The Use of Magnesium Carbonate in Fracture Stimulation Materials

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Carbonate in Fracturing: Background and Objectives

Magnesium carbonate has emerged as a promising material in fracture stimulation, marking a significant evolution in hydraulic fracturing technology. The use of this compound in fracturing fluids represents a shift towards more environmentally friendly and efficient stimulation methods. Historically, fracturing techniques have relied heavily on various chemicals and proppants to enhance oil and gas recovery from unconventional reservoirs. However, growing environmental concerns and the need for improved performance have driven the industry to explore alternative materials.

The development of magnesium carbonate as a fracturing material is rooted in the broader context of the oil and gas industry's pursuit of sustainable and effective extraction methods. This technology aims to address several key challenges faced by traditional fracturing techniques, including environmental impact, well productivity, and operational efficiency. The integration of magnesium carbonate into fracturing fluids represents a convergence of chemical engineering, geology, and environmental science, highlighting the multidisciplinary nature of modern oil and gas extraction technologies.

The primary objective of utilizing magnesium carbonate in fracture stimulation is to enhance the effectiveness of hydraulic fracturing while minimizing environmental footprint. This material is expected to improve proppant transport, increase fracture conductivity, and potentially reduce water usage in fracturing operations. Additionally, the use of magnesium carbonate aligns with the industry's goals of developing more sustainable practices and meeting increasingly stringent environmental regulations.

From a technical perspective, magnesium carbonate offers unique properties that make it suitable for fracturing applications. Its solubility characteristics and reaction with acidic components in the formation can lead to the creation of flow channels, potentially enhancing hydrocarbon recovery. The material's ability to degrade over time also presents opportunities for self-removing proppants, which could simplify well clean-up processes and reduce formation damage.

The evolution of this technology is closely tied to advancements in material science and a deeper understanding of reservoir dynamics. Researchers and industry professionals are exploring various formulations and applications of magnesium carbonate to optimize its performance under different geological conditions. This ongoing research aims to fine-tune the material's properties, such as particle size distribution, reactivity, and mechanical strength, to meet the specific requirements of diverse fracturing scenarios.

As the oil and gas industry continues to face pressure to reduce its environmental impact, the development of magnesium carbonate-based fracturing materials represents a significant step towards more sustainable extraction methods. The technology's potential to improve operational efficiency while addressing environmental concerns positions it as a key area of focus for future research and development in the field of hydraulic fracturing.

The development of magnesium carbonate as a fracturing material is rooted in the broader context of the oil and gas industry's pursuit of sustainable and effective extraction methods. This technology aims to address several key challenges faced by traditional fracturing techniques, including environmental impact, well productivity, and operational efficiency. The integration of magnesium carbonate into fracturing fluids represents a convergence of chemical engineering, geology, and environmental science, highlighting the multidisciplinary nature of modern oil and gas extraction technologies.

The primary objective of utilizing magnesium carbonate in fracture stimulation is to enhance the effectiveness of hydraulic fracturing while minimizing environmental footprint. This material is expected to improve proppant transport, increase fracture conductivity, and potentially reduce water usage in fracturing operations. Additionally, the use of magnesium carbonate aligns with the industry's goals of developing more sustainable practices and meeting increasingly stringent environmental regulations.

From a technical perspective, magnesium carbonate offers unique properties that make it suitable for fracturing applications. Its solubility characteristics and reaction with acidic components in the formation can lead to the creation of flow channels, potentially enhancing hydrocarbon recovery. The material's ability to degrade over time also presents opportunities for self-removing proppants, which could simplify well clean-up processes and reduce formation damage.

The evolution of this technology is closely tied to advancements in material science and a deeper understanding of reservoir dynamics. Researchers and industry professionals are exploring various formulations and applications of magnesium carbonate to optimize its performance under different geological conditions. This ongoing research aims to fine-tune the material's properties, such as particle size distribution, reactivity, and mechanical strength, to meet the specific requirements of diverse fracturing scenarios.

As the oil and gas industry continues to face pressure to reduce its environmental impact, the development of magnesium carbonate-based fracturing materials represents a significant step towards more sustainable extraction methods. The technology's potential to improve operational efficiency while addressing environmental concerns positions it as a key area of focus for future research and development in the field of hydraulic fracturing.

Market Analysis for Fracturing Materials

The fracturing materials market has experienced significant growth in recent years, driven by the increasing demand for oil and gas production through hydraulic fracturing techniques. This market segment is closely tied to the overall health of the oil and gas industry, which has shown resilience despite fluctuations in energy prices and environmental concerns.

