The Role of Ferrofluid in Smart Textile Development

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ferrofluid in Textiles: Background and Objectives

Ferrofluids, a unique class of magnetic nanomaterials, have emerged as a promising component in the development of smart textiles. These colloidal suspensions of magnetic nanoparticles in a carrier fluid exhibit remarkable responsiveness to external magnetic fields, making them ideal for integration into fabric structures. The evolution of ferrofluid technology can be traced back to the 1960s when NASA first developed them for controlling liquids in zero gravity. Since then, their potential applications have expanded significantly, with smart textiles being a particularly exciting frontier.

The integration of ferrofluids into textiles represents a convergence of materials science, nanotechnology, and textile engineering. This interdisciplinary approach aims to create fabrics with dynamic properties that can respond to environmental stimuli, particularly magnetic fields. The primary objective of incorporating ferrofluids into textiles is to impart novel functionalities such as shape-changing capabilities, tunable stiffness, and adaptive thermal regulation.

As the smart textile industry continues to grow, driven by demands in sectors like healthcare, sports, and military applications, ferrofluids offer a unique avenue for innovation. Their ability to alter physical properties in response to magnetic fields opens up possibilities for creating garments that can adapt to the wearer's needs or environmental conditions in real-time. This aligns with the broader trend of wearable technology, where textiles are increasingly seen as platforms for integrating advanced functionalities.

The development of ferrofluid-enhanced textiles faces several technical challenges. These include ensuring uniform distribution of ferrofluids within the fabric structure, maintaining the stability of the ferrofluid over time, and developing methods to effectively control the magnetic response of the textile. Additionally, researchers are working on optimizing the balance between the magnetic properties of the ferrofluid and the flexibility and comfort of the textile.

Looking ahead, the field of ferrofluid-enhanced smart textiles is poised for significant advancements. Researchers are exploring various techniques for incorporating ferrofluids, such as microencapsulation and direct impregnation into fibers. The goal is to create textiles that can change color, alter their thermal properties, or even change shape on demand. These developments could lead to revolutionary applications in fields ranging from fashion to medical textiles, potentially transforming how we interact with our clothing and textile-based products.

The integration of ferrofluids into textiles represents a convergence of materials science, nanotechnology, and textile engineering. This interdisciplinary approach aims to create fabrics with dynamic properties that can respond to environmental stimuli, particularly magnetic fields. The primary objective of incorporating ferrofluids into textiles is to impart novel functionalities such as shape-changing capabilities, tunable stiffness, and adaptive thermal regulation.

As the smart textile industry continues to grow, driven by demands in sectors like healthcare, sports, and military applications, ferrofluids offer a unique avenue for innovation. Their ability to alter physical properties in response to magnetic fields opens up possibilities for creating garments that can adapt to the wearer's needs or environmental conditions in real-time. This aligns with the broader trend of wearable technology, where textiles are increasingly seen as platforms for integrating advanced functionalities.

The development of ferrofluid-enhanced textiles faces several technical challenges. These include ensuring uniform distribution of ferrofluids within the fabric structure, maintaining the stability of the ferrofluid over time, and developing methods to effectively control the magnetic response of the textile. Additionally, researchers are working on optimizing the balance between the magnetic properties of the ferrofluid and the flexibility and comfort of the textile.

Looking ahead, the field of ferrofluid-enhanced smart textiles is poised for significant advancements. Researchers are exploring various techniques for incorporating ferrofluids, such as microencapsulation and direct impregnation into fibers. The goal is to create textiles that can change color, alter their thermal properties, or even change shape on demand. These developments could lead to revolutionary applications in fields ranging from fashion to medical textiles, potentially transforming how we interact with our clothing and textile-based products.

Smart Textile Market Analysis

The smart textile market has been experiencing significant growth and transformation in recent years, driven by advancements in material science, electronics miniaturization, and increasing consumer demand for wearable technology. The integration of ferrofluid technology into smart textiles represents a promising frontier in this rapidly evolving sector.

