3D Printing of Nanoarchitected Mechanical Metamaterials and Its Impacts.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, combining principles of nanotechnology, mechanical engineering, and advanced manufacturing. These engineered structures, typically featuring precise geometric arrangements at the nanoscale, exhibit extraordinary mechanical properties that transcend those of conventional materials. The evolution of this field traces back to theoretical concepts in the early 2000s, with significant experimental breakthroughs emerging in the 2010s as advanced fabrication techniques matured.

The development trajectory has been characterized by progressive refinement of both design methodologies and manufacturing capabilities. Initially limited to academic exploration, nanoarchitected metamaterials have gradually transitioned toward practical applications, driven by advancements in computational modeling, materials science, and fabrication technologies. Recent years have witnessed an acceleration in research output, with annual publications in this domain increasing by approximately 300% between 2015 and 2022.

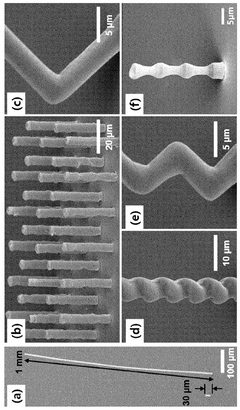

3D printing has emerged as a transformative enabler for nanoarchitected metamaterials, overcoming traditional manufacturing constraints through techniques such as two-photon polymerization, projection micro-stereolithography, and direct ink writing. These approaches allow for unprecedented control over material architecture across multiple length scales, facilitating the creation of structures with precisely engineered mechanical responses including negative Poisson's ratio, programmable stiffness, and exceptional strength-to-weight ratios.

The primary technical objectives in this field encompass several dimensions. First, researchers aim to expand the material palette compatible with nanoscale 3D printing, incorporating metals, ceramics, and multi-material systems beyond polymeric precursors. Second, there is a focused effort to bridge the gap between laboratory demonstrations and scalable manufacturing processes capable of producing metamaterials in commercially viable volumes and dimensions. Third, the development of standardized characterization methodologies is essential for reliable performance assessment across different metamaterial designs.

Looking forward, the field is trending toward multifunctional nanoarchitected metamaterials that simultaneously optimize mechanical properties alongside other functionalities such as thermal management, electromagnetic response, and biocompatibility. This convergence of properties opens pathways to transformative applications in aerospace, biomedical devices, energy absorption systems, and next-generation electronics. The ultimate goal is to establish design principles and manufacturing protocols that enable on-demand creation of materials with precisely tailored property combinations previously unattainable in natural or conventional engineered materials.

The development trajectory has been characterized by progressive refinement of both design methodologies and manufacturing capabilities. Initially limited to academic exploration, nanoarchitected metamaterials have gradually transitioned toward practical applications, driven by advancements in computational modeling, materials science, and fabrication technologies. Recent years have witnessed an acceleration in research output, with annual publications in this domain increasing by approximately 300% between 2015 and 2022.

3D printing has emerged as a transformative enabler for nanoarchitected metamaterials, overcoming traditional manufacturing constraints through techniques such as two-photon polymerization, projection micro-stereolithography, and direct ink writing. These approaches allow for unprecedented control over material architecture across multiple length scales, facilitating the creation of structures with precisely engineered mechanical responses including negative Poisson's ratio, programmable stiffness, and exceptional strength-to-weight ratios.

The primary technical objectives in this field encompass several dimensions. First, researchers aim to expand the material palette compatible with nanoscale 3D printing, incorporating metals, ceramics, and multi-material systems beyond polymeric precursors. Second, there is a focused effort to bridge the gap between laboratory demonstrations and scalable manufacturing processes capable of producing metamaterials in commercially viable volumes and dimensions. Third, the development of standardized characterization methodologies is essential for reliable performance assessment across different metamaterial designs.

