The Use of Calorimetry in Examining Propellant Stability

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propellant Stability Calorimetry Background

Calorimetry has been a cornerstone technique in examining propellant stability for several decades. This analytical method provides crucial insights into the thermal behavior and decomposition characteristics of propellants, which are essential for ensuring the safety and reliability of various propulsion systems. The background of propellant stability calorimetry is rooted in the fundamental need to understand and predict the long-term behavior of energetic materials under different environmental conditions.

The development of calorimetric techniques for propellant stability analysis can be traced back to the mid-20th century when the increasing complexity of propellant formulations necessitated more sophisticated analytical methods. Early studies focused on simple heat measurement techniques, which gradually evolved into more advanced differential scanning calorimetry (DSC) and isothermal microcalorimetry methods. These advancements allowed researchers to obtain more precise and detailed information about the thermal properties and stability of propellants.

Propellant stability is a critical factor in the performance and safety of rocket motors, missiles, and other propulsion systems. Unstable propellants can lead to catastrophic failures, posing significant risks to personnel and equipment. The use of calorimetry in examining propellant stability addresses this concern by providing quantitative data on heat generation, decomposition rates, and activation energies associated with propellant degradation processes.

One of the primary objectives of propellant stability calorimetry is to assess the shelf life of propellants under various storage conditions. This involves studying the slow decomposition processes that occur over extended periods, which can ultimately affect the propellant's performance and safety. Calorimetric techniques allow researchers to accelerate these processes through controlled heating, enabling the prediction of long-term stability from relatively short-term experiments.

The application of calorimetry in propellant stability analysis extends beyond simple thermal measurements. It encompasses a range of specialized techniques, including heat flow calorimetry, reaction calorimetry, and accelerating rate calorimetry. These methods provide complementary information on different aspects of propellant behavior, such as heat release rates, reaction kinetics, and self-heating tendencies.

As propellant formulations have become increasingly complex, incorporating a wide range of energetic materials, stabilizers, and additives, the role of calorimetry in stability assessment has grown more critical. Modern calorimetric studies often involve the analysis of multi-component systems, requiring sophisticated data interpretation and modeling techniques to extract meaningful stability parameters.

The background of propellant stability calorimetry also encompasses the development of standardized testing protocols and safety regulations. Organizations such as ASTM International and various military agencies have established guidelines for conducting calorimetric analyses of propellants, ensuring consistency and reliability in stability assessments across different laboratories and applications.

The development of calorimetric techniques for propellant stability analysis can be traced back to the mid-20th century when the increasing complexity of propellant formulations necessitated more sophisticated analytical methods. Early studies focused on simple heat measurement techniques, which gradually evolved into more advanced differential scanning calorimetry (DSC) and isothermal microcalorimetry methods. These advancements allowed researchers to obtain more precise and detailed information about the thermal properties and stability of propellants.

Propellant stability is a critical factor in the performance and safety of rocket motors, missiles, and other propulsion systems. Unstable propellants can lead to catastrophic failures, posing significant risks to personnel and equipment. The use of calorimetry in examining propellant stability addresses this concern by providing quantitative data on heat generation, decomposition rates, and activation energies associated with propellant degradation processes.

One of the primary objectives of propellant stability calorimetry is to assess the shelf life of propellants under various storage conditions. This involves studying the slow decomposition processes that occur over extended periods, which can ultimately affect the propellant's performance and safety. Calorimetric techniques allow researchers to accelerate these processes through controlled heating, enabling the prediction of long-term stability from relatively short-term experiments.

The application of calorimetry in propellant stability analysis extends beyond simple thermal measurements. It encompasses a range of specialized techniques, including heat flow calorimetry, reaction calorimetry, and accelerating rate calorimetry. These methods provide complementary information on different aspects of propellant behavior, such as heat release rates, reaction kinetics, and self-heating tendencies.

As propellant formulations have become increasingly complex, incorporating a wide range of energetic materials, stabilizers, and additives, the role of calorimetry in stability assessment has grown more critical. Modern calorimetric studies often involve the analysis of multi-component systems, requiring sophisticated data interpretation and modeling techniques to extract meaningful stability parameters.

The background of propellant stability calorimetry also encompasses the development of standardized testing protocols and safety regulations. Organizations such as ASTM International and various military agencies have established guidelines for conducting calorimetric analyses of propellants, ensuring consistency and reliability in stability assessments across different laboratories and applications.

