The Role of Polysilane in High-Frequency Communication Devices

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Evolution

Polysilane has undergone a remarkable evolution in the field of high-frequency communication devices, transforming from a niche material to a key component in advanced electronic systems. The journey of polysilane in this domain can be traced back to the early 1980s when researchers first recognized its potential for electronic applications due to its unique molecular structure and properties.

In the initial stages of development, polysilane was primarily studied for its photoconductivity and photoluminescence properties. These characteristics made it an interesting candidate for optoelectronic devices, but its role in high-frequency communication remained unexplored. As research progressed through the 1990s, scientists began to investigate the material's potential for use in semiconductor applications, particularly in thin-film transistors.

The turn of the millennium marked a significant shift in polysilane research, with a growing focus on its high-frequency capabilities. Researchers discovered that certain polysilane derivatives exhibited excellent dielectric properties at high frequencies, making them suitable for use in microwave and millimeter-wave devices. This breakthrough led to increased interest from the telecommunications industry, which was seeking new materials to support the development of faster and more efficient communication systems.

By the mid-2000s, polysilane had established itself as a promising material for high-frequency applications. Its low dielectric loss and high thermal stability made it an attractive option for the fabrication of high-performance circuit boards and antenna substrates. The material's ability to maintain its electrical properties at high frequencies also made it valuable for the development of 5G and beyond technologies.

In recent years, the evolution of polysilane in high-frequency communication devices has accelerated rapidly. Advanced synthesis techniques have allowed for the creation of tailored polysilane structures with optimized properties for specific applications. These developments have led to the integration of polysilane-based components in a wide range of communication devices, from smartphones to satellite systems.

The latest frontier in polysilane evolution involves its application in terahertz technology. Researchers are exploring the material's potential for use in terahertz wave generation and detection, which could revolutionize ultra-high-speed wireless communication and imaging systems. This ongoing research promises to further expand the role of polysilane in pushing the boundaries of high-frequency communication capabilities.

As we look to the future, the evolution of polysilane in high-frequency communication devices shows no signs of slowing down. With continued advancements in material science and increasing demand for faster, more efficient communication technologies, polysilane is poised to play an even more critical role in shaping the next generation of electronic devices and communication systems.

In the initial stages of development, polysilane was primarily studied for its photoconductivity and photoluminescence properties. These characteristics made it an interesting candidate for optoelectronic devices, but its role in high-frequency communication remained unexplored. As research progressed through the 1990s, scientists began to investigate the material's potential for use in semiconductor applications, particularly in thin-film transistors.

The turn of the millennium marked a significant shift in polysilane research, with a growing focus on its high-frequency capabilities. Researchers discovered that certain polysilane derivatives exhibited excellent dielectric properties at high frequencies, making them suitable for use in microwave and millimeter-wave devices. This breakthrough led to increased interest from the telecommunications industry, which was seeking new materials to support the development of faster and more efficient communication systems.

By the mid-2000s, polysilane had established itself as a promising material for high-frequency applications. Its low dielectric loss and high thermal stability made it an attractive option for the fabrication of high-performance circuit boards and antenna substrates. The material's ability to maintain its electrical properties at high frequencies also made it valuable for the development of 5G and beyond technologies.

In recent years, the evolution of polysilane in high-frequency communication devices has accelerated rapidly. Advanced synthesis techniques have allowed for the creation of tailored polysilane structures with optimized properties for specific applications. These developments have led to the integration of polysilane-based components in a wide range of communication devices, from smartphones to satellite systems.

The latest frontier in polysilane evolution involves its application in terahertz technology. Researchers are exploring the material's potential for use in terahertz wave generation and detection, which could revolutionize ultra-high-speed wireless communication and imaging systems. This ongoing research promises to further expand the role of polysilane in pushing the boundaries of high-frequency communication capabilities.

As we look to the future, the evolution of polysilane in high-frequency communication devices shows no signs of slowing down. With continued advancements in material science and increasing demand for faster, more efficient communication technologies, polysilane is poised to play an even more critical role in shaping the next generation of electronic devices and communication systems.

