Trends in AMOLED development for ultra-slim televisions.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED TV Evolution

The evolution of AMOLED technology in televisions has been a remarkable journey, characterized by continuous innovation and rapid advancements. Initially introduced in small-scale devices like smartphones, AMOLED displays have successfully transitioned into larger formats, including ultra-slim televisions.

In the early stages of AMOLED TV development, manufacturers faced significant challenges in scaling up the technology. The primary hurdles included maintaining uniform brightness across larger screens, addressing color accuracy issues, and managing power consumption. Despite these obstacles, the potential benefits of AMOLED, such as superior contrast ratios and vibrant colors, drove persistent research and development efforts.

The first generation of AMOLED TVs, introduced in the mid-2010s, showcased the technology's potential but were limited by high production costs and lower yields. These early models struggled to compete with established LCD and LED technologies in terms of price and screen size options. However, they set the stage for future improvements and captured the attention of consumers seeking premium viewing experiences.

As manufacturing processes improved, the second generation of AMOLED TVs emerged with enhanced picture quality and increased screen sizes. This phase saw the introduction of 4K resolution AMOLED panels, which significantly boosted the technology's appeal in the high-end TV market. Manufacturers also made strides in addressing the burn-in issues that had plagued earlier OLED displays, improving the longevity and reliability of AMOLED TVs.

The pursuit of ultra-slim designs became a key focus in the subsequent evolution of AMOLED TVs. Engineers developed innovative techniques to reduce panel thickness without compromising display quality. This led to the creation of "wallpaper" TVs, with screens measuring just a few millimeters in thickness. These ultra-slim designs not only showcased the aesthetic potential of AMOLED technology but also opened up new possibilities for TV placement and integration within home environments.

Recent developments in AMOLED TV technology have centered on enhancing brightness levels and color accuracy. The introduction of quantum dot technology in conjunction with AMOLED panels has resulted in QLED-OLED hybrid displays, combining the best attributes of both technologies. This fusion has enabled TVs to achieve higher peak brightness while maintaining the deep blacks and infinite contrast ratios characteristic of AMOLED displays.

Looking ahead, the evolution of AMOLED TVs is expected to continue with a focus on larger screen sizes, improved energy efficiency, and further refinements in picture quality. Emerging trends include the development of rollable and foldable AMOLED displays, which could revolutionize the concept of TV form factors and portability. As production costs decrease and yields improve, AMOLED technology is poised to capture a larger share of the television market, offering consumers unparalleled visual experiences in increasingly slim and versatile designs.

In the early stages of AMOLED TV development, manufacturers faced significant challenges in scaling up the technology. The primary hurdles included maintaining uniform brightness across larger screens, addressing color accuracy issues, and managing power consumption. Despite these obstacles, the potential benefits of AMOLED, such as superior contrast ratios and vibrant colors, drove persistent research and development efforts.

The first generation of AMOLED TVs, introduced in the mid-2010s, showcased the technology's potential but were limited by high production costs and lower yields. These early models struggled to compete with established LCD and LED technologies in terms of price and screen size options. However, they set the stage for future improvements and captured the attention of consumers seeking premium viewing experiences.

As manufacturing processes improved, the second generation of AMOLED TVs emerged with enhanced picture quality and increased screen sizes. This phase saw the introduction of 4K resolution AMOLED panels, which significantly boosted the technology's appeal in the high-end TV market. Manufacturers also made strides in addressing the burn-in issues that had plagued earlier OLED displays, improving the longevity and reliability of AMOLED TVs.

The pursuit of ultra-slim designs became a key focus in the subsequent evolution of AMOLED TVs. Engineers developed innovative techniques to reduce panel thickness without compromising display quality. This led to the creation of "wallpaper" TVs, with screens measuring just a few millimeters in thickness. These ultra-slim designs not only showcased the aesthetic potential of AMOLED technology but also opened up new possibilities for TV placement and integration within home environments.

Recent developments in AMOLED TV technology have centered on enhancing brightness levels and color accuracy. The introduction of quantum dot technology in conjunction with AMOLED panels has resulted in QLED-OLED hybrid displays, combining the best attributes of both technologies. This fusion has enabled TVs to achieve higher peak brightness while maintaining the deep blacks and infinite contrast ratios characteristic of AMOLED displays.

