Nanoarchitected Mechanical Metamaterials for Non-destructive Testing.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, emerging from the convergence of nanotechnology, mechanical engineering, and materials design. These engineered structures possess unique mechanical properties that transcend those of conventional materials, achieved through precise control of their architecture at the nanoscale. The historical development of this field traces back to theoretical work on metamaterials in the early 2000s, with significant experimental breakthroughs occurring in the past decade due to advances in nanofabrication techniques such as two-photon lithography and self-assembly processes.

The evolution of nanoarchitected metamaterials has been characterized by progressive improvements in design complexity, mechanical performance, and fabrication precision. Early research focused primarily on proof-of-concept demonstrations, while recent developments have expanded toward practical applications, including non-destructive testing (NDT) methodologies. The integration of these materials into NDT represents a particularly promising direction, as their unique mechanical responses to external stimuli can enable unprecedented sensitivity and specificity in defect detection.

Current research trends indicate a shift toward multifunctional nanoarchitected metamaterials that combine mechanical properties with other functionalities such as optical, thermal, or electrical responses. This multifunctionality is especially valuable in NDT applications, where multiple sensing modalities can provide complementary information about material integrity. Additionally, there is growing interest in scalable manufacturing techniques that can bridge the gap between laboratory demonstrations and industrial implementation.

The primary technical objectives for nanoarchitected metamaterials in NDT applications include enhancing detection sensitivity for microscopic defects, improving spatial resolution beyond conventional limits, and enabling real-time monitoring of structural health. These objectives address critical limitations in current NDT methodologies, particularly for advanced materials used in aerospace, automotive, and biomedical industries where undetected defects can lead to catastrophic failures.

Another key objective is the development of metamaterial-based sensors that can operate in harsh environments or confined spaces where traditional NDT equipment cannot function effectively. This includes high-temperature environments, radiation-exposed areas, or within complex geometries that are inaccessible to conventional probes. The ultimate goal is to create intelligent material systems that can not only detect damage but also provide quantitative information about defect type, size, and location.

From a broader perspective, the integration of nanoarchitected metamaterials into NDT systems aims to revolutionize quality control processes across manufacturing sectors, enabling 100% inspection rather than statistical sampling approaches. This transition would significantly reduce failure rates and enhance product reliability while potentially decreasing inspection costs through automation and improved efficiency.

The evolution of nanoarchitected metamaterials has been characterized by progressive improvements in design complexity, mechanical performance, and fabrication precision. Early research focused primarily on proof-of-concept demonstrations, while recent developments have expanded toward practical applications, including non-destructive testing (NDT) methodologies. The integration of these materials into NDT represents a particularly promising direction, as their unique mechanical responses to external stimuli can enable unprecedented sensitivity and specificity in defect detection.

Current research trends indicate a shift toward multifunctional nanoarchitected metamaterials that combine mechanical properties with other functionalities such as optical, thermal, or electrical responses. This multifunctionality is especially valuable in NDT applications, where multiple sensing modalities can provide complementary information about material integrity. Additionally, there is growing interest in scalable manufacturing techniques that can bridge the gap between laboratory demonstrations and industrial implementation.

The primary technical objectives for nanoarchitected metamaterials in NDT applications include enhancing detection sensitivity for microscopic defects, improving spatial resolution beyond conventional limits, and enabling real-time monitoring of structural health. These objectives address critical limitations in current NDT methodologies, particularly for advanced materials used in aerospace, automotive, and biomedical industries where undetected defects can lead to catastrophic failures.

Another key objective is the development of metamaterial-based sensors that can operate in harsh environments or confined spaces where traditional NDT equipment cannot function effectively. This includes high-temperature environments, radiation-exposed areas, or within complex geometries that are inaccessible to conventional probes. The ultimate goal is to create intelligent material systems that can not only detect damage but also provide quantitative information about defect type, size, and location.

From a broader perspective, the integration of nanoarchitected metamaterials into NDT systems aims to revolutionize quality control processes across manufacturing sectors, enabling 100% inspection rather than statistical sampling approaches. This transition would significantly reduce failure rates and enhance product reliability while potentially decreasing inspection costs through automation and improved efficiency.