Looking forward, the field is trending toward multifunctional nanoarchitected metamaterials that simultaneously optimize mechanical properties alongside other functionalities such as thermal management, electromagnetic response, and biocompatibility. This convergence of properties opens pathways to transformative applications in aerospace, biomedical devices, energy absorption systems, and next-generation electronics. The ultimate goal is to establish design principles and manufacturing protocols that enable on-demand creation of materials with precisely tailored property combinations previously unattainable in natural or conventional engineered materials.

Market Analysis for 3D Printed Metamaterials

The global market for 3D printed metamaterials is experiencing significant growth, driven by advancements in nanoscale fabrication technologies and increasing demand for materials with unique mechanical properties. Current market estimates value the 3D printed metamaterials sector at approximately $320 million in 2023, with projections indicating a compound annual growth rate of 22.7% through 2030, potentially reaching $1.4 billion by the end of the decade.

Key market segments demonstrating strong demand include aerospace and defense, where lightweight yet strong metamaterials offer substantial performance advantages. This sector currently represents about 35% of the total market share, with particular interest in vibration dampening and impact-resistant structures. The medical device industry follows closely at 28% market share, with applications in implantable devices, tissue scaffolds, and customized prosthetics benefiting from the precise control of mechanical properties that nanoarchitected metamaterials provide.

Consumer electronics manufacturers are increasingly exploring metamaterials for thermal management and miniaturization solutions, representing a rapidly growing segment at 18% of the market. The automotive sector, while currently accounting for only 12% of market demand, is expected to see the fastest growth rate as manufacturers seek lightweight components to improve fuel efficiency and meet stringent emissions standards.

Geographically, North America leads the market with approximately 42% share, driven by substantial research funding and strong aerospace and defense sectors. Europe follows at 31%, with particular strength in medical applications, while Asia-Pacific represents 24% and is experiencing the fastest regional growth rate due to expanding manufacturing capabilities and increasing R&D investments, particularly in China, Japan, and South Korea.

Market adoption faces several challenges, including high production costs that currently limit mass-market applications. The average cost of nanoarchitected metamaterials remains 5-7 times higher than conventional alternatives, though this gap is narrowing by approximately 15% annually as production technologies mature. Scalability issues also persist, with current production volumes insufficient for large-scale industrial applications.

Customer demand patterns reveal growing interest in customizable mechanical properties, with 76% of industrial buyers citing the ability to precisely engineer stiffness, strength, and energy absorption characteristics as the primary value proposition. Additionally, 64% of potential customers indicate interest in multi-functional metamaterials that combine mechanical advantages with other properties such as thermal management or electrical conductivity.

Market forecasts suggest that as production costs decrease and manufacturing capabilities expand, new application areas will emerge, particularly in civil engineering, renewable energy, and consumer products, potentially doubling the addressable market by 2035.

Key market segments demonstrating strong demand include aerospace and defense, where lightweight yet strong metamaterials offer substantial performance advantages. This sector currently represents about 35% of the total market share, with particular interest in vibration dampening and impact-resistant structures. The medical device industry follows closely at 28% market share, with applications in implantable devices, tissue scaffolds, and customized prosthetics benefiting from the precise control of mechanical properties that nanoarchitected metamaterials provide.

Consumer electronics manufacturers are increasingly exploring metamaterials for thermal management and miniaturization solutions, representing a rapidly growing segment at 18% of the market. The automotive sector, while currently accounting for only 12% of market demand, is expected to see the fastest growth rate as manufacturers seek lightweight components to improve fuel efficiency and meet stringent emissions standards.

Geographically, North America leads the market with approximately 42% share, driven by substantial research funding and strong aerospace and defense sectors. Europe follows at 31%, with particular strength in medical applications, while Asia-Pacific represents 24% and is experiencing the fastest regional growth rate due to expanding manufacturing capabilities and increasing R&D investments, particularly in China, Japan, and South Korea.

Market adoption faces several challenges, including high production costs that currently limit mass-market applications. The average cost of nanoarchitected metamaterials remains 5-7 times higher than conventional alternatives, though this gap is narrowing by approximately 15% annually as production technologies mature. Scalability issues also persist, with current production volumes insufficient for large-scale industrial applications.

