Nanoarchitected Mechanical Metamaterials for Vapor-Control Technologies.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary class of engineered materials that leverage precise nanoscale architectures to achieve extraordinary mechanical properties not found in conventional materials. The evolution of these materials traces back to the early 2000s when advances in nanofabrication techniques first enabled the creation of controlled structures at the nanoscale. Since then, the field has experienced exponential growth, particularly in the last decade, with significant breakthroughs in fabrication methods such as two-photon lithography, atomic layer deposition, and self-assembly techniques.

The technological trajectory of nanoarchitected metamaterials has been characterized by progressive improvements in structural complexity, mechanical performance, and functional integration. Early research focused primarily on demonstrating basic mechanical properties like ultra-lightweight strength and negative Poisson's ratio. Recent developments have shifted toward multifunctional capabilities, particularly in response to environmental stimuli such as temperature, humidity, and chemical vapors.

In the context of vapor-control technologies, nanoarchitected metamaterials offer unprecedented opportunities due to their high surface-to-volume ratio, tunable porosity, and responsive mechanical behavior. These characteristics enable selective vapor adsorption, controlled release, and mechanical actuation in response to specific vapor molecules—capabilities that are increasingly critical in applications ranging from environmental remediation to advanced sensing systems.

The primary technical objectives in this domain include developing nanoarchitectures that can selectively interact with target vapor molecules, creating responsive mechanical systems that can translate vapor adsorption into useful mechanical work, and designing scalable fabrication methods that can produce these complex structures at commercially viable scales and costs.

Current research aims to overcome several key challenges, including enhancing the specificity of vapor-material interactions, improving the durability of these materials under repeated vapor exposure cycles, and developing predictive models that can accurately simulate the complex interplay between vapor adsorption and mechanical response at the nanoscale.

The long-term vision for this technology encompasses the development of autonomous vapor-responsive systems capable of intelligent environmental adaptation, energy-efficient vapor capture and release mechanisms, and integration with existing industrial infrastructure for immediate practical applications in sectors such as air purification, humidity control, and volatile organic compound mitigation.

As we advance toward these objectives, interdisciplinary collaboration between materials scientists, mechanical engineers, chemical engineers, and computational modelers will be essential to fully realize the transformative potential of nanoarchitected mechanical metamaterials in vapor-control technologies.

The technological trajectory of nanoarchitected metamaterials has been characterized by progressive improvements in structural complexity, mechanical performance, and functional integration. Early research focused primarily on demonstrating basic mechanical properties like ultra-lightweight strength and negative Poisson's ratio. Recent developments have shifted toward multifunctional capabilities, particularly in response to environmental stimuli such as temperature, humidity, and chemical vapors.

In the context of vapor-control technologies, nanoarchitected metamaterials offer unprecedented opportunities due to their high surface-to-volume ratio, tunable porosity, and responsive mechanical behavior. These characteristics enable selective vapor adsorption, controlled release, and mechanical actuation in response to specific vapor molecules—capabilities that are increasingly critical in applications ranging from environmental remediation to advanced sensing systems.

The primary technical objectives in this domain include developing nanoarchitectures that can selectively interact with target vapor molecules, creating responsive mechanical systems that can translate vapor adsorption into useful mechanical work, and designing scalable fabrication methods that can produce these complex structures at commercially viable scales and costs.

Current research aims to overcome several key challenges, including enhancing the specificity of vapor-material interactions, improving the durability of these materials under repeated vapor exposure cycles, and developing predictive models that can accurately simulate the complex interplay between vapor adsorption and mechanical response at the nanoscale.

The long-term vision for this technology encompasses the development of autonomous vapor-responsive systems capable of intelligent environmental adaptation, energy-efficient vapor capture and release mechanisms, and integration with existing industrial infrastructure for immediate practical applications in sectors such as air purification, humidity control, and volatile organic compound mitigation.

As we advance toward these objectives, interdisciplinary collaboration between materials scientists, mechanical engineers, chemical engineers, and computational modelers will be essential to fully realize the transformative potential of nanoarchitected mechanical metamaterials in vapor-control technologies.