HF Comm Market Demand

The high-frequency communication market has experienced significant growth in recent years, driven by the increasing demand for faster and more reliable wireless communication technologies. This surge is particularly evident in the 5G and upcoming 6G networks, where high-frequency bands are crucial for achieving ultra-high data rates and low latency.

The global market for high-frequency communication devices is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the next five years. This growth is fueled by the widespread adoption of smartphones, the Internet of Things (IoT), and the increasing need for high-speed data transmission in various industries.

In the consumer sector, there is a growing demand for devices capable of supporting high-frequency communication, such as smartphones, tablets, and wearables. These devices require components that can efficiently operate at higher frequencies while maintaining signal integrity and minimizing power consumption.

The industrial and automotive sectors are also driving market demand for high-frequency communication devices. Smart factories and autonomous vehicles rely heavily on high-speed, low-latency communication for real-time data processing and decision-making. This has led to increased investment in research and development of advanced materials and components capable of operating at higher frequencies.

Polysilane, a silicon-based polymer, has emerged as a promising material for high-frequency communication devices due to its unique electrical and optical properties. The market for polysilane-based components is expected to grow as manufacturers seek to improve the performance and efficiency of their devices.

The aerospace and defense industries are also significant contributors to the demand for high-frequency communication devices. These sectors require robust, high-performance communication systems for radar, satellite communications, and electronic warfare applications. The use of advanced materials like polysilane in these applications is expected to drive further market growth.

Geographically, North America and Asia-Pacific are the leading regions in terms of market demand for high-frequency communication devices. The United States, China, Japan, and South Korea are at the forefront of 5G deployment and research into 6G technologies, creating substantial opportunities for manufacturers and suppliers of high-frequency components.

As the market continues to evolve, there is an increasing focus on developing more efficient and cost-effective solutions for high-frequency communication. This trend is likely to drive further innovation in materials science and device engineering, with polysilane and other advanced materials playing a crucial role in shaping the future of wireless communication technologies.

The global market for high-frequency communication devices is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the next five years. This growth is fueled by the widespread adoption of smartphones, the Internet of Things (IoT), and the increasing need for high-speed data transmission in various industries.

In the consumer sector, there is a growing demand for devices capable of supporting high-frequency communication, such as smartphones, tablets, and wearables. These devices require components that can efficiently operate at higher frequencies while maintaining signal integrity and minimizing power consumption.

The industrial and automotive sectors are also driving market demand for high-frequency communication devices. Smart factories and autonomous vehicles rely heavily on high-speed, low-latency communication for real-time data processing and decision-making. This has led to increased investment in research and development of advanced materials and components capable of operating at higher frequencies.

Polysilane, a silicon-based polymer, has emerged as a promising material for high-frequency communication devices due to its unique electrical and optical properties. The market for polysilane-based components is expected to grow as manufacturers seek to improve the performance and efficiency of their devices.

The aerospace and defense industries are also significant contributors to the demand for high-frequency communication devices. These sectors require robust, high-performance communication systems for radar, satellite communications, and electronic warfare applications. The use of advanced materials like polysilane in these applications is expected to drive further market growth.

Geographically, North America and Asia-Pacific are the leading regions in terms of market demand for high-frequency communication devices. The United States, China, Japan, and South Korea are at the forefront of 5G deployment and research into 6G technologies, creating substantial opportunities for manufacturers and suppliers of high-frequency components.

As the market continues to evolve, there is an increasing focus on developing more efficient and cost-effective solutions for high-frequency communication. This trend is likely to drive further innovation in materials science and device engineering, with polysilane and other advanced materials playing a crucial role in shaping the future of wireless communication technologies.

Polysilane Challenges

Despite the promising potential of polysilane in high-frequency communication devices, several significant challenges hinder its widespread adoption and implementation. One of the primary obstacles is the material's inherent instability when exposed to ultraviolet (UV) light. This photosensitivity can lead to degradation of the polysilane structure, potentially compromising the performance and longevity of devices incorporating this material.

Another major challenge lies in the synthesis and processing of polysilane. Current manufacturing methods often result in polydisperse products with varying chain lengths and molecular weights. This lack of uniformity can lead to inconsistent electrical and optical properties, making it difficult to achieve reliable and reproducible performance in high-frequency communication applications.

