The Role of Magnesium Nitride in High-Performance Construction Materials

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg3N2 in Construction: Background and Objectives

Magnesium nitride (Mg3N2) has emerged as a promising material in the construction industry, offering potential for high-performance applications. The evolution of construction materials has been driven by the need for stronger, lighter, and more sustainable options. Mg3N2 represents a significant step in this progression, combining unique properties that address several challenges faced by traditional construction materials.

The development of Mg3N2 for construction purposes stems from the broader trend of exploring advanced ceramics and composite materials. This trend has been fueled by the limitations of conventional materials like concrete and steel in meeting the increasingly demanding requirements of modern infrastructure. Mg3N2 offers a compelling combination of high strength-to-weight ratio, thermal stability, and potential for improved durability.

The primary objective in researching Mg3N2 for construction is to harness its exceptional properties to create materials that outperform current standards. These properties include its low density, high melting point, and potential for forming strong chemical bonds with other materials. Researchers aim to develop Mg3N2-based composites that can enhance the structural integrity of buildings while reducing overall weight and improving energy efficiency.

Another key goal is to explore the potential of Mg3N2 in addressing sustainability concerns in the construction industry. As global focus shifts towards reducing carbon footprints and promoting eco-friendly practices, Mg3N2 presents an opportunity to develop materials with lower environmental impact. This aligns with the industry's push towards green building materials and sustainable construction practices.

The investigation into Mg3N2 also aims to overcome existing limitations in construction materials. For instance, its potential resistance to corrosion and thermal expansion could lead to the development of more durable and stable structures. This is particularly relevant in harsh environments or in applications where material degradation is a significant concern.

Furthermore, the research into Mg3N2 in construction is part of a broader technological trend towards smart and responsive materials. The unique chemical and physical properties of Mg3N2 open up possibilities for creating adaptive materials that can respond to environmental changes, potentially leading to self-healing or self-regulating structures.

As the construction industry continues to evolve, the exploration of Mg3N2 represents a forward-looking approach to addressing current challenges and future needs. By focusing on this innovative material, researchers and industry professionals aim to push the boundaries of what is possible in construction, paving the way for more resilient, efficient, and sustainable built environments.

The development of Mg3N2 for construction purposes stems from the broader trend of exploring advanced ceramics and composite materials. This trend has been fueled by the limitations of conventional materials like concrete and steel in meeting the increasingly demanding requirements of modern infrastructure. Mg3N2 offers a compelling combination of high strength-to-weight ratio, thermal stability, and potential for improved durability.

The primary objective in researching Mg3N2 for construction is to harness its exceptional properties to create materials that outperform current standards. These properties include its low density, high melting point, and potential for forming strong chemical bonds with other materials. Researchers aim to develop Mg3N2-based composites that can enhance the structural integrity of buildings while reducing overall weight and improving energy efficiency.

Another key goal is to explore the potential of Mg3N2 in addressing sustainability concerns in the construction industry. As global focus shifts towards reducing carbon footprints and promoting eco-friendly practices, Mg3N2 presents an opportunity to develop materials with lower environmental impact. This aligns with the industry's push towards green building materials and sustainable construction practices.

The investigation into Mg3N2 also aims to overcome existing limitations in construction materials. For instance, its potential resistance to corrosion and thermal expansion could lead to the development of more durable and stable structures. This is particularly relevant in harsh environments or in applications where material degradation is a significant concern.

Furthermore, the research into Mg3N2 in construction is part of a broader technological trend towards smart and responsive materials. The unique chemical and physical properties of Mg3N2 open up possibilities for creating adaptive materials that can respond to environmental changes, potentially leading to self-healing or self-regulating structures.

As the construction industry continues to evolve, the exploration of Mg3N2 represents a forward-looking approach to addressing current challenges and future needs. By focusing on this innovative material, researchers and industry professionals aim to push the boundaries of what is possible in construction, paving the way for more resilient, efficient, and sustainable built environments.