Market Analysis for Vapor-Control Technologies

The vapor-control technologies market is experiencing significant growth driven by increasing environmental regulations and industrial demand for efficient gas management solutions. The global market for vapor recovery systems was valued at approximately $860 million in 2020 and is projected to reach $1.2 billion by 2025, representing a compound annual growth rate of 6.8%. This growth trajectory is supported by stringent emission control regulations across North America, Europe, and increasingly in Asia-Pacific regions.

Key market segments for vapor-control technologies include oil and gas, chemical processing, pharmaceuticals, and semiconductor manufacturing. The oil and gas sector currently dominates market share at roughly 40%, primarily due to extensive vapor recovery requirements during extraction, storage, and transportation processes. Chemical processing follows at 25%, with pharmaceuticals and semiconductors collectively representing about 20% of the market.

Nanoarchitected mechanical metamaterials present a disruptive innovation potential in this landscape. Traditional vapor control solutions rely predominantly on activated carbon adsorption, membrane separation, and thermal oxidation technologies. These conventional approaches face limitations in selectivity, energy efficiency, and operational lifespan. The introduction of precisely engineered nanomaterials could address these pain points, potentially capturing market share from established technologies.

Market research indicates that industries are willing to pay premium prices for vapor control solutions that offer superior performance metrics, particularly in selective adsorption capabilities and regeneration efficiency. A survey of industrial end-users revealed that 68% would consider adopting novel materials if they demonstrated at least 30% improvement in adsorption capacity or 25% reduction in energy consumption during regeneration cycles.

Regional market analysis shows North America leading with 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 8.5% annually through 2025, driven by rapid industrialization and increasingly stringent environmental regulations in China and India.

Competitive analysis reveals that the market is moderately fragmented, with the top five players controlling approximately 40% of market share. Major companies include Honeywell International, Siemens AG, and John Zink Hamworthy Combustion. These established players primarily focus on conventional technologies, creating potential market entry opportunities for disruptive solutions based on nanoarchitected metamaterials, particularly in high-value applications requiring precise molecular selectivity.

Key market segments for vapor-control technologies include oil and gas, chemical processing, pharmaceuticals, and semiconductor manufacturing. The oil and gas sector currently dominates market share at roughly 40%, primarily due to extensive vapor recovery requirements during extraction, storage, and transportation processes. Chemical processing follows at 25%, with pharmaceuticals and semiconductors collectively representing about 20% of the market.

Nanoarchitected mechanical metamaterials present a disruptive innovation potential in this landscape. Traditional vapor control solutions rely predominantly on activated carbon adsorption, membrane separation, and thermal oxidation technologies. These conventional approaches face limitations in selectivity, energy efficiency, and operational lifespan. The introduction of precisely engineered nanomaterials could address these pain points, potentially capturing market share from established technologies.

Market research indicates that industries are willing to pay premium prices for vapor control solutions that offer superior performance metrics, particularly in selective adsorption capabilities and regeneration efficiency. A survey of industrial end-users revealed that 68% would consider adopting novel materials if they demonstrated at least 30% improvement in adsorption capacity or 25% reduction in energy consumption during regeneration cycles.

Regional market analysis shows North America leading with 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 8.5% annually through 2025, driven by rapid industrialization and increasingly stringent environmental regulations in China and India.

Competitive analysis reveals that the market is moderately fragmented, with the top five players controlling approximately 40% of market share. Major companies include Honeywell International, Siemens AG, and John Zink Hamworthy Combustion. These established players primarily focus on conventional technologies, creating potential market entry opportunities for disruptive solutions based on nanoarchitected metamaterials, particularly in high-value applications requiring precise molecular selectivity.

Current State and Challenges in Nanoarchitected Materials

Nanoarchitected mechanical metamaterials represent a frontier in materials science, combining nanoscale precision with metamaterial design principles to create structures with unprecedented mechanical properties. Currently, these materials are being developed through various fabrication techniques including two-photon lithography, self-assembly, and direct laser writing, each offering different advantages in terms of resolution, scalability, and material compatibility.

The global research landscape shows significant advancements in both academic and industrial settings. Leading research institutions in North America, Europe, and East Asia have established specialized laboratories dedicated to nanoarchitected materials, with particular concentration in the United States, Germany, China, and South Korea. These geographical clusters have emerged due to the presence of advanced nanofabrication facilities and strong government funding initiatives.