Market Demand Analysis for NDT Metamaterial Solutions

The non-destructive testing (NDT) market is experiencing significant growth driven by increasing safety regulations across industries and the need for more sophisticated inspection methods. The global NDT market was valued at approximately 21.2 billion USD in 2022 and is projected to reach 30.7 billion USD by 2027, growing at a CAGR of 7.6%. Within this expanding market, nanoarchitected mechanical metamaterials represent an emerging segment with substantial potential to revolutionize traditional testing approaches.

Industrial sectors including aerospace, automotive, oil and gas, and power generation are primary drivers of demand for advanced NDT solutions. These industries face critical challenges in detecting microscopic defects in complex structures while minimizing downtime and maintenance costs. The aerospace industry, in particular, demonstrates urgent need for metamaterial-based NDT solutions due to the increasing use of composite materials that are difficult to inspect using conventional methods.

Market research indicates that approximately 65% of NDT professionals report dissatisfaction with current testing methods' sensitivity and reliability when examining advanced materials and complex geometries. This represents a significant opportunity for nanoarchitected metamaterial solutions that can overcome these limitations through their unique mechanical and wave-manipulation properties.

The healthcare sector is emerging as another promising market for metamaterial-based NDT applications. Medical device manufacturers require increasingly precise inspection methods to ensure product safety and compliance with stringent regulatory standards. The market for medical NDT equipment alone is expected to grow at 9.3% annually through 2028, outpacing the broader NDT market.

Geographically, North America and Europe currently dominate NDT technology adoption, accounting for approximately 60% of the global market. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.8% annually, driven by rapid industrialization and infrastructure development in countries like China and India.

Customer requirements analysis reveals five key demand factors driving interest in metamaterial-based NDT solutions: enhanced detection sensitivity for microscopic defects, ability to inspect complex geometries and heterogeneous materials, reduced inspection time, non-contact testing capabilities, and integration with automated inspection systems.

Economic analysis suggests that while initial implementation costs for metamaterial NDT solutions may be higher than conventional methods, the long-term value proposition is compelling. Organizations implementing advanced NDT technologies report average reductions of 35% in maintenance costs and 42% in unplanned downtime, representing significant operational savings that justify investment in next-generation inspection technologies.

Industrial sectors including aerospace, automotive, oil and gas, and power generation are primary drivers of demand for advanced NDT solutions. These industries face critical challenges in detecting microscopic defects in complex structures while minimizing downtime and maintenance costs. The aerospace industry, in particular, demonstrates urgent need for metamaterial-based NDT solutions due to the increasing use of composite materials that are difficult to inspect using conventional methods.

Market research indicates that approximately 65% of NDT professionals report dissatisfaction with current testing methods' sensitivity and reliability when examining advanced materials and complex geometries. This represents a significant opportunity for nanoarchitected metamaterial solutions that can overcome these limitations through their unique mechanical and wave-manipulation properties.

The healthcare sector is emerging as another promising market for metamaterial-based NDT applications. Medical device manufacturers require increasingly precise inspection methods to ensure product safety and compliance with stringent regulatory standards. The market for medical NDT equipment alone is expected to grow at 9.3% annually through 2028, outpacing the broader NDT market.

Geographically, North America and Europe currently dominate NDT technology adoption, accounting for approximately 60% of the global market. However, the Asia-Pacific region is witnessing the fastest growth rate at 9.8% annually, driven by rapid industrialization and infrastructure development in countries like China and India.

Customer requirements analysis reveals five key demand factors driving interest in metamaterial-based NDT solutions: enhanced detection sensitivity for microscopic defects, ability to inspect complex geometries and heterogeneous materials, reduced inspection time, non-contact testing capabilities, and integration with automated inspection systems.

Economic analysis suggests that while initial implementation costs for metamaterial NDT solutions may be higher than conventional methods, the long-term value proposition is compelling. Organizations implementing advanced NDT technologies report average reductions of 35% in maintenance costs and 42% in unplanned downtime, representing significant operational savings that justify investment in next-generation inspection technologies.