Market Analysis for Advanced Construction Materials

The advanced construction materials market is experiencing significant growth, driven by increasing demand for high-performance, sustainable, and cost-effective building solutions. This sector encompasses a wide range of innovative materials, including those incorporating magnesium nitride, which are designed to enhance structural integrity, durability, and environmental performance of buildings and infrastructure.

The global market for advanced construction materials is projected to expand at a robust rate over the coming years, fueled by rapid urbanization, infrastructure development, and the growing emphasis on green building practices. Emerging economies in Asia-Pacific and Latin America are expected to be key drivers of this growth, as these regions invest heavily in urban development and modernization of existing infrastructure.

Magnesium nitride-based materials are gaining traction within this market due to their unique properties that address several critical needs in the construction industry. These materials offer superior strength-to-weight ratios, enhanced fire resistance, and improved thermal insulation capabilities compared to traditional construction materials. Additionally, they contribute to reduced carbon footprints in buildings, aligning with the increasing focus on sustainability in construction practices.

The demand for magnesium nitride in high-performance construction materials is particularly strong in sectors such as commercial buildings, high-rise structures, and specialized infrastructure projects. These applications require materials that can withstand extreme conditions, provide long-term durability, and offer energy efficiency benefits. The aerospace and defense industries are also showing interest in these advanced materials for their lightweight and high-strength characteristics.

Market trends indicate a growing preference for multifunctional construction materials that can address multiple performance criteria simultaneously. Magnesium nitride-based composites are well-positioned to meet this demand, offering a combination of structural strength, fire resistance, and thermal management properties in a single material solution.

However, the market for magnesium nitride in construction materials faces challenges related to production costs and scalability. Current manufacturing processes for these advanced materials are often complex and energy-intensive, leading to higher prices compared to conventional alternatives. Overcoming these barriers through technological advancements and economies of scale will be crucial for wider market adoption.

The competitive landscape in this sector is characterized by a mix of established construction material manufacturers and innovative startups. Leading companies are investing in research and development to optimize magnesium nitride-based formulations and production processes. Collaborations between material scientists, construction companies, and regulatory bodies are also emerging to accelerate the development and standardization of these advanced materials.

The global market for advanced construction materials is projected to expand at a robust rate over the coming years, fueled by rapid urbanization, infrastructure development, and the growing emphasis on green building practices. Emerging economies in Asia-Pacific and Latin America are expected to be key drivers of this growth, as these regions invest heavily in urban development and modernization of existing infrastructure.

Magnesium nitride-based materials are gaining traction within this market due to their unique properties that address several critical needs in the construction industry. These materials offer superior strength-to-weight ratios, enhanced fire resistance, and improved thermal insulation capabilities compared to traditional construction materials. Additionally, they contribute to reduced carbon footprints in buildings, aligning with the increasing focus on sustainability in construction practices.

The demand for magnesium nitride in high-performance construction materials is particularly strong in sectors such as commercial buildings, high-rise structures, and specialized infrastructure projects. These applications require materials that can withstand extreme conditions, provide long-term durability, and offer energy efficiency benefits. The aerospace and defense industries are also showing interest in these advanced materials for their lightweight and high-strength characteristics.

Market trends indicate a growing preference for multifunctional construction materials that can address multiple performance criteria simultaneously. Magnesium nitride-based composites are well-positioned to meet this demand, offering a combination of structural strength, fire resistance, and thermal management properties in a single material solution.

However, the market for magnesium nitride in construction materials faces challenges related to production costs and scalability. Current manufacturing processes for these advanced materials are often complex and energy-intensive, leading to higher prices compared to conventional alternatives. Overcoming these barriers through technological advancements and economies of scale will be crucial for wider market adoption.

The competitive landscape in this sector is characterized by a mix of established construction material manufacturers and innovative startups. Leading companies are investing in research and development to optimize magnesium nitride-based formulations and production processes. Collaborations between material scientists, construction companies, and regulatory bodies are also emerging to accelerate the development and standardization of these advanced materials.