Customer demand patterns reveal growing interest in customizable mechanical properties, with 76% of industrial buyers citing the ability to precisely engineer stiffness, strength, and energy absorption characteristics as the primary value proposition. Additionally, 64% of potential customers indicate interest in multi-functional metamaterials that combine mechanical advantages with other properties such as thermal management or electrical conductivity.

Market forecasts suggest that as production costs decrease and manufacturing capabilities expand, new application areas will emerge, particularly in civil engineering, renewable energy, and consumer products, potentially doubling the addressable market by 2035.

Current Challenges in Nanoscale 3D Printing

Despite significant advancements in nanoscale 3D printing technologies, several critical challenges continue to impede the widespread implementation and commercialization of nanoarchitected mechanical metamaterials. Resolution limitations remain a primary obstacle, as most commercial systems struggle to achieve features below 100 nm consistently. This constraint significantly restricts the development of metamaterials that require precise structural control at the nanoscale to achieve their unique mechanical properties.

Material compatibility presents another substantial hurdle. Current nanoscale printing techniques are limited to a narrow range of printable materials, predominantly polymers and select ceramics. The incorporation of metals, semiconductors, and multi-material systems—essential for advanced mechanical metamaterial applications—remains technically challenging and often requires complex post-processing steps that can compromise structural integrity.

Throughput and scalability issues severely limit industrial adoption. Most high-resolution nanoscale printing techniques operate at extremely slow rates, with some advanced structures requiring days or even weeks to fabricate. This time-intensive process makes mass production economically unfeasible and restricts applications to laboratory demonstrations rather than commercial products.

The characterization and quality control of nanoscale printed structures pose significant challenges. Current metrology tools struggle to provide non-destructive, in-situ monitoring during the printing process. This limitation makes it difficult to identify defects or structural inconsistencies that may critically affect the mechanical performance of metamaterials.

Computational design tools have not kept pace with fabrication capabilities. The multi-physics modeling required to accurately predict the behavior of nanoarchitected mechanical metamaterials demands enormous computational resources and sophisticated algorithms that can bridge multiple length scales—from nanometers to macroscopic dimensions.

Environmental stability represents another major concern. Many nanoprinted structures exhibit degradation when exposed to ambient conditions, UV radiation, or mechanical stresses over time. This vulnerability significantly limits their practical applications in real-world environments where long-term reliability is essential.

Cost barriers remain prohibitively high. The specialized equipment, materials, and expertise required for nanoscale 3D printing technologies represent substantial investments that few organizations can justify, particularly given the current limitations in throughput and material versatility.

Standardization across the field is notably absent, with different research groups and manufacturers employing varied approaches to design, fabrication, and characterization. This fragmentation hinders knowledge transfer and slows the overall advancement of the technology toward commercial viability.

Material compatibility presents another substantial hurdle. Current nanoscale printing techniques are limited to a narrow range of printable materials, predominantly polymers and select ceramics. The incorporation of metals, semiconductors, and multi-material systems—essential for advanced mechanical metamaterial applications—remains technically challenging and often requires complex post-processing steps that can compromise structural integrity.

Throughput and scalability issues severely limit industrial adoption. Most high-resolution nanoscale printing techniques operate at extremely slow rates, with some advanced structures requiring days or even weeks to fabricate. This time-intensive process makes mass production economically unfeasible and restricts applications to laboratory demonstrations rather than commercial products.

The characterization and quality control of nanoscale printed structures pose significant challenges. Current metrology tools struggle to provide non-destructive, in-situ monitoring during the printing process. This limitation makes it difficult to identify defects or structural inconsistencies that may critically affect the mechanical performance of metamaterials.

Computational design tools have not kept pace with fabrication capabilities. The multi-physics modeling required to accurately predict the behavior of nanoarchitected mechanical metamaterials demands enormous computational resources and sophisticated algorithms that can bridge multiple length scales—from nanometers to macroscopic dimensions.