The global fracturing materials market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the rising energy demand, particularly in developing economies, and the continuous exploration of unconventional oil and gas reserves.

North America, especially the United States, remains the largest market for fracturing materials, owing to its extensive shale gas and tight oil operations. However, other regions such as Asia-Pacific and the Middle East are showing increasing potential for market expansion as they develop their unconventional hydrocarbon resources.

The market for fracturing materials is diverse, encompassing proppants, friction reducers, gelling agents, crosslinkers, and other specialty chemicals. Among these, proppants hold the largest market share, with sand being the most commonly used material due to its cost-effectiveness. However, there is a growing trend towards the use of synthetic and resin-coated proppants for enhanced performance in challenging well conditions.

Magnesium carbonate, while not a primary component in most fracturing fluids, is gaining attention as a potential additive due to its unique properties. Its use in fracturing materials is still relatively niche but shows promise in certain applications, particularly where pH control and fluid stability are critical factors.

The market is characterized by intense competition among key players, including both multinational corporations and regional suppliers. These companies are investing heavily in research and development to improve the efficiency and environmental profile of their products, responding to increasing regulatory pressures and public concerns about the environmental impact of hydraulic fracturing.

Environmental regulations and the push for sustainable practices are significant factors shaping the fracturing materials market. There is a growing demand for eco-friendly and biodegradable fracturing materials, which is driving innovation in the sector. This trend is likely to continue, potentially opening new opportunities for materials like magnesium carbonate that may offer environmental advantages over traditional options.

The global fracturing materials market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the rising energy demand, particularly in developing economies, and the continuous exploration of unconventional oil and gas reserves.

North America, especially the United States, remains the largest market for fracturing materials, owing to its extensive shale gas and tight oil operations. However, other regions such as Asia-Pacific and the Middle East are showing increasing potential for market expansion as they develop their unconventional hydrocarbon resources.

The market for fracturing materials is diverse, encompassing proppants, friction reducers, gelling agents, crosslinkers, and other specialty chemicals. Among these, proppants hold the largest market share, with sand being the most commonly used material due to its cost-effectiveness. However, there is a growing trend towards the use of synthetic and resin-coated proppants for enhanced performance in challenging well conditions.

Magnesium carbonate, while not a primary component in most fracturing fluids, is gaining attention as a potential additive due to its unique properties. Its use in fracturing materials is still relatively niche but shows promise in certain applications, particularly where pH control and fluid stability are critical factors.

The market is characterized by intense competition among key players, including both multinational corporations and regional suppliers. These companies are investing heavily in research and development to improve the efficiency and environmental profile of their products, responding to increasing regulatory pressures and public concerns about the environmental impact of hydraulic fracturing.

Environmental regulations and the push for sustainable practices are significant factors shaping the fracturing materials market. There is a growing demand for eco-friendly and biodegradable fracturing materials, which is driving innovation in the sector. This trend is likely to continue, potentially opening new opportunities for materials like magnesium carbonate that may offer environmental advantages over traditional options.

Current Status and Challenges in Fracturing Technology

Hydraulic fracturing technology has evolved significantly over the past few decades, becoming a cornerstone of unconventional oil and gas production. Currently, the industry employs sophisticated fracturing techniques that involve injecting high-pressure fluids mixed with proppants into wellbores to create and maintain fractures in rock formations. These fractures enhance the flow of hydrocarbons, dramatically increasing well productivity.

The current status of fracturing technology is characterized by a focus on optimizing fluid chemistry, proppant selection, and pumping schedules. Advanced monitoring systems, including microseismic and fiber optic sensing, allow real-time adjustment of fracturing parameters. Additionally, the industry has made strides in developing environmentally friendly fracturing fluids and more efficient proppant materials.

Despite these advancements, fracturing technology faces several significant challenges. One of the primary concerns is the environmental impact, particularly regarding water usage and potential groundwater contamination. The industry is under pressure to develop waterless fracturing methods or to significantly reduce water consumption in the process.

Another challenge lies in improving fracture propagation control and proppant transport. Achieving uniform proppant distribution throughout the created fractures remains difficult, especially in complex geological formations. This challenge directly affects the overall efficiency and productivity of the stimulation process.

The use of magnesium carbonate in fracture stimulation materials presents both opportunities and challenges. While it offers potential benefits such as being environmentally friendly and having favorable chemical properties, integrating it effectively into existing fracturing fluid systems and ensuring its performance under various downhole conditions pose technical hurdles.

