Unraveling Isocyanate Chemistry for Advanced Innovations

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Chemistry Evolution and Objectives

Isocyanate chemistry has undergone significant evolution since its inception in the early 20th century. The discovery of isocyanates by Wurtz in 1848 laid the foundation for a field that would revolutionize polymer science and materials engineering. The journey of isocyanate chemistry began with the synthesis of simple compounds but quickly expanded into the realm of polyurethanes, which have become ubiquitous in modern industry.

The development of isocyanate chemistry can be traced through several key milestones. In the 1930s, Otto Bayer's groundbreaking work on polyurethane synthesis marked a turning point, leading to the commercialization of these versatile materials. This breakthrough opened up new possibilities in foam production, coatings, adhesives, and elastomers. Subsequent decades saw rapid advancements in isocyanate technology, with the introduction of various types of isocyanates, including aromatic and aliphatic compounds, each offering unique properties and applications.

As the field progressed, researchers focused on enhancing the reactivity, selectivity, and environmental profile of isocyanates. The 1970s and 1980s witnessed a surge in efforts to develop safer and more sustainable isocyanate-based products, driven by growing environmental concerns and stricter regulations. This period saw the emergence of blocked isocyanates, water-based systems, and low-VOC formulations, addressing issues of toxicity and emissions.

The objectives of modern isocyanate chemistry are multifaceted and ambitious. One primary goal is to further improve the safety and sustainability of isocyanate-based materials. This includes developing non-toxic alternatives, reducing environmental impact, and enhancing the recyclability of polyurethane products. Another key objective is to expand the application range of isocyanates beyond traditional sectors, exploring their potential in cutting-edge fields such as biomedical materials, smart polymers, and nanotechnology.

Researchers are also focused on unraveling the complex reaction mechanisms of isocyanates at a molecular level. This fundamental understanding is crucial for designing more efficient and controlled polymerization processes, leading to materials with superior properties and performance. Additionally, there is a growing interest in leveraging isocyanate chemistry for the development of high-performance composites and hybrid materials, combining the unique properties of isocyanates with other advanced materials.

The future of isocyanate chemistry lies in pushing the boundaries of material science. Objectives include creating self-healing polymers, developing stimuli-responsive materials, and exploring the potential of isocyanates in additive manufacturing and 3D printing technologies. As the field continues to evolve, the integration of computational modeling and artificial intelligence is expected to accelerate innovation, enabling the prediction of material properties and the design of novel isocyanate-based systems with unprecedented precision.

The development of isocyanate chemistry can be traced through several key milestones. In the 1930s, Otto Bayer's groundbreaking work on polyurethane synthesis marked a turning point, leading to the commercialization of these versatile materials. This breakthrough opened up new possibilities in foam production, coatings, adhesives, and elastomers. Subsequent decades saw rapid advancements in isocyanate technology, with the introduction of various types of isocyanates, including aromatic and aliphatic compounds, each offering unique properties and applications.

As the field progressed, researchers focused on enhancing the reactivity, selectivity, and environmental profile of isocyanates. The 1970s and 1980s witnessed a surge in efforts to develop safer and more sustainable isocyanate-based products, driven by growing environmental concerns and stricter regulations. This period saw the emergence of blocked isocyanates, water-based systems, and low-VOC formulations, addressing issues of toxicity and emissions.

The objectives of modern isocyanate chemistry are multifaceted and ambitious. One primary goal is to further improve the safety and sustainability of isocyanate-based materials. This includes developing non-toxic alternatives, reducing environmental impact, and enhancing the recyclability of polyurethane products. Another key objective is to expand the application range of isocyanates beyond traditional sectors, exploring their potential in cutting-edge fields such as biomedical materials, smart polymers, and nanotechnology.

Researchers are also focused on unraveling the complex reaction mechanisms of isocyanates at a molecular level. This fundamental understanding is crucial for designing more efficient and controlled polymerization processes, leading to materials with superior properties and performance. Additionally, there is a growing interest in leveraging isocyanate chemistry for the development of high-performance composites and hybrid materials, combining the unique properties of isocyanates with other advanced materials.