Looking ahead, the evolution of AMOLED TVs is expected to continue with a focus on larger screen sizes, improved energy efficiency, and further refinements in picture quality. Emerging trends include the development of rollable and foldable AMOLED displays, which could revolutionize the concept of TV form factors and portability. As production costs decrease and yields improve, AMOLED technology is poised to capture a larger share of the television market, offering consumers unparalleled visual experiences in increasingly slim and versatile designs.

Ultra-Slim TV Market

The ultra-slim TV market has experienced significant growth in recent years, driven by consumer demand for sleek, space-saving designs that enhance the aesthetic appeal of living spaces. This trend has been particularly pronounced in urban areas where living spaces are often compact, making ultra-slim TVs an attractive option for consumers seeking to maximize their available space without compromising on screen size or picture quality.

Market research indicates that the global ultra-slim TV market is expanding at a robust pace, with AMOLED technology playing a crucial role in this growth. The adoption of AMOLED displays in ultra-slim TVs has been a game-changer, allowing manufacturers to produce incredibly thin panels with superior picture quality, vibrant colors, and deep blacks. This technological advancement has not only improved the viewing experience but also enabled the creation of TVs that are barely thicker than a smartphone.

Consumer preferences are shifting towards larger screen sizes, even in the ultra-slim category. There is a growing demand for 55-inch and larger models, with 65-inch and 75-inch ultra-slim TVs gaining popularity in premium segments. This trend is supported by advancements in AMOLED technology, which allow for the production of larger panels without significantly increasing the overall thickness of the TV.

The market is also seeing a surge in demand for smart features and connectivity options in ultra-slim TVs. Consumers are looking for devices that seamlessly integrate with their smart home ecosystems, offer voice control capabilities, and provide access to a wide range of streaming services. This has led to collaborations between TV manufacturers and technology companies to enhance the smart capabilities of ultra-slim TVs.

Energy efficiency is another key factor driving market growth. AMOLED technology's inherent energy-saving properties, combined with the overall reduction in material usage in ultra-slim designs, appeal to environmentally conscious consumers and align with global energy efficiency regulations.

Geographically, Asia-Pacific leads the ultra-slim TV market, with countries like South Korea, Japan, and China at the forefront of both production and consumption. However, North America and Europe are also significant markets, with high adoption rates of premium ultra-slim TV models.

The competitive landscape of the ultra-slim TV market is characterized by intense rivalry among major electronics manufacturers. Companies are investing heavily in R&D to push the boundaries of AMOLED technology and ultra-slim design, resulting in a rapid pace of innovation and product releases. This competition is beneficial for consumers, as it leads to more advanced features, improved picture quality, and competitive pricing.

Market research indicates that the global ultra-slim TV market is expanding at a robust pace, with AMOLED technology playing a crucial role in this growth. The adoption of AMOLED displays in ultra-slim TVs has been a game-changer, allowing manufacturers to produce incredibly thin panels with superior picture quality, vibrant colors, and deep blacks. This technological advancement has not only improved the viewing experience but also enabled the creation of TVs that are barely thicker than a smartphone.

Consumer preferences are shifting towards larger screen sizes, even in the ultra-slim category. There is a growing demand for 55-inch and larger models, with 65-inch and 75-inch ultra-slim TVs gaining popularity in premium segments. This trend is supported by advancements in AMOLED technology, which allow for the production of larger panels without significantly increasing the overall thickness of the TV.

The market is also seeing a surge in demand for smart features and connectivity options in ultra-slim TVs. Consumers are looking for devices that seamlessly integrate with their smart home ecosystems, offer voice control capabilities, and provide access to a wide range of streaming services. This has led to collaborations between TV manufacturers and technology companies to enhance the smart capabilities of ultra-slim TVs.

Energy efficiency is another key factor driving market growth. AMOLED technology's inherent energy-saving properties, combined with the overall reduction in material usage in ultra-slim designs, appeal to environmentally conscious consumers and align with global energy efficiency regulations.