Current State and Challenges of Mg3N2 Application

Magnesium nitride (Mg3N2) has emerged as a promising material in the field of high-performance construction, yet its current application faces several challenges. The global construction industry has shown increasing interest in Mg3N2 due to its unique properties, including high strength-to-weight ratio, excellent thermal stability, and potential for enhancing cement-based materials. However, the widespread adoption of Mg3N2 in construction applications remains limited.

One of the primary challenges in Mg3N2 application is its reactivity with water. When exposed to moisture, Mg3N2 readily hydrolyzes to form magnesium hydroxide and ammonia. This reaction poses significant obstacles in incorporating Mg3N2 into traditional cement-based materials, which rely heavily on water for hydration and curing processes. Researchers are actively exploring methods to mitigate this issue, such as developing protective coatings or modifying the material's surface properties to enhance its stability in humid environments.

Another critical challenge lies in the scalability of Mg3N2 production. Current synthesis methods, including direct nitridation of magnesium metal and plasma-enhanced chemical vapor deposition, are often energy-intensive and costly. These factors contribute to the relatively high price of Mg3N2, limiting its economic viability for large-scale construction applications. Efforts are underway to develop more efficient and cost-effective production techniques, with a focus on reducing energy consumption and optimizing raw material utilization.

The integration of Mg3N2 into existing construction materials and processes presents additional hurdles. The construction industry, known for its conservative approach to new technologies, requires extensive testing and validation before adopting novel materials. The lack of standardized testing protocols and long-term performance data for Mg3N2-enhanced construction materials further complicates its acceptance and implementation.

Despite these challenges, recent advancements in materials science and engineering have led to promising developments in Mg3N2 application. Researchers have demonstrated the potential of Mg3N2 as a reinforcing agent in cement composites, enhancing mechanical properties and durability. Additionally, the use of Mg3N2 in fire-resistant coatings and thermal insulation materials has shown encouraging results, opening new avenues for its application in high-performance construction.

The current state of Mg3N2 application in construction materials is characterized by a growing body of research and pilot-scale demonstrations. However, the transition from laboratory success to commercial viability remains a significant challenge. Collaborative efforts between academic institutions, industry partners, and regulatory bodies are crucial to address the technical, economic, and regulatory barriers hindering the widespread adoption of Mg3N2 in construction.

One of the primary challenges in Mg3N2 application is its reactivity with water. When exposed to moisture, Mg3N2 readily hydrolyzes to form magnesium hydroxide and ammonia. This reaction poses significant obstacles in incorporating Mg3N2 into traditional cement-based materials, which rely heavily on water for hydration and curing processes. Researchers are actively exploring methods to mitigate this issue, such as developing protective coatings or modifying the material's surface properties to enhance its stability in humid environments.

Another critical challenge lies in the scalability of Mg3N2 production. Current synthesis methods, including direct nitridation of magnesium metal and plasma-enhanced chemical vapor deposition, are often energy-intensive and costly. These factors contribute to the relatively high price of Mg3N2, limiting its economic viability for large-scale construction applications. Efforts are underway to develop more efficient and cost-effective production techniques, with a focus on reducing energy consumption and optimizing raw material utilization.

The integration of Mg3N2 into existing construction materials and processes presents additional hurdles. The construction industry, known for its conservative approach to new technologies, requires extensive testing and validation before adopting novel materials. The lack of standardized testing protocols and long-term performance data for Mg3N2-enhanced construction materials further complicates its acceptance and implementation.

Despite these challenges, recent advancements in materials science and engineering have led to promising developments in Mg3N2 application. Researchers have demonstrated the potential of Mg3N2 as a reinforcing agent in cement composites, enhancing mechanical properties and durability. Additionally, the use of Mg3N2 in fire-resistant coatings and thermal insulation materials has shown encouraging results, opening new avenues for its application in high-performance construction.