The future of isocyanate chemistry lies in pushing the boundaries of material science. Objectives include creating self-healing polymers, developing stimuli-responsive materials, and exploring the potential of isocyanates in additive manufacturing and 3D printing technologies. As the field continues to evolve, the integration of computational modeling and artificial intelligence is expected to accelerate innovation, enabling the prediction of material properties and the design of novel isocyanate-based systems with unprecedented precision.

Market Demand for Isocyanate-Based Products

The market demand for isocyanate-based products has been steadily growing, driven by their versatile applications across various industries. Polyurethanes, the primary product derived from isocyanates, have witnessed a significant surge in demand due to their exceptional properties and wide-ranging uses. The construction sector remains a major consumer of isocyanate-based products, particularly in insulation materials, sealants, and adhesives. The increasing focus on energy efficiency in buildings has further boosted the demand for polyurethane insulation, which offers superior thermal performance.

In the automotive industry, isocyanate-based products play a crucial role in manufacturing lightweight components, cushioning materials, and coatings. As the automotive sector shifts towards electric vehicles and emphasizes fuel efficiency, the demand for lightweight materials derived from isocyanates is expected to rise. The furniture and bedding industry also contributes significantly to the market demand, utilizing flexible polyurethane foams for mattresses, cushions, and upholstery.

The packaging industry has emerged as a growing market for isocyanate-based products, particularly in the form of rigid polyurethane foams used in insulated containers and refrigeration units. With the expansion of e-commerce and cold chain logistics, this segment is poised for substantial growth. Additionally, the footwear industry relies heavily on polyurethane materials for shoe soles and insoles, driven by the demand for comfortable and durable footwear.

The global polyurethane market, which is largely dependent on isocyanates, has been experiencing robust growth. Developing economies, particularly in Asia-Pacific, are witnessing rapid industrialization and urbanization, leading to increased consumption of isocyanate-based products across various applications. The growing middle-class population in these regions is driving demand for consumer goods, automobiles, and housing, all of which utilize isocyanate-derived materials.

However, the market demand for isocyanate-based products is not without challenges. Environmental concerns and regulatory pressures regarding the use of certain isocyanates, particularly those containing volatile organic compounds (VOCs), have led to a shift towards more sustainable and eco-friendly alternatives. This has spurred research and development efforts to create bio-based isocyanates and polyurethanes, which are expected to gain traction in the coming years.

Despite these challenges, the overall market demand for isocyanate-based products remains strong, with innovations in chemistry and applications continually expanding their potential uses. The development of specialized isocyanates for high-performance applications in aerospace, medical devices, and advanced coatings is opening up new market opportunities. As industries continue to seek materials with superior properties and versatility, isocyanate-based products are well-positioned to meet these evolving demands, ensuring sustained market growth in the foreseeable future.

In the automotive industry, isocyanate-based products play a crucial role in manufacturing lightweight components, cushioning materials, and coatings. As the automotive sector shifts towards electric vehicles and emphasizes fuel efficiency, the demand for lightweight materials derived from isocyanates is expected to rise. The furniture and bedding industry also contributes significantly to the market demand, utilizing flexible polyurethane foams for mattresses, cushions, and upholstery.

The packaging industry has emerged as a growing market for isocyanate-based products, particularly in the form of rigid polyurethane foams used in insulated containers and refrigeration units. With the expansion of e-commerce and cold chain logistics, this segment is poised for substantial growth. Additionally, the footwear industry relies heavily on polyurethane materials for shoe soles and insoles, driven by the demand for comfortable and durable footwear.

The global polyurethane market, which is largely dependent on isocyanates, has been experiencing robust growth. Developing economies, particularly in Asia-Pacific, are witnessing rapid industrialization and urbanization, leading to increased consumption of isocyanate-based products across various applications. The growing middle-class population in these regions is driving demand for consumer goods, automobiles, and housing, all of which utilize isocyanate-derived materials.

