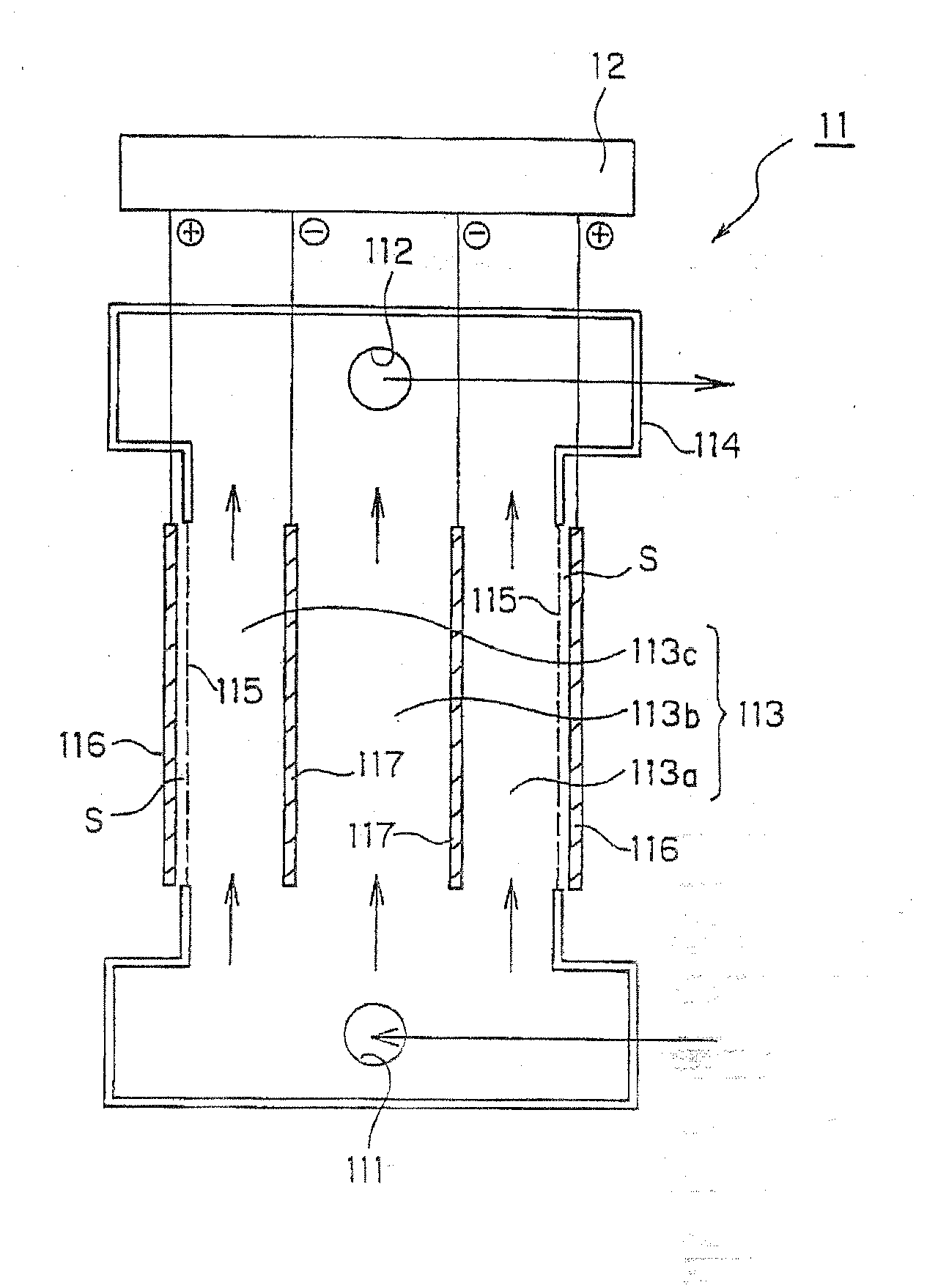

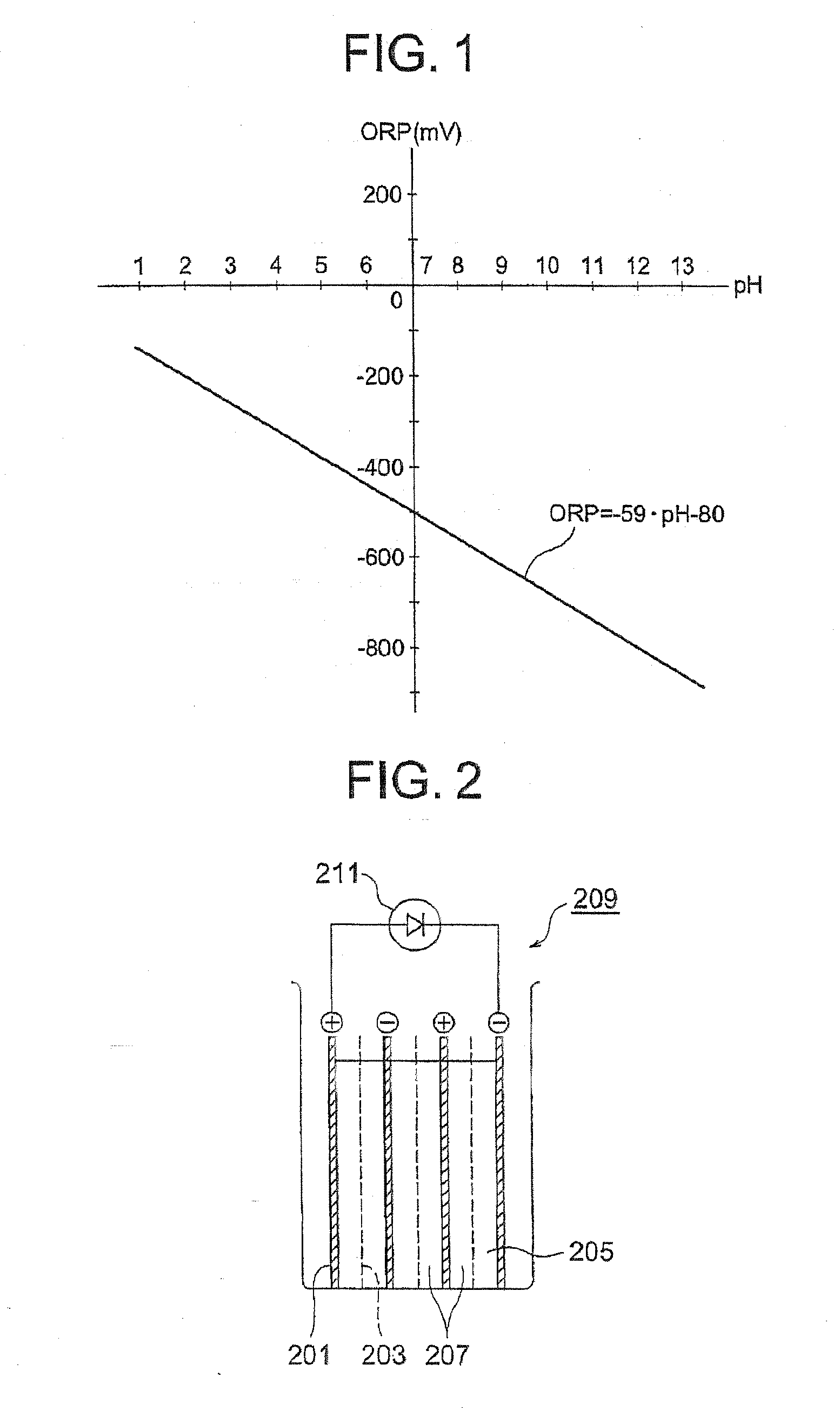

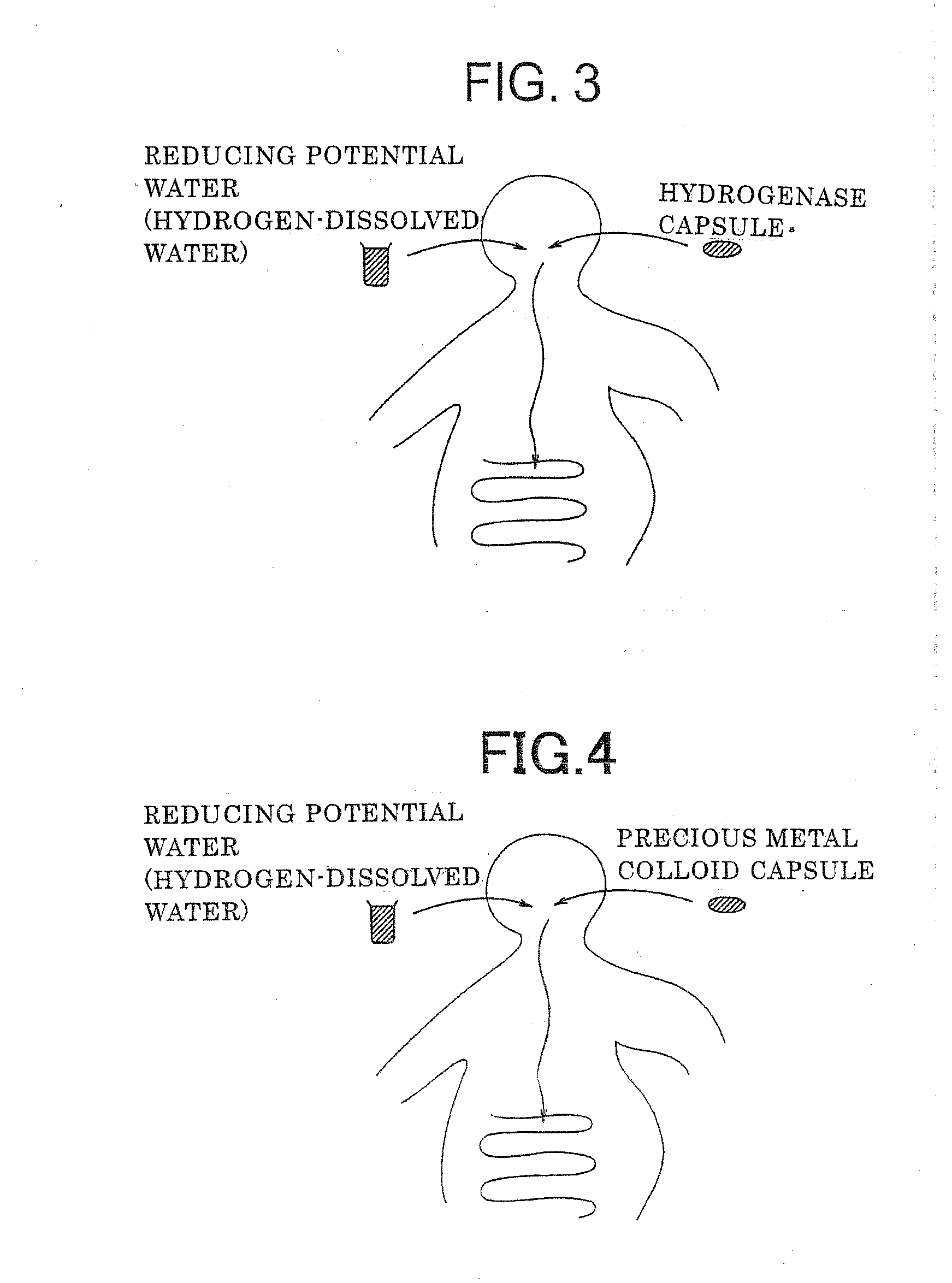

