The Role of Ammonium Hydroxide in Enhancing Ink Adhesion on Plastics

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonium Hydroxide in Ink Adhesion: Background and Objectives

The use of ammonium hydroxide in enhancing ink adhesion on plastics represents a significant advancement in printing technology, particularly for industries requiring durable and high-quality printed products on plastic surfaces. This technology has evolved over several decades, driven by the increasing demand for improved print quality and longevity on various plastic substrates.

Historically, printing on plastics has been challenging due to the inherent low surface energy of many polymeric materials, which results in poor ink wetting and adhesion. Traditional methods often involved surface treatments such as corona discharge or plasma treatment to increase surface energy. However, these methods can be costly, time-consuming, and may alter the physical properties of the plastic substrate.

The introduction of ammonium hydroxide as an adhesion promoter marks a pivotal point in addressing these challenges. Ammonium hydroxide, also known as aqueous ammonia, is a versatile compound that has found applications in various industries, from cleaning products to agricultural fertilizers. Its role in ink adhesion on plastics leverages its unique chemical properties to create a more receptive surface for ink bonding.

The primary objective of utilizing ammonium hydroxide in this context is to enhance the adhesion of ink to plastic surfaces without compromising the integrity of the substrate or the quality of the print. This technology aims to provide a cost-effective, efficient, and environmentally friendly alternative to traditional surface treatment methods.

Key goals of this technological approach include:

1. Improving ink adhesion strength and durability on a wide range of plastic materials.

2. Reducing production costs and processing time associated with surface preparation.

3. Minimizing the environmental impact of printing processes on plastic substrates.

4. Expanding the range of printable plastic materials without the need for specialized equipment.

5. Enhancing print quality and resolution on challenging plastic surfaces.

The development of this technology is driven by the growing demand in industries such as packaging, automotive, consumer electronics, and medical devices, where high-quality, durable printing on plastic components is essential. As sustainability becomes increasingly important, the use of ammonium hydroxide also aligns with efforts to reduce volatile organic compound (VOC) emissions in printing processes.

Understanding the role of ammonium hydroxide in ink adhesion involves exploring its chemical interactions with both the plastic substrate and the ink components. This includes investigating how ammonium hydroxide modifies surface properties, promotes chemical bonding, and influences the curing process of inks on plastic surfaces.

Historically, printing on plastics has been challenging due to the inherent low surface energy of many polymeric materials, which results in poor ink wetting and adhesion. Traditional methods often involved surface treatments such as corona discharge or plasma treatment to increase surface energy. However, these methods can be costly, time-consuming, and may alter the physical properties of the plastic substrate.

The introduction of ammonium hydroxide as an adhesion promoter marks a pivotal point in addressing these challenges. Ammonium hydroxide, also known as aqueous ammonia, is a versatile compound that has found applications in various industries, from cleaning products to agricultural fertilizers. Its role in ink adhesion on plastics leverages its unique chemical properties to create a more receptive surface for ink bonding.

The primary objective of utilizing ammonium hydroxide in this context is to enhance the adhesion of ink to plastic surfaces without compromising the integrity of the substrate or the quality of the print. This technology aims to provide a cost-effective, efficient, and environmentally friendly alternative to traditional surface treatment methods.

Key goals of this technological approach include:

1. Improving ink adhesion strength and durability on a wide range of plastic materials.

2. Reducing production costs and processing time associated with surface preparation.

3. Minimizing the environmental impact of printing processes on plastic substrates.

4. Expanding the range of printable plastic materials without the need for specialized equipment.

5. Enhancing print quality and resolution on challenging plastic surfaces.

The development of this technology is driven by the growing demand in industries such as packaging, automotive, consumer electronics, and medical devices, where high-quality, durable printing on plastic components is essential. As sustainability becomes increasingly important, the use of ammonium hydroxide also aligns with efforts to reduce volatile organic compound (VOC) emissions in printing processes.

Understanding the role of ammonium hydroxide in ink adhesion involves exploring its chemical interactions with both the plastic substrate and the ink components. This includes investigating how ammonium hydroxide modifies surface properties, promotes chemical bonding, and influences the curing process of inks on plastic surfaces.