Furthermore, the industry grapples with the challenge of reducing the overall cost of fracturing operations while maintaining or improving efficiency. This includes optimizing the use of materials, reducing equipment wear, and minimizing non-productive time during operations.

Lastly, there is an ongoing challenge to develop fracturing technologies suitable for increasingly complex and challenging reservoirs, such as ultra-tight formations or those with high temperatures and pressures. These extreme conditions push the limits of current materials and equipment, necessitating continuous innovation in fracturing technology.

The current status of fracturing technology is characterized by a focus on optimizing fluid chemistry, proppant selection, and pumping schedules. Advanced monitoring systems, including microseismic and fiber optic sensing, allow real-time adjustment of fracturing parameters. Additionally, the industry has made strides in developing environmentally friendly fracturing fluids and more efficient proppant materials.

Despite these advancements, fracturing technology faces several significant challenges. One of the primary concerns is the environmental impact, particularly regarding water usage and potential groundwater contamination. The industry is under pressure to develop waterless fracturing methods or to significantly reduce water consumption in the process.

Another challenge lies in improving fracture propagation control and proppant transport. Achieving uniform proppant distribution throughout the created fractures remains difficult, especially in complex geological formations. This challenge directly affects the overall efficiency and productivity of the stimulation process.

The use of magnesium carbonate in fracture stimulation materials presents both opportunities and challenges. While it offers potential benefits such as being environmentally friendly and having favorable chemical properties, integrating it effectively into existing fracturing fluid systems and ensuring its performance under various downhole conditions pose technical hurdles.

Furthermore, the industry grapples with the challenge of reducing the overall cost of fracturing operations while maintaining or improving efficiency. This includes optimizing the use of materials, reducing equipment wear, and minimizing non-productive time during operations.

Lastly, there is an ongoing challenge to develop fracturing technologies suitable for increasingly complex and challenging reservoirs, such as ultra-tight formations or those with high temperatures and pressures. These extreme conditions push the limits of current materials and equipment, necessitating continuous innovation in fracturing technology.

Existing Magnesium Carbonate-based Fracturing Solutions

01 Magnesium carbonate in pharmaceutical compositions

Magnesium carbonate is used in various pharmaceutical compositions as an excipient or active ingredient. It can be utilized in antacid formulations, oral care products, and as a filler or binder in tablets and capsules. Its properties make it suitable for improving drug stability, controlling release rates, and enhancing bioavailability of certain medications.- Magnesium carbonate in pharmaceutical compositions: Magnesium carbonate is used in various pharmaceutical compositions as an excipient or active ingredient. It can be utilized in antacid formulations, dietary supplements, and other medicinal preparations. The compound's properties make it suitable for improving drug stability, enhancing dissolution, and providing magnesium supplementation.

- Industrial applications of magnesium carbonate: Magnesium carbonate finds extensive use in industrial processes. It is employed as a filler in rubber and plastic products, a whitening agent in paper production, and a raw material in the manufacture of magnesium oxide. Its fire-retardant properties make it valuable in flame-resistant materials.

- Magnesium carbonate in personal care products: The compound is utilized in various personal care and cosmetic products. It serves as an anti-caking agent in powders, a mild abrasive in toothpaste, and a deodorant ingredient. Its absorbent properties make it useful in talcum powders and other body care formulations.

- Magnesium carbonate in food and beverage applications: In the food industry, magnesium carbonate is used as an acidity regulator, anti-caking agent, and color retention agent. It can be found in salt products, dried milk powders, and some confectionery items. The compound also finds application in brewing processes for beer and other fermented beverages.

- Environmental and agricultural uses of magnesium carbonate: Magnesium carbonate has applications in environmental remediation and agriculture. It can be used for soil pH adjustment, as a fertilizer component, and in wastewater treatment processes. The compound also shows potential in carbon capture technologies and as a component in eco-friendly building materials.