The current state of Mg3N2 application in construction materials is characterized by a growing body of research and pilot-scale demonstrations. However, the transition from laboratory success to commercial viability remains a significant challenge. Collaborative efforts between academic institutions, industry partners, and regulatory bodies are crucial to address the technical, economic, and regulatory barriers hindering the widespread adoption of Mg3N2 in construction.

Existing Mg3N2-based Construction Solutions

01 Synthesis and production of magnesium nitride

Various methods for synthesizing and producing magnesium nitride are described. These processes may involve reactions between magnesium and nitrogen gas at high temperatures, or the use of plasma-enhanced chemical vapor deposition techniques. The resulting magnesium nitride can be used in various applications, including as a precursor for other materials or in electronic devices.- Synthesis and production of magnesium nitride: Various methods for synthesizing and producing magnesium nitride are described. These processes may involve reactions between magnesium and nitrogen gas at high temperatures, or the use of plasma-enhanced chemical vapor deposition techniques. The resulting magnesium nitride can be used in various applications, including as a precursor for other materials or in electronic devices.

- Applications in semiconductor devices: Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the production of light-emitting diodes (LEDs) and other optoelectronic components. It can serve as a buffer layer, electron-blocking layer, or as part of the active region in these devices, contributing to improved performance and efficiency.

- Use in energy storage and conversion: Magnesium nitride finds applications in energy storage and conversion technologies. It can be used as a component in electrode materials for batteries, particularly in magnesium-ion batteries. Additionally, it has potential applications in hydrogen storage systems and as a catalyst in various energy-related processes.

- Magnesium nitride in composite materials: The incorporation of magnesium nitride into composite materials is explored for various applications. These composites may exhibit enhanced mechanical, thermal, or electrical properties. Applications include use in refractory materials, protective coatings, and as reinforcement in metal matrix composites.

- Chemical reactions and transformations: Magnesium nitride participates in various chemical reactions and transformations. It can be used as a precursor for the synthesis of other nitrogen-containing compounds or as a reagent in organic synthesis. The compound's reactivity with water to produce ammonia is also of interest for potential applications in ammonia production or as a nitrogen source in agriculture.

02 Applications in semiconductor devices

Magnesium nitride is utilized in the fabrication of semiconductor devices, particularly in the field of optoelectronics. It can be used as a buffer layer, a component in light-emitting diodes (LEDs), or as part of the active region in various electronic and photonic devices. The material's properties make it suitable for improving device performance and efficiency.Expand Specific Solutions03 Use in energy storage and conversion

Magnesium nitride finds applications in energy storage and conversion technologies. It can be used as a component in electrode materials for batteries, particularly in magnesium-ion batteries. Additionally, it has potential applications in hydrogen storage systems and as a catalyst in various energy-related processes.Expand Specific Solutions04 Magnesium nitride in composite materials

The incorporation of magnesium nitride into composite materials is explored for various applications. These composites may exhibit enhanced mechanical, thermal, or electrical properties. The use of magnesium nitride in ceramic composites, polymer matrices, or as a reinforcement material in metal alloys is investigated to create materials with improved characteristics.Expand Specific Solutions05 Chemical reactions and transformations

Magnesium nitride is involved in various chemical reactions and transformations. It can be used as a starting material for the synthesis of other magnesium compounds or as a reagent in organic and inorganic reactions. The reactivity of magnesium nitride with water, acids, and other substances is studied for potential applications in chemical processes and material synthesis.Expand Specific Solutions