The integration of polysilane into existing semiconductor fabrication processes presents additional hurdles. Traditional silicon-based manufacturing techniques may not be directly applicable to polysilane, necessitating the development of new fabrication methods and equipment. This requirement for specialized processing can significantly increase production costs and complexity, potentially limiting the commercial viability of polysilane-based devices.

Thermal stability is another area of concern for polysilane in high-frequency applications. As communication devices often operate at elevated temperatures, the potential for thermal decomposition of polysilane structures must be carefully considered and mitigated. This challenge is particularly relevant in the context of maintaining long-term device reliability and performance under various operating conditions.

Furthermore, the electrical properties of polysilane, while promising, still fall short of those exhibited by traditional semiconductor materials in certain aspects. Improving charge carrier mobility and reducing resistivity remain ongoing challenges that researchers must address to fully realize the potential of polysilane in high-frequency communication devices.

Environmental and health considerations also pose challenges to the widespread adoption of polysilane. The potential toxicity and environmental impact of polysilane and its precursors during manufacturing and disposal must be thoroughly evaluated and addressed to ensure compliance with increasingly stringent regulations and sustainability requirements.

Lastly, the relatively limited body of research and industrial experience with polysilane in high-frequency applications presents a knowledge gap that must be bridged. This lack of extensive real-world data and established best practices can make it difficult for manufacturers and designers to confidently incorporate polysilane into their products, potentially slowing its adoption in the competitive field of high-frequency communication devices.

Another major challenge lies in the synthesis and processing of polysilane. Current manufacturing methods often result in polydisperse products with varying chain lengths and molecular weights. This lack of uniformity can lead to inconsistent electrical and optical properties, making it difficult to achieve reliable and reproducible performance in high-frequency communication applications.

The integration of polysilane into existing semiconductor fabrication processes presents additional hurdles. Traditional silicon-based manufacturing techniques may not be directly applicable to polysilane, necessitating the development of new fabrication methods and equipment. This requirement for specialized processing can significantly increase production costs and complexity, potentially limiting the commercial viability of polysilane-based devices.

Thermal stability is another area of concern for polysilane in high-frequency applications. As communication devices often operate at elevated temperatures, the potential for thermal decomposition of polysilane structures must be carefully considered and mitigated. This challenge is particularly relevant in the context of maintaining long-term device reliability and performance under various operating conditions.

Furthermore, the electrical properties of polysilane, while promising, still fall short of those exhibited by traditional semiconductor materials in certain aspects. Improving charge carrier mobility and reducing resistivity remain ongoing challenges that researchers must address to fully realize the potential of polysilane in high-frequency communication devices.

Environmental and health considerations also pose challenges to the widespread adoption of polysilane. The potential toxicity and environmental impact of polysilane and its precursors during manufacturing and disposal must be thoroughly evaluated and addressed to ensure compliance with increasingly stringent regulations and sustainability requirements.

Lastly, the relatively limited body of research and industrial experience with polysilane in high-frequency applications presents a knowledge gap that must be bridged. This lack of extensive real-world data and established best practices can make it difficult for manufacturers and designers to confidently incorporate polysilane into their products, potentially slowing its adoption in the competitive field of high-frequency communication devices.

Polysilane Solutions

01 Synthesis and properties of polysilanes

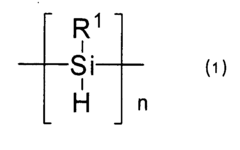

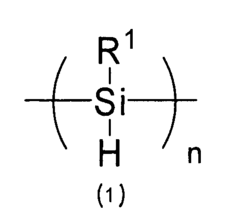

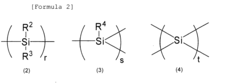

Polysilanes are silicon-based polymers with a backbone consisting of silicon atoms. They can be synthesized through various methods and exhibit unique optical and electronic properties. These materials have applications in photoresists, semiconductors, and optoelectronic devices due to their high thermal stability and conductivity.- Synthesis and properties of polysilanes: Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have a backbone consisting of silicon atoms and can be modified with different substituents. They possess interesting optical, electronic, and thermal properties, making them suitable for various applications in materials science and electronics.