Geographically, Asia-Pacific leads the ultra-slim TV market, with countries like South Korea, Japan, and China at the forefront of both production and consumption. However, North America and Europe are also significant markets, with high adoption rates of premium ultra-slim TV models.

The competitive landscape of the ultra-slim TV market is characterized by intense rivalry among major electronics manufacturers. Companies are investing heavily in R&D to push the boundaries of AMOLED technology and ultra-slim design, resulting in a rapid pace of innovation and product releases. This competition is beneficial for consumers, as it leads to more advanced features, improved picture quality, and competitive pricing.

AMOLED Challenges

Despite the rapid advancements in AMOLED technology for ultra-slim televisions, several significant challenges persist in its development and implementation. One of the primary obstacles is the high production cost associated with AMOLED panels, particularly for large-screen televisions. The complex manufacturing process and low yield rates contribute to the elevated expenses, making it difficult for manufacturers to achieve economies of scale and offer competitive pricing in the market.

Another critical challenge is the issue of burn-in or image retention. AMOLED displays are susceptible to permanent image retention when static elements are displayed for extended periods. This problem is particularly concerning for televisions, where channel logos, news tickers, or game interfaces may remain on-screen for hours. Manufacturers are actively working on solutions, such as pixel shifting and brightness adjustment algorithms, but a definitive solution remains elusive.

Lifespan and degradation of AMOLED panels also pose significant hurdles. The organic materials used in AMOLED displays degrade over time, leading to a reduction in brightness and color accuracy. This degradation is not uniform across all colors, with blue subpixels typically deteriorating faster than red and green. Consequently, maintaining consistent image quality throughout the television's lifespan becomes a considerable challenge for manufacturers.

Power consumption is another area of concern, especially for large-screen AMOLED televisions. While AMOLED technology is generally more energy-efficient than traditional LCD displays, the power requirements for ultra-slim televisions with high brightness levels and large screen sizes can be substantial. Balancing power efficiency with performance and picture quality remains an ongoing challenge for developers.

The pursuit of ever-thinner designs introduces structural integrity issues. As televisions become slimmer, ensuring adequate support and durability becomes increasingly difficult. Engineers must innovate in materials and design to create ultra-slim AMOLED televisions that can withstand normal use without compromising on picture quality or increasing the risk of damage.

Color accuracy and uniformity across large AMOLED panels present another set of challenges. Achieving consistent color reproduction and maintaining uniform brightness across the entire screen becomes more difficult as panel sizes increase. This issue is particularly noticeable in dark scenes, where even slight variations in black levels can be perceptible to viewers.

Lastly, the complexity of driving large AMOLED panels at high refresh rates and resolutions poses significant technical challenges. As consumers demand higher resolutions (4K and beyond) and faster refresh rates for smoother motion, the requirements for data processing and panel driving become increasingly demanding. Developing efficient and cost-effective solutions for these high-performance requirements remains a key focus area for AMOLED television manufacturers.

Another critical challenge is the issue of burn-in or image retention. AMOLED displays are susceptible to permanent image retention when static elements are displayed for extended periods. This problem is particularly concerning for televisions, where channel logos, news tickers, or game interfaces may remain on-screen for hours. Manufacturers are actively working on solutions, such as pixel shifting and brightness adjustment algorithms, but a definitive solution remains elusive.

Lifespan and degradation of AMOLED panels also pose significant hurdles. The organic materials used in AMOLED displays degrade over time, leading to a reduction in brightness and color accuracy. This degradation is not uniform across all colors, with blue subpixels typically deteriorating faster than red and green. Consequently, maintaining consistent image quality throughout the television's lifespan becomes a considerable challenge for manufacturers.

Power consumption is another area of concern, especially for large-screen AMOLED televisions. While AMOLED technology is generally more energy-efficient than traditional LCD displays, the power requirements for ultra-slim televisions with high brightness levels and large screen sizes can be substantial. Balancing power efficiency with performance and picture quality remains an ongoing challenge for developers.