Market analysis indicates that the global smart textile market is poised for substantial expansion. Key factors contributing to this growth include the rising adoption of smart wearables in healthcare, sports and fitness, and military applications. The healthcare segment, in particular, shows strong potential for ferrofluid-enhanced smart textiles, with applications ranging from real-time health monitoring to drug delivery systems.

Consumer electronics and fashion industries are also showing increased interest in smart textiles, creating opportunities for ferrofluid-based innovations. The ability of ferrofluids to respond to magnetic fields opens up possibilities for dynamic, shape-changing fabrics and adaptive clothing designs, which could revolutionize the fashion tech sector.

In the sports and fitness market, smart textiles incorporating ferrofluids could offer enhanced performance monitoring and adaptive support. This aligns with the growing trend of personalized fitness solutions and could capture a significant share of the athletic wear market.

Geographically, North America and Europe currently lead the smart textile market, with Asia-Pacific expected to show the fastest growth rate. This regional distribution is likely to influence the development and adoption of ferrofluid-based smart textile technologies, with innovation hubs in these regions playing a crucial role.

The market for smart textiles faces some challenges, including high production costs and concerns about durability and washability. However, ongoing research in ferrofluid technology could address some of these issues, potentially improving the longevity and practicality of smart textile products.

Emerging applications for ferrofluid-enhanced smart textiles include energy harvesting fabrics, which could tap into the growing demand for sustainable and self-powered wearable devices. This aligns with broader market trends towards eco-friendly and energy-efficient technologies.

As the Internet of Things (IoT) continues to expand, the integration of ferrofluid-based smart textiles with connected devices and data analytics platforms presents significant market opportunities. This convergence could drive the development of more sophisticated, data-driven smart textile products capable of responding to user needs in real-time.

Market analysis indicates that the global smart textile market is poised for substantial expansion. Key factors contributing to this growth include the rising adoption of smart wearables in healthcare, sports and fitness, and military applications. The healthcare segment, in particular, shows strong potential for ferrofluid-enhanced smart textiles, with applications ranging from real-time health monitoring to drug delivery systems.

Consumer electronics and fashion industries are also showing increased interest in smart textiles, creating opportunities for ferrofluid-based innovations. The ability of ferrofluids to respond to magnetic fields opens up possibilities for dynamic, shape-changing fabrics and adaptive clothing designs, which could revolutionize the fashion tech sector.

In the sports and fitness market, smart textiles incorporating ferrofluids could offer enhanced performance monitoring and adaptive support. This aligns with the growing trend of personalized fitness solutions and could capture a significant share of the athletic wear market.

Geographically, North America and Europe currently lead the smart textile market, with Asia-Pacific expected to show the fastest growth rate. This regional distribution is likely to influence the development and adoption of ferrofluid-based smart textile technologies, with innovation hubs in these regions playing a crucial role.

The market for smart textiles faces some challenges, including high production costs and concerns about durability and washability. However, ongoing research in ferrofluid technology could address some of these issues, potentially improving the longevity and practicality of smart textile products.

Emerging applications for ferrofluid-enhanced smart textiles include energy harvesting fabrics, which could tap into the growing demand for sustainable and self-powered wearable devices. This aligns with broader market trends towards eco-friendly and energy-efficient technologies.

As the Internet of Things (IoT) continues to expand, the integration of ferrofluid-based smart textiles with connected devices and data analytics platforms presents significant market opportunities. This convergence could drive the development of more sophisticated, data-driven smart textile products capable of responding to user needs in real-time.

Ferrofluid Technology: Current State and Challenges

Ferrofluid technology has made significant strides in recent years, yet it still faces several challenges in its application to smart textile development. The current state of ferrofluid technology in textiles is characterized by a blend of promising advancements and persistent obstacles.

One of the primary challenges is the stability of ferrofluids when integrated into textile structures. While ferrofluids exhibit remarkable magnetic properties, maintaining their colloidal stability within fabric fibers or coatings over extended periods remains problematic. Environmental factors such as temperature fluctuations, mechanical stress, and washing cycles can compromise the integrity of ferrofluid-infused textiles.