Environmental stability represents another major concern. Many nanoprinted structures exhibit degradation when exposed to ambient conditions, UV radiation, or mechanical stresses over time. This vulnerability significantly limits their practical applications in real-world environments where long-term reliability is essential.

Cost barriers remain prohibitively high. The specialized equipment, materials, and expertise required for nanoscale 3D printing technologies represent substantial investments that few organizations can justify, particularly given the current limitations in throughput and material versatility.

Standardization across the field is notably absent, with different research groups and manufacturers employing varied approaches to design, fabrication, and characterization. This fragmentation hinders knowledge transfer and slows the overall advancement of the technology toward commercial viability.

Current 3D Printing Technologies for Nanoarchitected Structures

01 Lattice-based nanoarchitected metamaterials

Lattice-based nanoarchitected metamaterials utilize precise geometric arrangements at the nanoscale to achieve unique mechanical properties. These structures often feature periodic arrangements of unit cells that can be designed to exhibit properties such as high strength-to-weight ratios, enhanced energy absorption, and tunable elasticity. The lattice architecture allows for controlled deformation mechanisms and can be optimized for specific mechanical responses, including programmable stiffness and tailored stress-strain behavior.- Lattice-based nanoarchitected metamaterials: Lattice-based nanoarchitected metamaterials utilize periodic arrangements of unit cells to create structures with exceptional mechanical properties. These materials feature carefully designed geometries at the nanoscale that enable properties such as high strength-to-weight ratios, enhanced energy absorption, and tunable stiffness. The lattice architecture allows for precise control over mechanical behavior through manipulation of cell geometry, strut dimensions, and connectivity patterns, resulting in materials that can outperform traditional engineering materials in specific applications.

- Hierarchical design in mechanical metamaterials: Hierarchical design principles in nanoarchitected mechanical metamaterials involve structuring across multiple length scales to achieve superior mechanical properties. By incorporating structural elements at different scales (nano, micro, and macro), these materials can exhibit enhanced toughness, improved damage tolerance, and controlled deformation mechanisms. The hierarchical approach enables the creation of metamaterials with tailored mechanical responses that can adapt to different loading conditions while maintaining structural integrity.

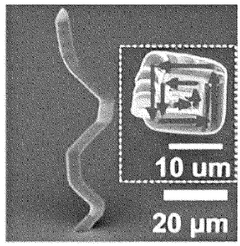

- Auxetic nanoarchitected metamaterials: Auxetic nanoarchitected metamaterials possess the unusual property of negative Poisson's ratio, causing them to expand laterally when stretched longitudinally. This counterintuitive behavior is achieved through specific geometric arrangements at the nanoscale, resulting in enhanced mechanical properties including improved indentation resistance, fracture toughness, and energy absorption capabilities. These materials can be designed with precisely controlled deformation mechanisms that enable novel applications in impact protection, flexible electronics, and biomedical devices.

- Dynamic mechanical properties of nanoarchitected metamaterials: Nanoarchitected metamaterials can be designed to exhibit specific dynamic mechanical properties, including vibration damping, wave attenuation, and acoustic filtering. These materials feature carefully engineered structures that control how mechanical waves propagate through them, creating frequency bandgaps and enabling properties like negative effective mass or stiffness. The dynamic response can be tuned by adjusting the geometry, material composition, and connectivity of the nanoarchitecture, allowing for applications in vibration isolation, acoustic cloaking, and mechanical signal processing.

- Mechanical property optimization through material composition: The mechanical properties of nanoarchitected metamaterials can be significantly enhanced through careful selection and combination of constituent materials. By incorporating high-performance materials such as carbon nanotubes, graphene, ceramic-polymer composites, or specialized alloys into the nanoarchitecture, these metamaterials can achieve exceptional strength, stiffness, and resilience. The synergistic effect between material composition and structural design enables the creation of metamaterials with mechanical properties that far exceed those of conventional materials, while maintaining advantages such as low density and customizable behavior.

