Transformational AMOLED applications in automotive interiors.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED in Automotive: Background and Objectives

Active-Matrix Organic Light-Emitting Diode (AMOLED) technology has emerged as a revolutionary force in display systems, and its application in automotive interiors represents a significant leap forward in vehicle design and user experience. The evolution of AMOLED technology can be traced back to the late 1980s, with the discovery of electroluminescent organic materials. However, it wasn't until the early 2000s that AMOLED displays began to gain traction in consumer electronics.

The automotive industry, traditionally conservative in adopting new technologies, has recently recognized the transformative potential of AMOLED displays. This shift is driven by the increasing demand for sophisticated in-vehicle infotainment systems, advanced driver assistance features, and the overall trend towards connected and autonomous vehicles. AMOLED technology offers several advantages over conventional display technologies, including superior contrast ratios, wider color gamuts, faster response times, and the ability to create flexible and curved displays.

The primary objective of integrating AMOLED technology into automotive interiors is to enhance the driver and passenger experience while improving safety and functionality. By providing high-quality, customizable displays, AMOLED technology enables the creation of more intuitive and responsive user interfaces. This can lead to reduced driver distraction and improved access to critical information and controls.

Another key goal is to revolutionize the aesthetic appeal of vehicle interiors. AMOLED's ability to produce vibrant colors and deep blacks, combined with its flexibility in form factor, allows for seamless integration of displays into various surfaces within the vehicle. This opens up new possibilities for interior design, potentially transforming entire dashboards, door panels, and even windows into interactive display surfaces.

The development of AMOLED technology for automotive applications also aims to address specific challenges unique to the automotive environment. These include the need for displays that can withstand extreme temperatures, vibrations, and varying light conditions. Additionally, there is a focus on developing energy-efficient AMOLED displays to minimize the impact on vehicle power consumption, particularly in electric vehicles where energy management is crucial.

Looking ahead, the trajectory of AMOLED technology in automotive interiors is expected to align with broader trends in the automotive industry, such as electrification, connectivity, and autonomous driving. As vehicles evolve into mobile living spaces, the role of display technology becomes increasingly central, with AMOLED positioned to play a pivotal role in shaping the future of automotive user interfaces and interior design.

The automotive industry, traditionally conservative in adopting new technologies, has recently recognized the transformative potential of AMOLED displays. This shift is driven by the increasing demand for sophisticated in-vehicle infotainment systems, advanced driver assistance features, and the overall trend towards connected and autonomous vehicles. AMOLED technology offers several advantages over conventional display technologies, including superior contrast ratios, wider color gamuts, faster response times, and the ability to create flexible and curved displays.

The primary objective of integrating AMOLED technology into automotive interiors is to enhance the driver and passenger experience while improving safety and functionality. By providing high-quality, customizable displays, AMOLED technology enables the creation of more intuitive and responsive user interfaces. This can lead to reduced driver distraction and improved access to critical information and controls.

Another key goal is to revolutionize the aesthetic appeal of vehicle interiors. AMOLED's ability to produce vibrant colors and deep blacks, combined with its flexibility in form factor, allows for seamless integration of displays into various surfaces within the vehicle. This opens up new possibilities for interior design, potentially transforming entire dashboards, door panels, and even windows into interactive display surfaces.

The development of AMOLED technology for automotive applications also aims to address specific challenges unique to the automotive environment. These include the need for displays that can withstand extreme temperatures, vibrations, and varying light conditions. Additionally, there is a focus on developing energy-efficient AMOLED displays to minimize the impact on vehicle power consumption, particularly in electric vehicles where energy management is crucial.

Looking ahead, the trajectory of AMOLED technology in automotive interiors is expected to align with broader trends in the automotive industry, such as electrification, connectivity, and autonomous driving. As vehicles evolve into mobile living spaces, the role of display technology becomes increasingly central, with AMOLED positioned to play a pivotal role in shaping the future of automotive user interfaces and interior design.

Market Analysis for In-Car AMOLED Displays

The automotive industry is witnessing a significant shift towards advanced display technologies, with AMOLED (Active-Matrix Organic Light-Emitting Diode) displays emerging as a transformative solution for in-car interiors. The market for in-car AMOLED displays is experiencing robust growth, driven by increasing consumer demand for enhanced user experiences and the automotive industry's push towards more sophisticated and connected vehicles.

The global market for automotive displays, including AMOLED technology, is expanding rapidly. This growth is fueled by the rising integration of advanced driver assistance systems (ADAS), infotainment systems, and digital instrument clusters in modern vehicles. AMOLED displays offer several advantages over traditional LCD screens, including higher contrast ratios, wider viewing angles, and improved color reproduction, making them particularly suitable for automotive applications.