- Applications in photoresists and lithography: Polysilanes are utilized in photoresist formulations and lithographic processes. Their photosensitivity and ability to undergo photochemical reactions make them valuable in the fabrication of microelectronic devices and semiconductor manufacturing. They can be used as positive or negative photoresists, offering high resolution and good etching resistance.

- Polysilane-based coatings and films: Polysilanes are employed in the development of functional coatings and thin films. These materials can be applied to various substrates to impart properties such as improved adhesion, chemical resistance, and optical characteristics. The films can be formed through techniques like spin-coating or vapor deposition, resulting in uniform and controllable thicknesses.

- Polysilane modifications and copolymers: Researchers have explored various modifications of polysilanes and the synthesis of copolymers to enhance their properties and expand their applications. This includes the incorporation of different functional groups, the creation of block copolymers, and the development of hybrid materials combining polysilanes with other polymers or inorganic components.

- Polysilanes in optoelectronic devices: Polysilanes have shown potential in optoelectronic applications due to their unique electronic properties. They can be used in the fabrication of light-emitting diodes, photovoltaic cells, and other electronic devices. The ability to tune their optical and electronic properties through structural modifications makes them versatile materials for these applications.

02 Polysilane-based coatings and films

Polysilanes can be used to create thin films and coatings with specific properties. These films can be applied to various substrates and may exhibit characteristics such as improved adhesion, chemical resistance, or optical properties. The formation of polysilane films often involves deposition techniques or solution-based methods.Expand Specific Solutions03 Polysilanes in photoresist applications

Polysilanes are utilized in photoresist formulations for semiconductor manufacturing. They can act as photosensitive materials or as additives to enhance the performance of photoresists. The silicon-based structure of polysilanes contributes to their effectiveness in lithography processes and pattern formation.Expand Specific Solutions04 Functionalization and modification of polysilanes

Polysilanes can be functionalized or modified to tailor their properties for specific applications. This may involve the incorporation of various functional groups, copolymerization with other monomers, or post-polymerization modifications. Such modifications can enhance the material's reactivity, solubility, or compatibility with other substances.Expand Specific Solutions05 Polysilanes in electronic and optoelectronic applications

The unique electronic structure of polysilanes makes them suitable for various electronic and optoelectronic applications. They can be used as charge transport materials, light-emitting components, or as precursors for silicon-based semiconductors. The delocalized σ-electrons along the silicon backbone contribute to their conductive and photoconductive properties.Expand Specific Solutions

HF Comm Key Players

The polysilane market in high-frequency communication devices is in an early growth stage, with increasing demand driven by the technology's potential to enhance device performance. The market size is relatively small but expanding rapidly as research and development efforts intensify. Technologically, polysilanes are still in the developmental phase, with companies like JSR Corp., Wacker Chemie AG, and Nippon Soda Co., Ltd. leading the way in advancing their applications. These firms are investing heavily in R&D to improve polysilane properties and manufacturing processes, aiming to unlock their full potential in high-frequency communications. As the technology matures, we can expect increased adoption and market growth, with competition likely to intensify among key players.

JSR Corp.

Technical Solution: JSR Corp. has developed advanced polysilane materials for high-frequency communication devices. Their proprietary synthesis method produces high-purity polysilanes with controlled molecular weight and narrow polydispersity[1]. These materials exhibit excellent dielectric properties, with low dielectric constants (k < 2.5) and low dielectric loss tangents (tan δ < 0.001) at frequencies up to 100 GHz[2]. JSR's polysilanes are incorporated into advanced substrates and packaging materials for 5G and mmWave applications, enabling improved signal integrity and reduced insertion loss in high-speed interconnects[3].

Strengths: Superior dielectric properties, precise molecular control, proven performance in high-frequency applications. Weaknesses: Potentially higher cost compared to traditional materials, limited long-term stability data.

Fujitsu Ltd.