Despite promising developments, several critical challenges impede widespread implementation of nanoarchitected materials for vapor-control technologies. Scalability remains a primary obstacle, as most current fabrication methods are limited to small sample sizes and face difficulties in industrial-scale production. The time-intensive nature of precision nanofabrication creates a significant bottleneck for commercial applications.

Material selection presents another substantial challenge. While polymeric nanoarchitected materials offer design flexibility, they often lack the chemical stability required for harsh vapor environments. Ceramic and metallic alternatives provide better stability but introduce fabrication complexities and reduced design freedom. The ideal material combination that balances mechanical properties, vapor interaction capabilities, and manufacturing feasibility remains elusive.

Performance consistency across environmental conditions represents a third major challenge. Nanoarchitected materials designed for vapor control must maintain structural integrity and functional performance across varying humidity levels, temperature ranges, and chemical exposures. Current designs often show performance degradation under fluctuating conditions, limiting their practical application.

Cost considerations further constrain development, with specialized equipment and expertise driving high production expenses. The economic viability of these materials for commercial vapor-control applications requires significant cost reduction through process optimization or alternative fabrication approaches.

Characterization techniques also present limitations, as standard methods struggle to accurately assess the complex 3D geometries and multiscale properties of nanoarchitected materials. Advanced imaging and testing protocols are needed to fully understand structure-property relationships, particularly regarding vapor-material interactions at the nanoscale.

These challenges collectively represent the current technological barriers that must be overcome to realize the full potential of nanoarchitected mechanical metamaterials in next-generation vapor-control technologies.

The global research landscape shows significant advancements in both academic and industrial settings. Leading research institutions in North America, Europe, and East Asia have established specialized laboratories dedicated to nanoarchitected materials, with particular concentration in the United States, Germany, China, and South Korea. These geographical clusters have emerged due to the presence of advanced nanofabrication facilities and strong government funding initiatives.

Despite promising developments, several critical challenges impede widespread implementation of nanoarchitected materials for vapor-control technologies. Scalability remains a primary obstacle, as most current fabrication methods are limited to small sample sizes and face difficulties in industrial-scale production. The time-intensive nature of precision nanofabrication creates a significant bottleneck for commercial applications.

Material selection presents another substantial challenge. While polymeric nanoarchitected materials offer design flexibility, they often lack the chemical stability required for harsh vapor environments. Ceramic and metallic alternatives provide better stability but introduce fabrication complexities and reduced design freedom. The ideal material combination that balances mechanical properties, vapor interaction capabilities, and manufacturing feasibility remains elusive.

Performance consistency across environmental conditions represents a third major challenge. Nanoarchitected materials designed for vapor control must maintain structural integrity and functional performance across varying humidity levels, temperature ranges, and chemical exposures. Current designs often show performance degradation under fluctuating conditions, limiting their practical application.

Cost considerations further constrain development, with specialized equipment and expertise driving high production expenses. The economic viability of these materials for commercial vapor-control applications requires significant cost reduction through process optimization or alternative fabrication approaches.

Characterization techniques also present limitations, as standard methods struggle to accurately assess the complex 3D geometries and multiscale properties of nanoarchitected materials. Advanced imaging and testing protocols are needed to fully understand structure-property relationships, particularly regarding vapor-material interactions at the nanoscale.

These challenges collectively represent the current technological barriers that must be overcome to realize the full potential of nanoarchitected mechanical metamaterials in next-generation vapor-control technologies.

Current Vapor-Control Technical Solutions

01 Nanoarchitected metamaterials for vapor sensing and control

Nanoarchitected metamaterials can be designed with specific structures that respond to vapor presence. These materials utilize nanoscale architectures to create highly sensitive vapor detection systems. The metamaterials can change their mechanical or optical properties when exposed to specific vapors, allowing for precise sensing and control applications. These structures often incorporate responsive elements that can detect minute changes in vapor concentration in the surrounding environment.- Nanoarchitected metamaterials for vapor sensing and control: Nanoarchitected metamaterials can be designed with specific structures that respond to vapor presence. These materials utilize nanoscale architectures to create highly sensitive vapor detection systems. The metamaterials can change their mechanical properties, such as stiffness or resonant frequency, when exposed to specific vapors, allowing for precise detection and control of vapor environments.

