Understanding the physics of AMOLED bending capabilities.

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AMOLED Bending Physics Background and Objectives

Active-Matrix Organic Light-Emitting Diode (AMOLED) technology has revolutionized the display industry, offering superior image quality, energy efficiency, and flexibility. The ability to bend AMOLED displays has opened up new possibilities for innovative device designs and user experiences. Understanding the physics behind AMOLED bending capabilities is crucial for advancing this technology and pushing the boundaries of flexible electronics.

The development of bendable AMOLED displays can be traced back to the early 2000s when researchers began exploring the potential of organic materials for flexible electronics. The key breakthrough came with the development of thin-film transistor (TFT) backplanes on flexible substrates, which allowed for the creation of active-matrix displays that could be bent without losing functionality.

As the technology progressed, several milestones were achieved, including the introduction of plastic substrates, the development of more robust organic materials, and the implementation of advanced encapsulation techniques. These advancements collectively contributed to the realization of commercially viable flexible AMOLED displays.

The physics of AMOLED bending involves a complex interplay of material properties, structural design, and electronic behavior. At its core, the bending capability relies on the inherent flexibility of organic semiconductors and the ability to create ultra-thin device structures. The organic layers in an AMOLED display, typically only a few hundred nanometers thick, can withstand significant deformation without compromising their electronic properties.

However, bending an AMOLED display introduces various challenges that must be addressed. These include stress-induced changes in the organic layer morphology, potential delamination of layers, and the impact on charge transport and light emission efficiency. Understanding these phenomena requires a multidisciplinary approach, combining knowledge from materials science, solid-state physics, and mechanical engineering.

The primary objective of researching AMOLED bending physics is to develop displays that can withstand repeated bending cycles without degradation in performance or lifespan. This involves optimizing the mechanical properties of each component in the display stack, from the substrate to the encapsulation layer, to ensure uniform stress distribution and minimal fatigue.

Another critical goal is to expand the bending radius capabilities of AMOLED displays. Current commercial flexible displays typically have a minimum bending radius of several millimeters, but researchers aim to achieve sub-millimeter bending radii without compromising display quality or durability. This would enable the creation of truly foldable devices and even displays that can be rolled up like a scroll.

Furthermore, understanding the physics of AMOLED bending is essential for developing new applications beyond traditional mobile devices. Potential areas of exploration include wearable displays, automotive interiors, and architectural elements. Each of these applications presents unique challenges in terms of environmental conditions, user interaction, and integration with other technologies.

The development of bendable AMOLED displays can be traced back to the early 2000s when researchers began exploring the potential of organic materials for flexible electronics. The key breakthrough came with the development of thin-film transistor (TFT) backplanes on flexible substrates, which allowed for the creation of active-matrix displays that could be bent without losing functionality.

As the technology progressed, several milestones were achieved, including the introduction of plastic substrates, the development of more robust organic materials, and the implementation of advanced encapsulation techniques. These advancements collectively contributed to the realization of commercially viable flexible AMOLED displays.

The physics of AMOLED bending involves a complex interplay of material properties, structural design, and electronic behavior. At its core, the bending capability relies on the inherent flexibility of organic semiconductors and the ability to create ultra-thin device structures. The organic layers in an AMOLED display, typically only a few hundred nanometers thick, can withstand significant deformation without compromising their electronic properties.

However, bending an AMOLED display introduces various challenges that must be addressed. These include stress-induced changes in the organic layer morphology, potential delamination of layers, and the impact on charge transport and light emission efficiency. Understanding these phenomena requires a multidisciplinary approach, combining knowledge from materials science, solid-state physics, and mechanical engineering.

The primary objective of researching AMOLED bending physics is to develop displays that can withstand repeated bending cycles without degradation in performance or lifespan. This involves optimizing the mechanical properties of each component in the display stack, from the substrate to the encapsulation layer, to ensure uniform stress distribution and minimal fatigue.