Technical Solution: Fujitsu has developed polysilane-based materials for high-frequency communication devices, focusing on their application in next-generation wireless networks. Their research has led to the creation of polysilane-composite materials that exhibit low dielectric loss and high thermal stability[1]. These materials are utilized in the fabrication of high-performance antenna substrates and radomes for 5G and beyond 5G (B5G) systems. Fujitsu's polysilane technology enables the production of lightweight, highly transparent, and thermally resistant components that can withstand the demanding conditions of high-frequency operations[2]. The company has also explored the integration of polysilanes into flexible electronics for wearable communication devices[3].

Strengths: Advanced composite formulations, proven applications in 5G systems, versatility in form factors. Weaknesses: Potential scalability challenges, limited public data on long-term reliability.

Polysilane Innovations

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Polysilane and resin composition containing polysilane

PatentInactiveEP1958979A1

Innovation

- Introducing a Si-H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups such as hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Regulatory Framework

The regulatory framework surrounding the use of polysilane in high-frequency communication devices is a complex and evolving landscape. As the technology advances, regulatory bodies worldwide are adapting their policies to ensure safety, compatibility, and fair competition in the market.

At the international level, the International Telecommunication Union (ITU) plays a crucial role in setting standards for high-frequency communication devices. The ITU-R (Radiocommunication Sector) regularly updates its recommendations to accommodate new technologies, including those incorporating polysilane-based components. These guidelines influence national regulatory policies and help maintain global interoperability of communication systems.

In the United States, the Federal Communications Commission (FCC) oversees the regulation of high-frequency communication devices. The FCC's Part 15 rules govern unlicensed radio frequency devices, which may include polysilane-based technologies. Manufacturers must ensure their products comply with emission limits and other technical requirements set forth by the FCC before bringing them to market.

The European Union has established the Radio Equipment Directive (RED) 2014/53/EU, which applies to all radio equipment placed on the EU market. This directive includes essential requirements for safety, electromagnetic compatibility, and efficient use of the radio spectrum. Polysilane-based high-frequency communication devices must meet these standards to receive CE marking and be sold within the EU.

In Asia, countries like Japan and South Korea have their own regulatory bodies overseeing high-frequency communication devices. Japan's Ministry of Internal Affairs and Communications (MIC) and South Korea's National Radio Research Agency (RRA) set specific technical standards and certification processes for such devices.

As polysilane technology continues to develop, regulatory frameworks are likely to evolve. Emerging concerns such as data privacy, cybersecurity, and environmental impact may lead to additional regulations. For instance, the potential use of polysilane in 5G and future 6G networks may prompt regulators to address specific safety and performance standards for these applications.

Manufacturers and researchers working with polysilane in high-frequency communication devices must stay informed about these regulatory developments. Compliance with current and emerging regulations is essential for successful market entry and long-term viability of products incorporating this technology. Additionally, active engagement with regulatory bodies and industry associations can help shape future policies that support innovation while ensuring public safety and fair competition.

At the international level, the International Telecommunication Union (ITU) plays a crucial role in setting standards for high-frequency communication devices. The ITU-R (Radiocommunication Sector) regularly updates its recommendations to accommodate new technologies, including those incorporating polysilane-based components. These guidelines influence national regulatory policies and help maintain global interoperability of communication systems.

In the United States, the Federal Communications Commission (FCC) oversees the regulation of high-frequency communication devices. The FCC's Part 15 rules govern unlicensed radio frequency devices, which may include polysilane-based technologies. Manufacturers must ensure their products comply with emission limits and other technical requirements set forth by the FCC before bringing them to market.

The European Union has established the Radio Equipment Directive (RED) 2014/53/EU, which applies to all radio equipment placed on the EU market. This directive includes essential requirements for safety, electromagnetic compatibility, and efficient use of the radio spectrum. Polysilane-based high-frequency communication devices must meet these standards to receive CE marking and be sold within the EU.

In Asia, countries like Japan and South Korea have their own regulatory bodies overseeing high-frequency communication devices. Japan's Ministry of Internal Affairs and Communications (MIC) and South Korea's National Radio Research Agency (RRA) set specific technical standards and certification processes for such devices.