Market Demand Analysis

The market demand for calorimetry in examining propellant stability has been steadily growing, driven by the increasing focus on safety and reliability in various industries that utilize propellants. The aerospace and defense sectors are the primary drivers of this demand, as they require precise and reliable methods to assess the stability of propellants used in rockets, missiles, and other propulsion systems.

In the aerospace industry, the global market for propulsion systems is projected to reach significant values in the coming years, with a substantial portion dedicated to research and development of propellant technologies. This growth directly correlates with the demand for advanced calorimetry techniques in propellant stability testing.

The defense sector also contributes significantly to the market demand. With ongoing geopolitical tensions and the need for modernization of military equipment, there is a continuous requirement for advanced propellant technologies. This, in turn, fuels the demand for sophisticated calorimetry methods to ensure the safety and longevity of these propellants.

Beyond aerospace and defense, other industries such as automotive, mining, and oil & gas also utilize propellants in various applications, further expanding the market for calorimetry in propellant stability testing. The automotive industry, in particular, is showing increased interest in alternative propellants for next-generation vehicles, necessitating advanced stability testing methods.

The market is also being driven by stringent safety regulations and standards imposed by government agencies and industry bodies. These regulations require thorough testing and validation of propellant stability, creating a sustained demand for calorimetry techniques.

Technological advancements in calorimetry equipment are another factor influencing market growth. Manufacturers are developing more sensitive, accurate, and automated calorimetry systems, making them more attractive to end-users and potentially expanding the market.

Geographically, North America and Europe currently dominate the market due to their well-established aerospace and defense industries. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by increasing investments in space programs and defense modernization efforts in countries like China and India.

In conclusion, the market demand for calorimetry in examining propellant stability is robust and expected to grow. This growth is primarily fueled by the aerospace and defense sectors, supported by other industries, and driven by factors such as safety regulations, technological advancements, and expanding applications of propellants across various fields.

In the aerospace industry, the global market for propulsion systems is projected to reach significant values in the coming years, with a substantial portion dedicated to research and development of propellant technologies. This growth directly correlates with the demand for advanced calorimetry techniques in propellant stability testing.

The defense sector also contributes significantly to the market demand. With ongoing geopolitical tensions and the need for modernization of military equipment, there is a continuous requirement for advanced propellant technologies. This, in turn, fuels the demand for sophisticated calorimetry methods to ensure the safety and longevity of these propellants.

Beyond aerospace and defense, other industries such as automotive, mining, and oil & gas also utilize propellants in various applications, further expanding the market for calorimetry in propellant stability testing. The automotive industry, in particular, is showing increased interest in alternative propellants for next-generation vehicles, necessitating advanced stability testing methods.

The market is also being driven by stringent safety regulations and standards imposed by government agencies and industry bodies. These regulations require thorough testing and validation of propellant stability, creating a sustained demand for calorimetry techniques.

Technological advancements in calorimetry equipment are another factor influencing market growth. Manufacturers are developing more sensitive, accurate, and automated calorimetry systems, making them more attractive to end-users and potentially expanding the market.

Geographically, North America and Europe currently dominate the market due to their well-established aerospace and defense industries. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years, driven by increasing investments in space programs and defense modernization efforts in countries like China and India.

In conclusion, the market demand for calorimetry in examining propellant stability is robust and expected to grow. This growth is primarily fueled by the aerospace and defense sectors, supported by other industries, and driven by factors such as safety regulations, technological advancements, and expanding applications of propellants across various fields.

Current Challenges

The use of calorimetry in examining propellant stability faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the complexity of propellant compositions, which often contain multiple ingredients interacting in intricate ways. This complexity makes it difficult to isolate and accurately measure the thermal properties of individual components, potentially leading to misinterpretation of calorimetric data.

Another challenge lies in the sensitivity of calorimetric measurements to environmental factors. Temperature fluctuations, humidity, and atmospheric pressure can all influence the results, necessitating stringent control measures that are often difficult to maintain consistently across different testing environments. This sensitivity can lead to variability in results and challenges in reproducing experiments, which is crucial for validating propellant stability assessments.

The time-dependent nature of propellant degradation poses an additional hurdle. Calorimetric techniques must be capable of detecting subtle changes over extended periods, as some degradation processes occur slowly. This requirement for long-term monitoring increases the cost and complexity of stability studies, making it challenging to implement in large-scale production or quality control settings.

Furthermore, the high-energy nature of propellants presents safety concerns when conducting calorimetric tests. Specialized equipment and safety protocols are necessary to prevent accidental ignition or explosion during analysis, which can limit the accessibility of these techniques to specialized laboratories with appropriate facilities.