Another critical goal is to expand the bending radius capabilities of AMOLED displays. Current commercial flexible displays typically have a minimum bending radius of several millimeters, but researchers aim to achieve sub-millimeter bending radii without compromising display quality or durability. This would enable the creation of truly foldable devices and even displays that can be rolled up like a scroll.

Furthermore, understanding the physics of AMOLED bending is essential for developing new applications beyond traditional mobile devices. Potential areas of exploration include wearable displays, automotive interiors, and architectural elements. Each of these applications presents unique challenges in terms of environmental conditions, user interaction, and integration with other technologies.

Flexible Display Market Analysis

The flexible display market has experienced significant growth in recent years, driven by the increasing demand for innovative and portable electronic devices. This market segment encompasses various technologies, with AMOLED (Active-Matrix Organic Light-Emitting Diode) displays at the forefront due to their superior flexibility and image quality. The global flexible display market is expected to continue its upward trajectory, with substantial growth projected over the next decade.

Consumer electronics, particularly smartphones and wearable devices, are the primary drivers of the flexible display market. As manufacturers strive to differentiate their products and offer enhanced user experiences, the integration of flexible displays has become a key selling point. The ability to create curved, foldable, and rollable devices has opened up new design possibilities and use cases, attracting both consumers and businesses alike.

The automotive industry is emerging as another significant market for flexible displays. Advanced driver assistance systems (ADAS) and in-vehicle infotainment systems are increasingly incorporating curved and flexible displays to improve ergonomics and aesthetics within vehicle interiors. This trend is expected to accelerate as autonomous vehicles become more prevalent, creating additional opportunities for flexible display technologies.

In the context of AMOLED bending capabilities, market demand is shifting towards displays that can withstand repeated flexing without compromising performance or durability. This has led to increased research and development efforts focused on understanding and improving the physics behind AMOLED bending. Manufacturers are investing heavily in materials science and engineering to create more resilient and flexible AMOLED panels that can meet the rigorous demands of foldable and rollable devices.

The market analysis reveals a growing interest in larger flexible displays for applications in advertising, public information systems, and smart home devices. These emerging applications are expected to contribute significantly to market growth in the coming years, as the technology becomes more cost-effective and scalable.

Geographically, Asia-Pacific dominates the flexible display market, with South Korea and China leading in both production and consumption. However, North America and Europe are also significant markets, particularly in terms of research and development and high-end consumer adoption.

As the flexible display market continues to evolve, challenges such as production costs, yield rates, and long-term reliability remain key factors influencing market dynamics. Overcoming these challenges will be crucial for widespread adoption and continued market expansion. The industry's ability to address these issues while pushing the boundaries of AMOLED bending capabilities will shape the future of the flexible display market and its potential applications across various sectors.

Consumer electronics, particularly smartphones and wearable devices, are the primary drivers of the flexible display market. As manufacturers strive to differentiate their products and offer enhanced user experiences, the integration of flexible displays has become a key selling point. The ability to create curved, foldable, and rollable devices has opened up new design possibilities and use cases, attracting both consumers and businesses alike.

The automotive industry is emerging as another significant market for flexible displays. Advanced driver assistance systems (ADAS) and in-vehicle infotainment systems are increasingly incorporating curved and flexible displays to improve ergonomics and aesthetics within vehicle interiors. This trend is expected to accelerate as autonomous vehicles become more prevalent, creating additional opportunities for flexible display technologies.

In the context of AMOLED bending capabilities, market demand is shifting towards displays that can withstand repeated flexing without compromising performance or durability. This has led to increased research and development efforts focused on understanding and improving the physics behind AMOLED bending. Manufacturers are investing heavily in materials science and engineering to create more resilient and flexible AMOLED panels that can meet the rigorous demands of foldable and rollable devices.

The market analysis reveals a growing interest in larger flexible displays for applications in advertising, public information systems, and smart home devices. These emerging applications are expected to contribute significantly to market growth in the coming years, as the technology becomes more cost-effective and scalable.

Geographically, Asia-Pacific dominates the flexible display market, with South Korea and China leading in both production and consumption. However, North America and Europe are also significant markets, particularly in terms of research and development and high-end consumer adoption.