Current State and Challenges in Nanoarchitected Metamaterials

The field of nanoarchitected mechanical metamaterials has witnessed significant advancements globally, with research institutions across North America, Europe, and Asia making substantial contributions. Current state-of-the-art fabrication techniques include two-photon lithography, direct laser writing, and self-assembly methods, which have enabled the creation of complex 3D architectures at the nanoscale. These techniques allow for precise control over structural features, though they remain limited in terms of scalability for industrial applications.

A major challenge in this domain is the trade-off between resolution and manufacturing volume. While laboratory-scale production can achieve remarkable precision down to features of approximately 100 nm, scaling these processes for commercial non-destructive testing (NDT) applications presents significant hurdles. The time-intensive nature of high-precision fabrication techniques creates bottlenecks in production capacity, limiting widespread adoption.

Material constraints represent another critical challenge. Current metamaterials often utilize polymers, metals, or ceramics, each with inherent limitations. Polymeric structures offer design flexibility but lack mechanical robustness for repeated NDT applications. Metallic nanoarchitectures provide superior mechanical properties but present challenges in achieving the fine features necessary for specific acoustic or electromagnetic responses required in advanced NDT scenarios.

The integration of multifunctionality remains an ongoing technical hurdle. Effective NDT metamaterials must simultaneously exhibit specific mechanical, acoustic, and sometimes electromagnetic properties. Achieving this multifunctionality while maintaining structural integrity and performance consistency has proven difficult, particularly when designing materials that can operate across multiple frequency ranges or testing conditions.

Characterization techniques for these materials constitute another significant challenge. Traditional testing methods often prove inadequate for fully understanding the behavior of nanoarchitected metamaterials, particularly under dynamic loading conditions relevant to NDT applications. Advanced in-situ characterization tools are still evolving to meet these specialized needs.

Computational modeling capabilities, while advanced, still struggle with accurately predicting the behavior of complex hierarchical structures across multiple length scales. The gap between theoretical models and experimental results creates uncertainty in design optimization, particularly when considering the interaction between nanoarchitectured materials and various testing modalities such as ultrasound, X-ray, or electromagnetic waves.

Geographical distribution of expertise shows concentration in specific research hubs. Leading institutions in the United States (MIT, Caltech), Germany (Max Planck Institutes), and China (Chinese Academy of Sciences) have established centers of excellence, though collaborative international efforts are increasingly common as the field matures and applications in NDT become more commercially relevant.

A major challenge in this domain is the trade-off between resolution and manufacturing volume. While laboratory-scale production can achieve remarkable precision down to features of approximately 100 nm, scaling these processes for commercial non-destructive testing (NDT) applications presents significant hurdles. The time-intensive nature of high-precision fabrication techniques creates bottlenecks in production capacity, limiting widespread adoption.

Material constraints represent another critical challenge. Current metamaterials often utilize polymers, metals, or ceramics, each with inherent limitations. Polymeric structures offer design flexibility but lack mechanical robustness for repeated NDT applications. Metallic nanoarchitectures provide superior mechanical properties but present challenges in achieving the fine features necessary for specific acoustic or electromagnetic responses required in advanced NDT scenarios.

The integration of multifunctionality remains an ongoing technical hurdle. Effective NDT metamaterials must simultaneously exhibit specific mechanical, acoustic, and sometimes electromagnetic properties. Achieving this multifunctionality while maintaining structural integrity and performance consistency has proven difficult, particularly when designing materials that can operate across multiple frequency ranges or testing conditions.

Characterization techniques for these materials constitute another significant challenge. Traditional testing methods often prove inadequate for fully understanding the behavior of nanoarchitected metamaterials, particularly under dynamic loading conditions relevant to NDT applications. Advanced in-situ characterization tools are still evolving to meet these specialized needs.

Computational modeling capabilities, while advanced, still struggle with accurately predicting the behavior of complex hierarchical structures across multiple length scales. The gap between theoretical models and experimental results creates uncertainty in design optimization, particularly when considering the interaction between nanoarchitectured materials and various testing modalities such as ultrasound, X-ray, or electromagnetic waves.

Geographical distribution of expertise shows concentration in specific research hubs. Leading institutions in the United States (MIT, Caltech), Germany (Max Planck Institutes), and China (Chinese Academy of Sciences) have established centers of excellence, though collaborative international efforts are increasingly common as the field matures and applications in NDT become more commercially relevant.