There is also a lack of standardization in calorimetric methods for propellant stability testing. Different laboratories and researchers may employ varying protocols, making it difficult to compare results across studies or establish industry-wide benchmarks. This absence of standardization hampers the development of universal stability criteria and complicates regulatory compliance efforts.

The interpretation of calorimetric data for complex propellant systems remains a significant challenge. Advanced modeling and data analysis techniques are required to extract meaningful information from the thermal profiles, particularly when dealing with multi-component propellants or those with non-linear degradation behaviors. The development of robust analytical models that can accurately predict long-term stability from short-term calorimetric data is an ongoing area of research.

Lastly, the cost and expertise required for sophisticated calorimetric equipment and analysis can be prohibitive for smaller organizations or research groups. This limitation may impede innovation in propellant development and restrict stability testing to larger, well-funded institutions, potentially slowing overall progress in the field.

Another challenge lies in the sensitivity of calorimetric measurements to environmental factors. Temperature fluctuations, humidity, and atmospheric pressure can all influence the results, necessitating stringent control measures that are often difficult to maintain consistently across different testing environments. This sensitivity can lead to variability in results and challenges in reproducing experiments, which is crucial for validating propellant stability assessments.

The time-dependent nature of propellant degradation poses an additional hurdle. Calorimetric techniques must be capable of detecting subtle changes over extended periods, as some degradation processes occur slowly. This requirement for long-term monitoring increases the cost and complexity of stability studies, making it challenging to implement in large-scale production or quality control settings.

Furthermore, the high-energy nature of propellants presents safety concerns when conducting calorimetric tests. Specialized equipment and safety protocols are necessary to prevent accidental ignition or explosion during analysis, which can limit the accessibility of these techniques to specialized laboratories with appropriate facilities.

There is also a lack of standardization in calorimetric methods for propellant stability testing. Different laboratories and researchers may employ varying protocols, making it difficult to compare results across studies or establish industry-wide benchmarks. This absence of standardization hampers the development of universal stability criteria and complicates regulatory compliance efforts.

The interpretation of calorimetric data for complex propellant systems remains a significant challenge. Advanced modeling and data analysis techniques are required to extract meaningful information from the thermal profiles, particularly when dealing with multi-component propellants or those with non-linear degradation behaviors. The development of robust analytical models that can accurately predict long-term stability from short-term calorimetric data is an ongoing area of research.

Lastly, the cost and expertise required for sophisticated calorimetric equipment and analysis can be prohibitive for smaller organizations or research groups. This limitation may impede innovation in propellant development and restrict stability testing to larger, well-funded institutions, potentially slowing overall progress in the field.

Existing Calorimetry Methods

01 Thermal stability in calorimetry devices

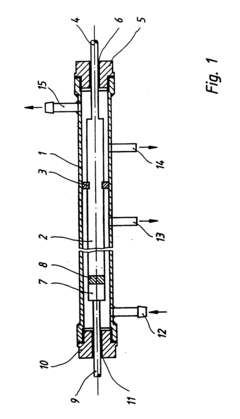

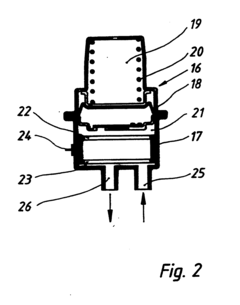

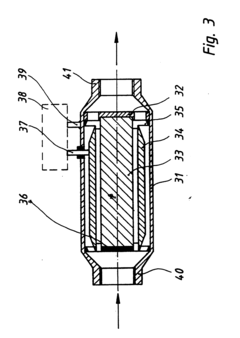

Calorimetry devices are designed with features to enhance thermal stability during measurements. This includes temperature control systems, insulation materials, and structural designs that minimize heat loss or gain. Improved thermal stability ensures more accurate and reliable calorimetric measurements across various applications.- Thermal stability in calorimetry devices: Calorimetry devices are designed with features to ensure thermal stability during measurements. This includes temperature control systems, insulation materials, and heat flow sensors that maintain consistent conditions for accurate results. Improved thermal stability allows for more precise measurements of heat changes in chemical or physical processes.

- Calibration techniques for calorimetry stability: Various calibration techniques are employed to enhance the stability and accuracy of calorimetry measurements. These may include the use of reference materials, standardized procedures, and automated calibration systems. Regular calibration helps to compensate for instrument drift and ensures consistent results over time.