As the flexible display market continues to evolve, challenges such as production costs, yield rates, and long-term reliability remain key factors influencing market dynamics. Overcoming these challenges will be crucial for widespread adoption and continued market expansion. The industry's ability to address these issues while pushing the boundaries of AMOLED bending capabilities will shape the future of the flexible display market and its potential applications across various sectors.

AMOLED Bending Challenges and Limitations

AMOLED (Active-Matrix Organic Light-Emitting Diode) displays have revolutionized the mobile device industry with their superior image quality and energy efficiency. However, as the demand for flexible and foldable devices grows, AMOLED technology faces significant challenges in maintaining its performance under bending conditions.

One of the primary limitations of AMOLED bending capabilities lies in the structural integrity of the organic layers. These layers, which are responsible for light emission, are extremely thin and sensitive to mechanical stress. When subjected to repeated bending, the organic materials can develop microcracks, leading to pixel degradation and eventual failure. This issue is particularly pronounced in areas of sharp bending, where stress concentrations are highest.

Another challenge is the durability of the thin-film transistor (TFT) backplane that controls each pixel. Traditional amorphous silicon (a-Si) or low-temperature polycrystalline silicon (LTPS) TFTs are rigid and prone to cracking under bending stress. While more flexible alternatives like indium gallium zinc oxide (IGZO) have been developed, they still face limitations in extreme bending scenarios.

The encapsulation layer, crucial for protecting the organic materials from moisture and oxygen, also presents a significant hurdle. Traditional glass encapsulation is inherently inflexible, necessitating the development of thin-film encapsulation (TFE) technologies. However, ensuring the impermeability of TFE under repeated bending cycles remains a challenge, as even microscopic defects can lead to rapid device degradation.

Electrical interconnects within the display pose another limitation. As the display bends, these connections are subjected to tensile and compressive forces, potentially leading to disconnections or short circuits. Developing stretchable and durable interconnect materials and designs is crucial for overcoming this challenge.

The physics of bending also introduces optical challenges. As the display curves, light emission patterns change, potentially leading to color shifts and brightness variations across the bent surface. Compensating for these effects through both material engineering and software algorithms is necessary to maintain image quality in flexible displays.

Temperature management in bent configurations presents another limitation. AMOLED displays generate heat during operation, and bending can affect heat dissipation pathways. Localized heating in bent areas can accelerate degradation of organic materials and affect display performance.

Lastly, the mechanical stress induced by bending can cause delamination between the various layers of the AMOLED stack. This separation can lead to air gaps, altering the optical properties of the display and potentially causing visible defects. Developing adhesives and interface materials that maintain strong bonds under repeated bending cycles is essential for addressing this limitation.

One of the primary limitations of AMOLED bending capabilities lies in the structural integrity of the organic layers. These layers, which are responsible for light emission, are extremely thin and sensitive to mechanical stress. When subjected to repeated bending, the organic materials can develop microcracks, leading to pixel degradation and eventual failure. This issue is particularly pronounced in areas of sharp bending, where stress concentrations are highest.

Another challenge is the durability of the thin-film transistor (TFT) backplane that controls each pixel. Traditional amorphous silicon (a-Si) or low-temperature polycrystalline silicon (LTPS) TFTs are rigid and prone to cracking under bending stress. While more flexible alternatives like indium gallium zinc oxide (IGZO) have been developed, they still face limitations in extreme bending scenarios.

The encapsulation layer, crucial for protecting the organic materials from moisture and oxygen, also presents a significant hurdle. Traditional glass encapsulation is inherently inflexible, necessitating the development of thin-film encapsulation (TFE) technologies. However, ensuring the impermeability of TFE under repeated bending cycles remains a challenge, as even microscopic defects can lead to rapid device degradation.

Electrical interconnects within the display pose another limitation. As the display bends, these connections are subjected to tensile and compressive forces, potentially leading to disconnections or short circuits. Developing stretchable and durable interconnect materials and designs is crucial for overcoming this challenge.