However, the market demand for isocyanate-based products is not without challenges. Environmental concerns and regulatory pressures regarding the use of certain isocyanates, particularly those containing volatile organic compounds (VOCs), have led to a shift towards more sustainable and eco-friendly alternatives. This has spurred research and development efforts to create bio-based isocyanates and polyurethanes, which are expected to gain traction in the coming years.

Despite these challenges, the overall market demand for isocyanate-based products remains strong, with innovations in chemistry and applications continually expanding their potential uses. The development of specialized isocyanates for high-performance applications in aerospace, medical devices, and advanced coatings is opening up new market opportunities. As industries continue to seek materials with superior properties and versatility, isocyanate-based products are well-positioned to meet these evolving demands, ensuring sustained market growth in the foreseeable future.

Current Challenges in Isocyanate Synthesis

Isocyanate synthesis, while a cornerstone of numerous industrial applications, faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the high reactivity of isocyanates, which makes them difficult to handle and store safely. This reactivity also leads to unwanted side reactions during synthesis, reducing yield and purity.

The traditional methods of isocyanate production, such as the phosgenation of amines, pose severe environmental and safety concerns. Phosgene, a key reagent in this process, is highly toxic and corrosive, necessitating stringent safety measures and specialized equipment. This not only increases production costs but also raises ethical questions about the use of such hazardous materials in industrial processes.

Another significant challenge lies in the development of more sustainable and eco-friendly synthesis routes. Current methods often rely on petroleum-based feedstocks, contributing to the carbon footprint of isocyanate production. The search for bio-based alternatives or renewable resources for isocyanate synthesis is ongoing but faces hurdles in terms of scalability and economic viability.

The energy-intensive nature of isocyanate synthesis presents another obstacle. Many reactions require high temperatures and pressures, leading to substantial energy consumption and associated costs. Developing catalysts that can lower reaction temperatures and improve selectivity is a key area of research, but progress has been limited by the complexity of isocyanate chemistry.

Furthermore, the production of specialty isocyanates, particularly those with complex structures or specific functionalities, remains challenging. These compounds often require multi-step syntheses with low overall yields, making them expensive and limiting their potential applications.

The control of isocyanate functionality and molecular weight distribution in polymer applications is another area of concern. Achieving precise control over these parameters is crucial for producing materials with desired properties, but it remains difficult due to the high reactivity of isocyanates and the complexity of polymerization processes.

Lastly, regulatory pressures and increasing awareness of health and environmental impacts pose challenges to the isocyanate industry. Stricter regulations on emissions, exposure limits, and waste management necessitate continuous innovation in production processes and handling techniques. This regulatory landscape drives the need for safer alternatives or improved containment strategies, adding another layer of complexity to isocyanate synthesis and application.

The traditional methods of isocyanate production, such as the phosgenation of amines, pose severe environmental and safety concerns. Phosgene, a key reagent in this process, is highly toxic and corrosive, necessitating stringent safety measures and specialized equipment. This not only increases production costs but also raises ethical questions about the use of such hazardous materials in industrial processes.

Another significant challenge lies in the development of more sustainable and eco-friendly synthesis routes. Current methods often rely on petroleum-based feedstocks, contributing to the carbon footprint of isocyanate production. The search for bio-based alternatives or renewable resources for isocyanate synthesis is ongoing but faces hurdles in terms of scalability and economic viability.

The energy-intensive nature of isocyanate synthesis presents another obstacle. Many reactions require high temperatures and pressures, leading to substantial energy consumption and associated costs. Developing catalysts that can lower reaction temperatures and improve selectivity is a key area of research, but progress has been limited by the complexity of isocyanate chemistry.

Furthermore, the production of specialty isocyanates, particularly those with complex structures or specific functionalities, remains challenging. These compounds often require multi-step syntheses with low overall yields, making them expensive and limiting their potential applications.