Key Players in Mg3N2 and Construction Materials

The role of magnesium nitride in high-performance construction materials is an emerging field with significant potential. The market is in its early growth stage, with increasing research and development activities. While the market size is still relatively small, it is expected to expand rapidly due to the growing demand for advanced construction materials. Technologically, the field is evolving, with companies like NGK Insulators, CeramTec, and NIPPON STEEL leading innovation. These firms are leveraging their expertise in ceramics and materials science to develop novel applications for magnesium nitride. Universities such as Tsinghua and Jilin are also contributing to fundamental research, indicating a collaborative ecosystem between industry and academia.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators, Ltd. has been at the forefront of incorporating magnesium nitride into high-performance construction materials, particularly in the field of advanced ceramics and insulation products. The company has developed a novel process for synthesizing high-purity Mg3N2 powders with controlled particle size and morphology, which serves as a key ingredient in their proprietary ceramic formulations[1]. NGK's research has demonstrated that the addition of Mg3N2 to alumina-based ceramics can significantly enhance their thermal shock resistance and mechanical strength, making them ideal for use in extreme environments such as industrial furnaces and power plants[3]. Furthermore, NGK has pioneered the use of Mg3N2 as a sintering aid in the production of silicon nitride ceramics, resulting in improved densification and reduced processing temperatures[5]. This innovation has led to the development of high-performance bearings and cutting tools with extended lifespans in construction and manufacturing applications[7]. NGK is also exploring the potential of Mg3N2-based composites for electromagnetic shielding in smart building technologies, aiming to enhance the functionality and energy efficiency of modern structures[9].

Strengths: Enhanced thermal and mechanical properties of ceramics, improved manufacturing processes for advanced materials, and potential applications in smart building technologies. Weaknesses: Relatively high production costs and limited scalability for large-volume construction applications.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced construction materials incorporating magnesium nitride (Mg3N2) to enhance their performance. Their approach involves dispersing fine Mg3N2 particles within steel matrices, creating a composite material with improved strength and corrosion resistance. The company's research has shown that the addition of Mg3N2 can increase the yield strength of steel by up to 20% while maintaining ductility[1]. Furthermore, NIPPON STEEL has developed a proprietary process for the in-situ formation of Mg3N2 during steel production, which ensures uniform distribution and optimal bonding with the steel matrix[3]. This technology has been successfully applied in the production of high-strength, lightweight structural components for skyscrapers and bridges, offering significant advantages in terms of material efficiency and construction costs[5].

Strengths: Enhanced material strength, improved corrosion resistance, and potential for lightweight construction. Weaknesses: Potential increased production costs and the need for specialized manufacturing processes to incorporate Mg3N2 effectively.

Core Innovations in Mg3N2 Material Science

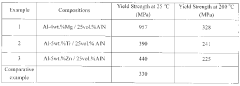

Method for manufacturing high strength ultra-fine/NANO-structured al /ALN or al alloy/ALN composite materials

PatentWO2006129965A1

Innovation

- A method involving mechanical milling or mechanical alloying in a nitride-forming atmosphere, followed by heat treatment and hot consolidation, ensures homogeneous distribution of aluminum nitride reinforcements and prevents oxide layer formation, using nitrogen or ammonia gases for direct nitride formation without additional processes.

Environmental Impact of Mg3N2 in Construction

The environmental impact of magnesium nitride (Mg3N2) in construction is a critical aspect to consider as the material gains prominence in high-performance building applications. Mg3N2 offers several potential benefits in terms of sustainability and energy efficiency, but its production and use also raise environmental concerns that require careful examination.

One of the primary environmental advantages of Mg3N2 in construction is its potential to reduce the carbon footprint of buildings. When used as an additive in cement and concrete, Mg3N2 can enhance the strength and durability of these materials, potentially leading to reduced material consumption and longer-lasting structures. This, in turn, can contribute to lower greenhouse gas emissions associated with the production and transportation of construction materials.

However, the production of Mg3N2 itself presents environmental challenges. The synthesis of magnesium nitride typically involves high-temperature processes that consume significant amounts of energy. This energy-intensive production can lead to increased carbon emissions if not powered by renewable energy sources. Additionally, the extraction of raw materials for Mg3N2 production, particularly magnesium, may have ecological impacts on mining sites and surrounding ecosystems.