Consumer preferences are shifting towards more immersive and interactive in-car experiences, driving the adoption of larger, curved, and flexible AMOLED displays. These displays not only enhance the aesthetic appeal of vehicle interiors but also improve functionality and user engagement. The trend towards electric and autonomous vehicles is further accelerating the demand for advanced display technologies, as these vehicles rely heavily on digital interfaces for both driver information and passenger entertainment.

The automotive AMOLED display market is segmented based on various factors, including display size, application type, and vehicle category. Center stack displays, instrument clusters, and rear-seat entertainment systems are among the primary applications driving market growth. Luxury and premium vehicle segments currently lead in AMOLED adoption, but the technology is gradually penetrating mid-range and entry-level vehicles as production costs decrease.

Regional market dynamics play a crucial role in the adoption of AMOLED displays in automotive interiors. Asia-Pacific, particularly countries like China, Japan, and South Korea, leads in both production and consumption of automotive AMOLED displays, supported by a strong presence of display manufacturers and automotive OEMs. North America and Europe follow closely, with increasing integration of AMOLED technology in high-end and electric vehicles.

Key market challenges include the high cost of AMOLED displays compared to traditional LCD screens, concerns about long-term durability in harsh automotive environments, and the need for specialized manufacturing processes. However, ongoing technological advancements and economies of scale are expected to address these challenges, potentially leading to wider adoption across various vehicle segments in the coming years.

The global market for automotive displays, including AMOLED technology, is expanding rapidly. This growth is fueled by the rising integration of advanced driver assistance systems (ADAS), infotainment systems, and digital instrument clusters in modern vehicles. AMOLED displays offer several advantages over traditional LCD screens, including higher contrast ratios, wider viewing angles, and improved color reproduction, making them particularly suitable for automotive applications.

Consumer preferences are shifting towards more immersive and interactive in-car experiences, driving the adoption of larger, curved, and flexible AMOLED displays. These displays not only enhance the aesthetic appeal of vehicle interiors but also improve functionality and user engagement. The trend towards electric and autonomous vehicles is further accelerating the demand for advanced display technologies, as these vehicles rely heavily on digital interfaces for both driver information and passenger entertainment.

The automotive AMOLED display market is segmented based on various factors, including display size, application type, and vehicle category. Center stack displays, instrument clusters, and rear-seat entertainment systems are among the primary applications driving market growth. Luxury and premium vehicle segments currently lead in AMOLED adoption, but the technology is gradually penetrating mid-range and entry-level vehicles as production costs decrease.

Regional market dynamics play a crucial role in the adoption of AMOLED displays in automotive interiors. Asia-Pacific, particularly countries like China, Japan, and South Korea, leads in both production and consumption of automotive AMOLED displays, supported by a strong presence of display manufacturers and automotive OEMs. North America and Europe follow closely, with increasing integration of AMOLED technology in high-end and electric vehicles.

Key market challenges include the high cost of AMOLED displays compared to traditional LCD screens, concerns about long-term durability in harsh automotive environments, and the need for specialized manufacturing processes. However, ongoing technological advancements and economies of scale are expected to address these challenges, potentially leading to wider adoption across various vehicle segments in the coming years.

AMOLED Technology: Current State and Challenges

AMOLED (Active-Matrix Organic Light-Emitting Diode) technology has made significant strides in recent years, particularly in its application to automotive interiors. The current state of AMOLED technology in this context is characterized by high-resolution displays with vibrant colors, excellent contrast ratios, and wide viewing angles. These displays are increasingly being integrated into dashboard clusters, infotainment systems, and even passenger entertainment screens.

One of the primary advantages of AMOLED in automotive applications is its ability to produce true blacks by turning off individual pixels, resulting in energy savings and improved visibility in low-light conditions. This feature is particularly beneficial for nighttime driving. Additionally, AMOLED displays offer faster response times compared to traditional LCD screens, which is crucial for displaying real-time information and responding to user inputs in a vehicle environment.

However, the implementation of AMOLED technology in automotive interiors faces several challenges. Durability and longevity are significant concerns, as automotive displays must withstand extreme temperatures, vibrations, and prolonged exposure to sunlight. The organic materials used in AMOLED displays are susceptible to degradation over time, which can lead to color shifts and reduced brightness. Manufacturers are actively working on developing more robust materials and protective coatings to address these issues.

Another challenge is the cost of production. AMOLED displays are generally more expensive to manufacture than traditional LCD screens, which can impact the overall cost of vehicles. As the technology matures and production scales up, it is expected that costs will decrease, making AMOLED more accessible for a wider range of automotive applications.

Power consumption is also a consideration, especially in electric vehicles where energy efficiency is paramount. While AMOLED displays can be more energy-efficient in certain scenarios, they can consume more power when displaying bright content. Balancing power consumption with display performance remains an ongoing challenge for automotive engineers.