02 Hierarchical design in mechanical metamaterials

Hierarchical design principles in nanoarchitected metamaterials involve structuring across multiple length scales to enhance mechanical performance. By incorporating structural elements at different scales (nano, micro, and macro), these materials can achieve superior combinations of properties such as strength, toughness, and resilience. The hierarchical organization enables mechanisms like crack deflection and energy dissipation that contribute to improved mechanical behavior, while allowing for optimization of density-normalized properties beyond what conventional materials can achieve.Expand Specific Solutions03 Stimuli-responsive nanoarchitected metamaterials

Stimuli-responsive nanoarchitected metamaterials can dynamically alter their mechanical properties in response to external triggers such as temperature, light, electric fields, or mechanical stress. These smart materials incorporate responsive elements at the nanoscale that enable programmable behavior, including on-demand stiffness changes, shape memory effects, and controlled actuation. The ability to switch mechanical properties makes these materials valuable for applications requiring adaptive performance, such as soft robotics, biomedical devices, and smart structural components.Expand Specific Solutions04 Fabrication techniques for nanoarchitected metamaterials

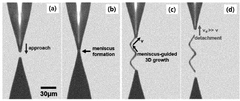

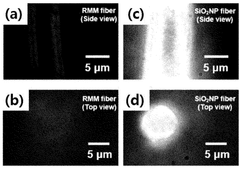

Advanced fabrication techniques are essential for creating nanoarchitected metamaterials with precise control over structure and resulting mechanical properties. Methods such as two-photon lithography, nanoimprint lithography, self-assembly, and additive manufacturing enable the creation of complex 3D architectures at the nanoscale. These fabrication approaches allow for the realization of theoretical designs with minimal defects, ensuring that the intended mechanical properties such as negative Poisson's ratio, programmable stiffness, and enhanced energy absorption are achieved in the final material.Expand Specific Solutions05 Mechanical property characterization and modeling

Characterization and modeling of nanoarchitected metamaterials are crucial for understanding and predicting their mechanical behavior. Advanced techniques such as in-situ nanomechanical testing, atomic force microscopy, and nanoindentation provide insights into properties like elastic modulus, yield strength, and energy dissipation mechanisms. Computational methods including finite element analysis, multiscale modeling, and topology optimization enable the design of metamaterials with tailored mechanical responses. These approaches facilitate the development of structure-property relationships that guide the creation of materials with unprecedented mechanical performance.Expand Specific Solutions

Leading Researchers and Companies in Metamaterial Fabrication

The 3D printing of nanoarchitected mechanical metamaterials is currently in a transitional phase from early research to commercial application, with a rapidly expanding market projected to reach $1.5 billion by 2025. The technology maturity varies significantly across players: research institutions like MIT, Northwestern University, and Shanghai Jiao Tong University are advancing fundamental science, while companies such as HRL Laboratories and Divergent Technologies are commercializing applications. HRL Laboratories leads in aerospace and defense implementations, while Divergent Technologies focuses on automotive applications. Academic-industrial partnerships are accelerating development, with universities providing theoretical frameworks and companies scaling manufacturing processes. The field is characterized by intense competition in materials development, printing techniques, and application-specific optimizations.

HRL Laboratories LLC

Technical Solution: HRL Laboratories has pioneered significant advancements in 3D printing of nanoarchitected mechanical metamaterials through their proprietary photopolymer waveguide technology. Their approach utilizes self-propagating photopolymer waveguides that enable the creation of complex lattice structures with feature sizes down to 100 nanometers[1]. This technology allows for the fabrication of ultralight, ultrastiff mechanical metamaterials with unprecedented strength-to-weight ratios. HRL's process involves a specialized photoresin that, when exposed to specific wavelengths of light, creates self-developing waveguides that propagate and cure additional material, enabling the formation of complex 3D nanoarchitectures[2]. Their technology has demonstrated the ability to create materials with densities below 10 mg/cm³ while maintaining structural integrity, representing a significant breakthrough in lightweight material design for aerospace and defense applications[3].