The pursuit of ever-thinner designs introduces structural integrity issues. As televisions become slimmer, ensuring adequate support and durability becomes increasingly difficult. Engineers must innovate in materials and design to create ultra-slim AMOLED televisions that can withstand normal use without compromising on picture quality or increasing the risk of damage.

Color accuracy and uniformity across large AMOLED panels present another set of challenges. Achieving consistent color reproduction and maintaining uniform brightness across the entire screen becomes more difficult as panel sizes increase. This issue is particularly noticeable in dark scenes, where even slight variations in black levels can be perceptible to viewers.

Lastly, the complexity of driving large AMOLED panels at high refresh rates and resolutions poses significant technical challenges. As consumers demand higher resolutions (4K and beyond) and faster refresh rates for smoother motion, the requirements for data processing and panel driving become increasingly demanding. Developing efficient and cost-effective solutions for these high-performance requirements remains a key focus area for AMOLED television manufacturers.

Current AMOLED Solutions

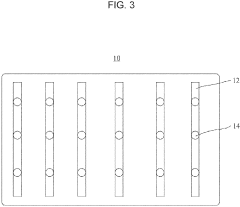

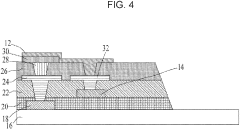

01 Thin-film transistor (TFT) design for AMOLED displays

Advanced TFT designs are implemented to improve the performance and reduce the thickness of AMOLED displays. These designs focus on optimizing the structure and materials of TFTs to enhance electron mobility, reduce power consumption, and minimize the overall thickness of the display panel.- Thin-film transistor (TFT) design for AMOLED displays: Advanced TFT designs are employed to reduce the overall thickness of AMOLED displays. These designs include optimized semiconductor layers, gate structures, and electrode configurations to minimize the vertical stack while maintaining performance. Such improvements contribute to the slimness of AMOLED panels without compromising display quality or functionality.

- Flexible AMOLED substrates: Utilizing flexible substrates, such as plastic or ultra-thin glass, enables the production of slimmer AMOLED displays. These substrates allow for reduced overall thickness and can conform to curved or foldable form factors. The flexibility also contributes to improved durability and potential for novel device designs.

- Integrated touch sensors for AMOLED displays: Incorporating touch sensors directly into the AMOLED display stack eliminates the need for a separate touch layer, reducing overall thickness. This integration can be achieved through in-cell or on-cell touch technologies, which combine touch functionality with display elements, contributing to a slimmer profile.

- Optimized OLED material stack: Advancements in OLED materials and deposition techniques allow for thinner organic layers without sacrificing luminous efficiency. This includes the development of high-performance emissive materials, improved charge transport layers, and precise deposition methods that minimize layer thickness while maintaining optimal device performance.

- Slim bezel and edge sealing techniques: Innovative bezel designs and edge sealing methods contribute to overall AMOLED slimness by reducing the non-display area around the panel. Advanced encapsulation techniques protect the organic materials from moisture and oxygen while minimizing the thickness added by traditional sealing methods, allowing for ultra-thin display edges.

02 Flexible AMOLED substrates

Utilizing flexible substrates, such as plastic or ultra-thin glass, enables the production of slimmer and more bendable AMOLED displays. These substrates allow for reduced overall thickness while maintaining durability and display quality, making them suitable for various applications including wearable devices and foldable smartphones.Expand Specific Solutions03 Pixel circuit optimization

Innovative pixel circuit designs are developed to enhance the efficiency and reduce the complexity of AMOLED displays. These optimizations include improved driving schemes, reduced number of transistors per pixel, and advanced compensation techniques, all contributing to a slimmer display profile while maintaining image quality.Expand Specific Solutions04 Integration of touch and display layers

Integrating touch functionality directly into the display stack reduces the overall thickness of AMOLED panels. This approach eliminates the need for a separate touch layer, resulting in a slimmer device profile while maintaining touch sensitivity and display performance.Expand Specific Solutions05 Advanced encapsulation techniques

Developing thin-film encapsulation methods that provide effective protection against moisture and oxygen while minimizing the thickness of the encapsulation layer. These techniques utilize advanced materials and deposition processes to create ultra-thin barrier layers, contributing to the overall slimness of AMOLED displays.Expand Specific Solutions