The control of isocyanate functionality and molecular weight distribution in polymer applications is another area of concern. Achieving precise control over these parameters is crucial for producing materials with desired properties, but it remains difficult due to the high reactivity of isocyanates and the complexity of polymerization processes.

Lastly, regulatory pressures and increasing awareness of health and environmental impacts pose challenges to the isocyanate industry. Stricter regulations on emissions, exposure limits, and waste management necessitate continuous innovation in production processes and handling techniques. This regulatory landscape drives the need for safer alternatives or improved containment strategies, adding another layer of complexity to isocyanate synthesis and application.

Existing Isocyanate Production Methods

01 Synthesis and modification of isocyanates

This category focuses on the synthesis of isocyanates and their chemical modifications. It includes methods for producing various isocyanate compounds, as well as techniques for altering their properties through chemical reactions. These processes are crucial for creating isocyanates with specific characteristics for different applications.- Synthesis and modification of isocyanates: This category focuses on the synthesis of isocyanates and their chemical modifications. It includes methods for producing various isocyanate compounds, as well as techniques for altering their properties through chemical reactions. These processes are crucial for creating isocyanates with specific characteristics for different applications.

- Polyurethane production using isocyanates: Isocyanates are key components in the production of polyurethanes. This category covers methods for using isocyanates in polyurethane synthesis, including reaction conditions, catalysts, and formulation techniques. It also encompasses the development of novel polyurethane materials with enhanced properties.

- Isocyanate-based coatings and adhesives: This category deals with the application of isocyanates in coatings and adhesives. It includes formulations, curing mechanisms, and performance characteristics of isocyanate-based coatings and adhesives. The focus is on developing products with improved durability, adhesion, and chemical resistance.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, this category addresses safety measures and handling procedures. It covers methods for reducing exposure risks, proper storage techniques, and strategies for mitigating potential hazards associated with isocyanate chemistry in industrial settings.

- Analytical methods for isocyanates: This category focuses on analytical techniques for detecting, quantifying, and characterizing isocyanates. It includes spectroscopic methods, chromatography, and other analytical approaches for monitoring isocyanate reactions, determining purity, and identifying isocyanate-based compounds in various matrices.

02 Polyurethane production using isocyanates

Isocyanates are key components in the production of polyurethanes. This category covers methods for using isocyanates in polyurethane synthesis, including reaction conditions, catalysts, and formulation techniques. It also encompasses the development of specialized polyurethanes for various industrial and consumer applications.Expand Specific Solutions03 Isocyanate-based coatings and adhesives

This category deals with the use of isocyanates in the formulation of coatings and adhesives. It includes techniques for creating durable, weather-resistant coatings and strong, versatile adhesives. The chemistry involved focuses on optimizing cure times, adhesion properties, and resistance to environmental factors.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, this category addresses safety measures and handling procedures. It covers methods for reducing exposure risks, proper storage techniques, and the development of less hazardous isocyanate alternatives. This area is crucial for ensuring worker safety and environmental protection in industries using isocyanates.Expand Specific Solutions05 Analytical methods for isocyanates

This category focuses on analytical techniques for detecting, quantifying, and characterizing isocyanates. It includes the development of spectroscopic methods, chromatographic techniques, and sensor technologies for monitoring isocyanate levels in various environments and products. These methods are essential for quality control and safety monitoring in isocyanate-related industries.Expand Specific Solutions

Key Players in Isocyanate Industry

The isocyanate chemistry market is in a mature growth stage, with a global market size estimated to exceed $30 billion by 2025. The technology has reached a high level of maturity, with established players like BASF, Covestro, and Wanhua Chemical Group dominating the industry. These companies have extensive R&D capabilities and production facilities, allowing them to offer a wide range of isocyanate-based products for various applications. The competitive landscape is characterized by ongoing innovation in product formulations, process efficiencies, and sustainability initiatives. Emerging players like Momentive Performance Materials and Evonik are also making significant contributions to advancing isocyanate chemistry through specialized offerings and technological improvements.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has made significant strides in isocyanate chemistry, particularly in the development of high-performance MDI (methylene diphenyl diisocyanate) and TDI (toluene diisocyanate) products. Their innovative approach includes the optimization of isocyanate synthesis processes, resulting in improved product purity and reduced environmental impact[5]. Wanhua has also developed proprietary catalyst systems that enhance the selectivity and efficiency of isocyanate reactions[6]. Furthermore, they have invested in research on novel isocyanate-based materials with advanced properties, such as improved flame retardancy and thermal insulation for construction and automotive applications[7].