Current Technical Solutions for NDT Using Metamaterials

01 Nanoarchitected metamaterials with unique mechanical properties

Nanoarchitected mechanical metamaterials are engineered structures with precisely designed geometries at the nanoscale that exhibit extraordinary mechanical properties not found in conventional materials. These materials can demonstrate exceptional strength-to-weight ratios, unusual elasticity, and controlled deformation behaviors. The nanoscale architecture enables properties such as ultra-lightweight structures with high mechanical strength, programmable stiffness, and enhanced energy absorption capabilities.- Nanoarchitected metamaterials with unique mechanical properties: Nanoarchitected mechanical metamaterials are engineered structures with precisely designed geometries at the nanoscale that exhibit extraordinary mechanical properties not found in conventional materials. These materials can demonstrate exceptional strength-to-weight ratios, unusual elasticity, and controlled deformation behaviors. The nanoscale architecture allows for tailoring of properties such as stiffness, energy absorption, and resilience beyond what is possible with traditional materials.

- Fabrication techniques for nanoarchitected metamaterials: Various advanced manufacturing techniques are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These include additive manufacturing methods, lithography-based techniques, self-assembly processes, and hybrid approaches. These fabrication methods enable the creation of complex three-dimensional architectures with feature sizes ranging from nanometers to micrometers, allowing for unprecedented control over material properties through structural design rather than chemical composition.

- Applications in energy absorption and impact resistance: Nanoarchitected mechanical metamaterials offer superior performance in energy absorption and impact resistance applications. Their carefully designed structures can efficiently dissipate kinetic energy through controlled deformation mechanisms, making them ideal for protective equipment, packaging, and structural components in transportation. These materials can be engineered to exhibit programmable crushing behaviors, recoverable deformation, and hierarchical energy dissipation pathways that outperform conventional materials in protecting against impacts and vibrations.

- Integration with electronic and photonic systems: Nanoarchitected mechanical metamaterials can be integrated with electronic and photonic systems to create multifunctional devices. These hybrid systems combine the unique mechanical properties of metamaterials with electronic or optical functionalities, enabling applications such as flexible electronics, sensors, actuators, and energy harvesting devices. The mechanical metamaterial structure can provide protection for delicate electronic components while also enabling novel functionalities through the interaction between mechanical deformation and electronic or optical properties.

- Responsive and adaptive nanoarchitected metamaterials: Advanced nanoarchitected mechanical metamaterials can be designed to respond and adapt to external stimuli such as temperature, light, electric fields, or mechanical forces. These responsive materials can change their properties or configurations in a controlled manner, enabling applications in soft robotics, adaptive structures, and smart materials. By incorporating responsive elements into the nanoarchitecture, these materials can perform complex functions such as self-healing, shape-morphing, or property-switching in response to environmental conditions.

02 Fabrication techniques for nanoarchitected metamaterials

Various advanced manufacturing techniques are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These include additive manufacturing methods like two-photon lithography, nanoimprint lithography, and 3D printing at the nanoscale. Other approaches involve self-assembly processes, template-assisted fabrication, and hybrid manufacturing techniques that combine multiple methods to achieve complex hierarchical structures with tailored mechanical responses.Expand Specific Solutions03 Applications in energy absorption and impact resistance

Nanoarchitected mechanical metamaterials offer superior energy absorption capabilities and impact resistance due to their engineered deformation mechanisms. These materials can be designed to absorb mechanical energy through controlled buckling, bending, or twisting of structural elements at the nanoscale. Such properties make them valuable for applications in protective equipment, packaging materials, vibration damping, and impact-resistant structures where lightweight solutions with high energy dissipation are required.Expand Specific Solutions04 Electronic and photonic applications of mechanical metamaterials

Beyond purely mechanical applications, nanoarchitected metamaterials can be designed to exhibit unique electronic and photonic properties. These materials can feature tunable electromagnetic responses, phononic bandgaps, and programmable electrical conductivity. The integration of mechanical and electronic/photonic functionalities enables applications in sensors, actuators, waveguides, and devices with mechanically tunable electronic properties, creating multifunctional materials for next-generation technologies.Expand Specific Solutions05 Biomimetic and responsive nanoarchitected metamaterials