02 Industrial applications of magnesium carbonate

Magnesium carbonate finds applications in various industrial processes. It is used as a filler in rubber and plastic manufacturing, as a flame retardant in polymers, and as a raw material in the production of magnesium oxide. Additionally, it serves as a drying agent, a color retention additive in foods, and a component in fireproofing materials.Expand Specific Solutions03 Magnesium carbonate in personal care products

Magnesium carbonate is incorporated into various personal care products due to its absorbent and anti-caking properties. It is used in deodorants, body powders, and cosmetics to control moisture and improve texture. In some formulations, it acts as a mild abrasive or helps to neutralize odors.Expand Specific Solutions04 Synthesis and production methods of magnesium carbonate

Various methods are employed for the synthesis and production of magnesium carbonate. These include precipitation reactions between magnesium salts and carbonate sources, carbonation of magnesium hydroxide, and extraction from natural mineral deposits. Different techniques are used to control particle size, morphology, and purity of the final product.Expand Specific Solutions05 Environmental and agricultural uses of magnesium carbonate

Magnesium carbonate has applications in environmental remediation and agriculture. It is used in soil treatment to adjust pH levels and improve soil structure. In wastewater treatment, it can help remove heavy metals and other contaminants. Additionally, it serves as a source of magnesium in fertilizers and animal feed supplements.Expand Specific Solutions

Key Players in Fracturing Industry

The use of magnesium carbonate in fracture stimulation materials is an emerging technology in the oil and gas industry, currently in its early development stage. The market size is relatively small but growing, driven by the increasing demand for more efficient and environmentally friendly fracking materials. The technology's maturity is still evolving, with companies like Schlumberger, Halliburton, and China National Petroleum Corp. leading research and development efforts. Smaller players such as Chongqing Yuhua New Material Co., Ltd. and Jiangsu Sinagrt Materials Technologies Co., Ltd. are also contributing to advancements in this field. As the industry progresses, collaboration between academic institutions like the University of Pittsburgh and New York University and major oil service companies is expected to accelerate innovation and commercialization of magnesium carbonate-based fracturing materials.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has focused on developing magnesium carbonate-based fracturing materials suited for the high-temperature, high-pressure conditions of Middle Eastern reservoirs. Their research has yielded advanced MgCO3-based fluid systems that maintain stability and performance at extreme downhole conditions[10]. The company has also pioneered the use of magnesium carbonate as a component in their environmentally friendly fracturing fluids, aiming to reduce water consumption and environmental impact[11]. Furthermore, Saudi Aramco's R&D efforts have explored the potential of MgCO3 nanoparticles for enhanced oil recovery in carbonate reservoirs, which are prevalent in the region[12].

Strengths: Vast financial resources, cutting-edge research facilities, and extensive experience in challenging reservoir conditions. Weaknesses: Heavy reliance on oil exports and potential challenges in adapting to global energy transition.

Services Petroliers Schlumberger SA

Technical Solution: Schlumberger has developed advanced fracturing fluids incorporating magnesium carbonate as a pH buffer and scale inhibitor. Their proprietary MgCO3-based additives help maintain optimal pH levels during fracturing operations, enhancing fluid performance and reducing formation damage[1]. The company has also engineered novel proppant coating technologies using magnesium carbonate to improve proppant transport and placement in fractures[2]. Additionally, Schlumberger's research has focused on using MgCO3 nanoparticles to create self-healing cement systems for wellbore integrity, addressing long-term zonal isolation challenges in hydraulic fracturing operations[3].

Strengths: Industry-leading expertise in oilfield services, extensive R&D capabilities, and global presence. Weaknesses: High operational costs and dependence on oil and gas market fluctuations.

Core Innovations in Magnesium Carbonate Fracturing Materials

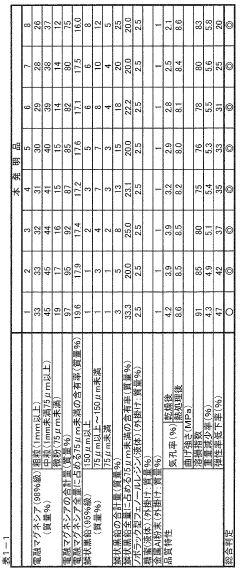

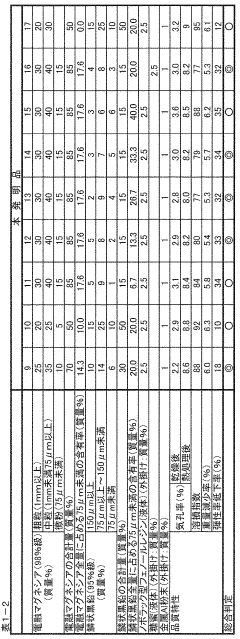

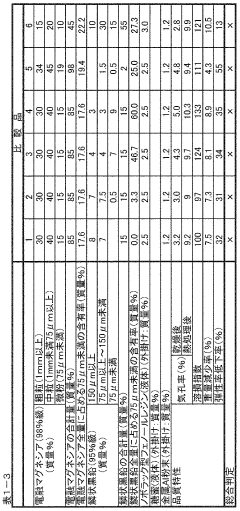

Magnesia carbon refractory material

PatentActiveJP2020066540A

Innovation

- Optimizing the particle size composition of magnesia and graphite in the refractory by limiting the content of fine magnesia powder and adjusting the particle size distribution of graphite within specific ranges, along with the inclusion of additives like Al, Si, Al-Si alloy, Al-Mg alloy, carbon black, and boron carbide, to maintain fine pores and suppress oxidation-reduction reactions.