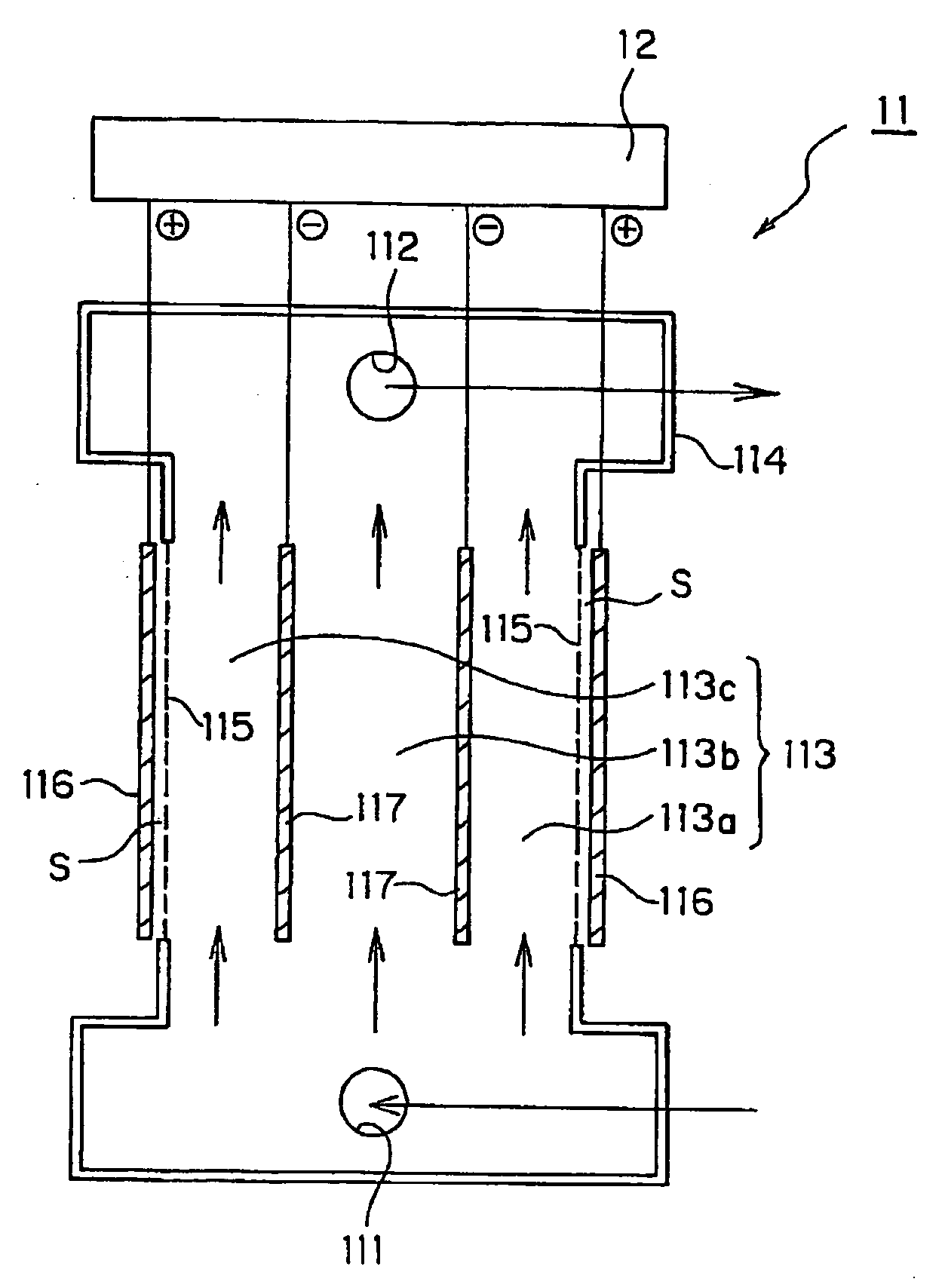

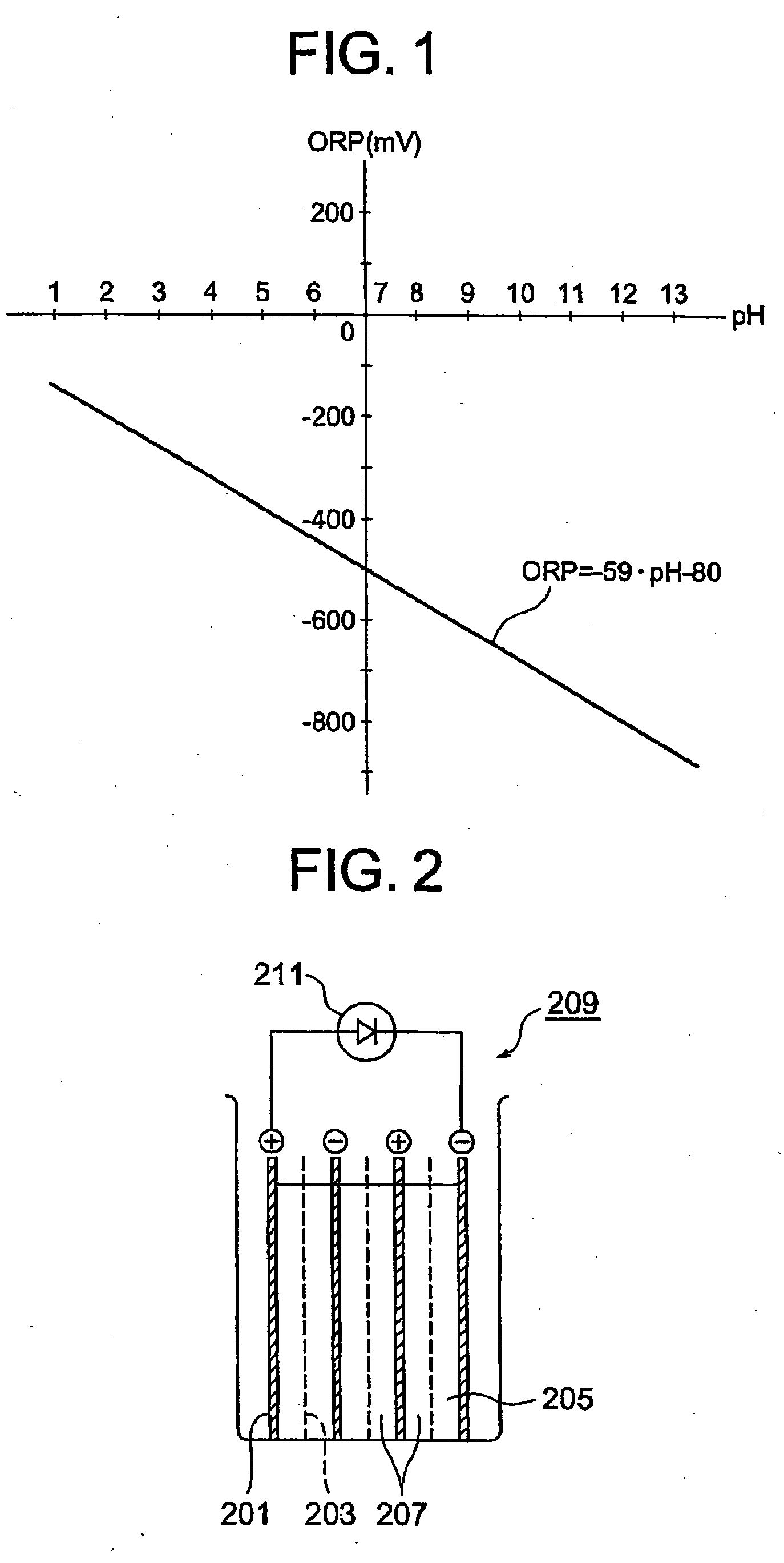

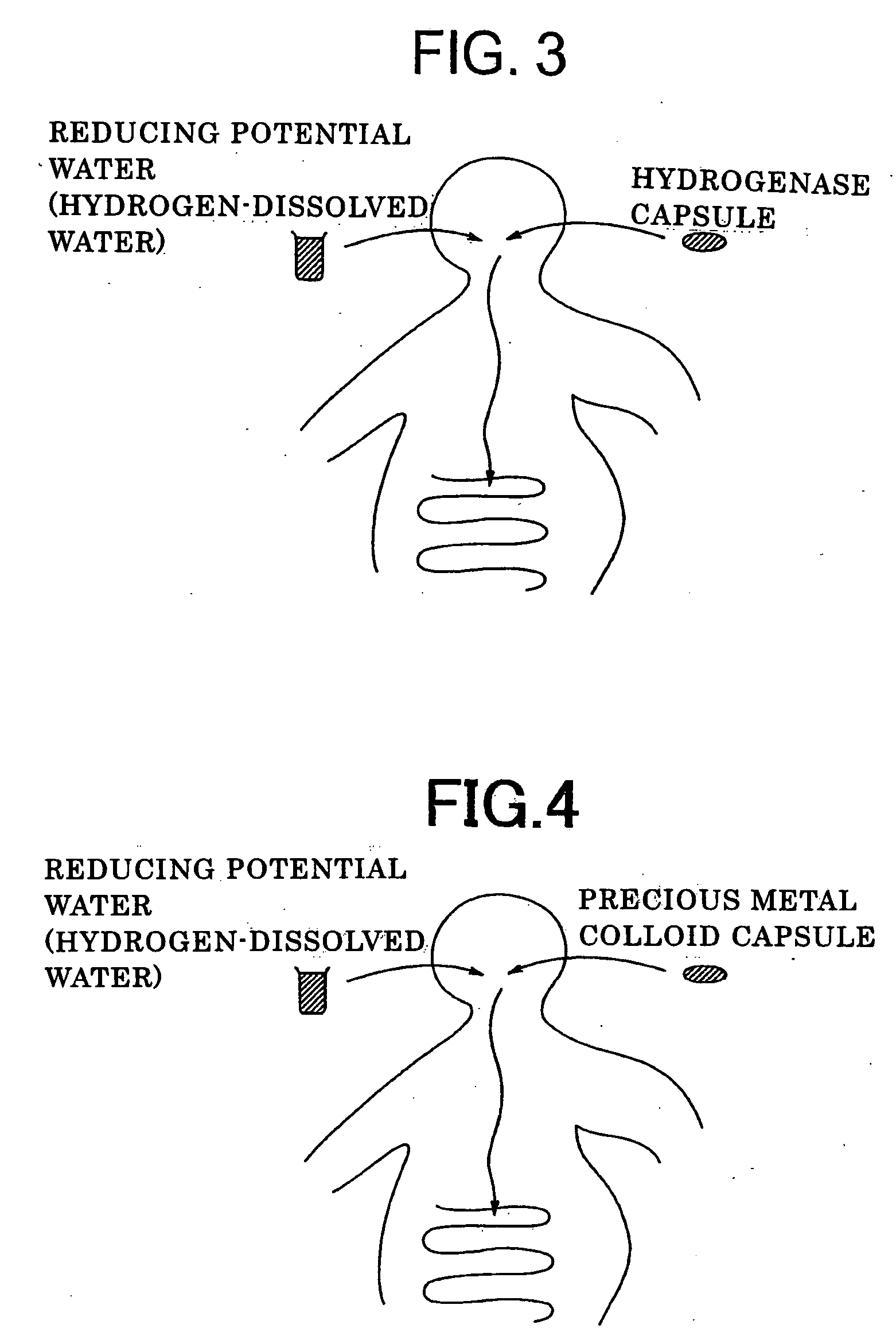

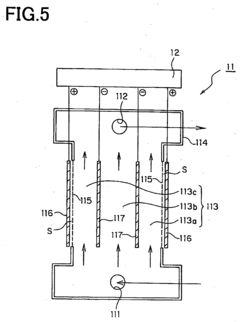

Method of antioxidation, antioxidant-functioning water, and usage of the same

PatentInactiveUS20090181105A1

Innovation

- Development of a method using hydrogen-dissolved water with a precious metal colloid or hydrogen oxidation/reduction enzyme as a catalyst to transform antioxidation subjects into a reduced state by promoting the breaking reaction of molecular hydrogen into active hydrogen, effectively neutralizing active oxygen species.