Lastly, the integration of touch functionality with AMOLED displays presents its own set of challenges. Ensuring accurate touch response while maintaining the thinness and flexibility of AMOLED panels requires advanced engineering solutions. The automotive industry is exploring various technologies, such as in-cell touch sensors, to seamlessly combine touch capabilities with AMOLED displays.

Despite these challenges, the potential for AMOLED technology in automotive interiors is immense. Ongoing research and development efforts are focused on addressing these issues, with promising advancements in materials science, manufacturing processes, and integration techniques. As these challenges are overcome, AMOLED displays are poised to revolutionize the way we interact with and experience automotive interiors.

One of the primary advantages of AMOLED in automotive applications is its ability to produce true blacks by turning off individual pixels, resulting in energy savings and improved visibility in low-light conditions. This feature is particularly beneficial for nighttime driving. Additionally, AMOLED displays offer faster response times compared to traditional LCD screens, which is crucial for displaying real-time information and responding to user inputs in a vehicle environment.

However, the implementation of AMOLED technology in automotive interiors faces several challenges. Durability and longevity are significant concerns, as automotive displays must withstand extreme temperatures, vibrations, and prolonged exposure to sunlight. The organic materials used in AMOLED displays are susceptible to degradation over time, which can lead to color shifts and reduced brightness. Manufacturers are actively working on developing more robust materials and protective coatings to address these issues.

Another challenge is the cost of production. AMOLED displays are generally more expensive to manufacture than traditional LCD screens, which can impact the overall cost of vehicles. As the technology matures and production scales up, it is expected that costs will decrease, making AMOLED more accessible for a wider range of automotive applications.

Power consumption is also a consideration, especially in electric vehicles where energy efficiency is paramount. While AMOLED displays can be more energy-efficient in certain scenarios, they can consume more power when displaying bright content. Balancing power consumption with display performance remains an ongoing challenge for automotive engineers.

Lastly, the integration of touch functionality with AMOLED displays presents its own set of challenges. Ensuring accurate touch response while maintaining the thinness and flexibility of AMOLED panels requires advanced engineering solutions. The automotive industry is exploring various technologies, such as in-cell touch sensors, to seamlessly combine touch capabilities with AMOLED displays.

Despite these challenges, the potential for AMOLED technology in automotive interiors is immense. Ongoing research and development efforts are focused on addressing these issues, with promising advancements in materials science, manufacturing processes, and integration techniques. As these challenges are overcome, AMOLED displays are poised to revolutionize the way we interact with and experience automotive interiors.