The physics of bending also introduces optical challenges. As the display curves, light emission patterns change, potentially leading to color shifts and brightness variations across the bent surface. Compensating for these effects through both material engineering and software algorithms is necessary to maintain image quality in flexible displays.

Temperature management in bent configurations presents another limitation. AMOLED displays generate heat during operation, and bending can affect heat dissipation pathways. Localized heating in bent areas can accelerate degradation of organic materials and affect display performance.

Lastly, the mechanical stress induced by bending can cause delamination between the various layers of the AMOLED stack. This separation can lead to air gaps, altering the optical properties of the display and potentially causing visible defects. Developing adhesives and interface materials that maintain strong bonds under repeated bending cycles is essential for addressing this limitation.

Current AMOLED Bending Solutions

01 Flexible AMOLED display structures

AMOLED displays can be designed with flexible structures that allow for bending capabilities. This involves using flexible substrates, thin-film transistors, and organic light-emitting materials that can withstand deformation without compromising display performance. The flexible structure enables the creation of curved, foldable, or rollable displays for various applications.- Flexible AMOLED display structures: AMOLED displays can be made flexible by using specialized structures and materials. These structures often include flexible substrates, thin-film transistors, and organic light-emitting layers that can withstand bending without compromising display performance. The flexibility allows for curved or foldable displays, expanding the potential applications of AMOLED technology.

- Bending stress management in AMOLED displays: Various techniques are employed to manage bending stress in AMOLED displays. These may include using stress-relief layers, optimizing the placement of components, and designing specific pixel structures that can accommodate bending. Such approaches help maintain display integrity and functionality even when the screen is flexed or folded repeatedly.

- Foldable AMOLED display configurations: Foldable AMOLED displays represent an advanced application of bending capabilities. These displays can be folded along one or more axes, allowing for compact devices that can expand into larger screens. Special hinge mechanisms, flexible encapsulation methods, and durable protective layers are key components in creating reliable foldable AMOLED displays.

- Touch sensitivity in flexible AMOLED displays: Maintaining touch sensitivity in flexible AMOLED displays presents unique challenges. Solutions include developing flexible touch sensors that can bend with the display, integrating touch functionality directly into the display layers, and implementing software algorithms to compensate for changes in touch response when the display is bent or folded.

- Durability and lifespan of bendable AMOLED displays: Enhancing the durability and lifespan of bendable AMOLED displays is crucial for their practical application. This involves developing robust encapsulation methods to protect organic materials from moisture and oxygen, creating scratch-resistant and flexible cover materials, and designing display structures that can withstand repeated bending cycles without degradation in performance or appearance.

02 Stress distribution and compensation in bent displays

When AMOLED displays are bent, stress is distributed across the display components. To maintain display quality and prevent damage, various compensation techniques are employed. These may include stress-relieving layers, optimized pixel layouts, and algorithms that adjust pixel brightness and color based on the bending angle and stress distribution.Expand Specific Solutions03 Touch sensitivity in flexible AMOLED displays

Integrating touch sensitivity into flexible AMOLED displays presents unique challenges. Solutions include developing touch sensors that can maintain accuracy and responsiveness when bent, as well as implementing algorithms that can compensate for changes in touch detection due to display deformation. This enables the creation of fully functional flexible touchscreen devices.Expand Specific Solutions04 Foldable and rollable AMOLED display designs

Advanced AMOLED display designs allow for folding or rolling of the display. These designs incorporate specialized hinge mechanisms, flexible encapsulation layers, and strain-resistant electrode materials. The ability to fold or roll the display enables the development of compact devices with larger screen sizes when unfolded or unrolled.Expand Specific Solutions05 Durability and lifespan of flexible AMOLED displays

Ensuring the durability and longevity of flexible AMOLED displays is crucial for their practical application. This involves developing materials and structures that can withstand repeated bending cycles without degradation. Techniques such as using robust encapsulation layers, optimizing organic layer compositions, and implementing stress-relief mechanisms are employed to extend the lifespan of flexible displays.Expand Specific Solutions