- Advanced sensor technology for improved stability: Calorimetry devices incorporate advanced sensor technologies to improve measurement stability. This includes high-precision thermocouples, thermistors, and other temperature-sensing elements that can detect minute changes in heat flow. These sensors are often coupled with signal processing algorithms to reduce noise and enhance overall stability.

- Software and data analysis for stability enhancement: Sophisticated software and data analysis techniques are used to enhance the stability of calorimetry measurements. These may include real-time data processing, statistical analysis, and error correction algorithms. Such software tools can help identify and compensate for factors that may affect measurement stability, such as environmental fluctuations or sample inconsistencies.

- Design innovations for long-term stability: Calorimetry instruments are designed with features that promote long-term stability. This may include the use of corrosion-resistant materials, modular components for easy maintenance, and robust construction to minimize wear and tear. These design innovations help ensure consistent performance over extended periods of use and reduce the need for frequent recalibration or replacement.

02 Calibration methods for calorimetry stability

Calibration techniques are crucial for maintaining calorimetry stability. These methods involve using reference materials, standardized procedures, and advanced algorithms to ensure accurate and consistent measurements. Regular calibration helps compensate for instrument drift and environmental factors that may affect calorimetric results.Expand Specific Solutions03 Advanced sensor technologies for stable calorimetry

Innovative sensor technologies are employed to enhance calorimetry stability. These may include high-precision thermocouples, thermistors, or optical sensors that offer improved sensitivity and reduced noise. Advanced sensors contribute to more stable and accurate temperature measurements in calorimetric analyses.Expand Specific Solutions04 Software algorithms for data processing and stability

Sophisticated software algorithms are developed to process calorimetric data and improve measurement stability. These algorithms can compensate for environmental fluctuations, apply drift corrections, and filter out noise. By enhancing data processing, the overall stability and reliability of calorimetric measurements are improved.Expand Specific Solutions05 Design of sample holders for improved stability

Specialized sample holders are designed to enhance calorimetry stability. These holders may incorporate materials with low thermal conductivity, precise volume control, or unique geometries that minimize thermal gradients. Well-designed sample holders contribute to more stable and reproducible calorimetric measurements across various sample types.Expand Specific Solutions

Key Industry Players

The use of calorimetry in examining propellant stability is a critical area of research in the aerospace and defense industries, currently in a mature development stage. The market for this technology is substantial, driven by the growing demand for reliable and safe propellants in various applications. Companies like Shanghai Aerospace Chemical Industry Application Research Institute, Xi'an Modern Chemistry Research Institute, and Airbus Defence & Space SAS are at the forefront of this field, leveraging advanced calorimetric techniques to assess and enhance propellant stability. The technology's maturity is evident in its widespread adoption across academic institutions such as Northwestern Polytechnical University and Texas A&M University, as well as research organizations like the Naval Research Laboratory, indicating a well-established ecosystem of knowledge and expertise in this domain.

Shanghai Aerospace Chemical Industry Application Research Institute

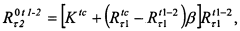

Technical Solution: The institute has developed advanced calorimetry techniques for examining propellant stability. They utilize differential scanning calorimetry (DSC) and accelerating rate calorimetry (ARC) to analyze the thermal behavior and decomposition kinetics of solid propellants[1]. Their method involves precise temperature control and measurement of heat flow, allowing for the detection of exothermic reactions that indicate propellant instability. The institute has also implemented isothermal microcalorimetry for long-term stability studies, enabling the prediction of propellant shelf life under various storage conditions[2].

Strengths: Comprehensive calorimetry techniques, long-term stability prediction capabilities. Weaknesses: Potential limitations in simulating real-world storage and usage conditions.

Hubei Aerospace Chemical Technology Research Institute

Technical Solution: The institute employs a multi-faceted approach to propellant stability examination using calorimetry. They have developed a high-precision adiabatic calorimeter specifically designed for energetic materials[3]. This system allows for the measurement of heat generation rates as low as 50 μW/g, enabling the detection of subtle changes in propellant composition over time. Additionally, they utilize thermogravimetric analysis (TGA) in conjunction with DSC to correlate mass loss with thermal events, providing insights into the degradation mechanisms of propellants[4].

Strengths: High-precision measurements, correlation of thermal events with mass changes. Weaknesses: Complexity of equipment may limit widespread adoption.

Core Calorimetric Innovations

Method for the determination of the alcohol content and/or the calorific value of fuels

PatentInactiveEP0379644A1

Innovation

- A method utilizing a capacitor dielectric measurement with a component of the fuel system acting as a counter-electrode, combined with conductance measurement, to provide precise and reliable determination of fuel properties, reducing costs and improving mechanical and electrical protection.