Current AMOLED Solutions for Vehicle Interiors

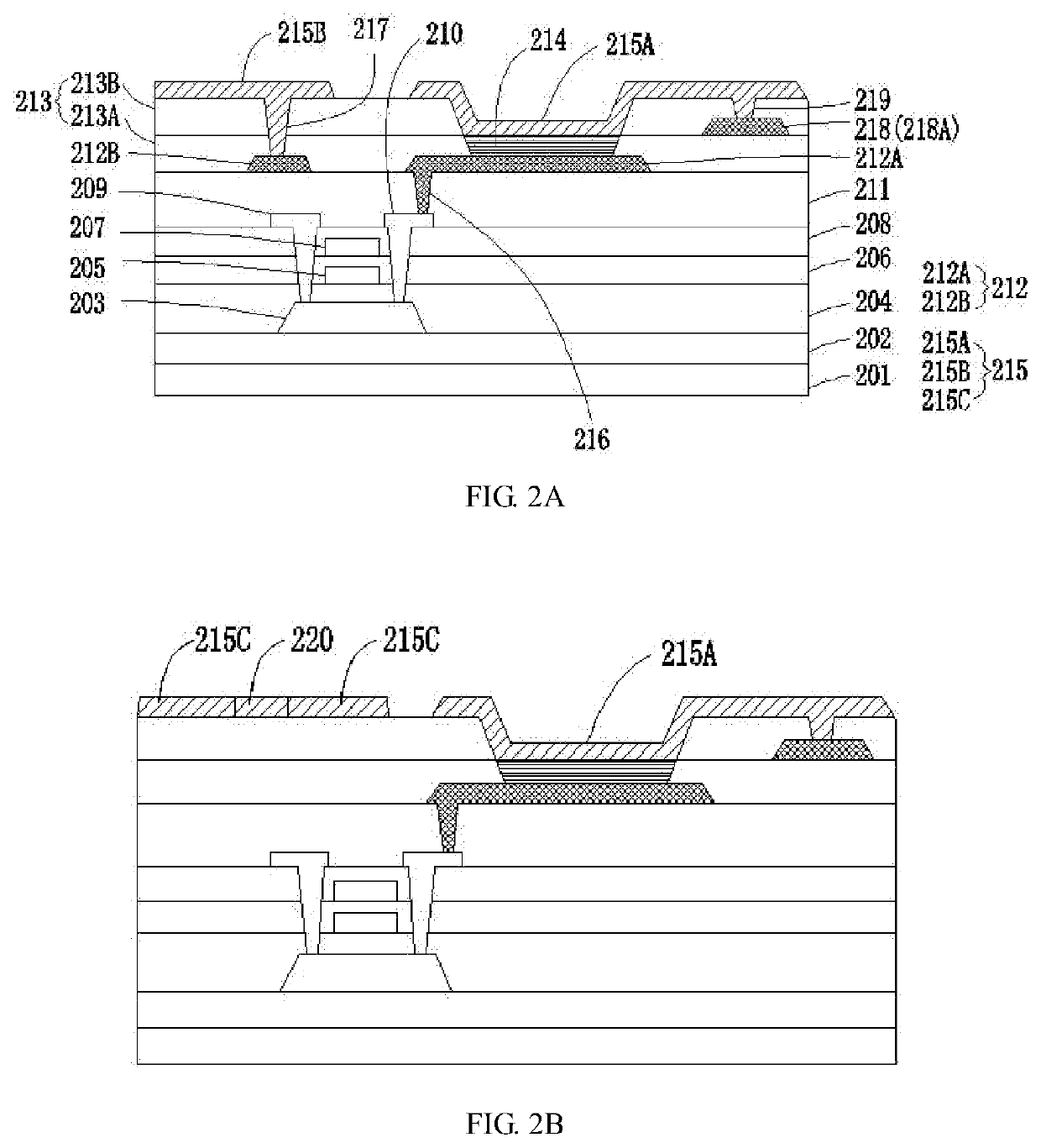

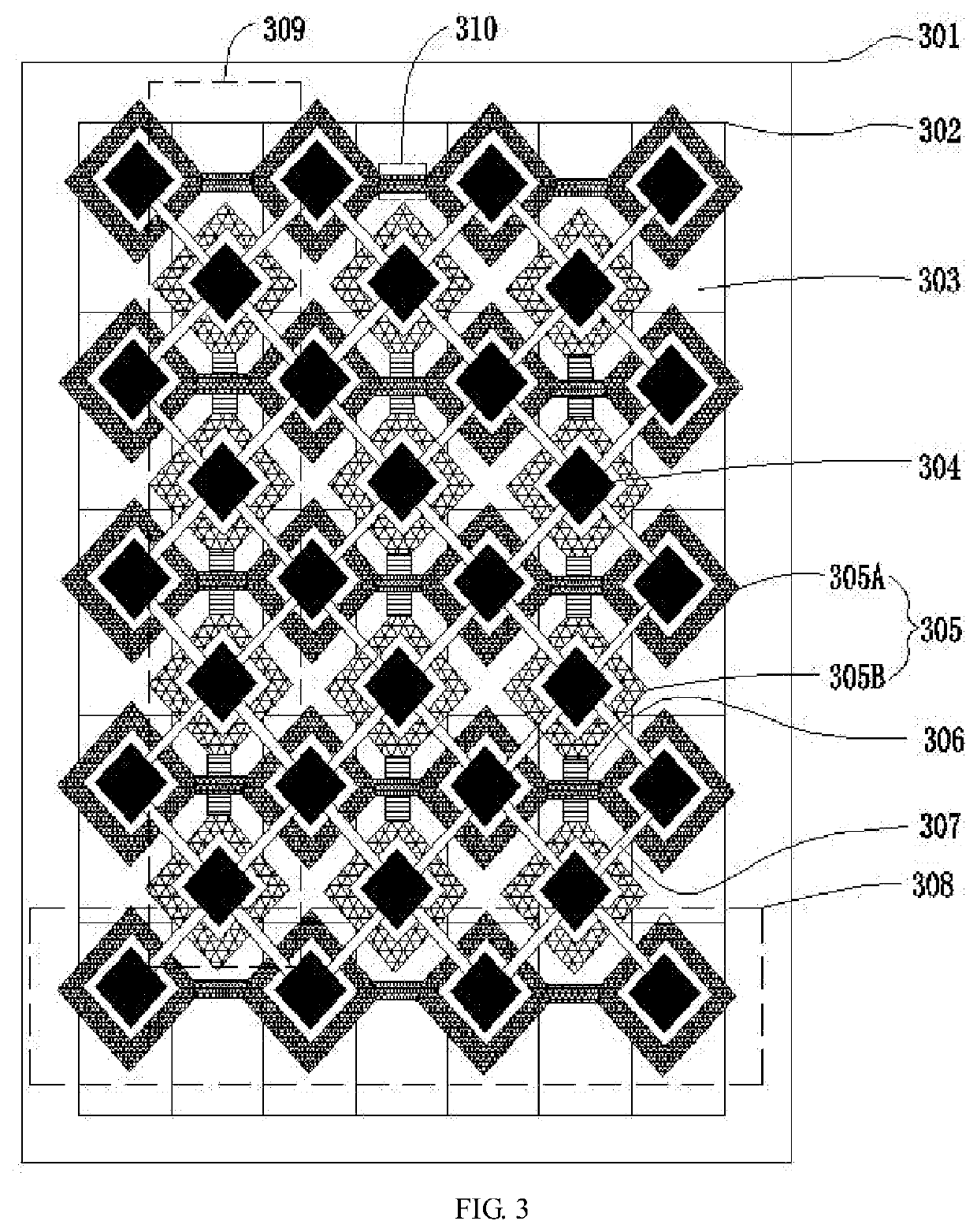

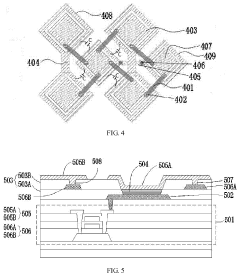

01 AMOLED display structure and fabrication

AMOLED displays utilize organic light-emitting diodes (OLEDs) arranged in an active matrix. The structure typically includes thin-film transistors (TFTs) for pixel control, organic layers for light emission, and encapsulation to protect against environmental factors. Advanced fabrication techniques are employed to achieve high-resolution displays with improved efficiency and longevity.- AMOLED display structure and manufacturing: This category focuses on the structural design and manufacturing processes of AMOLED displays. It includes innovations in pixel arrangements, thin-film transistor (TFT) designs, and fabrication techniques to improve display performance, efficiency, and yield.

- Driving and control methods for AMOLED displays: This category covers various driving and control methods for AMOLED displays, including pixel compensation techniques, voltage control schemes, and current driving methods. These innovations aim to improve display uniformity, reduce power consumption, and enhance overall image quality.

- AMOLED display panel design and integration: This category encompasses innovations in AMOLED display panel design and integration, including flexible and foldable displays, touch integration, and bezel-less designs. These advancements aim to improve form factor, durability, and user interaction with AMOLED displays.

- Power management and efficiency in AMOLED displays: This category focuses on power management techniques and efficiency improvements in AMOLED displays. It includes innovations in low-power driving schemes, adaptive brightness control, and energy-efficient pixel designs to extend battery life in mobile devices and reduce overall power consumption.

- Color management and image quality enhancement: This category covers techniques for improving color reproduction, contrast, and overall image quality in AMOLED displays. It includes innovations in color calibration, gamut mapping, and high dynamic range (HDR) implementation to enhance the visual experience for users.

02 Driving and control methods for AMOLED displays

Various driving and control methods are implemented to optimize AMOLED display performance. These include techniques for pixel compensation, current control, and voltage programming. Advanced algorithms are used to address issues such as non-uniformity, image sticking, and power consumption, resulting in improved image quality and display lifespan.Expand Specific Solutions03 Color management and image quality enhancement