Key Players in Flexible AMOLED Industry

The AMOLED bending capabilities market is in a growth phase, driven by increasing demand for flexible displays in smartphones, wearables, and other consumer electronics. The global flexible display market is projected to reach significant size in the coming years, indicating substantial potential for AMOLED bending technology. In terms of technological maturity, companies like Samsung Electronics, BOE Technology, and LG Display are leading the way with advanced AMOLED bending solutions. These firms, along with others like Visionox and TCL CSOT, are investing heavily in R&D to improve flexibility, durability, and production efficiency. The competition is intensifying as more players enter the market, pushing for innovations in materials science and manufacturing processes to enhance AMOLED bending capabilities.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has made significant strides in understanding and implementing AMOLED bending capabilities. Their approach focuses on developing flexible OLED displays using a combination of advanced materials and innovative structural designs. BOE's flexible AMOLED panels can achieve a bending radius of 3mm with minimal impact on display performance[4]. They employ a multi-layer structure that includes a flexible substrate, thin-film transistor (TFT) array, and organic light-emitting materials optimized for bending stress distribution[5]. BOE has also developed proprietary encapsulation technologies to protect the sensitive OLED materials from moisture and oxygen ingress during bending[6].

Strengths: Strong R&D investment in flexible display technologies and growing market share in AMOLED production. Weaknesses: Still catching up to market leaders in terms of bending performance and commercialization of foldable devices.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has been investing in research to understand and improve AMOLED bending capabilities. Their approach focuses on developing flexible OLED displays using a combination of advanced materials and innovative structural designs. TCL CSOT's flexible AMOLED panels can achieve a bending radius of approximately 5mm while maintaining display performance[13]. They utilize a multi-layer structure that includes a flexible polyimide substrate, low-temperature polycrystalline silicon (LTPS) TFT backplane, and organic light-emitting materials optimized for stress distribution during bending[14]. TCL CSOT has also developed proprietary thin-film encapsulation technologies to protect the OLED materials from environmental factors during repeated bending cycles[15].

Strengths: Growing expertise in flexible display technologies and increasing production capacity. Weaknesses: Still behind market leaders in terms of bending performance and commercialization of foldable devices.

Core Innovations in Flexible AMOLED Physics

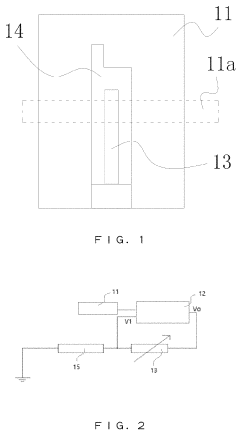

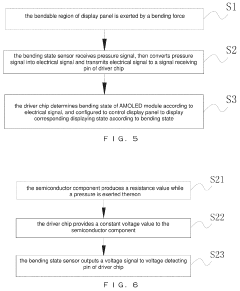

Active-matrix organic light emitting diode module operable in bendable states and displaying method thereof

PatentActiveUS20190355299A1

Innovation

- An AMOLED module with a bending state sensor and driver chip, where the sensor receives pressure signals and converts them into electrical signals to directly control the display panel's state, reducing the reliance on the main control chip for determining and processing bending states.

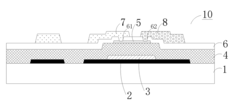

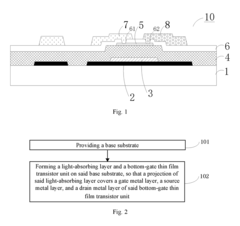

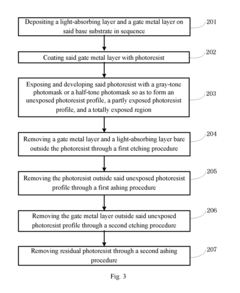

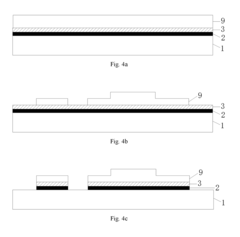

Array substrate, display device, and method for manufacturing array substrate

PatentActiveUS20170148862A1

Innovation

- An array substrate with a light-absorbing layer covering the gate, source, and drain metal layers of a bottom-gate thin film transistor unit, preventing ambient light irradiation while allowing useful light to pass through.