Strengths: Achieves exceptionally fine feature resolution (sub-micron) with high aspect ratios; enables creation of ultralight materials with superior mechanical properties; scalable manufacturing potential for industrial applications. Weaknesses: Requires specialized photopolymer materials that may limit material selection; complex process control needed for consistent results; higher production costs compared to conventional manufacturing methods.

Divergent Technologies, Inc.

Technical Solution: Divergent Technologies has revolutionized the 3D printing of nanoarchitected mechanical metamaterials through their proprietary Digital Manufacturing System (DMS). This integrated platform combines computational design, additive manufacturing, and automated assembly to create complex nanoarchitected structures for automotive and aerospace applications[1]. Their approach utilizes laser powder bed fusion technology enhanced with proprietary process controls that enable the creation of optimized lattice structures with feature sizes down to 200 microns while maintaining exceptional mechanical properties[2]. Divergent's system incorporates machine learning algorithms that continuously optimize printing parameters based on real-time monitoring data, ensuring consistent quality across complex geometries. Their technology has demonstrated the ability to create vehicle structures that are up to 75% lighter than traditional designs while meeting or exceeding performance requirements[3]. Divergent has successfully implemented this technology in commercial applications, producing lightweight components for high-performance vehicles that exhibit tailored mechanical responses, including programmed energy absorption zones and optimized stiffness distributions.

Strengths: Highly scalable production capability suitable for industrial applications; integrated design-to-manufacturing workflow reduces development time; proven commercial implementation demonstrates real-world viability. Weaknesses: Limited to metal-based metamaterials; higher minimum feature size compared to specialized laboratory techniques; significant capital investment required for implementation.

Key Patents and Innovations in Metamaterial Design

3-dimensional nanostructure based on metamaterials and fabrication method thereof

PatentWO2025135802A1

Innovation

- A metamaterial-based three-dimensional nanostructure comprising metamolecules with a conductive nanoparticle surrounding a non-conductive nanoparticle, and a fiber with conductive nanoparticles positioned between metamolecules, allowing for flexible shapes and controlled optical properties.

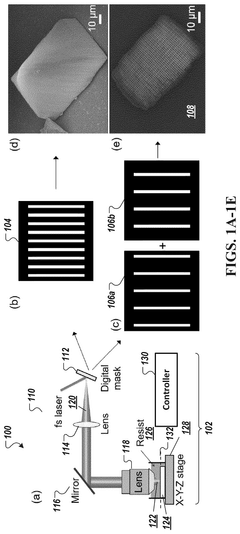

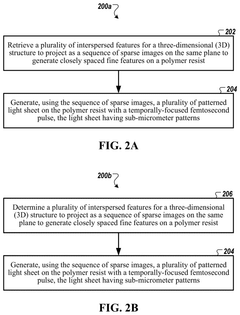

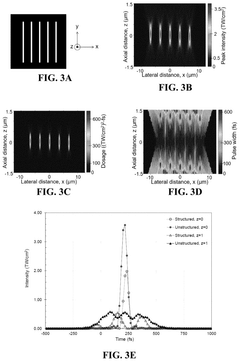

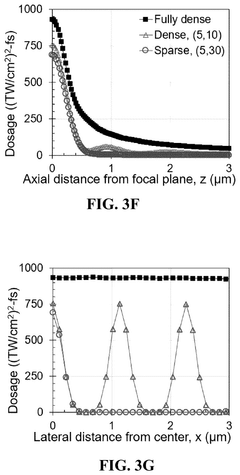

Projection two-photon lithography method and system for rapid printing of 3D structures with sub-micrometer features and porosities

PatentPendingUS20240351272A1

Innovation

- The method involves projecting a sequence of sparse images using a two-photon lithography system with a temporally-focused femtosecond pulse to generate patterned light sheets on a polymer resist, mitigating proximity effects by controlling the duration, intensity, and size of the light spot based on an optical dosage per pulse model, and using a polymer resist with a photoinitiator, radical quencher, and monomer to produce sub-micrometer features and porosities.