Key AMOLED Players

The AMOLED development for ultra-slim televisions is in a mature growth stage, with the market size expanding rapidly due to increasing consumer demand for thinner, higher-quality displays. The technology has reached a high level of maturity, with key players like BOE Technology, LG Display, and TCL China Star Optoelectronics leading innovation. These companies are investing heavily in research and development to enhance AMOLED performance, focusing on improving color accuracy, energy efficiency, and reducing production costs. Emerging players like Everdisplay Optronics and Visionox are also contributing to the competitive landscape, driving further advancements in AMOLED technology for ultra-slim TV applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has been at the forefront of AMOLED development for ultra-slim televisions. They have introduced innovative technologies such as oxide semiconductor backplanes and inkjet-printed OLED displays[1]. Their latest AMOLED panels for TVs feature a thickness of less than 1mm, achieving an impressive screen-to-body ratio of over 99%[2]. BOE has also developed a 55-inch 8K AMOLED display with a resolution of 7680x4320 pixels, demonstrating their capability in producing high-resolution, large-size AMOLED panels for premium TV markets[3]. Additionally, BOE has implemented advanced pixel compensation techniques to enhance image quality and longevity, addressing common OLED issues like burn-in and color shift[4].

Strengths: Leading position in large-size AMOLED production, advanced thin-film technology, and high-resolution capabilities. Weaknesses: Higher production costs compared to traditional LCD technology, potential for supply chain constraints in scaling up production.

Wuhan China Star Optoelectronics Semicon Display Tech Co.

Technical Solution: Wuhan CSOT, a subsidiary of TCL, has been actively developing AMOLED technologies for ultra-slim televisions. They have focused on advancing oxide TFT backplane technology, which enables higher electron mobility and better stability for large-size AMOLED displays[11]. Wuhan CSOT has also made progress in implementing advanced compensation algorithms to improve image quality and reduce power consumption in AMOLED panels[12]. Their research includes the development of top-emission OLED structures, which can potentially increase the aperture ratio and overall efficiency of AMOLED displays for TVs[13]. Furthermore, Wuhan CSOT has been exploring the use of AI-driven manufacturing processes to enhance yield rates and reduce defects in large-size AMOLED panel production.

Strengths: Strong focus on oxide TFT technology, advanced compensation techniques, and AI-driven manufacturing processes. Weaknesses: Limited track record in mass production of large-size AMOLED panels compared to more established players.

AMOLED Innovations

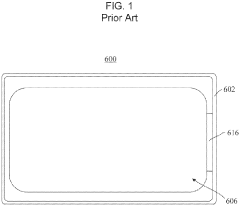

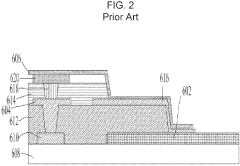

Active matrix organic light emitting diode array substrate, fabricating method, and display apparatus

PatentWO2017024851A1

Innovation

- Utilizes an independent thin film transistor (TFT) to control each pixel in AMOLED, allowing continuous and independent driving for lighting.

- Addresses the issue of organic light-emitting layer entering via holes in the planarization layer, which can cause point discharge and pixel breakdown.

- Aims to eliminate defective pixel display dark spots caused by organic light-emitting layer breakdown, thereby improving overall display quality.

Active-matrix organic light-emitting diode (AMOLED) display module

PatentActiveUS11257882B2

Innovation

- A second conductive layer is uniformly arranged across the AMOLED display panel to ensure consistent common ground voltage distribution to the cathode, maintaining a uniform voltage difference across each OLED element, thereby enhancing luminance uniformity.

AMOLED Manufacturing

AMOLED manufacturing for ultra-slim televisions has seen significant advancements in recent years, driven by the demand for thinner, more energy-efficient displays with superior picture quality. The process involves several key steps, each crucial for producing high-performance AMOLED panels.

The first stage in AMOLED manufacturing is the preparation of the substrate, typically made of ultra-thin glass or plastic. For ultra-slim TVs, manufacturers are increasingly using flexible plastic substrates, which allow for thinner profiles and potential curved designs. These substrates undergo rigorous cleaning and surface treatment to ensure optimal adhesion of subsequent layers.