Strengths: Strong market position in Asia, vertically integrated production, and focus on high-value applications. Weaknesses: Potential exposure to raw material price fluctuations and environmental regulations.

Covestro Deutschland AG

Technical Solution: Covestro has been at the forefront of isocyanate chemistry innovation, focusing on sustainable and high-performance solutions. They have developed novel aliphatic isocyanates with improved UV stability and weathering resistance for coatings applications[8]. Covestro's research also includes the development of bio-based isocyanates, utilizing renewable raw materials to reduce the carbon footprint of their products[9]. Additionally, they have made advancements in isocyanate-based adhesives with enhanced bonding strength and durability for automotive and electronics industries[10]. Covestro has also explored the use of isocyanates in the production of thermoplastic polyurethanes with improved mechanical properties and chemical resistance[11].

Strengths: Strong focus on sustainability, broad application expertise, and global market presence. Weaknesses: Dependence on cyclical end markets and potential regulatory challenges.

Breakthrough Innovations in Isocyanate Chemistry

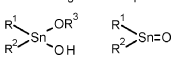

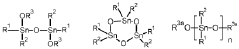

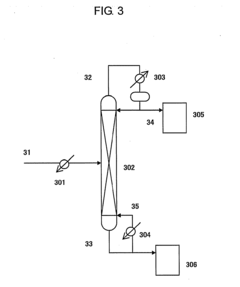

Process for preparing isocyanate compound

PatentWO2016177761A1

Innovation

- A process involving the reaction of an amine compound with CO2 and an organotin compound to form a carbamate, which is then cleaved to produce the isocyanate compound, allowing for the avoidance of phosgene and reducing by-product formation, with the potential for recycling of reactants.

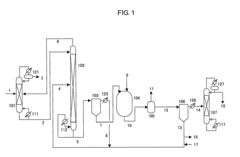

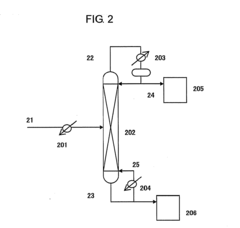

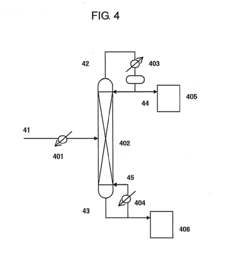

Process for producing isocyanate using diaryl carbonate

PatentInactiveEP2275405A1

Innovation

- A process involving the reaction of diaryl carbonates with amine compounds to form aryl carbamates, followed by transferring the reaction mixture to a thermal decomposition vessel where the aryl carbamates undergo thermal decomposition to produce isocyanates, with specific conditions and solvents used to enhance yield and purity, including the use of aromatic hydroxy compounds as solvents and acid cleaning to remove high-boiling point by-products.

Environmental Impact of Isocyanate Production

The production of isocyanates, a crucial component in polyurethane manufacturing, has significant environmental implications that warrant careful consideration. The primary environmental concerns associated with isocyanate production stem from the use of hazardous raw materials, energy-intensive processes, and potential emissions of toxic substances.

Isocyanate production typically involves the reaction of amines with phosgene, a highly toxic gas. This process requires stringent safety measures and containment systems to prevent accidental releases. The use of phosgene also raises concerns about transportation and storage risks, necessitating robust safety protocols throughout the supply chain.