AMOLED displays employ sophisticated color management techniques to achieve wide color gamut and high contrast ratios. This includes methods for color calibration, gamma correction, and dynamic range expansion. Advanced image processing algorithms are utilized to enhance picture quality, reduce motion blur, and optimize content for AMOLED characteristics.Expand Specific Solutions04 Power efficiency and lifespan improvement

Techniques are developed to enhance power efficiency and extend the lifespan of AMOLED displays. These include optimized pixel designs, improved organic materials, and advanced power management schemes. Methods for compensating for OLED degradation over time are implemented to maintain consistent display performance throughout the device's lifetime.Expand Specific Solutions05 Flexible and foldable AMOLED displays

Advancements in flexible and foldable AMOLED technology enable new form factors for display devices. This involves developing flexible substrates, bendable encapsulation methods, and stress-resistant pixel structures. Innovations in materials and manufacturing processes allow for the creation of durable and highly flexible AMOLED displays suitable for various applications.Expand Specific Solutions

Key Players in Automotive AMOLED Industry

The transformational AMOLED applications in automotive interiors represent an emerging market at the intersection of display technology and automotive design. This sector is in its early growth stage, with significant potential for expansion as automakers increasingly integrate advanced displays into vehicle interiors. The market size is expected to grow rapidly, driven by consumer demand for connected and luxurious in-car experiences. Technologically, AMOLED displays are maturing, with key players like Samsung Display, LG Electronics, and BOE Technology Group leading innovation. These companies are developing flexible, energy-efficient AMOLED panels tailored for automotive use, addressing challenges such as durability and sunlight readability. As the technology advances, we can expect increased adoption across various vehicle segments, transforming the driving experience.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed flexible AMOLED displays specifically for automotive interiors. Their technology includes a 12.3-inch flexible AMOLED instrument panel with a curvature radius of 100R, providing a seamless and immersive viewing experience[1]. They have also introduced a 27-inch AMOLED display for in-vehicle entertainment systems, featuring 4K resolution and a 95% DCI-P3 color gamut[2]. BOE's AMOLED displays utilize LTPO (Low-Temperature Polycrystalline Oxide) backplane technology, which enables variable refresh rates from 1Hz to 120Hz, significantly reducing power consumption[3]. The company has also implemented advanced touch integration and anti-reflection coatings to enhance usability and visibility in various lighting conditions[4].