Market Demand for Enhanced Ink Adhesion on Plastics

The demand for enhanced ink adhesion on plastics has been steadily growing across various industries, driven by the increasing use of plastic materials in packaging, automotive, consumer electronics, and medical devices. This market trend is fueled by the need for durable, high-quality printing on plastic surfaces that can withstand environmental factors and maintain legibility over extended periods.

In the packaging industry, there is a significant push for improved ink adhesion on plastic containers and films. This is particularly crucial for food and beverage packaging, where regulations require clear and lasting product information. The demand extends to cosmetics and personal care products, where brand identity and product information must remain intact throughout the product's lifecycle.

The automotive sector presents another substantial market for enhanced ink adhesion technologies. As plastic components become more prevalent in vehicle interiors and exteriors, there is an increasing need for permanent markings and decorative prints that can withstand harsh conditions, including exposure to UV light, temperature fluctuations, and chemical interactions.

Consumer electronics manufacturers are also driving demand for better ink adhesion solutions. With the proliferation of plastic-bodied devices, from smartphones to household appliances, there is a growing requirement for durable printing that can resist wear from frequent handling and cleaning.

In the medical device industry, the need for clear and permanent labeling on plastic equipment and packaging is critical for patient safety and regulatory compliance. This sector demands ink adhesion technologies that can withstand sterilization processes and maintain readability in clinical environments.

The market is also seeing increased demand from the textile industry, particularly in the realm of synthetic fabrics and performance wear. Manufacturers are seeking solutions to improve the durability of prints on plastic-based textiles, ensuring that designs and logos remain vibrant after repeated washing and wear.

Environmental concerns and sustainability initiatives are shaping market demands as well. There is a growing interest in eco-friendly ink adhesion solutions that can work effectively on recycled plastics or bio-based polymers, aligning with the broader trend towards more sustainable packaging and product materials.

As industries continue to innovate and expand their use of plastic materials, the market for enhanced ink adhesion technologies is expected to grow. This presents opportunities for chemical companies and ink manufacturers to develop advanced solutions that can meet the diverse and evolving needs of various sectors, potentially opening new revenue streams and market segments.

In the packaging industry, there is a significant push for improved ink adhesion on plastic containers and films. This is particularly crucial for food and beverage packaging, where regulations require clear and lasting product information. The demand extends to cosmetics and personal care products, where brand identity and product information must remain intact throughout the product's lifecycle.

The automotive sector presents another substantial market for enhanced ink adhesion technologies. As plastic components become more prevalent in vehicle interiors and exteriors, there is an increasing need for permanent markings and decorative prints that can withstand harsh conditions, including exposure to UV light, temperature fluctuations, and chemical interactions.

Consumer electronics manufacturers are also driving demand for better ink adhesion solutions. With the proliferation of plastic-bodied devices, from smartphones to household appliances, there is a growing requirement for durable printing that can resist wear from frequent handling and cleaning.

In the medical device industry, the need for clear and permanent labeling on plastic equipment and packaging is critical for patient safety and regulatory compliance. This sector demands ink adhesion technologies that can withstand sterilization processes and maintain readability in clinical environments.

The market is also seeing increased demand from the textile industry, particularly in the realm of synthetic fabrics and performance wear. Manufacturers are seeking solutions to improve the durability of prints on plastic-based textiles, ensuring that designs and logos remain vibrant after repeated washing and wear.

Environmental concerns and sustainability initiatives are shaping market demands as well. There is a growing interest in eco-friendly ink adhesion solutions that can work effectively on recycled plastics or bio-based polymers, aligning with the broader trend towards more sustainable packaging and product materials.

As industries continue to innovate and expand their use of plastic materials, the market for enhanced ink adhesion technologies is expected to grow. This presents opportunities for chemical companies and ink manufacturers to develop advanced solutions that can meet the diverse and evolving needs of various sectors, potentially opening new revenue streams and market segments.

Current Challenges in Ink Adhesion on Plastic Surfaces

Ink adhesion on plastic surfaces remains a significant challenge in various industries, particularly in packaging, automotive, and consumer goods. The inherent properties of plastics, such as low surface energy and chemical inertness, make it difficult for inks to form strong bonds with the substrate. This results in poor adhesion, leading to issues like smudging, flaking, and reduced durability of printed designs.

One of the primary challenges is the diverse range of plastic materials used in manufacturing. Different plastics exhibit varying surface characteristics, requiring tailored ink formulations and adhesion techniques. Polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are among the most commonly used plastics, each presenting unique adhesion challenges due to their specific molecular structures and surface properties.