Inspired by biological structures, researchers are developing biomimetic nanoarchitected metamaterials that mimic natural systems' mechanical efficiency and adaptability. These materials can exhibit responsive behaviors, changing their mechanical properties in response to external stimuli such as temperature, pH, or applied forces. Such responsive metamaterials enable applications in soft robotics, artificial muscles, drug delivery systems, and adaptive structural components that can self-regulate their mechanical performance based on environmental conditions.Expand Specific Solutions

Key Industry Players in Nanoarchitected Metamaterials

The field of nanoarchitected mechanical metamaterials for non-destructive testing is currently in its early growth phase, characterized by rapid technological advancement but limited commercial deployment. The global market is estimated at approximately $300-500 million, with projected annual growth of 15-20% as industries recognize the potential for enhanced structural integrity assessment. The technology maturity varies significantly across key players: academic institutions (CNRS, Rice University, California Institute of Technology) lead fundamental research; government laboratories (Naval Research Laboratory, KIST) focus on specialized applications; while industrial entities (Airbus, Boeing, Siemens) are transitioning from R&D to implementation. Companies like Nanoprobes and Hybrid Plastics are developing specialized nanomaterial solutions, positioning themselves at the forefront of commercialization efforts in this emerging field.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has developed advanced nanoarchitected mechanical metamaterials specifically designed for non-destructive testing in maritime and defense applications. Their approach utilizes hierarchical metamaterials with tailored mechanical and acoustic properties that can detect structural defects in naval vessels and underwater structures. NRL's technology incorporates auxetic metamaterials (materials with negative Poisson's ratio) that exhibit enhanced sensitivity to stress concentrations around defects. These materials are engineered with precise nanoscale features that create unique wave propagation characteristics, allowing for detection of defects that would be invisible to conventional NDT methods. The laboratory has demonstrated metamaterial-based sensors that can operate effectively in underwater environments, detecting corrosion and fatigue cracks in ship hulls and submarine components without requiring dry-docking. Their metamaterials are designed to withstand harsh marine environments, including high pressure, saltwater exposure, and biofouling, while maintaining their sensing capabilities over extended deployment periods.

Strengths: Exceptional performance in underwater and marine environments; ability to detect defects through complex geometries and multiple material layers; resilience to harsh operational conditions. Weaknesses: Higher manufacturing complexity compared to conventional sensors; requires specialized signal processing algorithms to interpret the data effectively.

The Regents of the University of California

Technical Solution: The University of California system has developed groundbreaking nanoarchitected mechanical metamaterials for non-destructive testing through collaborative research across multiple campuses. Their approach centers on biomimetic metamaterials inspired by natural structures like bone and mollusk shells, which combine exceptional mechanical properties with self-sensing capabilities. UC researchers have created hierarchical metamaterials with tailored mechanical impedance that can guide and focus elastic waves with unprecedented precision, enabling detection of microscopic defects in complex structures. Their technology incorporates stimuli-responsive materials that can change their mechanical properties in response to external triggers, allowing for adaptive testing protocols that can focus on different types of defects. The UC system has demonstrated metamaterial-based sensors that can detect damage in composite materials used in aerospace and automotive applications, with sensitivity far exceeding conventional ultrasonic testing methods. Their research has also explored self-healing metamaterials that can not only detect damage but also initiate repair processes, potentially extending the service life of critical components in various applications.

Strengths: Highly adaptable systems that can be optimized for different materials and defect types; multifunctional capabilities combining sensing with other properties like self-healing; strong theoretical foundation based on extensive modeling. Weaknesses: Still primarily in research phase with limited large-scale implementation; complex fabrication processes that may limit commercial scalability.