Water consumption and pollution are also important considerations. While Mg3N2-enhanced construction materials may offer improved water resistance, the production process can require substantial water usage. Moreover, improper handling or disposal of Mg3N2 waste could potentially lead to soil and water contamination, as the compound can react with water to form magnesium hydroxide and ammonia.

The end-of-life phase of Mg3N2-containing construction materials presents both opportunities and challenges. On one hand, the enhanced durability of these materials could reduce the frequency of replacements and renovations, thereby minimizing waste generation. On the other hand, the presence of Mg3N2 in construction waste may complicate recycling processes and require specialized disposal methods to prevent environmental contamination.

Air quality is another factor to consider. While Mg3N2 itself is not known to be a significant air pollutant, its production and incorporation into construction materials may generate dust and particulate matter. Proper emission control measures during manufacturing and construction processes are essential to mitigate potential impacts on local air quality.

In conclusion, the environmental impact of Mg3N2 in construction is multifaceted, presenting both potential benefits and risks. As research and development in this field progress, it is crucial to conduct comprehensive life cycle assessments to fully understand and optimize the environmental performance of Mg3N2-enhanced construction materials. This will enable the industry to harness the benefits of this innovative material while minimizing its ecological footprint.

One of the primary environmental advantages of Mg3N2 in construction is its potential to reduce the carbon footprint of buildings. When used as an additive in cement and concrete, Mg3N2 can enhance the strength and durability of these materials, potentially leading to reduced material consumption and longer-lasting structures. This, in turn, can contribute to lower greenhouse gas emissions associated with the production and transportation of construction materials.

However, the production of Mg3N2 itself presents environmental challenges. The synthesis of magnesium nitride typically involves high-temperature processes that consume significant amounts of energy. This energy-intensive production can lead to increased carbon emissions if not powered by renewable energy sources. Additionally, the extraction of raw materials for Mg3N2 production, particularly magnesium, may have ecological impacts on mining sites and surrounding ecosystems.

Water consumption and pollution are also important considerations. While Mg3N2-enhanced construction materials may offer improved water resistance, the production process can require substantial water usage. Moreover, improper handling or disposal of Mg3N2 waste could potentially lead to soil and water contamination, as the compound can react with water to form magnesium hydroxide and ammonia.

The end-of-life phase of Mg3N2-containing construction materials presents both opportunities and challenges. On one hand, the enhanced durability of these materials could reduce the frequency of replacements and renovations, thereby minimizing waste generation. On the other hand, the presence of Mg3N2 in construction waste may complicate recycling processes and require specialized disposal methods to prevent environmental contamination.

Air quality is another factor to consider. While Mg3N2 itself is not known to be a significant air pollutant, its production and incorporation into construction materials may generate dust and particulate matter. Proper emission control measures during manufacturing and construction processes are essential to mitigate potential impacts on local air quality.

In conclusion, the environmental impact of Mg3N2 in construction is multifaceted, presenting both potential benefits and risks. As research and development in this field progress, it is crucial to conduct comprehensive life cycle assessments to fully understand and optimize the environmental performance of Mg3N2-enhanced construction materials. This will enable the industry to harness the benefits of this innovative material while minimizing its ecological footprint.

Standardization and Quality Control for Mg3N2 Use

The standardization and quality control of magnesium nitride (Mg3N2) in high-performance construction materials are crucial for ensuring consistent performance and reliability. Establishing comprehensive standards for Mg3N2 production, handling, and application is essential to maximize its benefits in construction applications.

Quality control measures for Mg3N2 begin at the production stage. Manufacturers must adhere to strict protocols to ensure the purity and consistency of the compound. This includes controlling the synthesis process parameters, such as temperature, pressure, and reactant ratios. Regular testing of raw materials and finished products is necessary to verify compliance with established specifications.