Surface tension mismatch between the ink and the plastic substrate is another critical issue. Most plastics have low surface energy, while inks typically have higher surface tension. This disparity leads to poor wetting and spreading of the ink on the plastic surface, resulting in inadequate adhesion. Overcoming this mismatch often requires surface treatment methods or the use of specialized ink formulations.

The presence of additives and plasticizers in plastic materials further complicates ink adhesion. These compounds can migrate to the surface over time, interfering with the ink-substrate interface and potentially causing adhesion failure. This phenomenon is particularly problematic in flexible packaging applications, where plasticizers are commonly used to enhance material properties.

Environmental factors also play a significant role in ink adhesion challenges. Temperature fluctuations, humidity, and exposure to UV light can affect the stability of the ink-substrate bond. This is especially relevant in outdoor applications or products subjected to varying environmental conditions during their lifecycle.

The increasing demand for eco-friendly and recyclable packaging solutions adds another layer of complexity. Traditional ink formulations and adhesion-promoting additives may not be compatible with recycling processes or may not meet stringent environmental regulations. This necessitates the development of new, sustainable ink technologies that maintain strong adhesion properties while being environmentally benign.

Lastly, the speed and efficiency requirements of modern printing processes pose additional challenges. High-speed printing lines demand rapid ink drying and curing, which can limit the time available for optimal ink-substrate interaction. Balancing these production needs with the requirement for durable ink adhesion remains a significant hurdle in the industry.

One of the primary challenges is the diverse range of plastic materials used in manufacturing. Different plastics exhibit varying surface characteristics, requiring tailored ink formulations and adhesion techniques. Polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are among the most commonly used plastics, each presenting unique adhesion challenges due to their specific molecular structures and surface properties.

Surface tension mismatch between the ink and the plastic substrate is another critical issue. Most plastics have low surface energy, while inks typically have higher surface tension. This disparity leads to poor wetting and spreading of the ink on the plastic surface, resulting in inadequate adhesion. Overcoming this mismatch often requires surface treatment methods or the use of specialized ink formulations.

The presence of additives and plasticizers in plastic materials further complicates ink adhesion. These compounds can migrate to the surface over time, interfering with the ink-substrate interface and potentially causing adhesion failure. This phenomenon is particularly problematic in flexible packaging applications, where plasticizers are commonly used to enhance material properties.

Environmental factors also play a significant role in ink adhesion challenges. Temperature fluctuations, humidity, and exposure to UV light can affect the stability of the ink-substrate bond. This is especially relevant in outdoor applications or products subjected to varying environmental conditions during their lifecycle.

The increasing demand for eco-friendly and recyclable packaging solutions adds another layer of complexity. Traditional ink formulations and adhesion-promoting additives may not be compatible with recycling processes or may not meet stringent environmental regulations. This necessitates the development of new, sustainable ink technologies that maintain strong adhesion properties while being environmentally benign.

Lastly, the speed and efficiency requirements of modern printing processes pose additional challenges. High-speed printing lines demand rapid ink drying and curing, which can limit the time available for optimal ink-substrate interaction. Balancing these production needs with the requirement for durable ink adhesion remains a significant hurdle in the industry.

Existing Solutions for Improving Ink Adhesion on Plastics

01 Use of ammonium hydroxide in ink formulations

Ammonium hydroxide can be incorporated into ink formulations to improve adhesion properties. It acts as a pH regulator and can help in stabilizing the ink composition, potentially enhancing its ability to adhere to various surfaces.- Use of ammonium hydroxide in ink formulations: Ammonium hydroxide is utilized in ink formulations to improve adhesion properties. It can act as a pH adjuster and solubilizing agent, helping to stabilize the ink and enhance its ability to adhere to various surfaces. The alkaline nature of ammonium hydroxide can also help in opening up the fibers of certain substrates, allowing for better ink penetration and adhesion.

- Ammonium hydroxide as a surface treatment: Ammonium hydroxide can be used as a surface treatment prior to ink application. This pre-treatment process can modify the surface properties of the substrate, making it more receptive to ink adhesion. The treatment can clean the surface, remove contaminants, and create a more favorable surface energy for ink bonding.