Next, the thin-film transistor (TFT) backplane is fabricated. This layer contains the circuitry that controls each pixel. For ultra-slim TVs, low-temperature polycrystalline silicon (LTPS) or oxide TFT technologies are preferred due to their higher electron mobility and ability to be fabricated on flexible substrates. The TFT layer is crucial for achieving high refresh rates and quick response times in large AMOLED displays.

The OLED emission layer is then deposited onto the TFT backplane. This process typically uses vacuum thermal evaporation for small molecule OLEDs or solution processing for polymer OLEDs. For ultra-slim TVs, manufacturers are developing advanced deposition techniques that allow for more uniform and thinner OLED layers, contributing to the overall slimness of the display.

Encapsulation is a critical step in AMOLED manufacturing, especially for ultra-slim TVs. Traditional glass encapsulation is being replaced by thin-film encapsulation (TFE) technologies. TFE involves depositing alternating layers of inorganic and organic materials to protect the OLED from moisture and oxygen, while maintaining the display's slim profile.

To enhance display performance, additional optical layers are often incorporated. These may include polarizers, color filters, and light outcoupling structures. For ultra-slim TVs, manufacturers are developing ultra-thin versions of these components to minimize the overall thickness of the display stack.

The final stages of AMOLED manufacturing involve module assembly and testing. This includes attaching driver ICs, flexible printed circuits, and other necessary components. For ultra-slim TVs, innovative integration techniques are employed to minimize the space required for these components, often utilizing the edges or back of the display to maintain a slim front profile.

Throughout the manufacturing process, stringent quality control measures are implemented to ensure uniformity and prevent defects. Advanced inspection systems, including automated optical inspection (AOI) and electrical testing, are used to detect any irregularities in the AMOLED panels.

The first stage in AMOLED manufacturing is the preparation of the substrate, typically made of ultra-thin glass or plastic. For ultra-slim TVs, manufacturers are increasingly using flexible plastic substrates, which allow for thinner profiles and potential curved designs. These substrates undergo rigorous cleaning and surface treatment to ensure optimal adhesion of subsequent layers.

Next, the thin-film transistor (TFT) backplane is fabricated. This layer contains the circuitry that controls each pixel. For ultra-slim TVs, low-temperature polycrystalline silicon (LTPS) or oxide TFT technologies are preferred due to their higher electron mobility and ability to be fabricated on flexible substrates. The TFT layer is crucial for achieving high refresh rates and quick response times in large AMOLED displays.

The OLED emission layer is then deposited onto the TFT backplane. This process typically uses vacuum thermal evaporation for small molecule OLEDs or solution processing for polymer OLEDs. For ultra-slim TVs, manufacturers are developing advanced deposition techniques that allow for more uniform and thinner OLED layers, contributing to the overall slimness of the display.

Encapsulation is a critical step in AMOLED manufacturing, especially for ultra-slim TVs. Traditional glass encapsulation is being replaced by thin-film encapsulation (TFE) technologies. TFE involves depositing alternating layers of inorganic and organic materials to protect the OLED from moisture and oxygen, while maintaining the display's slim profile.

To enhance display performance, additional optical layers are often incorporated. These may include polarizers, color filters, and light outcoupling structures. For ultra-slim TVs, manufacturers are developing ultra-thin versions of these components to minimize the overall thickness of the display stack.

The final stages of AMOLED manufacturing involve module assembly and testing. This includes attaching driver ICs, flexible printed circuits, and other necessary components. For ultra-slim TVs, innovative integration techniques are employed to minimize the space required for these components, often utilizing the edges or back of the display to maintain a slim front profile.

Throughout the manufacturing process, stringent quality control measures are implemented to ensure uniformity and prevent defects. Advanced inspection systems, including automated optical inspection (AOI) and electrical testing, are used to detect any irregularities in the AMOLED panels.

Energy Efficiency

Energy efficiency is a critical factor in the development of AMOLED displays for ultra-slim televisions. As consumers increasingly demand thinner and more energy-efficient devices, manufacturers are focusing on improving the power consumption of AMOLED panels without compromising picture quality.