Strengths: High flexibility, excellent color reproduction, and energy efficiency. Weaknesses: Potentially higher production costs compared to traditional displays, and concerns about long-term durability in automotive environments.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed automotive AMOLED displays with advanced features tailored for in-vehicle use. Their technology includes a 49-inch pillar-to-pillar display with a resolution of 7680x1080 pixels, providing a wide and immersive viewing experience[5]. Samsung's AMOLED displays for automotive use incorporate their proprietary LTPO technology, allowing for variable refresh rates and reduced power consumption[6]. They have also implemented advanced touch and haptic feedback systems, enhancing user interaction within the vehicle interior[7]. Samsung's displays feature a peak brightness of up to 1,500 nits, ensuring visibility in bright sunlight, and utilize quantum dot technology for enhanced color accuracy and vibrancy[8].

Strengths: Industry-leading display technology, high brightness, and advanced touch integration. Weaknesses: Potential for higher costs and complexity in implementation within existing vehicle architectures.

Core Innovations in Automotive AMOLED Tech

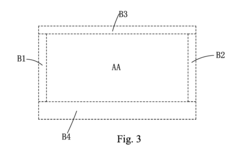

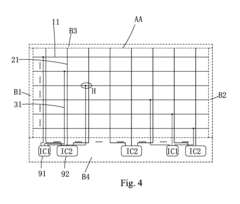

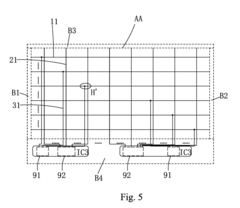

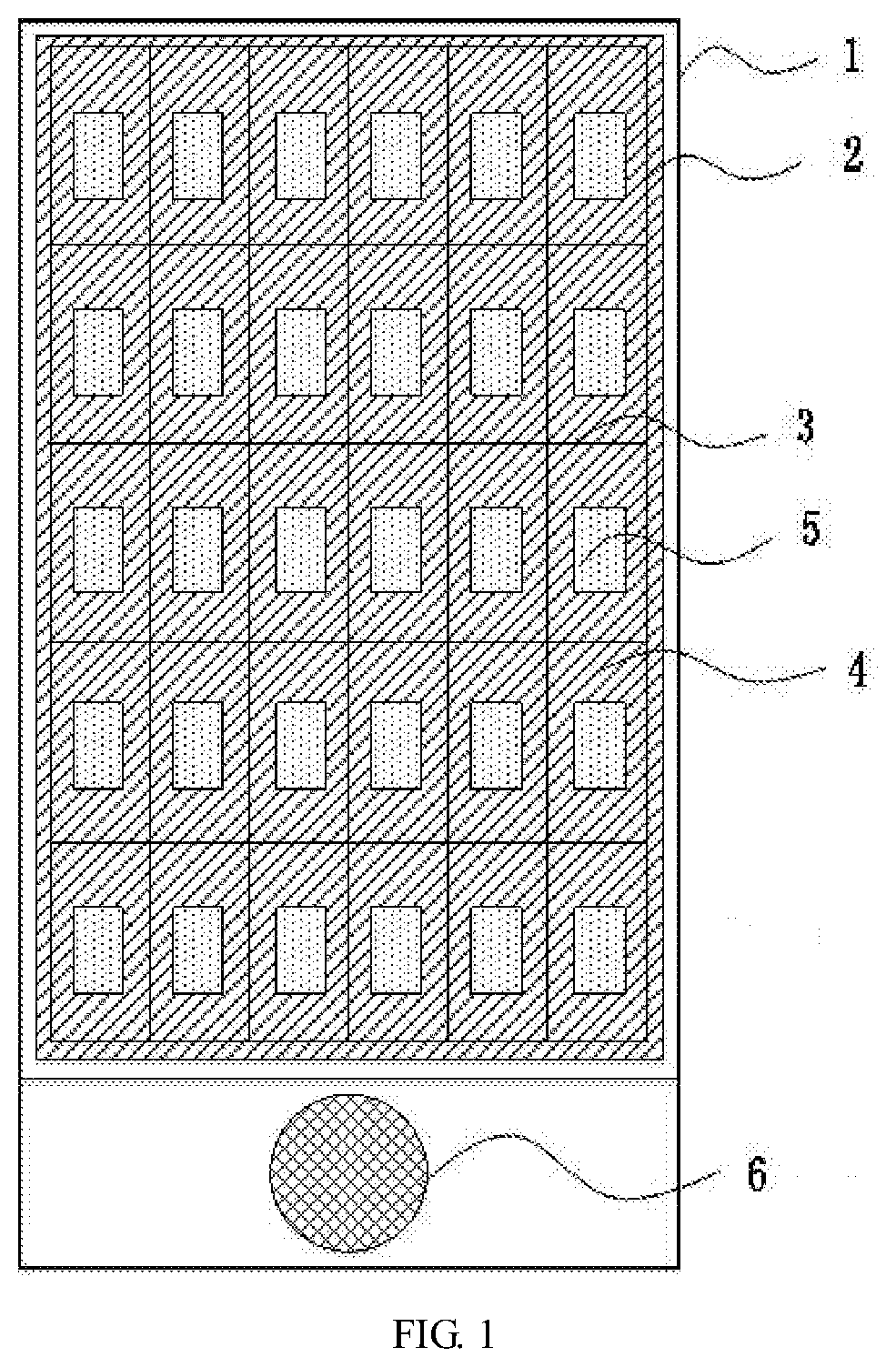

Active matrix organic light emitting diode display panel structure

PatentActiveUS10181505B2

Innovation

- The AMOLED display panel structure features ultra-narrow border frames by relocating row and column driving circuits to the lower border frame region, using vertically extending switching lines coupled to horizontally extending scan lines, and employing thin film packaging in the left, right, and upper border frames for packaging only, with a substrate and layers optimized for efficient signal transmission.

Active matrix organic light emitting diode (amoled) display panel

PatentInactiveUS20210343972A1

Innovation

- The integration of sensing electrodes into the AMOLED display panel allows for underscreen fingerprint identification, utilizing a patterned cathode layer with insulated first and second electrode rows and conductive bridges to form capacitors for fingerprint recognition, thereby embedding fingerprint identification within the screen and increasing the display area ratio.

Safety and Regulatory Considerations

The integration of AMOLED displays in automotive interiors brings forth critical safety and regulatory considerations that must be addressed to ensure compliance and passenger well-being. One primary concern is the potential for driver distraction, as these high-resolution, vibrant displays may divert attention from the road. Regulatory bodies, such as the National Highway Traffic Safety Administration (NHTSA) in the United States, have established guidelines for in-vehicle electronic devices to minimize distraction risks. Manufacturers must adhere to these guidelines, implementing features like automatic brightness adjustment and limiting certain functionalities while the vehicle is in motion.