Another significant hurdle is the scalability of ferrofluid production for large-scale textile manufacturing. Current methods of synthesizing ferrofluids with consistent quality and properties are often limited to laboratory scales. Translating these processes to industrial-level production while maintaining cost-effectiveness and quality control presents a considerable challenge for widespread adoption in the textile industry.

The biocompatibility and safety of ferrofluids in close contact with human skin is an ongoing concern. While progress has been made in developing non-toxic ferrofluids, long-term studies on their effects when used in wearable textiles are still limited. This gap in knowledge poses regulatory challenges and potential barriers to commercialization.

Integration of ferrofluids with other smart textile components, such as sensors and actuators, presents both opportunities and difficulties. The unique properties of ferrofluids offer potential for novel functionalities, but achieving seamless integration without compromising the performance of either the ferrofluid or the electronic components requires further research and development.

Control and manipulation of ferrofluid behavior within textiles at a micro-scale level remain challenging. While macro-scale effects can be achieved, precise control over ferrofluid distribution and movement within individual fibers or specific areas of a fabric is still an area of active research. This limitation affects the ability to create highly localized or patterned magnetic responses in smart textiles.

Despite these challenges, the current state of ferrofluid technology in smart textiles shows promise. Advances in nanoparticle synthesis, surface modification techniques, and encapsulation methods are gradually addressing stability issues. Novel approaches to ferrofluid integration, such as microfluidic systems and advanced coating technologies, are expanding the possibilities for functional smart textiles.

One of the primary challenges is the stability of ferrofluids when integrated into textile structures. While ferrofluids exhibit remarkable magnetic properties, maintaining their colloidal stability within fabric fibers or coatings over extended periods remains problematic. Environmental factors such as temperature fluctuations, mechanical stress, and washing cycles can compromise the integrity of ferrofluid-infused textiles.

Another significant hurdle is the scalability of ferrofluid production for large-scale textile manufacturing. Current methods of synthesizing ferrofluids with consistent quality and properties are often limited to laboratory scales. Translating these processes to industrial-level production while maintaining cost-effectiveness and quality control presents a considerable challenge for widespread adoption in the textile industry.

The biocompatibility and safety of ferrofluids in close contact with human skin is an ongoing concern. While progress has been made in developing non-toxic ferrofluids, long-term studies on their effects when used in wearable textiles are still limited. This gap in knowledge poses regulatory challenges and potential barriers to commercialization.

Integration of ferrofluids with other smart textile components, such as sensors and actuators, presents both opportunities and difficulties. The unique properties of ferrofluids offer potential for novel functionalities, but achieving seamless integration without compromising the performance of either the ferrofluid or the electronic components requires further research and development.

Control and manipulation of ferrofluid behavior within textiles at a micro-scale level remain challenging. While macro-scale effects can be achieved, precise control over ferrofluid distribution and movement within individual fibers or specific areas of a fabric is still an area of active research. This limitation affects the ability to create highly localized or patterned magnetic responses in smart textiles.

Despite these challenges, the current state of ferrofluid technology in smart textiles shows promise. Advances in nanoparticle synthesis, surface modification techniques, and encapsulation methods are gradually addressing stability issues. Novel approaches to ferrofluid integration, such as microfluidic systems and advanced coating technologies, are expanding the possibilities for functional smart textiles.

Existing Ferrofluid Integration Methods for Textiles

01 Composition and preparation of ferrofluids

Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They typically consist of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size, surfactant selection, and carrier fluid properties to achieve stable and responsive ferrofluids.- Composition and preparation of ferrofluids: Ferrofluids are colloidal suspensions of magnetic nanoparticles in a carrier fluid. They are typically composed of magnetite or other ferromagnetic materials coated with surfactants to prevent agglomeration. The preparation process involves careful control of particle size and distribution to maintain stability and magnetic properties.