Materials Science Advancements for Flexible Displays

The field of flexible displays has witnessed significant advancements in materials science, particularly in the development of AMOLED (Active-Matrix Organic Light-Emitting Diode) technology. These breakthroughs have been crucial in enhancing the bending capabilities of displays, paving the way for innovative form factors in consumer electronics.

One of the key areas of focus has been the development of flexible substrate materials. Traditional glass substrates have been replaced with more pliable alternatives such as polyimide films. These materials offer excellent thermal stability, low coefficient of thermal expansion, and high mechanical strength, allowing for repeated bending without compromising the display's integrity.

The organic light-emitting materials used in AMOLED displays have also undergone substantial improvements. Researchers have developed new organic compounds that maintain their electroluminescent properties even when subjected to mechanical stress. These materials exhibit enhanced flexibility and durability, enabling displays to withstand thousands of bending cycles without significant degradation in performance.

Advancements in thin-film encapsulation technologies have played a crucial role in protecting the sensitive organic layers from moisture and oxygen. Multi-layer barrier films, combining inorganic and organic materials, have been developed to provide effective protection while maintaining flexibility. These barrier films have significantly improved the lifespan and reliability of flexible AMOLED displays.

The development of stretchable electrodes has been another critical area of research. Traditional indium tin oxide (ITO) electrodes are brittle and prone to cracking when bent. New materials such as silver nanowires, carbon nanotubes, and graphene-based composites have emerged as promising alternatives, offering high conductivity and excellent mechanical properties.

Innovations in manufacturing processes have also contributed to the advancement of flexible displays. Roll-to-roll fabrication techniques have been refined to enable large-scale production of flexible AMOLED panels. Additionally, novel patterning methods, such as photolithography on curved surfaces, have been developed to address the challenges of fabricating high-resolution displays on non-planar substrates.

The integration of additional functional layers, such as touch sensors and polarizers, into flexible displays has required further materials science innovations. Researchers have developed new formulations for these layers that maintain their functionality while conforming to the bending requirements of the overall display structure.

One of the key areas of focus has been the development of flexible substrate materials. Traditional glass substrates have been replaced with more pliable alternatives such as polyimide films. These materials offer excellent thermal stability, low coefficient of thermal expansion, and high mechanical strength, allowing for repeated bending without compromising the display's integrity.

The organic light-emitting materials used in AMOLED displays have also undergone substantial improvements. Researchers have developed new organic compounds that maintain their electroluminescent properties even when subjected to mechanical stress. These materials exhibit enhanced flexibility and durability, enabling displays to withstand thousands of bending cycles without significant degradation in performance.

Advancements in thin-film encapsulation technologies have played a crucial role in protecting the sensitive organic layers from moisture and oxygen. Multi-layer barrier films, combining inorganic and organic materials, have been developed to provide effective protection while maintaining flexibility. These barrier films have significantly improved the lifespan and reliability of flexible AMOLED displays.

The development of stretchable electrodes has been another critical area of research. Traditional indium tin oxide (ITO) electrodes are brittle and prone to cracking when bent. New materials such as silver nanowires, carbon nanotubes, and graphene-based composites have emerged as promising alternatives, offering high conductivity and excellent mechanical properties.

Innovations in manufacturing processes have also contributed to the advancement of flexible displays. Roll-to-roll fabrication techniques have been refined to enable large-scale production of flexible AMOLED panels. Additionally, novel patterning methods, such as photolithography on curved surfaces, have been developed to address the challenges of fabricating high-resolution displays on non-planar substrates.

The integration of additional functional layers, such as touch sensors and polarizers, into flexible displays has required further materials science innovations. Researchers have developed new formulations for these layers that maintain their functionality while conforming to the bending requirements of the overall display structure.