- Combination with other additives for enhanced adhesion: Ammonium hydroxide can be combined with other additives to further improve ink adhesion. These additives may include binders, surfactants, or other chemicals that work synergistically with ammonium hydroxide to enhance the overall adhesion properties of the ink. The combination can lead to improved durability and resistance to wear and environmental factors.

- Application in specific ink types: Ammonium hydroxide is particularly useful in certain types of inks, such as water-based or aqueous inks. Its properties make it suitable for improving adhesion in these formulations, especially on challenging substrates. The use of ammonium hydroxide can be tailored to specific ink compositions and printing applications to optimize adhesion performance.

- Role in ink curing and drying processes: Ammonium hydroxide can play a role in the curing and drying processes of inks, which can impact adhesion. It may influence the rate of solvent evaporation or participate in chemical reactions during ink setting. These effects can contribute to the formation of stronger bonds between the ink and the substrate, resulting in improved adhesion and overall print quality.

02 Surface treatment with ammonium hydroxide

Treating surfaces with ammonium hydroxide prior to ink application can improve ink adhesion. This process can modify the surface properties, making it more receptive to ink and enhancing overall adhesion strength.Expand Specific Solutions03 Ammonium hydroxide in cleaning and preparation processes

Ammonium hydroxide can be used in cleaning and preparation processes before ink application. It can help remove contaminants and create a more suitable surface for ink adhesion, particularly on challenging substrates.Expand Specific Solutions04 Combination of ammonium hydroxide with other additives

Combining ammonium hydroxide with other additives in ink formulations can synergistically improve adhesion properties. These combinations may include surfactants, binders, or other pH modifiers to optimize ink performance and adhesion.Expand Specific Solutions05 Ammonium hydroxide in specialized ink applications

Ammonium hydroxide can be utilized in specialized ink applications, such as textile printing or industrial marking, where enhanced adhesion is crucial. Its properties can be particularly beneficial in these specific use cases, improving overall ink performance and durability.Expand Specific Solutions

Key Players in Ink and Plastic Surface Treatment Industry

The market for ammonium hydroxide in enhancing ink adhesion on plastics is in a growth phase, driven by increasing demand for high-quality printing on plastic substrates across various industries. The global market size is expanding, with key players like Konica Minolta, Eastman Kodak, and HP Development Co. investing in research and development to improve ink adhesion technologies. The technology is reaching maturity, with companies like LG Chem and Scott Bader Co. offering advanced solutions. However, there is still room for innovation, particularly in eco-friendly formulations and application methods, as evidenced by ongoing research at institutions like Shandong University and companies such as Sun Chemical Corp.

Eastman Kodak Co.

Technical Solution: Eastman Kodak Co. has developed a novel ink formulation incorporating ammonium hydroxide to enhance adhesion on plastic substrates. Their approach involves creating a pH-sensitive ink system where ammonium hydroxide acts as a volatile base. As the ink dries, the ammonium hydroxide evaporates, causing a pH shift that triggers crosslinking reactions within the ink components[1]. This process significantly improves the ink's bonding to plastic surfaces. Additionally, Kodak has implemented a multi-layer coating technique, where an ammonium hydroxide-rich primer layer is applied before the main ink layer, further enhancing adhesion through chemical etching of the plastic surface[3].

Strengths: Improved adhesion on various plastic substrates, versatile application in different printing processes. Weaknesses: Potential for ammonia odor during printing, may require specialized ventilation systems.

HP Development Co. LP

Technical Solution: HP has pioneered an innovative ink technology utilizing ammonium hydroxide for enhanced plastic adhesion. Their approach involves a dual-action mechanism: first, the ammonium hydroxide temporarily softens the plastic surface, creating micro-pores for better ink penetration[2]. Second, it acts as a pH buffer in the ink formulation, optimizing the ink's rheological properties for improved wetting and spreading on plastic surfaces. HP's technology also incorporates specially designed polymers that react with ammonium hydroxide during the drying process, forming a durable, cross-linked network that anchors the ink to the substrate[4]. This technology has been successfully implemented in their latest generation of inkjet printers designed for industrial plastic printing applications.

Strengths: Excellent adhesion on a wide range of plastics, including challenging substrates like polyethylene and polypropylene. Weaknesses: May require longer drying times compared to conventional inks, potential compatibility issues with certain plastic additives.