One of the key trends in AMOLED energy efficiency is the development of more efficient organic materials. Researchers are exploring new emissive compounds that can produce brighter light with less power input. These advanced materials not only reduce energy consumption but also extend the lifespan of AMOLED displays by minimizing degradation over time.

Another significant advancement is the implementation of advanced pixel structures. Manufacturers are adopting new pixel designs that allow for better light emission and reduced current leakage. This includes the use of micro-cavity structures and optimized electrode configurations, which enhance light extraction efficiency and reduce power loss.

Power management systems are also evolving to support AMOLED energy efficiency. Adaptive brightness control and local dimming technologies are being refined to dynamically adjust display brightness based on ambient light conditions and content. These systems can significantly reduce power consumption, especially in low-light environments or when displaying darker scenes.

The integration of low-temperature polycrystalline silicon (LTPS) backplanes is another trend contributing to improved energy efficiency. LTPS technology allows for smaller transistors and higher electron mobility, resulting in lower power consumption and improved display performance. This is particularly beneficial for ultra-slim televisions, where space constraints make energy efficiency even more crucial.

Furthermore, advancements in driving schemes are playing a role in reducing power consumption. Manufacturers are implementing more sophisticated voltage modulation techniques and optimizing refresh rates to minimize unnecessary power usage. Variable refresh rate technologies, for instance, can adjust the display's refresh rate based on the content being shown, saving energy when displaying static images or slow-moving scenes.

Thermal management is also a focus area for improving AMOLED energy efficiency. As ultra-slim televisions have limited space for heat dissipation, manufacturers are developing innovative cooling solutions and heat-spreading materials. These advancements help maintain optimal operating temperatures, which is essential for preserving energy efficiency and prolonging the lifespan of AMOLED displays.

In conclusion, the trends in AMOLED development for ultra-slim televisions are strongly focused on enhancing energy efficiency through multiple approaches. From material innovations to advanced pixel structures and power management systems, these developments are crucial for meeting consumer demands for thinner, more energy-efficient televisions without sacrificing display quality.

One of the key trends in AMOLED energy efficiency is the development of more efficient organic materials. Researchers are exploring new emissive compounds that can produce brighter light with less power input. These advanced materials not only reduce energy consumption but also extend the lifespan of AMOLED displays by minimizing degradation over time.

Another significant advancement is the implementation of advanced pixel structures. Manufacturers are adopting new pixel designs that allow for better light emission and reduced current leakage. This includes the use of micro-cavity structures and optimized electrode configurations, which enhance light extraction efficiency and reduce power loss.

Power management systems are also evolving to support AMOLED energy efficiency. Adaptive brightness control and local dimming technologies are being refined to dynamically adjust display brightness based on ambient light conditions and content. These systems can significantly reduce power consumption, especially in low-light environments or when displaying darker scenes.

The integration of low-temperature polycrystalline silicon (LTPS) backplanes is another trend contributing to improved energy efficiency. LTPS technology allows for smaller transistors and higher electron mobility, resulting in lower power consumption and improved display performance. This is particularly beneficial for ultra-slim televisions, where space constraints make energy efficiency even more crucial.

Furthermore, advancements in driving schemes are playing a role in reducing power consumption. Manufacturers are implementing more sophisticated voltage modulation techniques and optimizing refresh rates to minimize unnecessary power usage. Variable refresh rate technologies, for instance, can adjust the display's refresh rate based on the content being shown, saving energy when displaying static images or slow-moving scenes.

Thermal management is also a focus area for improving AMOLED energy efficiency. As ultra-slim televisions have limited space for heat dissipation, manufacturers are developing innovative cooling solutions and heat-spreading materials. These advancements help maintain optimal operating temperatures, which is essential for preserving energy efficiency and prolonging the lifespan of AMOLED displays.

In conclusion, the trends in AMOLED development for ultra-slim televisions are strongly focused on enhancing energy efficiency through multiple approaches. From material innovations to advanced pixel structures and power management systems, these developments are crucial for meeting consumer demands for thinner, more energy-efficient televisions without sacrificing display quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!