Material Sustainability and Environmental Impact Assessment

The sustainability implications of 3D printing nanoarchitected mechanical metamaterials represent a critical dimension of this emerging technology. When evaluating material sustainability, these advanced manufacturing processes demonstrate significant advantages over traditional manufacturing methods. The reduced material waste through precise deposition techniques stands in stark contrast to subtractive manufacturing approaches, where up to 90% of raw materials may be discarded. This efficiency is particularly valuable for rare or expensive nanomaterials used in metamaterial production.

Energy consumption patterns across the lifecycle of nanoarchitected metamaterials reveal complex trade-offs. While the printing process itself may require substantial energy input, particularly for high-resolution techniques like two-photon polymerization, the operational benefits often compensate for this initial investment. Lightweight metamaterial structures in aerospace or automotive applications can dramatically reduce fuel consumption and associated emissions throughout product lifespans.

Raw material sourcing presents both challenges and opportunities. Many advanced metamaterials rely on specialized polymers, metals, or ceramics that may have complex supply chains with varying environmental footprints. However, recent research demonstrates promising developments in bio-based and recyclable feedstocks compatible with nanoscale 3D printing, potentially creating circular material pathways that minimize environmental impact.

End-of-life considerations for nanoarchitected metamaterials remain underdeveloped in current research. The complex multi-material compositions and intricate geometries that enable their remarkable mechanical properties can simultaneously complicate recycling efforts. Developing specialized recovery processes for these materials represents an important frontier for sustainability research.

Life cycle assessment (LCA) studies specifically targeting nanoarchitected metamaterials remain limited but growing. Preliminary findings suggest that the environmental benefits of these materials are highly application-dependent. For instance, metamaterial-based thermal insulators may deliver substantial energy savings in buildings, while other applications might prioritize performance over environmental considerations.

Regulatory frameworks addressing the environmental implications of nanomaterials in 3D printing are still evolving. Concerns regarding nanoparticle release during manufacturing, use, or disposal require careful monitoring and mitigation strategies. Industry-academic partnerships are increasingly focusing on developing standardized protocols for assessing the environmental health and safety aspects of these advanced materials throughout their lifecycle.

Energy consumption patterns across the lifecycle of nanoarchitected metamaterials reveal complex trade-offs. While the printing process itself may require substantial energy input, particularly for high-resolution techniques like two-photon polymerization, the operational benefits often compensate for this initial investment. Lightweight metamaterial structures in aerospace or automotive applications can dramatically reduce fuel consumption and associated emissions throughout product lifespans.

Raw material sourcing presents both challenges and opportunities. Many advanced metamaterials rely on specialized polymers, metals, or ceramics that may have complex supply chains with varying environmental footprints. However, recent research demonstrates promising developments in bio-based and recyclable feedstocks compatible with nanoscale 3D printing, potentially creating circular material pathways that minimize environmental impact.

End-of-life considerations for nanoarchitected metamaterials remain underdeveloped in current research. The complex multi-material compositions and intricate geometries that enable their remarkable mechanical properties can simultaneously complicate recycling efforts. Developing specialized recovery processes for these materials represents an important frontier for sustainability research.

Life cycle assessment (LCA) studies specifically targeting nanoarchitected metamaterials remain limited but growing. Preliminary findings suggest that the environmental benefits of these materials are highly application-dependent. For instance, metamaterial-based thermal insulators may deliver substantial energy savings in buildings, while other applications might prioritize performance over environmental considerations.

Regulatory frameworks addressing the environmental implications of nanomaterials in 3D printing are still evolving. Concerns regarding nanoparticle release during manufacturing, use, or disposal require careful monitoring and mitigation strategies. Industry-academic partnerships are increasingly focusing on developing standardized protocols for assessing the environmental health and safety aspects of these advanced materials throughout their lifecycle.