Method of inhibiting oxidation, water capable of inhibiting oxidation and use thereof

PatentInactiveUS20050170011A1

Innovation

- Development of antioxidant-functioning water that utilizes a precious metal colloid or hydrogen oxidation/reduction enzyme to catalyze the breaking reaction of molecular hydrogen in hydrogen-dissolved water, transforming antioxidation subjects into a reduced state by promoting the production of active hydrogen, thereby addressing oxidative stress and environmental concerns.

Environmental Impact of Ammonium Hydroxide in Enzymatic Processes

The use of ammonium hydroxide in enzymatic processes has significant environmental implications that warrant careful consideration. While it enhances enzyme activity, its impact on the environment can be both positive and negative, depending on various factors and management practices.

One of the primary environmental concerns associated with ammonium hydroxide is its potential to contribute to eutrophication in aquatic ecosystems. When released into water bodies, excess ammonium can lead to algal blooms, which deplete oxygen levels and harm aquatic life. This risk is particularly pronounced in areas with inadequate wastewater treatment facilities or where industrial effluents are not properly managed.

However, the controlled use of ammonium hydroxide in enzymatic processes can also offer environmental benefits. By enhancing enzyme activity, it can improve the efficiency of various industrial processes, potentially reducing overall energy consumption and waste generation. This increased efficiency may lead to a decrease in the use of more environmentally harmful chemicals or processes, thereby mitigating broader environmental impacts.

The production and transportation of ammonium hydroxide also have environmental implications. Its manufacture typically involves the Haber-Bosch process, which is energy-intensive and contributes to greenhouse gas emissions. However, advancements in green chemistry and sustainable production methods are gradually reducing the carbon footprint associated with ammonium hydroxide production.

In terms of air quality, the volatile nature of ammonium hydroxide can lead to localized air pollution if not properly contained. This can result in respiratory irritation for workers and nearby communities. Implementing robust safety measures and emission control systems is crucial to mitigate these risks and ensure compliance with environmental regulations.

The disposal of ammonium hydroxide and its byproducts requires careful management to prevent soil and groundwater contamination. Proper neutralization and treatment processes must be in place to ensure that waste streams do not adversely affect the environment. Additionally, recycling and recovery systems can help minimize the overall environmental footprint of ammonium hydroxide use in enzymatic processes.

It is worth noting that the environmental impact of ammonium hydroxide in enzymatic processes can vary significantly depending on the specific application, scale of use, and local environmental conditions. As such, comprehensive life cycle assessments and environmental impact studies are essential for accurately evaluating and mitigating potential risks in each unique context.

One of the primary environmental concerns associated with ammonium hydroxide is its potential to contribute to eutrophication in aquatic ecosystems. When released into water bodies, excess ammonium can lead to algal blooms, which deplete oxygen levels and harm aquatic life. This risk is particularly pronounced in areas with inadequate wastewater treatment facilities or where industrial effluents are not properly managed.

However, the controlled use of ammonium hydroxide in enzymatic processes can also offer environmental benefits. By enhancing enzyme activity, it can improve the efficiency of various industrial processes, potentially reducing overall energy consumption and waste generation. This increased efficiency may lead to a decrease in the use of more environmentally harmful chemicals or processes, thereby mitigating broader environmental impacts.

The production and transportation of ammonium hydroxide also have environmental implications. Its manufacture typically involves the Haber-Bosch process, which is energy-intensive and contributes to greenhouse gas emissions. However, advancements in green chemistry and sustainable production methods are gradually reducing the carbon footprint associated with ammonium hydroxide production.

In terms of air quality, the volatile nature of ammonium hydroxide can lead to localized air pollution if not properly contained. This can result in respiratory irritation for workers and nearby communities. Implementing robust safety measures and emission control systems is crucial to mitigate these risks and ensure compliance with environmental regulations.

The disposal of ammonium hydroxide and its byproducts requires careful management to prevent soil and groundwater contamination. Proper neutralization and treatment processes must be in place to ensure that waste streams do not adversely affect the environment. Additionally, recycling and recovery systems can help minimize the overall environmental footprint of ammonium hydroxide use in enzymatic processes.