Core Patents and Research in Nanoarchitected NDT Materials

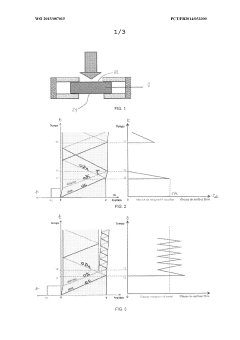

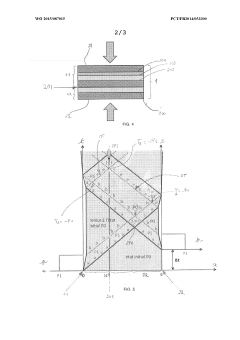

Method of non-destructive testing comprising the generation of a state of localised and controlled traction in a multi-material and/or multi-layer assembly

PatentInactiveEP3079854A2

Innovation

- A non-destructive testing method using simultaneous or successive shock waves generated on opposite faces of a multi-material and/or multi-layer assembly, allowing for a localized and controlled tensile state to be created at specific interfaces, utilizing shock waves to evaluate the mechanical strength of interfaces without damaging the assembly, by calculating the time lag between shock waves based on material properties and wave propagation speeds.

Method of non-destructive testing comprising the generation of a state of localised and controlled traction in a multi-material and/or multi-layer assembly

PatentWO2015087015A2

Innovation

- A non-destructive testing method using simultaneous or successive shock waves generated on opposite faces of multi-material and/or multi-layer assemblies to create a localized and controlled tensile state, allowing for precise evaluation of interface resistance by adjusting shock parameters and calculating time lags for optimal traction localization.

Standardization and Certification Requirements for NDT Applications

The integration of nanoarchitected mechanical metamaterials into non-destructive testing (NDT) applications necessitates robust standardization and certification frameworks to ensure reliability, repeatability, and industry-wide acceptance. Currently, there exists a significant gap in standardization specific to these advanced materials in NDT contexts, creating barriers to their widespread industrial adoption.

International standards organizations including ISO, ASTM International, and the American Society for Nondestructive Testing (ASNT) have begun preliminary discussions on developing certification protocols for metamaterial-based NDT technologies. These efforts aim to establish uniform testing methodologies, performance metrics, and quality assurance parameters that can validate the effectiveness of nanoarchitected metamaterials across different inspection scenarios.

Key standardization requirements emerging in this field include calibration protocols for metamaterial-based sensors, signal interpretation guidelines, and performance benchmarks against conventional NDT methods. The unique properties of mechanical metamaterials—particularly their programmable mechanical responses and frequency-dependent behaviors—require specialized calibration standards that differ significantly from those used with traditional NDT equipment.

Certification pathways for NDT personnel utilizing metamaterial technologies represent another critical requirement. Training programs and competency assessments must be developed to ensure technicians can properly deploy, calibrate, and interpret results from these advanced material systems. This includes understanding the fundamental physics of metamaterial behavior and recognizing potential interference patterns or signal anomalies specific to these materials.

Regulatory bodies in aerospace, nuclear, and medical industries have expressed particular interest in establishing certification requirements for metamaterial NDT applications in safety-critical components. These sectors demand extremely high reliability standards and extensive validation testing before new inspection technologies can be approved for routine use.

Traceability and measurement uncertainty quantification present unique challenges for nanoarchitected metamaterials due to their complex geometries and scale-dependent properties. Standards development organizations are working to establish reference materials and measurement protocols that can provide consistent benchmarks across different manufacturing processes and material compositions.

International harmonization of these standards remains a significant challenge, with different regional approaches to certification creating potential barriers to global technology deployment. Collaborative efforts between standards bodies, research institutions, and industry stakeholders will be essential to develop consensus-based standards that facilitate rather than impede innovation in this rapidly evolving field.

International standards organizations including ISO, ASTM International, and the American Society for Nondestructive Testing (ASNT) have begun preliminary discussions on developing certification protocols for metamaterial-based NDT technologies. These efforts aim to establish uniform testing methodologies, performance metrics, and quality assurance parameters that can validate the effectiveness of nanoarchitected metamaterials across different inspection scenarios.

Key standardization requirements emerging in this field include calibration protocols for metamaterial-based sensors, signal interpretation guidelines, and performance benchmarks against conventional NDT methods. The unique properties of mechanical metamaterials—particularly their programmable mechanical responses and frequency-dependent behaviors—require specialized calibration standards that differ significantly from those used with traditional NDT equipment.