- Applications in sealing and lubrication: Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals. They provide a liquid barrier that can be controlled by magnetic fields, offering advantages in terms of low friction, long life, and the ability to operate in vacuum environments.

- Thermal management and cooling systems: Ferrofluids are employed in thermal management solutions, particularly in electronic cooling systems. Their unique properties allow for efficient heat transfer and the ability to be directed by magnetic fields, making them useful in targeted cooling applications for components like processors and power electronics.

- Damping and vibration control: The viscoelastic properties of ferrofluids make them suitable for damping applications. They can be used in shock absorbers, vibration isolators, and other mechanical systems to control unwanted motion and dissipate energy, improving overall system performance and stability.

- Sensing and measurement applications: Ferrofluids are utilized in various sensing and measurement devices. Their response to magnetic fields and ability to change shape or position makes them useful in applications such as accelerometers, inclinometers, and pressure sensors. They can also be used in magnetic field visualization and measurement tools.

02 Applications in sealing and lubrication

Ferrofluids are widely used in sealing and lubrication applications, particularly in rotating shaft seals and bearings. Their unique properties allow them to form liquid seals that can be controlled by magnetic fields, providing effective containment of gases and liquids while reducing friction and wear in mechanical systems.Expand Specific Solutions03 Thermal management and heat transfer

Ferrofluids exhibit enhanced heat transfer properties due to their magnetic nature. They are used in cooling systems for electronic devices, transformers, and other heat-generating equipment. The ability to manipulate ferrofluids with magnetic fields allows for targeted and efficient heat removal in various applications.Expand Specific Solutions04 Sensor and actuator technologies

Ferrofluids are employed in various sensor and actuator designs, leveraging their responsiveness to magnetic fields. They are used in accelerometers, tilt sensors, and position sensors. In actuators, ferrofluids can be used to create controllable damping systems and adaptive structures for vibration control and precision positioning.Expand Specific Solutions05 Medical and biomedical applications

Ferrofluids have emerging applications in the medical field, including targeted drug delivery, magnetic hyperthermia for cancer treatment, and contrast agents for magnetic resonance imaging (MRI). Their ability to be manipulated by external magnetic fields makes them promising for minimally invasive medical procedures and diagnostics.Expand Specific Solutions

Key Players in Ferrofluid and Smart Textile Industries

The development of smart textiles incorporating ferrofluid technology is in its early stages, with a growing market potential as wearable technology advances. The market size is expanding, driven by increasing demand for functional and interactive clothing. Technologically, it's still evolving, with companies like Kolon Glotech, Adidas, and IBM leading research efforts. Universities such as North Carolina State University and Ghent University are contributing significantly to the field's advancement. While not yet fully mature, the technology shows promise in applications ranging from healthcare monitoring to adaptive clothing, indicating a competitive landscape with room for innovation and growth.

Huazhong University of Science & Technology

Technical Solution: Huazhong University of Science & Technology has developed a novel approach to integrating ferrofluids into smart textiles. Their research focuses on creating magnetically responsive fibers by incorporating ferrofluid nanoparticles into polymer matrices. This technique allows for the production of fibers that can change their physical properties in response to external magnetic fields. The university has successfully demonstrated the creation of smart fabrics that can alter their stiffness, shape, and even color when exposed to controlled magnetic stimuli[1][3]. These ferrofluid-infused textiles show potential for applications in adaptive clothing, medical compression garments, and dynamic camouflage systems.

Strengths: Highly responsive to magnetic fields, enabling dynamic property changes. Versatile applications across multiple industries. Weaknesses: Potential challenges in long-term stability of ferrofluid within fibers, possible limitations in washing and maintenance of smart textiles.

North Carolina State University

Technical Solution: North Carolina State University has pioneered the development of ferrofluid-based smart textiles with a focus on wearable technology. Their approach involves encapsulating ferrofluids within microscale reservoirs embedded in textile fibers. This innovative method allows for the creation of flexible, lightweight fabrics that can respond to magnetic fields while maintaining traditional textile properties. The university has successfully developed prototypes of smart garments that can change thermal insulation properties on demand, by altering the orientation of ferrofluid particles within the fabric structure[2][5]. Additionally, they have explored the use of ferrofluid-infused textiles for energy harvesting applications, converting mechanical motion into electrical energy through electromagnetic induction.