Method for determining the concentration of hot gases in an oxygen-containing medium

PatentWO2000050881A1

Innovation

- The method involves measuring the resistance of a thermal catalytic element at specific moments before and during electric current pulses, calculating a constant coefficient to determine gas concentrations without the need for thermal shock heating, allowing for compensation of temperature changes and reducing energy consumption.

Safety Regulations

The use of calorimetry in examining propellant stability necessitates strict adherence to safety regulations due to the potentially hazardous nature of the materials and processes involved. These regulations are designed to protect personnel, facilities, and the environment from the risks associated with propellant handling and testing.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) in the United States, as well as their counterparts in other countries, have established comprehensive guidelines for the safe handling and testing of propellants. These regulations cover various aspects of calorimetric testing, including laboratory design, equipment specifications, and operational procedures.

One of the primary safety concerns in propellant calorimetry is the potential for uncontrolled exothermic reactions. To mitigate this risk, regulations mandate the use of specialized calorimeters designed to withstand sudden pressure increases and contain potential explosions. These instruments must be equipped with robust pressure relief systems and be housed in reinforced testing chambers.

Personal protective equipment (PPE) requirements are another crucial aspect of safety regulations in propellant calorimetry. Operators are typically required to wear flame-resistant clothing, safety goggles, and appropriate gloves. In some cases, full-body protective suits and respirators may be necessary, depending on the specific propellants being tested and the nature of the calorimetric experiments.

Regulations also dictate strict protocols for sample preparation and handling. This includes limitations on sample size to minimize the potential impact of an uncontrolled reaction, as well as guidelines for proper storage and transportation of propellant materials. Many jurisdictions require special licensing and permits for facilities conducting propellant calorimetry, with regular inspections to ensure compliance with safety standards.

Emergency response planning is a critical component of safety regulations in this field. Facilities must have well-documented and regularly practiced emergency procedures, including evacuation plans, fire suppression systems, and protocols for containing and neutralizing chemical spills. Additionally, regulations often mandate the presence of specialized fire-fighting equipment and trained personnel capable of responding to propellant-related incidents.

Environmental considerations are also addressed in safety regulations for propellant calorimetry. This includes proper disposal methods for waste materials, emissions control, and measures to prevent contamination of soil and water resources. Facilities are typically required to maintain detailed records of all testing activities, including any safety incidents or near-misses, to facilitate regulatory oversight and continuous improvement of safety practices.

In conclusion, safety regulations play a vital role in ensuring that calorimetric examinations of propellant stability are conducted with minimal risk to personnel and the environment. Compliance with these regulations is not only a legal requirement but also an ethical imperative in the field of propellant research and development.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) in the United States, as well as their counterparts in other countries, have established comprehensive guidelines for the safe handling and testing of propellants. These regulations cover various aspects of calorimetric testing, including laboratory design, equipment specifications, and operational procedures.

One of the primary safety concerns in propellant calorimetry is the potential for uncontrolled exothermic reactions. To mitigate this risk, regulations mandate the use of specialized calorimeters designed to withstand sudden pressure increases and contain potential explosions. These instruments must be equipped with robust pressure relief systems and be housed in reinforced testing chambers.

Personal protective equipment (PPE) requirements are another crucial aspect of safety regulations in propellant calorimetry. Operators are typically required to wear flame-resistant clothing, safety goggles, and appropriate gloves. In some cases, full-body protective suits and respirators may be necessary, depending on the specific propellants being tested and the nature of the calorimetric experiments.

Regulations also dictate strict protocols for sample preparation and handling. This includes limitations on sample size to minimize the potential impact of an uncontrolled reaction, as well as guidelines for proper storage and transportation of propellant materials. Many jurisdictions require special licensing and permits for facilities conducting propellant calorimetry, with regular inspections to ensure compliance with safety standards.

Emergency response planning is a critical component of safety regulations in this field. Facilities must have well-documented and regularly practiced emergency procedures, including evacuation plans, fire suppression systems, and protocols for containing and neutralizing chemical spills. Additionally, regulations often mandate the presence of specialized fire-fighting equipment and trained personnel capable of responding to propellant-related incidents.

Environmental considerations are also addressed in safety regulations for propellant calorimetry. This includes proper disposal methods for waste materials, emissions control, and measures to prevent contamination of soil and water resources. Facilities are typically required to maintain detailed records of all testing activities, including any safety incidents or near-misses, to facilitate regulatory oversight and continuous improvement of safety practices.