Core Innovations in Ammonium Hydroxide-Based Adhesion Enhancement

An adhesion promoting compound

PatentWO2012028882A1

Innovation

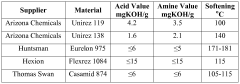

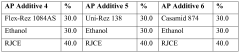

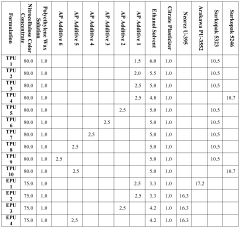

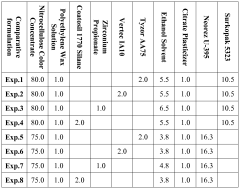

- An adhesion promoter comprising an organotitanate compound combined with a polyamide having an acid and amine value of 1 to 25 mg KOH/g, along with a volatile organic solvent, which allows for immediate adhesion on various substrates without the need for elevated temperatures, reduces odor, and maintains lamination performance without high acid value resins, thereby stabilizing ink viscosity and preventing discoloration.

Scroll

PatentInactiveUS20080292818A1

Innovation

- Development of a flexible, water-resistant, and non-tacky kosher black ink using carbon black pigment with binding materials like acrylic polymers and ethylene vinyl acetate, which adheres well to parchment and maintains its properties over time.

Environmental Impact of Ammonium Hydroxide in Printing Processes

The use of ammonium hydroxide in printing processes, particularly for enhancing ink adhesion on plastics, raises significant environmental concerns. As a volatile compound, ammonium hydroxide can contribute to air pollution through the release of ammonia gas during printing operations. This emission can lead to the formation of particulate matter and contribute to smog formation, potentially impacting local air quality and human health.

Water pollution is another critical environmental issue associated with ammonium hydroxide in printing. Wastewater from printing facilities may contain residual ammonium hydroxide, which can alter the pH of water bodies and harm aquatic ecosystems if not properly treated before discharge. The increased nitrogen content in water systems can also promote algal blooms, leading to eutrophication and oxygen depletion in aquatic environments.

The production and transportation of ammonium hydroxide for printing applications contribute to the overall carbon footprint of the printing industry. The energy-intensive manufacturing process and the need for specialized handling and transportation due to its corrosive nature add to greenhouse gas emissions and resource consumption.

Workplace safety is an additional concern, as exposure to ammonium hydroxide vapors can cause respiratory irritation and other health issues for printing facility workers. Proper ventilation systems and personal protective equipment are necessary to mitigate these risks, which in turn require additional energy and resource inputs.

The disposal of ammonium hydroxide-containing waste presents further environmental challenges. Improper disposal can lead to soil contamination and groundwater pollution, potentially affecting ecosystems and human health in surrounding areas. Specialized waste treatment processes are often required to neutralize and safely dispose of these materials, adding to the environmental burden of printing operations.

Despite these environmental concerns, it is important to note that ammonium hydroxide plays a crucial role in improving ink adhesion on plastics, which can lead to more durable and longer-lasting printed products. This durability may reduce the need for reprinting and potentially decrease overall material consumption and waste generation in the long term.

To address the environmental impact of ammonium hydroxide in printing processes, the industry is exploring alternative solutions. These include the development of water-based inks with improved adhesion properties, the use of UV-curable inks that require no volatile compounds, and the implementation of closed-loop systems to capture and recycle ammonia emissions. Additionally, advancements in plasma treatment and other surface modification techniques for plastics may reduce the reliance on chemical adhesion promoters like ammonium hydroxide.

Water pollution is another critical environmental issue associated with ammonium hydroxide in printing. Wastewater from printing facilities may contain residual ammonium hydroxide, which can alter the pH of water bodies and harm aquatic ecosystems if not properly treated before discharge. The increased nitrogen content in water systems can also promote algal blooms, leading to eutrophication and oxygen depletion in aquatic environments.

The production and transportation of ammonium hydroxide for printing applications contribute to the overall carbon footprint of the printing industry. The energy-intensive manufacturing process and the need for specialized handling and transportation due to its corrosive nature add to greenhouse gas emissions and resource consumption.

Workplace safety is an additional concern, as exposure to ammonium hydroxide vapors can cause respiratory irritation and other health issues for printing facility workers. Proper ventilation systems and personal protective equipment are necessary to mitigate these risks, which in turn require additional energy and resource inputs.