- Responsive mechanical metamaterials with vapor-triggered actuation: Mechanical metamaterials can be engineered to respond to vapor stimuli through actuation mechanisms. These materials incorporate structures that physically deform, expand, contract, or change shape when exposed to specific vapors. The responsive behavior enables applications in environmental control, smart ventilation systems, and adaptive building materials that automatically respond to humidity or chemical vapor presence.

- Wireless communication systems for vapor-responsive metamaterials: Integration of wireless communication technologies with vapor-responsive metamaterials enables remote monitoring and control capabilities. These systems can transmit data about vapor conditions and material responses in real-time, allowing for automated environmental management. The wireless networks facilitate the coordination of multiple metamaterial components across distributed areas for comprehensive vapor control strategies.

- Thermal management in vapor-controlling metamaterials: Thermal properties play a crucial role in the performance of vapor-controlling metamaterials. These materials can be designed with specific thermal conductivity characteristics to manage heat transfer during vapor interactions. Advanced thermal management approaches include phase-change mechanisms, temperature-responsive elements, and thermally-activated vapor control features that enhance the efficiency and responsiveness of the metamaterial systems.

- Biomedical applications of vapor-controlling metamaterials: Vapor-controlling metamaterials offer significant potential in biomedical applications. These materials can be engineered to interact with biological vapors for diagnostic purposes, drug delivery systems, or therapeutic interventions. The nanoarchitected structures can be designed to selectively respond to biomarkers in breath or other vapor emissions from the body, enabling non-invasive monitoring and treatment approaches.

02 Responsive mechanical metamaterials with vapor-triggered actuation

Mechanical metamaterials can be engineered to respond to vapor stimuli through actuation mechanisms. These materials undergo controlled deformation or mechanical property changes when exposed to specific vapors. The responsive behavior can be utilized for applications such as smart filters, adaptive barriers, or mechanical switches that operate based on vapor presence. The actuation can be reversible, allowing the material to return to its original state when the vapor stimulus is removed.Expand Specific Solutions03 Wireless communication systems for vapor-responsive metamaterials

Integration of wireless communication technologies with vapor-responsive metamaterials enables remote monitoring and control capabilities. These systems can transmit data about vapor detection and material response to central monitoring stations. The wireless networks allow for real-time tracking of vapor conditions and automated response mechanisms. Such systems are particularly valuable in hazardous environments where direct human monitoring may be dangerous or impractical.Expand Specific Solutions04 Thermal management in vapor-control metamaterials

Thermal properties play a crucial role in the performance of vapor-control metamaterials. These materials can be designed with specific thermal conductivity and heat dissipation characteristics to maintain optimal operating conditions. Temperature control mechanisms can enhance the sensitivity and selectivity of vapor detection systems. Advanced thermal management approaches allow these materials to function effectively across a wide range of environmental conditions and vapor concentrations.Expand Specific Solutions05 Biomedical applications of vapor-responsive metamaterials

Vapor-responsive metamaterials have significant potential in biomedical applications. These materials can be used for controlled drug delivery systems that release therapeutic agents in response to specific vapor or humidity conditions. They can also serve as biosensors for detecting disease markers in breath or other vapor-phase biological samples. The biocompatible versions of these materials enable integration with medical devices for monitoring patient conditions or delivering treatments based on detected vapor biomarkers.Expand Specific Solutions

Key Industry Players in Nanoarchitected Materials

Nanoarchitected mechanical metamaterials for vapor-control technologies are currently in an early growth phase, with the market expanding as applications in environmental control, energy efficiency, and smart materials gain traction. The global market is projected to reach significant scale as industries recognize the potential for precise vapor management. Technologically, research institutions like Massachusetts Institute of Technology, King Abdullah University of Science & Technology, and The Regents of the University of California are leading fundamental research, while companies including 3M, Airbus, and Samsung Electronics are developing commercial applications. Government entities such as CNRS and SRI International bridge the gap between academic research and industrial implementation. The field is advancing from laboratory demonstrations toward scalable manufacturing processes, with increasing focus on durability, cost-effectiveness, and integration with existing systems.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed sophisticated nanoarchitected mechanical metamaterials for vapor control technologies through their interdisciplinary research combining materials science, chemistry, and mechanical engineering. Their approach focuses on creating hierarchical structures with precisely controlled mechanical properties that respond selectively to different vapor molecules. CNRS's technology utilizes a combination of responsive polymers and inorganic components arranged in complex 3D architectures that can dynamically alter their configuration upon vapor exposure. These metamaterials feature gradient porosity designs that create directional vapor transport pathways, significantly enhancing capture efficiency and release kinetics. CNRS researchers have pioneered vapor-selective metamaterials that incorporate molecular recognition elements within the mechanical structure, enabling highly specific interactions with target vapor compounds. Their systems demonstrate remarkable selectivity coefficients exceeding 80:1 for specific volatile organic compounds while maintaining structural integrity through hundreds of adsorption-desorption cycles. Recent innovations include photothermally responsive metamaterials that can be remotely triggered to release captured vapors using specific wavelengths of light, enabling precise control over the vapor capture and release process without requiring direct contact or additional energy inputs during operation.