Electromagnetic compatibility (EMC) is another crucial aspect, as AMOLED displays must not interfere with other electronic systems in the vehicle. Stringent EMC testing and certification processes are required to ensure that these displays do not compromise the functionality of safety-critical systems such as airbags, anti-lock brakes, or engine control units. Additionally, automotive-grade AMOLED displays must meet specific durability and reliability standards to withstand the harsh environmental conditions typical in vehicles, including extreme temperatures, vibrations, and humidity.

The use of AMOLED technology in automotive interiors also raises concerns about glare and readability in various lighting conditions. Manufacturers must ensure that these displays remain visible and legible under direct sunlight without causing excessive reflections that could impair driver visibility. This necessitates the development of advanced anti-glare coatings and adaptive display technologies that can adjust to ambient light conditions.

Safety considerations extend to the materials used in AMOLED displays, particularly in the event of a collision. The displays must be designed to minimize the risk of shattering or releasing harmful substances upon impact. This requires the use of shatter-resistant materials and careful integration into the vehicle's interior design to prevent injury to occupants during accidents.

As vehicles become increasingly connected, data privacy and cybersecurity regulations also come into play. AMOLED displays often serve as interfaces for infotainment systems and vehicle controls, potentially accessing sensitive user data. Manufacturers must implement robust security measures to protect against unauthorized access and ensure compliance with data protection regulations such as the General Data Protection Regulation (GDPR) in Europe.

Lastly, end-of-life considerations and environmental regulations are becoming increasingly important. The complex nature of AMOLED displays, which contain various electronic components and potentially hazardous materials, necessitates careful consideration of recycling and disposal processes. Manufacturers must design these systems with recyclability in mind and establish proper channels for responsible disposal in compliance with electronic waste regulations.

Electromagnetic compatibility (EMC) is another crucial aspect, as AMOLED displays must not interfere with other electronic systems in the vehicle. Stringent EMC testing and certification processes are required to ensure that these displays do not compromise the functionality of safety-critical systems such as airbags, anti-lock brakes, or engine control units. Additionally, automotive-grade AMOLED displays must meet specific durability and reliability standards to withstand the harsh environmental conditions typical in vehicles, including extreme temperatures, vibrations, and humidity.