As polysilane technology continues to develop, regulatory frameworks are likely to evolve. Emerging concerns such as data privacy, cybersecurity, and environmental impact may lead to additional regulations. For instance, the potential use of polysilane in 5G and future 6G networks may prompt regulators to address specific safety and performance standards for these applications.

Manufacturers and researchers working with polysilane in high-frequency communication devices must stay informed about these regulatory developments. Compliance with current and emerging regulations is essential for successful market entry and long-term viability of products incorporating this technology. Additionally, active engagement with regulatory bodies and industry associations can help shape future policies that support innovation while ensuring public safety and fair competition.

Environmental Impact

The environmental impact of polysilane in high-frequency communication devices is a critical aspect that requires careful consideration. As these devices become increasingly prevalent in our interconnected world, understanding their ecological footprint is essential for sustainable technological advancement.

Polysilane, a silicon-based polymer, offers unique properties that make it valuable for high-frequency communication applications. However, its production and use have several environmental implications. The synthesis of polysilane often involves energy-intensive processes and the use of potentially hazardous chemicals, which can contribute to air and water pollution if not properly managed.

One of the primary environmental concerns is the disposal of devices containing polysilane at the end of their lifecycle. Electronic waste (e-waste) is a growing global issue, and the presence of silicon-based polymers in communication devices adds to the complexity of recycling and proper disposal. Improper handling of e-waste containing polysilane can lead to soil and groundwater contamination.

On the other hand, the use of polysilane in high-frequency communication devices may offer some environmental benefits. The material's unique properties can potentially lead to more energy-efficient devices, reducing power consumption and extending battery life. This, in turn, could result in lower overall energy demand and reduced carbon emissions associated with device charging and operation.

Furthermore, the durability and stability of polysilane-based components may contribute to longer-lasting devices, potentially reducing the frequency of replacements and, consequently, the volume of e-waste generated. However, this potential benefit must be balanced against the challenges of recycling and disposing of these more complex materials.

Research into more environmentally friendly synthesis methods for polysilane is ongoing. Green chemistry approaches, such as using less toxic solvents and catalysts, are being explored to minimize the environmental impact of production processes. Additionally, efforts are being made to develop more efficient recycling techniques specifically tailored for devices containing silicon-based polymers.

As the demand for high-frequency communication devices continues to grow, it is crucial to consider the entire lifecycle of polysilane-based components. This includes not only their production and use but also their eventual disposal or recycling. Implementing circular economy principles in the design and manufacturing of these devices could significantly mitigate their environmental impact.

Polysilane, a silicon-based polymer, offers unique properties that make it valuable for high-frequency communication applications. However, its production and use have several environmental implications. The synthesis of polysilane often involves energy-intensive processes and the use of potentially hazardous chemicals, which can contribute to air and water pollution if not properly managed.

One of the primary environmental concerns is the disposal of devices containing polysilane at the end of their lifecycle. Electronic waste (e-waste) is a growing global issue, and the presence of silicon-based polymers in communication devices adds to the complexity of recycling and proper disposal. Improper handling of e-waste containing polysilane can lead to soil and groundwater contamination.

On the other hand, the use of polysilane in high-frequency communication devices may offer some environmental benefits. The material's unique properties can potentially lead to more energy-efficient devices, reducing power consumption and extending battery life. This, in turn, could result in lower overall energy demand and reduced carbon emissions associated with device charging and operation.

Furthermore, the durability and stability of polysilane-based components may contribute to longer-lasting devices, potentially reducing the frequency of replacements and, consequently, the volume of e-waste generated. However, this potential benefit must be balanced against the challenges of recycling and disposing of these more complex materials.

Research into more environmentally friendly synthesis methods for polysilane is ongoing. Green chemistry approaches, such as using less toxic solvents and catalysts, are being explored to minimize the environmental impact of production processes. Additionally, efforts are being made to develop more efficient recycling techniques specifically tailored for devices containing silicon-based polymers.

As the demand for high-frequency communication devices continues to grow, it is crucial to consider the entire lifecycle of polysilane-based components. This includes not only their production and use but also their eventual disposal or recycling. Implementing circular economy principles in the design and manufacturing of these devices could significantly mitigate their environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!