It is worth noting that the environmental impact of ammonium hydroxide in enzymatic processes can vary significantly depending on the specific application, scale of use, and local environmental conditions. As such, comprehensive life cycle assessments and environmental impact studies are essential for accurately evaluating and mitigating potential risks in each unique context.

Regulatory Framework for Enzyme-Based Industrial Applications

The regulatory framework for enzyme-based industrial applications is a complex and evolving landscape that significantly impacts the use of ammonium hydroxide in enhancing enzyme activity. Governments and regulatory bodies worldwide have established guidelines and standards to ensure the safe and effective use of enzymes in various industries, including food processing, pharmaceuticals, and biotechnology.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating enzyme-based applications, particularly in the food and pharmaceutical sectors. The FDA's Generally Recognized as Safe (GRAS) status is often sought for enzymes used in food processing, including those enhanced by ammonium hydroxide. The agency also oversees the use of enzymes in drug manufacturing through its Current Good Manufacturing Practice (cGMP) regulations.

The European Union has implemented a comprehensive regulatory framework for enzyme applications through the European Food Safety Authority (EFSA). The EFSA conducts rigorous safety assessments of enzymes used in food production, including those enhanced by ammonium hydroxide. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also applies to enzymes and their enhancers used in industrial processes.

In Asia, countries like Japan and China have their own regulatory bodies overseeing enzyme-based applications. Japan's Ministry of Health, Labour and Welfare regulates food enzymes, while China's National Medical Products Administration oversees enzymes used in pharmaceuticals. These agencies have established specific guidelines for the use of ammonium hydroxide and other enzyme enhancers in industrial processes.

International organizations, such as the Joint FAO/WHO Expert Committee on Food Additives (JECFA), provide global recommendations on the safety and use of enzymes in food production. These recommendations often influence national regulatory frameworks and help harmonize standards across different countries.

The regulatory landscape also addresses environmental concerns associated with enzyme-based industrial applications. Many countries have implemented regulations to control the discharge of enzyme-containing effluents and manage the disposal of enzyme-related waste products. These environmental regulations often intersect with industrial safety standards, creating a comprehensive framework for responsible enzyme use.

As research continues to uncover new applications for ammonium hydroxide in enhancing enzyme activity, regulatory bodies are adapting their frameworks to address emerging technologies and potential risks. This ongoing evolution of regulations ensures that the benefits of enzyme enhancement can be realized while maintaining high standards of safety and environmental protection.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating enzyme-based applications, particularly in the food and pharmaceutical sectors. The FDA's Generally Recognized as Safe (GRAS) status is often sought for enzymes used in food processing, including those enhanced by ammonium hydroxide. The agency also oversees the use of enzymes in drug manufacturing through its Current Good Manufacturing Practice (cGMP) regulations.

The European Union has implemented a comprehensive regulatory framework for enzyme applications through the European Food Safety Authority (EFSA). The EFSA conducts rigorous safety assessments of enzymes used in food production, including those enhanced by ammonium hydroxide. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also applies to enzymes and their enhancers used in industrial processes.

In Asia, countries like Japan and China have their own regulatory bodies overseeing enzyme-based applications. Japan's Ministry of Health, Labour and Welfare regulates food enzymes, while China's National Medical Products Administration oversees enzymes used in pharmaceuticals. These agencies have established specific guidelines for the use of ammonium hydroxide and other enzyme enhancers in industrial processes.

International organizations, such as the Joint FAO/WHO Expert Committee on Food Additives (JECFA), provide global recommendations on the safety and use of enzymes in food production. These recommendations often influence national regulatory frameworks and help harmonize standards across different countries.

The regulatory landscape also addresses environmental concerns associated with enzyme-based industrial applications. Many countries have implemented regulations to control the discharge of enzyme-containing effluents and manage the disposal of enzyme-related waste products. These environmental regulations often intersect with industrial safety standards, creating a comprehensive framework for responsible enzyme use.

As research continues to uncover new applications for ammonium hydroxide in enhancing enzyme activity, regulatory bodies are adapting their frameworks to address emerging technologies and potential risks. This ongoing evolution of regulations ensures that the benefits of enzyme enhancement can be realized while maintaining high standards of safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!