Energy consumption in isocyanate production is substantial, contributing to greenhouse gas emissions and climate change. The high temperatures and pressures required for synthesis reactions result in a considerable carbon footprint. Additionally, the production of precursor chemicals, such as nitric acid and aniline, further amplifies the overall environmental impact.

Emissions from isocyanate manufacturing facilities can include volatile organic compounds (VOCs), particulate matter, and nitrogen oxides. These pollutants contribute to air quality degradation and may pose health risks to nearby communities. Proper emission control technologies, such as scrubbers and thermal oxidizers, are essential to mitigate these impacts.

Water pollution is another environmental concern in isocyanate production. Wastewater from manufacturing processes may contain toxic compounds that require specialized treatment before discharge. Ensuring proper wastewater management is crucial to protect aquatic ecosystems and maintain water quality standards.

The disposal of by-products and waste materials from isocyanate production presents additional environmental challenges. Some waste streams may be classified as hazardous, requiring specialized handling and disposal methods to prevent soil and groundwater contamination.

To address these environmental concerns, the isocyanate industry has been implementing various sustainability initiatives. These include developing alternative production methods that reduce or eliminate the use of phosgene, improving energy efficiency through process optimization, and investing in cleaner technologies for emission control and waste management.

Regulatory frameworks play a crucial role in mitigating the environmental impact of isocyanate production. Stringent environmental regulations, such as those imposed by the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in Europe, set standards for emissions, waste management, and worker safety in isocyanate manufacturing facilities.

As the demand for polyurethane products continues to grow, balancing production needs with environmental stewardship remains a key challenge for the isocyanate industry. Ongoing research and development efforts focus on greener production methods, bio-based alternatives, and improved recycling technologies to reduce the overall environmental footprint of isocyanate chemistry.

Isocyanate production typically involves the reaction of amines with phosgene, a highly toxic gas. This process requires stringent safety measures and containment systems to prevent accidental releases. The use of phosgene also raises concerns about transportation and storage risks, necessitating robust safety protocols throughout the supply chain.

Energy consumption in isocyanate production is substantial, contributing to greenhouse gas emissions and climate change. The high temperatures and pressures required for synthesis reactions result in a considerable carbon footprint. Additionally, the production of precursor chemicals, such as nitric acid and aniline, further amplifies the overall environmental impact.

Emissions from isocyanate manufacturing facilities can include volatile organic compounds (VOCs), particulate matter, and nitrogen oxides. These pollutants contribute to air quality degradation and may pose health risks to nearby communities. Proper emission control technologies, such as scrubbers and thermal oxidizers, are essential to mitigate these impacts.

Water pollution is another environmental concern in isocyanate production. Wastewater from manufacturing processes may contain toxic compounds that require specialized treatment before discharge. Ensuring proper wastewater management is crucial to protect aquatic ecosystems and maintain water quality standards.

The disposal of by-products and waste materials from isocyanate production presents additional environmental challenges. Some waste streams may be classified as hazardous, requiring specialized handling and disposal methods to prevent soil and groundwater contamination.

To address these environmental concerns, the isocyanate industry has been implementing various sustainability initiatives. These include developing alternative production methods that reduce or eliminate the use of phosgene, improving energy efficiency through process optimization, and investing in cleaner technologies for emission control and waste management.

Regulatory frameworks play a crucial role in mitigating the environmental impact of isocyanate production. Stringent environmental regulations, such as those imposed by the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) in Europe, set standards for emissions, waste management, and worker safety in isocyanate manufacturing facilities.

As the demand for polyurethane products continues to grow, balancing production needs with environmental stewardship remains a key challenge for the isocyanate industry. Ongoing research and development efforts focus on greener production methods, bio-based alternatives, and improved recycling technologies to reduce the overall environmental footprint of isocyanate chemistry.

Safety Regulations in Isocyanate Handling

The handling of isocyanates in industrial settings is subject to stringent safety regulations due to their potential health hazards and reactivity. These regulations are designed to protect workers, the environment, and the general public from exposure to these chemicals. In the United States, the Occupational Safety and Health Administration (OSHA) has established specific standards for isocyanate handling, including permissible exposure limits (PELs) and requirements for personal protective equipment (PPE).