The use of AMOLED technology in automotive interiors also raises concerns about glare and readability in various lighting conditions. Manufacturers must ensure that these displays remain visible and legible under direct sunlight without causing excessive reflections that could impair driver visibility. This necessitates the development of advanced anti-glare coatings and adaptive display technologies that can adjust to ambient light conditions.

Safety considerations extend to the materials used in AMOLED displays, particularly in the event of a collision. The displays must be designed to minimize the risk of shattering or releasing harmful substances upon impact. This requires the use of shatter-resistant materials and careful integration into the vehicle's interior design to prevent injury to occupants during accidents.

As vehicles become increasingly connected, data privacy and cybersecurity regulations also come into play. AMOLED displays often serve as interfaces for infotainment systems and vehicle controls, potentially accessing sensitive user data. Manufacturers must implement robust security measures to protect against unauthorized access and ensure compliance with data protection regulations such as the General Data Protection Regulation (GDPR) in Europe.

Lastly, end-of-life considerations and environmental regulations are becoming increasingly important. The complex nature of AMOLED displays, which contain various electronic components and potentially hazardous materials, necessitates careful consideration of recycling and disposal processes. Manufacturers must design these systems with recyclability in mind and establish proper channels for responsible disposal in compliance with electronic waste regulations.

Environmental Impact and Sustainability

The integration of AMOLED displays in automotive interiors presents both opportunities and challenges from an environmental and sustainability perspective. These advanced displays offer potential energy savings compared to traditional LCD screens, particularly in their ability to selectively illuminate pixels, reducing power consumption when displaying darker content. This energy efficiency can contribute to improved fuel economy or extended range in electric vehicles, indirectly reducing overall environmental impact.

However, the production of AMOLED displays involves complex manufacturing processes and rare earth elements, which raise concerns about resource depletion and environmental degradation. The extraction and processing of these materials can have significant ecological consequences, including habitat destruction and water pollution. As the automotive industry increasingly adopts AMOLED technology, there is a pressing need to develop more sustainable sourcing and production methods.

End-of-life considerations for AMOLED displays in vehicles also present environmental challenges. The intricate composition of these displays makes recycling difficult, potentially contributing to electronic waste. Developing efficient recycling processes for AMOLED components is crucial to mitigate this issue and promote a circular economy within the automotive sector.

On the positive side, the durability and longevity of AMOLED displays can contribute to sustainability by reducing the need for frequent replacements. Their ability to withstand extreme temperatures and maintain performance over time aligns well with the demanding environment of automotive interiors, potentially extending the lifespan of in-vehicle display systems.

The versatility of AMOLED technology also opens up possibilities for more sustainable vehicle designs. By integrating display functions into various surfaces, manufacturers can potentially reduce the overall number of components in a vehicle, leading to weight reduction and improved fuel efficiency. This consolidation of functions could also simplify manufacturing processes, potentially reducing energy consumption and waste in production.

As the automotive industry continues to embrace AMOLED technology, there is a growing emphasis on developing more environmentally friendly production techniques. Research into bio-based materials for OLED substrates and the use of water-based solvents in manufacturing processes are promising avenues for reducing the environmental footprint of AMOLED displays. Additionally, advancements in low-temperature polycrystalline silicon (LTPS) technology are enabling more energy-efficient production methods.

However, the production of AMOLED displays involves complex manufacturing processes and rare earth elements, which raise concerns about resource depletion and environmental degradation. The extraction and processing of these materials can have significant ecological consequences, including habitat destruction and water pollution. As the automotive industry increasingly adopts AMOLED technology, there is a pressing need to develop more sustainable sourcing and production methods.

End-of-life considerations for AMOLED displays in vehicles also present environmental challenges. The intricate composition of these displays makes recycling difficult, potentially contributing to electronic waste. Developing efficient recycling processes for AMOLED components is crucial to mitigate this issue and promote a circular economy within the automotive sector.

On the positive side, the durability and longevity of AMOLED displays can contribute to sustainability by reducing the need for frequent replacements. Their ability to withstand extreme temperatures and maintain performance over time aligns well with the demanding environment of automotive interiors, potentially extending the lifespan of in-vehicle display systems.

The versatility of AMOLED technology also opens up possibilities for more sustainable vehicle designs. By integrating display functions into various surfaces, manufacturers can potentially reduce the overall number of components in a vehicle, leading to weight reduction and improved fuel efficiency. This consolidation of functions could also simplify manufacturing processes, potentially reducing energy consumption and waste in production.

As the automotive industry continues to embrace AMOLED technology, there is a growing emphasis on developing more environmentally friendly production techniques. Research into bio-based materials for OLED substrates and the use of water-based solvents in manufacturing processes are promising avenues for reducing the environmental footprint of AMOLED displays. Additionally, advancements in low-temperature polycrystalline silicon (LTPS) technology are enabling more energy-efficient production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!