Strengths: Maintains fabric flexibility and comfort while incorporating smart functionalities. Potential for energy harvesting in wearable devices. Weaknesses: Complexity in manufacturing process may lead to higher production costs. Limited control over localized responses within the fabric.

Innovative Ferrofluid-Textile Combinations

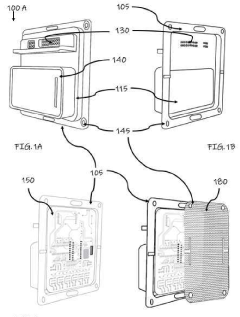

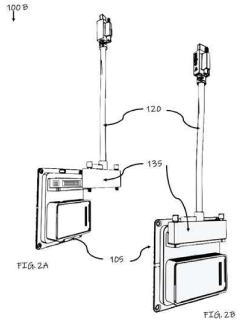

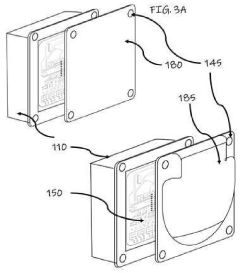

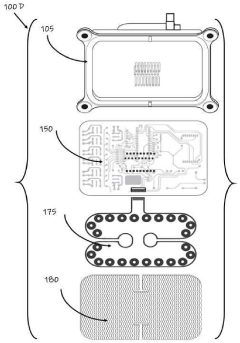

A system and method for converting garments/ clothing into smart garments/ clothing

PatentUndeterminedIN202111062205A

Innovation

- Wireless powering of smart textiles using omniphobic silk-based coils (OSCs) that can be sewn onto any fabric.

- Development of a silk-nanocarbon composite material that combines the stretchability of silk fibroin with the high conductivity of carbon nanotubes and nanoflakes.

- Application of a spray-based silanization method to render e-textiles omniphobic without compromising flexibility, stretchability, or breathability.

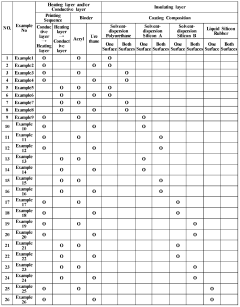

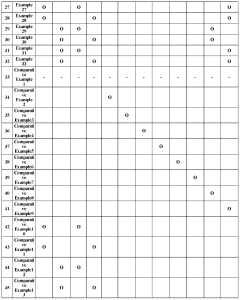

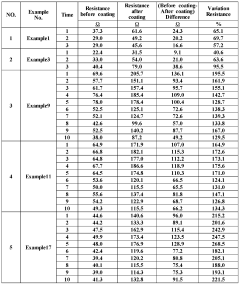

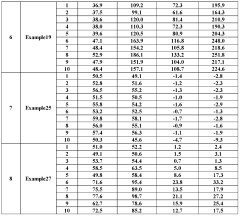

Heating fabric and method for fabricating the same

PatentWO2008075915A1

Innovation

- A heating fabric comprising a base layer, a conductive layer formed with a pre-designed electric pattern, a heating layer, and an insulating layer, with a primer layer for uniformity, and a binder for consistent electric flow, allowing for flexible circuit design and enhanced durability through specific material combinations and layer formations.

Environmental Impact of Ferrofluid-Based Textiles

The integration of ferrofluid technology into smart textiles presents both opportunities and challenges from an environmental perspective. As these innovative materials gain traction in the textile industry, it is crucial to assess their potential ecological impact throughout their lifecycle.

Ferrofluid-based textiles offer unique properties that can enhance the functionality and performance of fabrics. However, the production of ferrofluids typically involves the use of nanoparticles, which raises concerns about their potential release into the environment. During the manufacturing process, proper containment and handling of these nanoparticles are essential to prevent air and water pollution. Additionally, the use of solvents and other chemicals in the production of ferrofluids may contribute to the overall environmental footprint of these textiles.