In conclusion, safety regulations play a vital role in ensuring that calorimetric examinations of propellant stability are conducted with minimal risk to personnel and the environment. Compliance with these regulations is not only a legal requirement but also an ethical imperative in the field of propellant research and development.

Environmental Impact

The use of calorimetry in examining propellant stability has significant environmental implications that extend beyond the immediate scope of propellant research. As propellants are inherently energetic materials, their stability and decomposition processes can have far-reaching effects on the environment.

One of the primary environmental concerns associated with propellant stability is the potential release of harmful substances during storage, handling, and disposal. Calorimetric studies help identify the thermal decomposition pathways of propellants, which can lead to the formation of toxic gases, particulate matter, and other pollutants. By understanding these processes, researchers can develop strategies to minimize environmental contamination and implement safer storage and disposal protocols.

The environmental impact of propellant instability is particularly pronounced in cases of accidental ignition or uncontrolled decomposition. Calorimetry provides crucial data on the heat release rates and activation energies of propellants, allowing for more accurate risk assessments and the development of improved safety measures. This information is vital for preventing catastrophic events that could result in widespread environmental damage, including soil and water contamination.

Furthermore, calorimetric analysis contributes to the development of more environmentally friendly propellants. By identifying the specific chemical reactions and energy transfers involved in propellant decomposition, researchers can design formulations with reduced environmental footprints. This may include propellants that produce fewer toxic byproducts or those that degrade more readily in the environment without leaving persistent contaminants.

The use of calorimetry also plays a role in assessing the long-term environmental effects of propellant residues. As propellants age or are subjected to various environmental conditions, their stability can change, potentially leading to the slow release of harmful compounds into the surrounding ecosystem. Calorimetric studies help predict these long-term behaviors, enabling the implementation of proactive measures to protect soil, water resources, and local flora and fauna.

In the context of climate change, the stability of propellants takes on additional significance. Calorimetric investigations can reveal how propellants respond to changing environmental conditions, such as increased temperatures or humidity levels. This information is crucial for adapting storage and handling practices to mitigate the potential for increased instability and environmental risks in a changing climate.

Lastly, the environmental impact of propellant stability extends to the realm of space exploration and satellite technology. Calorimetric studies contribute to the development of propellants that not only perform efficiently but also minimize space debris and atmospheric contamination upon re-entry. This aspect of environmental consideration is becoming increasingly important as space activities intensify and the need for sustainable space practices grows.

One of the primary environmental concerns associated with propellant stability is the potential release of harmful substances during storage, handling, and disposal. Calorimetric studies help identify the thermal decomposition pathways of propellants, which can lead to the formation of toxic gases, particulate matter, and other pollutants. By understanding these processes, researchers can develop strategies to minimize environmental contamination and implement safer storage and disposal protocols.

The environmental impact of propellant instability is particularly pronounced in cases of accidental ignition or uncontrolled decomposition. Calorimetry provides crucial data on the heat release rates and activation energies of propellants, allowing for more accurate risk assessments and the development of improved safety measures. This information is vital for preventing catastrophic events that could result in widespread environmental damage, including soil and water contamination.

Furthermore, calorimetric analysis contributes to the development of more environmentally friendly propellants. By identifying the specific chemical reactions and energy transfers involved in propellant decomposition, researchers can design formulations with reduced environmental footprints. This may include propellants that produce fewer toxic byproducts or those that degrade more readily in the environment without leaving persistent contaminants.

The use of calorimetry also plays a role in assessing the long-term environmental effects of propellant residues. As propellants age or are subjected to various environmental conditions, their stability can change, potentially leading to the slow release of harmful compounds into the surrounding ecosystem. Calorimetric studies help predict these long-term behaviors, enabling the implementation of proactive measures to protect soil, water resources, and local flora and fauna.

In the context of climate change, the stability of propellants takes on additional significance. Calorimetric investigations can reveal how propellants respond to changing environmental conditions, such as increased temperatures or humidity levels. This information is crucial for adapting storage and handling practices to mitigate the potential for increased instability and environmental risks in a changing climate.

Lastly, the environmental impact of propellant stability extends to the realm of space exploration and satellite technology. Calorimetric studies contribute to the development of propellants that not only perform efficiently but also minimize space debris and atmospheric contamination upon re-entry. This aspect of environmental consideration is becoming increasingly important as space activities intensify and the need for sustainable space practices grows.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!