Cross-Industry Applications and Commercial Viability

Nanoarchitected mechanical metamaterials produced through 3D printing technologies demonstrate remarkable versatility across multiple industries, positioning them as transformative innovations with significant commercial potential. In aerospace and defense sectors, these materials offer unprecedented strength-to-weight ratios, enabling the development of lighter aircraft components, advanced thermal protection systems, and impact-resistant structures that can withstand extreme conditions while reducing fuel consumption and operational costs.

The medical industry represents another promising application domain, where nanoarchitected metamaterials are revolutionizing implant design, tissue engineering scaffolds, and drug delivery systems. Their precisely controlled microstructures can mimic natural biological tissues, promoting better integration with the human body and reducing rejection risks. Companies like Stryker and Johnson & Johnson have already begun investing in research partnerships to commercialize these applications, with market analysts projecting a compound annual growth rate of 15-20% for medical metamaterials over the next decade.

In the automotive sector, these materials address critical challenges related to vehicle lightweighting, crash absorption, and thermal management. Major manufacturers including BMW and Toyota have established dedicated research divisions exploring metamaterial applications for next-generation vehicles, particularly focusing on electric vehicle battery protection systems and structural components that can enhance safety while reducing mass.

From a commercial viability perspective, the initial high production costs represent the primary barrier to widespread adoption. Current manufacturing processes for nanoarchitected metamaterials remain relatively slow and expensive, with specialized equipment requirements limiting scalability. However, recent advancements in high-throughput printing technologies and material formulations are steadily reducing production costs, with some estimates suggesting a 30-40% cost reduction within the next three years.

The intellectual property landscape surrounding these technologies is increasingly competitive, with over 500 patents filed in the last five years related to nanoarchitected metamaterials and their applications. This indicates strong commercial interest and investment potential, particularly as manufacturing processes mature and unit economics improve. Several startups specializing in metamaterial production have secured significant venture capital funding, including Metamaterial Technologies Inc. and Metawave, demonstrating investor confidence in the commercial trajectory.

Market forecasts suggest the global market for 3D printed metamaterials could reach $1.2 billion by 2028, with applications in consumer electronics, construction, and energy storage emerging alongside the more established aerospace and medical sectors. As production scales and costs decrease, these materials are positioned to transition from specialized niche applications to mainstream industrial adoption.

The medical industry represents another promising application domain, where nanoarchitected metamaterials are revolutionizing implant design, tissue engineering scaffolds, and drug delivery systems. Their precisely controlled microstructures can mimic natural biological tissues, promoting better integration with the human body and reducing rejection risks. Companies like Stryker and Johnson & Johnson have already begun investing in research partnerships to commercialize these applications, with market analysts projecting a compound annual growth rate of 15-20% for medical metamaterials over the next decade.

In the automotive sector, these materials address critical challenges related to vehicle lightweighting, crash absorption, and thermal management. Major manufacturers including BMW and Toyota have established dedicated research divisions exploring metamaterial applications for next-generation vehicles, particularly focusing on electric vehicle battery protection systems and structural components that can enhance safety while reducing mass.

From a commercial viability perspective, the initial high production costs represent the primary barrier to widespread adoption. Current manufacturing processes for nanoarchitected metamaterials remain relatively slow and expensive, with specialized equipment requirements limiting scalability. However, recent advancements in high-throughput printing technologies and material formulations are steadily reducing production costs, with some estimates suggesting a 30-40% cost reduction within the next three years.

The intellectual property landscape surrounding these technologies is increasingly competitive, with over 500 patents filed in the last five years related to nanoarchitected metamaterials and their applications. This indicates strong commercial interest and investment potential, particularly as manufacturing processes mature and unit economics improve. Several startups specializing in metamaterial production have secured significant venture capital funding, including Metamaterial Technologies Inc. and Metawave, demonstrating investor confidence in the commercial trajectory.

Market forecasts suggest the global market for 3D printed metamaterials could reach $1.2 billion by 2028, with applications in consumer electronics, construction, and energy storage emerging alongside the more established aerospace and medical sectors. As production scales and costs decrease, these materials are positioned to transition from specialized niche applications to mainstream industrial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!