Environmental Impact of Flexible AMOLED Production

The production of flexible AMOLED displays has significant environmental implications that warrant careful consideration. The manufacturing process involves several energy-intensive steps and the use of various chemicals, which can contribute to environmental degradation if not properly managed.

One of the primary environmental concerns is the high energy consumption associated with AMOLED production. The fabrication of these displays requires precise temperature control and clean room environments, leading to substantial electricity usage. This energy demand often relies on fossil fuel-based power sources, contributing to greenhouse gas emissions and climate change.

Chemical usage in flexible AMOLED production also poses environmental risks. The process involves the application of organic materials and the use of solvents, some of which may be toxic or harmful to ecosystems if released untreated. Proper handling, disposal, and treatment of these chemicals are crucial to prevent soil and water contamination.

Water consumption is another significant factor. The production of flexible AMOLEDs requires large volumes of ultra-pure water for cleaning and processing. This not only strains local water resources but also generates wastewater that must be carefully treated before release to prevent pollution of water bodies.

The use of rare earth elements and precious metals in AMOLED displays raises concerns about resource depletion and the environmental impact of mining operations. Extraction of these materials can lead to habitat destruction, soil erosion, and water pollution in mining regions.

However, it's important to note that the flexible nature of these displays could potentially lead to more durable and longer-lasting devices, which might reduce electronic waste in the long term. Additionally, the thinness and flexibility of AMOLEDs could result in more energy-efficient devices, potentially offsetting some of the environmental costs of production.

Manufacturers are increasingly aware of these environmental challenges and are implementing measures to mitigate their impact. This includes investing in renewable energy sources for production facilities, developing more efficient manufacturing processes, and improving chemical recycling and waste management systems. Some companies are also exploring bio-based materials and green chemistry approaches to reduce the environmental footprint of AMOLED production.

As the demand for flexible AMOLED displays continues to grow, it is crucial for the industry to prioritize sustainable production methods and circular economy principles. This may involve further research into eco-friendly materials, more efficient production techniques, and improved recycling processes for end-of-life displays. Balancing technological advancement with environmental stewardship will be key to ensuring the long-term sustainability of flexible AMOLED technology.

One of the primary environmental concerns is the high energy consumption associated with AMOLED production. The fabrication of these displays requires precise temperature control and clean room environments, leading to substantial electricity usage. This energy demand often relies on fossil fuel-based power sources, contributing to greenhouse gas emissions and climate change.

Chemical usage in flexible AMOLED production also poses environmental risks. The process involves the application of organic materials and the use of solvents, some of which may be toxic or harmful to ecosystems if released untreated. Proper handling, disposal, and treatment of these chemicals are crucial to prevent soil and water contamination.

Water consumption is another significant factor. The production of flexible AMOLEDs requires large volumes of ultra-pure water for cleaning and processing. This not only strains local water resources but also generates wastewater that must be carefully treated before release to prevent pollution of water bodies.

The use of rare earth elements and precious metals in AMOLED displays raises concerns about resource depletion and the environmental impact of mining operations. Extraction of these materials can lead to habitat destruction, soil erosion, and water pollution in mining regions.

However, it's important to note that the flexible nature of these displays could potentially lead to more durable and longer-lasting devices, which might reduce electronic waste in the long term. Additionally, the thinness and flexibility of AMOLEDs could result in more energy-efficient devices, potentially offsetting some of the environmental costs of production.

Manufacturers are increasingly aware of these environmental challenges and are implementing measures to mitigate their impact. This includes investing in renewable energy sources for production facilities, developing more efficient manufacturing processes, and improving chemical recycling and waste management systems. Some companies are also exploring bio-based materials and green chemistry approaches to reduce the environmental footprint of AMOLED production.

As the demand for flexible AMOLED displays continues to grow, it is crucial for the industry to prioritize sustainable production methods and circular economy principles. This may involve further research into eco-friendly materials, more efficient production techniques, and improved recycling processes for end-of-life displays. Balancing technological advancement with environmental stewardship will be key to ensuring the long-term sustainability of flexible AMOLED technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!