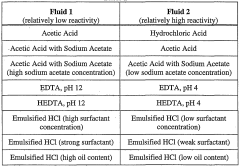

Fracture stimulation process for carbonate reservoirs

PatentWO2004035988A1

Innovation

- A novel process that varies the reactivity of the fracture stimulation fluid from low to high, controlling the flow rate and viscosity to maintain an optimum fracture stimulation efficiency number of 0.1 to 0.3, creating deep, conductive etch patterns by gradually increasing the reactivity from the fracture tip to the wellbore, reducing wormhole formation and reactant consumption.

Environmental Impact of Magnesium Carbonate in Fracturing

The environmental impact of magnesium carbonate in fracturing operations is a critical consideration for the oil and gas industry. Magnesium carbonate, when used as a fracturing material, interacts with the surrounding ecosystem in various ways, both during the fracturing process and in its aftermath.

One of the primary environmental concerns is the potential for groundwater contamination. While magnesium carbonate itself is not highly soluble in water, the fracturing process can create pathways for it to enter aquifers. This may lead to changes in water chemistry, potentially affecting the quality of drinking water sources. However, compared to some other fracturing materials, magnesium carbonate's lower solubility may reduce the risk of widespread contamination.

The release of magnesium carbonate into surface waters is another environmental consideration. If not properly managed, flowback and produced water containing magnesium carbonate can impact aquatic ecosystems. Elevated levels of magnesium in water bodies can alter pH levels and mineral content, potentially affecting aquatic flora and fauna. This necessitates careful treatment and disposal of wastewater from fracturing operations.

Air quality is also a factor to consider. During the handling and injection of magnesium carbonate, dust particles can be released into the atmosphere. While magnesium carbonate dust is generally considered less harmful than silica dust, prolonged exposure may still pose respiratory risks to workers and nearby communities. Proper dust control measures are essential to mitigate these potential health impacts.

The long-term fate of magnesium carbonate in the subsurface environment is an area of ongoing research. As a relatively inert compound, it may remain in fractures for extended periods. This persistence could have both positive and negative implications. On one hand, it may provide long-term fracture support without significant chemical degradation. On the other hand, it could potentially alter subsurface geochemistry over time.

From a lifecycle perspective, the production and transportation of magnesium carbonate also contribute to its environmental footprint. Mining and processing of magnesite, the primary source of magnesium carbonate, can have localized environmental impacts, including habitat disruption and energy consumption. The carbon footprint associated with transporting the material to fracturing sites is another consideration in assessing its overall environmental impact.

In comparison to other fracturing materials, magnesium carbonate may offer some environmental advantages. Its lower toxicity and reactivity compared to certain chemical additives could reduce the risk of harmful contamination. Additionally, its potential for reuse or recycling in subsequent fracturing operations could help minimize waste and resource consumption.

One of the primary environmental concerns is the potential for groundwater contamination. While magnesium carbonate itself is not highly soluble in water, the fracturing process can create pathways for it to enter aquifers. This may lead to changes in water chemistry, potentially affecting the quality of drinking water sources. However, compared to some other fracturing materials, magnesium carbonate's lower solubility may reduce the risk of widespread contamination.

The release of magnesium carbonate into surface waters is another environmental consideration. If not properly managed, flowback and produced water containing magnesium carbonate can impact aquatic ecosystems. Elevated levels of magnesium in water bodies can alter pH levels and mineral content, potentially affecting aquatic flora and fauna. This necessitates careful treatment and disposal of wastewater from fracturing operations.

Air quality is also a factor to consider. During the handling and injection of magnesium carbonate, dust particles can be released into the atmosphere. While magnesium carbonate dust is generally considered less harmful than silica dust, prolonged exposure may still pose respiratory risks to workers and nearby communities. Proper dust control measures are essential to mitigate these potential health impacts.