The disposal of ammonium hydroxide-containing waste presents further environmental challenges. Improper disposal can lead to soil contamination and groundwater pollution, potentially affecting ecosystems and human health in surrounding areas. Specialized waste treatment processes are often required to neutralize and safely dispose of these materials, adding to the environmental burden of printing operations.

Despite these environmental concerns, it is important to note that ammonium hydroxide plays a crucial role in improving ink adhesion on plastics, which can lead to more durable and longer-lasting printed products. This durability may reduce the need for reprinting and potentially decrease overall material consumption and waste generation in the long term.

To address the environmental impact of ammonium hydroxide in printing processes, the industry is exploring alternative solutions. These include the development of water-based inks with improved adhesion properties, the use of UV-curable inks that require no volatile compounds, and the implementation of closed-loop systems to capture and recycle ammonia emissions. Additionally, advancements in plasma treatment and other surface modification techniques for plastics may reduce the reliance on chemical adhesion promoters like ammonium hydroxide.

Regulatory Compliance for Chemical Use in Printing Industry

The printing industry is subject to a complex web of regulations governing the use of chemicals in its processes. Compliance with these regulations is crucial for ensuring worker safety, environmental protection, and product quality. In the context of using ammonium hydroxide to enhance ink adhesion on plastics, several regulatory frameworks come into play.

Occupational Safety and Health Administration (OSHA) standards are paramount in the United States. These regulations mandate proper handling, storage, and disposal of ammonium hydroxide, as well as appropriate personal protective equipment for workers. Employers must provide safety data sheets (SDS) and conduct regular training on chemical hazards and safe handling procedures.

Environmental Protection Agency (EPA) regulations address the potential environmental impact of chemical use in printing. The Clean Air Act and Clean Water Act set limits on emissions and effluents, respectively. Printers using ammonium hydroxide must ensure proper ventilation systems and wastewater treatment to comply with these regulations.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation affects global supply chains. Manufacturers and importers must register chemicals used in their products, including those in printing inks. This regulation aims to protect human health and the environment from the risks posed by chemicals.

Food and Drug Administration (FDA) regulations are relevant when printing on packaging materials that come into contact with food. The use of ammonium hydroxide in such applications must comply with FDA guidelines to ensure food safety.

State and local regulations may impose additional requirements. For example, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm.

Compliance with these regulations requires ongoing monitoring and adaptation. Companies must stay informed about regulatory changes, conduct regular audits, and maintain detailed records of chemical usage and disposal. Implementation of an environmental management system, such as ISO 14001, can help ensure systematic compliance and continuous improvement in environmental performance.

Failure to comply with these regulations can result in severe penalties, including fines, legal action, and reputational damage. Therefore, printing companies must invest in compliance programs, employee training, and proper equipment to meet regulatory standards while using ammonium hydroxide and other chemicals in their processes.

Occupational Safety and Health Administration (OSHA) standards are paramount in the United States. These regulations mandate proper handling, storage, and disposal of ammonium hydroxide, as well as appropriate personal protective equipment for workers. Employers must provide safety data sheets (SDS) and conduct regular training on chemical hazards and safe handling procedures.

Environmental Protection Agency (EPA) regulations address the potential environmental impact of chemical use in printing. The Clean Air Act and Clean Water Act set limits on emissions and effluents, respectively. Printers using ammonium hydroxide must ensure proper ventilation systems and wastewater treatment to comply with these regulations.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation affects global supply chains. Manufacturers and importers must register chemicals used in their products, including those in printing inks. This regulation aims to protect human health and the environment from the risks posed by chemicals.

Food and Drug Administration (FDA) regulations are relevant when printing on packaging materials that come into contact with food. The use of ammonium hydroxide in such applications must comply with FDA guidelines to ensure food safety.

State and local regulations may impose additional requirements. For example, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm.

Compliance with these regulations requires ongoing monitoring and adaptation. Companies must stay informed about regulatory changes, conduct regular audits, and maintain detailed records of chemical usage and disposal. Implementation of an environmental management system, such as ISO 14001, can help ensure systematic compliance and continuous improvement in environmental performance.

Failure to comply with these regulations can result in severe penalties, including fines, legal action, and reputational damage. Therefore, printing companies must invest in compliance programs, employee training, and proper equipment to meet regulatory standards while using ammonium hydroxide and other chemicals in their processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!