The durability and longevity of ferrofluid-infused textiles play a significant role in their environmental impact. If these materials prove to be more resilient and longer-lasting than traditional textiles, they could potentially reduce the need for frequent replacements, thereby decreasing overall textile waste. However, the complex nature of these smart textiles may pose challenges for recycling and disposal at the end of their lifecycle.

Water consumption and pollution are critical factors to consider in the production and maintenance of ferrofluid-based textiles. The manufacturing process may require substantial amounts of water, and the potential release of nanoparticles during washing could lead to water contamination. Developing effective filtration systems and closed-loop water recycling processes will be crucial in mitigating these risks.

Energy consumption is another important aspect to evaluate. The production of ferrofluids and their integration into textiles may require more energy-intensive processes compared to conventional textile manufacturing. However, if the resulting smart textiles offer energy-saving features in their applications, such as improved thermal regulation or reduced need for electronic components, they could potentially offset their initial energy footprint over time.

Biodegradability and bioaccumulation of ferrofluid components in the environment are areas that require thorough investigation. The long-term effects of nanoparticles on ecosystems and human health are not yet fully understood, necessitating ongoing research and monitoring. Developing biodegradable alternatives or encapsulation methods for ferrofluids could help address these concerns and improve the overall environmental profile of these smart textiles.

As the field of ferrofluid-based textiles continues to evolve, it is imperative to adopt a lifecycle approach to environmental assessment. This includes considering the sourcing of raw materials, production processes, use phase, and end-of-life management. Implementing sustainable practices, such as using renewable energy sources in manufacturing and developing efficient recycling methods, will be key to minimizing the environmental impact of these innovative materials.

Ferrofluid-based textiles offer unique properties that can enhance the functionality and performance of fabrics. However, the production of ferrofluids typically involves the use of nanoparticles, which raises concerns about their potential release into the environment. During the manufacturing process, proper containment and handling of these nanoparticles are essential to prevent air and water pollution. Additionally, the use of solvents and other chemicals in the production of ferrofluids may contribute to the overall environmental footprint of these textiles.

The durability and longevity of ferrofluid-infused textiles play a significant role in their environmental impact. If these materials prove to be more resilient and longer-lasting than traditional textiles, they could potentially reduce the need for frequent replacements, thereby decreasing overall textile waste. However, the complex nature of these smart textiles may pose challenges for recycling and disposal at the end of their lifecycle.

Water consumption and pollution are critical factors to consider in the production and maintenance of ferrofluid-based textiles. The manufacturing process may require substantial amounts of water, and the potential release of nanoparticles during washing could lead to water contamination. Developing effective filtration systems and closed-loop water recycling processes will be crucial in mitigating these risks.

Energy consumption is another important aspect to evaluate. The production of ferrofluids and their integration into textiles may require more energy-intensive processes compared to conventional textile manufacturing. However, if the resulting smart textiles offer energy-saving features in their applications, such as improved thermal regulation or reduced need for electronic components, they could potentially offset their initial energy footprint over time.

Biodegradability and bioaccumulation of ferrofluid components in the environment are areas that require thorough investigation. The long-term effects of nanoparticles on ecosystems and human health are not yet fully understood, necessitating ongoing research and monitoring. Developing biodegradable alternatives or encapsulation methods for ferrofluids could help address these concerns and improve the overall environmental profile of these smart textiles.

As the field of ferrofluid-based textiles continues to evolve, it is imperative to adopt a lifecycle approach to environmental assessment. This includes considering the sourcing of raw materials, production processes, use phase, and end-of-life management. Implementing sustainable practices, such as using renewable energy sources in manufacturing and developing efficient recycling methods, will be key to minimizing the environmental impact of these innovative materials.