The long-term fate of magnesium carbonate in the subsurface environment is an area of ongoing research. As a relatively inert compound, it may remain in fractures for extended periods. This persistence could have both positive and negative implications. On one hand, it may provide long-term fracture support without significant chemical degradation. On the other hand, it could potentially alter subsurface geochemistry over time.

From a lifecycle perspective, the production and transportation of magnesium carbonate also contribute to its environmental footprint. Mining and processing of magnesite, the primary source of magnesium carbonate, can have localized environmental impacts, including habitat disruption and energy consumption. The carbon footprint associated with transporting the material to fracturing sites is another consideration in assessing its overall environmental impact.

In comparison to other fracturing materials, magnesium carbonate may offer some environmental advantages. Its lower toxicity and reactivity compared to certain chemical additives could reduce the risk of harmful contamination. Additionally, its potential for reuse or recycling in subsequent fracturing operations could help minimize waste and resource consumption.

Regulatory Framework for Fracturing Materials

The regulatory framework for fracturing materials plays a crucial role in ensuring the safe and responsible use of substances like magnesium carbonate in fracture stimulation operations. In the United States, the primary regulatory body overseeing the use of fracturing materials is the Environmental Protection Agency (EPA). The EPA has established guidelines under the Safe Drinking Water Act (SDWA) to regulate the underground injection of fluids used in hydraulic fracturing.

At the federal level, the EPA requires operators to disclose the chemical composition of fracturing fluids through the FracFocus Chemical Disclosure Registry. This transparency measure allows for public scrutiny and helps regulators assess potential environmental and health impacts. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for worker safety when handling fracturing materials, including magnesium carbonate.

State-level regulations often complement federal guidelines, with some states imposing stricter requirements. For instance, California's Senate Bill 4 mandates comprehensive disclosure of fracturing fluid components and requires operators to obtain permits before conducting hydraulic fracturing operations. Similarly, Texas has implemented the Hydraulic Fracturing Chemical Disclosure Rule, which requires companies to disclose the total volume of water used and the chemical ingredients of fracturing fluids on the FracFocus website.

Internationally, regulatory approaches vary. The European Union has adopted a precautionary stance, with some member states imposing moratoriums on hydraulic fracturing. In contrast, countries like Canada and Australia have developed regulatory frameworks that balance environmental protection with energy development needs.

The use of magnesium carbonate in fracturing materials is subject to these broader regulatory frameworks. While it is generally considered a relatively benign substance, its use must still comply with disclosure requirements and safety standards. Operators must demonstrate that the use of magnesium carbonate does not pose significant risks to groundwater resources or human health.

As the understanding of fracturing materials' environmental impacts evolves, regulatory frameworks continue to adapt. Recent trends indicate a move towards more stringent regulations, increased transparency, and greater emphasis on sustainable practices in hydraulic fracturing operations. This evolving regulatory landscape necessitates ongoing compliance efforts from industry stakeholders and may influence the selection and use of fracturing materials, including magnesium carbonate, in future operations.

At the federal level, the EPA requires operators to disclose the chemical composition of fracturing fluids through the FracFocus Chemical Disclosure Registry. This transparency measure allows for public scrutiny and helps regulators assess potential environmental and health impacts. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for worker safety when handling fracturing materials, including magnesium carbonate.

State-level regulations often complement federal guidelines, with some states imposing stricter requirements. For instance, California's Senate Bill 4 mandates comprehensive disclosure of fracturing fluid components and requires operators to obtain permits before conducting hydraulic fracturing operations. Similarly, Texas has implemented the Hydraulic Fracturing Chemical Disclosure Rule, which requires companies to disclose the total volume of water used and the chemical ingredients of fracturing fluids on the FracFocus website.

Internationally, regulatory approaches vary. The European Union has adopted a precautionary stance, with some member states imposing moratoriums on hydraulic fracturing. In contrast, countries like Canada and Australia have developed regulatory frameworks that balance environmental protection with energy development needs.

The use of magnesium carbonate in fracturing materials is subject to these broader regulatory frameworks. While it is generally considered a relatively benign substance, its use must still comply with disclosure requirements and safety standards. Operators must demonstrate that the use of magnesium carbonate does not pose significant risks to groundwater resources or human health.

As the understanding of fracturing materials' environmental impacts evolves, regulatory frameworks continue to adapt. Recent trends indicate a move towards more stringent regulations, increased transparency, and greater emphasis on sustainable practices in hydraulic fracturing operations. This evolving regulatory landscape necessitates ongoing compliance efforts from industry stakeholders and may influence the selection and use of fracturing materials, including magnesium carbonate, in future operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!