Strengths: Highly selective vapor capture through integrated molecular recognition elements; excellent mechanical durability allowing for extended operational lifetimes; energy-efficient operation through innovative triggering mechanisms. Weaknesses: Complex synthesis procedures that may limit large-scale manufacturing; potential performance variations under fluctuating environmental conditions; higher initial cost compared to conventional vapor control materials.

King Abdullah University of Science & Technology

Technical Solution: KAUST has developed innovative nanoarchitected mechanical metamaterials for vapor control technologies that leverage the unique properties of metal-organic frameworks (MOFs) integrated with responsive mechanical structures. Their approach combines advanced MOF chemistry with precision mechanical engineering to create hierarchical structures that respond dynamically to vapor conditions. KAUST's technology features nanolattice structures with tunable pore sizes ranging from 2-50 nm that can be mechanically actuated to control vapor adsorption and desorption kinetics. These metamaterials incorporate stimuli-responsive components that can change their configuration in response to temperature, humidity, or specific vapor molecules, enabling selective capture and release. KAUST researchers have demonstrated systems with vapor selectivity coefficients exceeding 100 for target compounds and adsorption capacities up to 2.5 g/g material. Their vapor-control metamaterials utilize a multi-scale design approach, incorporating nanoscale features for molecular selectivity within microscale mechanical structures that provide robustness and actuation capabilities. Recent developments include self-healing capabilities that maintain performance even after mechanical damage, significantly extending operational lifetime in industrial applications.

Strengths: Exceptional selectivity for target vapor molecules through combined chemical and mechanical filtering mechanisms; high adsorption capacity due to optimized pore architecture; excellent stability in harsh environmental conditions including high temperature and humidity. Weaknesses: Complex fabrication processes requiring specialized equipment; higher production costs compared to conventional materials; potential challenges in scaling to industrial quantities.

Core Patents and Research in Nanoarchitected Metamaterials

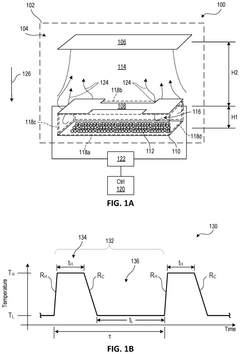

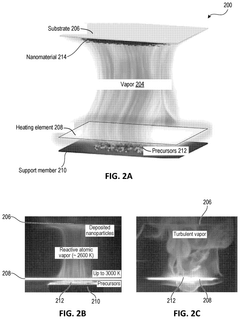

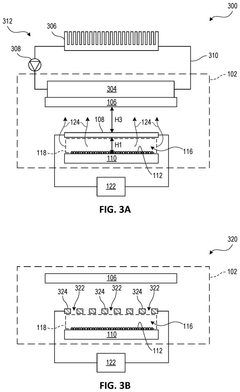

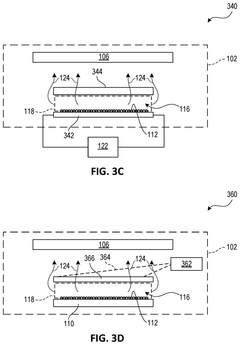

Vapor deposition systems and methods, and nanomaterials formed by vapor deposition

PatentPendingUS20250051924A1

Innovation

- A novel vapor deposition technique that involves subjecting solid-state precursors to high temperatures (≥2200 K) to produce high-temperature reactive vapor, which is then directed towards a lower-temperature noncatalytic substrate using a baffle member to achieve spatially-confined flow and deposition of highly-uniform multi-element nanomaterials.