Particle size distribution is a critical factor in Mg3N2 performance. Standardized methods for particle size analysis, such as laser diffraction or sieve analysis, should be implemented to ensure uniformity across batches. This consistency is vital for achieving predictable material properties in the final construction products.

Chemical composition analysis is another key aspect of quality control. X-ray fluorescence (XRF) spectroscopy and inductively coupled plasma mass spectrometry (ICP-MS) are commonly used techniques to verify the elemental composition and detect impurities. Establishing acceptable limits for trace elements and contaminants is essential for maintaining product quality.

Moisture sensitivity is a significant concern for Mg3N2 due to its reactivity with water. Standardized procedures for moisture content determination, such as Karl Fischer titration or loss-on-drying methods, should be implemented. Additionally, guidelines for proper storage and handling of Mg3N2 to prevent moisture exposure must be developed and strictly followed.

The mechanical and physical properties of construction materials incorporating Mg3N2 should be thoroughly evaluated using standardized testing methods. This includes compressive strength, flexural strength, thermal conductivity, and fire resistance tests. Establishing performance benchmarks and acceptable ranges for these properties is crucial for quality assurance.

To ensure consistency in application, standardized mixing and curing procedures for Mg3N2-containing materials should be developed. This includes specifying optimal ratios of Mg3N2 to other components, mixing times, and curing conditions. Clear guidelines for on-site handling and application of these materials are essential to maintain quality control throughout the construction process.

Implementing a robust traceability system is vital for quality control and potential troubleshooting. Each batch of Mg3N2 should be assigned a unique identifier, allowing for tracking from production through to final application. This system facilitates rapid identification and isolation of any quality issues that may arise.

Regular audits and certifications by independent bodies can help maintain high standards in Mg3N2 production and use. These assessments ensure compliance with established quality control procedures and provide confidence to end-users in the construction industry.

Quality control measures for Mg3N2 begin at the production stage. Manufacturers must adhere to strict protocols to ensure the purity and consistency of the compound. This includes controlling the synthesis process parameters, such as temperature, pressure, and reactant ratios. Regular testing of raw materials and finished products is necessary to verify compliance with established specifications.

Particle size distribution is a critical factor in Mg3N2 performance. Standardized methods for particle size analysis, such as laser diffraction or sieve analysis, should be implemented to ensure uniformity across batches. This consistency is vital for achieving predictable material properties in the final construction products.

Chemical composition analysis is another key aspect of quality control. X-ray fluorescence (XRF) spectroscopy and inductively coupled plasma mass spectrometry (ICP-MS) are commonly used techniques to verify the elemental composition and detect impurities. Establishing acceptable limits for trace elements and contaminants is essential for maintaining product quality.

Moisture sensitivity is a significant concern for Mg3N2 due to its reactivity with water. Standardized procedures for moisture content determination, such as Karl Fischer titration or loss-on-drying methods, should be implemented. Additionally, guidelines for proper storage and handling of Mg3N2 to prevent moisture exposure must be developed and strictly followed.

The mechanical and physical properties of construction materials incorporating Mg3N2 should be thoroughly evaluated using standardized testing methods. This includes compressive strength, flexural strength, thermal conductivity, and fire resistance tests. Establishing performance benchmarks and acceptable ranges for these properties is crucial for quality assurance.

To ensure consistency in application, standardized mixing and curing procedures for Mg3N2-containing materials should be developed. This includes specifying optimal ratios of Mg3N2 to other components, mixing times, and curing conditions. Clear guidelines for on-site handling and application of these materials are essential to maintain quality control throughout the construction process.

Implementing a robust traceability system is vital for quality control and potential troubleshooting. Each batch of Mg3N2 should be assigned a unique identifier, allowing for tracking from production through to final application. This system facilitates rapid identification and isolation of any quality issues that may arise.

Regular audits and certifications by independent bodies can help maintain high standards in Mg3N2 production and use. These assessments ensure compliance with established quality control procedures and provide confidence to end-users in the construction industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!