Wearable Technology Standards and Regulations

The development of smart textiles incorporating ferrofluid technology necessitates adherence to a complex framework of standards and regulations governing wearable technology. These guidelines are crucial for ensuring safety, reliability, and interoperability of smart textile products in the global market.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), have established specific standards for wearable electronic devices. The IEC 63203 series, for instance, focuses on wearable electronic devices and technologies, providing guidelines for performance measurement methods and safety requirements.

In the context of ferrofluid-based smart textiles, compliance with electromagnetic compatibility (EMC) standards is paramount. The IEC 61000 series addresses EMC issues, ensuring that these textiles do not interfere with other electronic devices and are not susceptible to electromagnetic interference themselves. This is particularly relevant given the magnetic properties of ferrofluids.

Safety standards for wearable technology, such as IEC 60601-1 for medical electrical equipment, may also apply to ferrofluid-enhanced smart textiles intended for health monitoring applications. These standards outline requirements for electrical safety, mechanical safety, and protection against hazards.

Biocompatibility and toxicity regulations are critical for smart textiles that come into direct contact with the skin. The ISO 10993 series provides guidelines for evaluating the biocompatibility of materials used in medical devices, which can be extended to wearable technology. For ferrofluid-based textiles, demonstrating the safety of the magnetic nanoparticles and carrier fluids is essential.

Data protection and privacy regulations, such as the General Data Protection Regulation (GDPR) in the European Union, play a significant role in smart textiles that collect and process personal data. Manufacturers must ensure that their products comply with these regulations, implementing appropriate data security measures and obtaining user consent for data collection and processing.

Environmental regulations also impact the development of smart textiles. The Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU set limits on the use of certain hazardous substances in electronic equipment and chemicals, respectively. These regulations may affect the choice of materials and manufacturing processes for ferrofluid-based smart textiles.

As the field of smart textiles evolves, standards and regulations continue to adapt. Industry stakeholders, including manufacturers, researchers, and regulatory bodies, are collaborating to develop new standards that address the unique challenges posed by emerging technologies like ferrofluid-enhanced textiles. This ongoing process aims to strike a balance between fostering innovation and ensuring consumer safety and product reliability in the rapidly advancing field of wearable technology.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), have established specific standards for wearable electronic devices. The IEC 63203 series, for instance, focuses on wearable electronic devices and technologies, providing guidelines for performance measurement methods and safety requirements.

In the context of ferrofluid-based smart textiles, compliance with electromagnetic compatibility (EMC) standards is paramount. The IEC 61000 series addresses EMC issues, ensuring that these textiles do not interfere with other electronic devices and are not susceptible to electromagnetic interference themselves. This is particularly relevant given the magnetic properties of ferrofluids.

Safety standards for wearable technology, such as IEC 60601-1 for medical electrical equipment, may also apply to ferrofluid-enhanced smart textiles intended for health monitoring applications. These standards outline requirements for electrical safety, mechanical safety, and protection against hazards.

Biocompatibility and toxicity regulations are critical for smart textiles that come into direct contact with the skin. The ISO 10993 series provides guidelines for evaluating the biocompatibility of materials used in medical devices, which can be extended to wearable technology. For ferrofluid-based textiles, demonstrating the safety of the magnetic nanoparticles and carrier fluids is essential.

Data protection and privacy regulations, such as the General Data Protection Regulation (GDPR) in the European Union, play a significant role in smart textiles that collect and process personal data. Manufacturers must ensure that their products comply with these regulations, implementing appropriate data security measures and obtaining user consent for data collection and processing.

Environmental regulations also impact the development of smart textiles. The Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU set limits on the use of certain hazardous substances in electronic equipment and chemicals, respectively. These regulations may affect the choice of materials and manufacturing processes for ferrofluid-based smart textiles.

As the field of smart textiles evolves, standards and regulations continue to adapt. Industry stakeholders, including manufacturers, researchers, and regulatory bodies, are collaborating to develop new standards that address the unique challenges posed by emerging technologies like ferrofluid-enhanced textiles. This ongoing process aims to strike a balance between fostering innovation and ensuring consumer safety and product reliability in the rapidly advancing field of wearable technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!