Methods for preparing and depositing nanometer- or angstrom-scale particles on media

PatentWO2010063907A2

Innovation

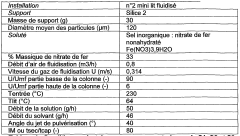

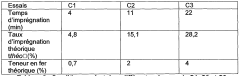

- A hybrid process combining chemical vapor deposition on a fluidized bed with organometallic compound vapor phase deposition, optimizing parameters such as impregnation modulus, calcination conditions, and using a separator membrane with nano pores to control nanoparticle deposition and size, allowing for precise control over the deposition process on various supports.

Environmental Impact and Sustainability Considerations

The environmental implications of nanoarchitected mechanical metamaterials for vapor-control technologies extend far beyond their immediate applications. These advanced materials offer significant potential for reducing environmental footprints across multiple industries by enabling more efficient vapor capture, separation, and control processes. Their precisely engineered structures can achieve higher performance with less material input, potentially reducing resource consumption and waste generation compared to conventional technologies.

When evaluating the sustainability of these metamaterials, lifecycle assessment reveals both advantages and challenges. The production phase often requires energy-intensive nanofabrication techniques, including lithography, atomic layer deposition, and precision manufacturing processes. However, these initial environmental costs may be offset by the extended operational lifespan and enhanced efficiency these materials provide in vapor-control applications.

Material selection represents a critical sustainability consideration. While some nanoarchitected metamaterials incorporate rare or potentially toxic elements, research trends show increasing focus on bio-inspired designs and environmentally benign constituents. Recent innovations have demonstrated promising results with biodegradable polymers, recyclable metals, and naturally derived compounds that maintain performance while reducing environmental impact.

The end-of-life management of these advanced materials presents unique challenges. Their complex architectures may complicate conventional recycling processes, necessitating specialized recovery techniques. Forward-thinking design approaches are increasingly incorporating disassembly and material recovery considerations from the outset, enabling circular economy principles to be applied even to these sophisticated materials.

Water conservation represents a particularly promising environmental benefit of these technologies. By enabling more efficient atmospheric water harvesting, selective vapor capture, and advanced dehumidification systems, these metamaterials could significantly reduce freshwater withdrawal requirements in water-intensive industries. This application holds particular promise for addressing water scarcity challenges in arid regions.

Energy efficiency gains constitute another environmental advantage. The precisely engineered structures of these metamaterials can achieve vapor control functions with minimal energy inputs compared to conventional approaches. This translates to reduced operational carbon footprints across applications ranging from industrial drying processes to HVAC systems in buildings.

Regulatory frameworks and environmental standards will play a crucial role in guiding the sustainable development of these technologies. As these materials transition from laboratory research to commercial applications, proactive engagement with environmental assessment protocols and safety standards will ensure their benefits are realized without unintended consequences.

When evaluating the sustainability of these metamaterials, lifecycle assessment reveals both advantages and challenges. The production phase often requires energy-intensive nanofabrication techniques, including lithography, atomic layer deposition, and precision manufacturing processes. However, these initial environmental costs may be offset by the extended operational lifespan and enhanced efficiency these materials provide in vapor-control applications.

Material selection represents a critical sustainability consideration. While some nanoarchitected metamaterials incorporate rare or potentially toxic elements, research trends show increasing focus on bio-inspired designs and environmentally benign constituents. Recent innovations have demonstrated promising results with biodegradable polymers, recyclable metals, and naturally derived compounds that maintain performance while reducing environmental impact.

The end-of-life management of these advanced materials presents unique challenges. Their complex architectures may complicate conventional recycling processes, necessitating specialized recovery techniques. Forward-thinking design approaches are increasingly incorporating disassembly and material recovery considerations from the outset, enabling circular economy principles to be applied even to these sophisticated materials.

Water conservation represents a particularly promising environmental benefit of these technologies. By enabling more efficient atmospheric water harvesting, selective vapor capture, and advanced dehumidification systems, these metamaterials could significantly reduce freshwater withdrawal requirements in water-intensive industries. This application holds particular promise for addressing water scarcity challenges in arid regions.

Energy efficiency gains constitute another environmental advantage. The precisely engineered structures of these metamaterials can achieve vapor control functions with minimal energy inputs compared to conventional approaches. This translates to reduced operational carbon footprints across applications ranging from industrial drying processes to HVAC systems in buildings.