OSHA's PEL for most isocyanates is set at 0.02 parts per million (ppm) for an 8-hour time-weighted average, with a short-term exposure limit of 0.15 ppm for any 15-minute period. Employers are required to implement engineering controls and work practices to reduce employee exposure below these limits. When these measures are insufficient, respiratory protection must be provided.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which include specific provisions for isocyanates. Under REACH, manufacturers and importers must register isocyanates and provide safety data sheets detailing proper handling procedures and exposure controls.

Safety regulations also mandate proper storage and transportation of isocyanates. They must be kept in tightly sealed containers in cool, dry areas away from moisture and heat sources. Transportation of isocyanates is regulated under the United Nations' Recommendations on the Transport of Dangerous Goods, which classifies them as hazardous materials requiring special packaging and labeling.

Training is a crucial component of isocyanate safety regulations. Workers must be educated on the hazards associated with isocyanates, proper handling techniques, emergency procedures, and the correct use of PPE. Many jurisdictions require regular refresher training to ensure ongoing compliance and safety awareness.

Environmental regulations also play a significant role in isocyanate handling. The U.S. Environmental Protection Agency (EPA) regulates isocyanates under the Toxic Substances Control Act (TSCA) and requires reporting of significant new uses of these chemicals. Similarly, the EU's Industrial Emissions Directive sets limits on isocyanate emissions from industrial processes.

Monitoring and record-keeping are essential aspects of compliance with isocyanate safety regulations. Employers must conduct regular air monitoring to ensure exposure levels remain below established limits and maintain detailed records of exposure assessments, medical examinations, and incident reports.

As research continues to uncover potential long-term health effects of isocyanate exposure, regulations are evolving. There is a growing trend towards more stringent controls and a push for the development of safer alternatives in various applications. This ongoing regulatory development underscores the importance of staying informed about the latest safety requirements in isocyanate handling across different regions and industries.

OSHA's PEL for most isocyanates is set at 0.02 parts per million (ppm) for an 8-hour time-weighted average, with a short-term exposure limit of 0.15 ppm for any 15-minute period. Employers are required to implement engineering controls and work practices to reduce employee exposure below these limits. When these measures are insufficient, respiratory protection must be provided.

The European Union has implemented REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, which include specific provisions for isocyanates. Under REACH, manufacturers and importers must register isocyanates and provide safety data sheets detailing proper handling procedures and exposure controls.

Safety regulations also mandate proper storage and transportation of isocyanates. They must be kept in tightly sealed containers in cool, dry areas away from moisture and heat sources. Transportation of isocyanates is regulated under the United Nations' Recommendations on the Transport of Dangerous Goods, which classifies them as hazardous materials requiring special packaging and labeling.

Training is a crucial component of isocyanate safety regulations. Workers must be educated on the hazards associated with isocyanates, proper handling techniques, emergency procedures, and the correct use of PPE. Many jurisdictions require regular refresher training to ensure ongoing compliance and safety awareness.

Environmental regulations also play a significant role in isocyanate handling. The U.S. Environmental Protection Agency (EPA) regulates isocyanates under the Toxic Substances Control Act (TSCA) and requires reporting of significant new uses of these chemicals. Similarly, the EU's Industrial Emissions Directive sets limits on isocyanate emissions from industrial processes.

Monitoring and record-keeping are essential aspects of compliance with isocyanate safety regulations. Employers must conduct regular air monitoring to ensure exposure levels remain below established limits and maintain detailed records of exposure assessments, medical examinations, and incident reports.

As research continues to uncover potential long-term health effects of isocyanate exposure, regulations are evolving. There is a growing trend towards more stringent controls and a push for the development of safer alternatives in various applications. This ongoing regulatory development underscores the importance of staying informed about the latest safety requirements in isocyanate handling across different regions and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!