Regulatory frameworks and environmental standards will play a crucial role in guiding the sustainable development of these technologies. As these materials transition from laboratory research to commercial applications, proactive engagement with environmental assessment protocols and safety standards will ensure their benefits are realized without unintended consequences.

Scalability and Manufacturing Challenges

The scalability and manufacturing of nanoarchitected mechanical metamaterials for vapor-control technologies present significant challenges that must be addressed before widespread industrial adoption can occur. Current fabrication methods such as two-photon lithography, direct laser writing, and projection micro-stereolithography offer precise control over nanoscale features but remain limited in production volume and speed. These techniques typically operate on small sample areas (often less than 1 cm²) with lengthy processing times, making them impractical for large-scale applications.

Cost considerations further complicate scalability, as specialized equipment and materials for nanofabrication involve substantial capital investment. The production of vapor-control metamaterials requires high-precision machinery operating in cleanroom environments, with material costs often exceeding conventional alternatives by orders of magnitude. These economic barriers significantly restrict commercial viability beyond niche applications.

Material selection presents another critical challenge. While laboratory demonstrations have utilized specialized polymers, ceramics, and metals, transitioning to industrially viable materials that maintain the desired mechanical and vapor-responsive properties remains difficult. Many materials that perform well in controlled laboratory settings may degrade under real-world conditions or fail to meet regulatory standards for specific applications.

Quality control and reproducibility issues become increasingly prominent at larger scales. The vapor-control functionality of these metamaterials depends on precise geometric features at the nanoscale, where even minor manufacturing variations can significantly alter performance characteristics. Developing robust quality assurance protocols that can efficiently validate large production volumes represents a substantial technical hurdle.

Recent advances in roll-to-roll nanoimprint lithography and self-assembly techniques show promise for addressing some scalability concerns. These approaches potentially enable continuous production of nanoarchitected materials over larger areas, though they currently sacrifice some degree of structural complexity and precision compared to direct writing methods.

Integration challenges also exist when incorporating these metamaterials into existing products and systems. The interface between nanoarchitected components and conventional materials often creates weak points or performance bottlenecks. Developing effective integration strategies requires interdisciplinary collaboration between materials scientists, mechanical engineers, and manufacturing specialists.

Regulatory considerations further complicate commercialization pathways, particularly for applications involving human exposure or environmental release. The novel properties of these materials may require new testing protocols and safety standards before receiving regulatory approval in sensitive sectors such as healthcare, food packaging, or consumer products.

Cost considerations further complicate scalability, as specialized equipment and materials for nanofabrication involve substantial capital investment. The production of vapor-control metamaterials requires high-precision machinery operating in cleanroom environments, with material costs often exceeding conventional alternatives by orders of magnitude. These economic barriers significantly restrict commercial viability beyond niche applications.

Material selection presents another critical challenge. While laboratory demonstrations have utilized specialized polymers, ceramics, and metals, transitioning to industrially viable materials that maintain the desired mechanical and vapor-responsive properties remains difficult. Many materials that perform well in controlled laboratory settings may degrade under real-world conditions or fail to meet regulatory standards for specific applications.

Quality control and reproducibility issues become increasingly prominent at larger scales. The vapor-control functionality of these metamaterials depends on precise geometric features at the nanoscale, where even minor manufacturing variations can significantly alter performance characteristics. Developing robust quality assurance protocols that can efficiently validate large production volumes represents a substantial technical hurdle.

Recent advances in roll-to-roll nanoimprint lithography and self-assembly techniques show promise for addressing some scalability concerns. These approaches potentially enable continuous production of nanoarchitected materials over larger areas, though they currently sacrifice some degree of structural complexity and precision compared to direct writing methods.

Integration challenges also exist when incorporating these metamaterials into existing products and systems. The interface between nanoarchitected components and conventional materials often creates weak points or performance bottlenecks. Developing effective integration strategies requires interdisciplinary collaboration between materials scientists, mechanical engineers, and manufacturing specialists.

Regulatory considerations further complicate commercialization pathways, particularly for applications involving human exposure or environmental release. The novel properties of these materials may require new testing protocols and safety standards before receiving regulatory approval in sensitive sectors such as healthcare, food packaging, or consumer products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!