Certification pathways for NDT personnel utilizing metamaterial technologies represent another critical requirement. Training programs and competency assessments must be developed to ensure technicians can properly deploy, calibrate, and interpret results from these advanced material systems. This includes understanding the fundamental physics of metamaterial behavior and recognizing potential interference patterns or signal anomalies specific to these materials.

Regulatory bodies in aerospace, nuclear, and medical industries have expressed particular interest in establishing certification requirements for metamaterial NDT applications in safety-critical components. These sectors demand extremely high reliability standards and extensive validation testing before new inspection technologies can be approved for routine use.

Traceability and measurement uncertainty quantification present unique challenges for nanoarchitected metamaterials due to their complex geometries and scale-dependent properties. Standards development organizations are working to establish reference materials and measurement protocols that can provide consistent benchmarks across different manufacturing processes and material compositions.

International harmonization of these standards remains a significant challenge, with different regional approaches to certification creating potential barriers to global technology deployment. Collaborative efforts between standards bodies, research institutions, and industry stakeholders will be essential to develop consensus-based standards that facilitate rather than impede innovation in this rapidly evolving field.

Industrial Implementation Challenges and Strategies

The implementation of nanoarchitected mechanical metamaterials for non-destructive testing faces significant industrial challenges despite their promising theoretical advantages. Manufacturing scalability remains a primary obstacle, as current fabrication techniques like two-photon lithography and nanoimprint lithography are predominantly laboratory-scale processes with limited throughput. The transition to mass production requires substantial investment in specialized equipment and process optimization to maintain the precise nano-scale features critical for metamaterial performance.

Cost considerations present another major barrier to widespread adoption. The high-precision manufacturing processes and specialized materials required for these metamaterials currently result in prohibitive production costs for many potential industrial applications. This economic challenge is compounded by the need for specialized handling and integration protocols that add further expense to implementation.

Quality control and standardization issues also impede industrial implementation. The performance of nanoarchitected metamaterials depends critically on structural precision at the nanoscale, necessitating advanced metrology systems capable of verifying structural integrity without compromising the materials themselves. The lack of established industry standards for these novel materials further complicates quality assurance processes.

Integration with existing non-destructive testing (NDT) workflows presents additional challenges. Current NDT equipment and methodologies are not designed to accommodate or fully leverage the unique properties of nanoarchitected metamaterials. Significant redesign of testing protocols and equipment interfaces is necessary to realize the full potential of these advanced materials in practical testing scenarios.

Effective implementation strategies must address these challenges through multi-faceted approaches. Industry-academic partnerships can accelerate the development of cost-effective manufacturing techniques and establish preliminary standards. Phased implementation beginning with high-value applications where performance advantages justify premium costs can create initial market entry points while economies of scale develop.

Modular design approaches that allow metamaterial components to interface with existing NDT equipment can reduce integration barriers. Additionally, development of specialized training programs for NDT technicians and engineers will be essential to build the workforce capabilities needed to effectively deploy these advanced materials in industrial settings.

Cost considerations present another major barrier to widespread adoption. The high-precision manufacturing processes and specialized materials required for these metamaterials currently result in prohibitive production costs for many potential industrial applications. This economic challenge is compounded by the need for specialized handling and integration protocols that add further expense to implementation.

Quality control and standardization issues also impede industrial implementation. The performance of nanoarchitected metamaterials depends critically on structural precision at the nanoscale, necessitating advanced metrology systems capable of verifying structural integrity without compromising the materials themselves. The lack of established industry standards for these novel materials further complicates quality assurance processes.

Integration with existing non-destructive testing (NDT) workflows presents additional challenges. Current NDT equipment and methodologies are not designed to accommodate or fully leverage the unique properties of nanoarchitected metamaterials. Significant redesign of testing protocols and equipment interfaces is necessary to realize the full potential of these advanced materials in practical testing scenarios.

Effective implementation strategies must address these challenges through multi-faceted approaches. Industry-academic partnerships can accelerate the development of cost-effective manufacturing techniques and establish preliminary standards. Phased implementation beginning with high-value applications where performance advantages justify premium costs can create initial market entry points while economies of scale develop.

Modular design approaches that allow metamaterial components to interface with existing NDT equipment can reduce integration barriers. Additionally, development of specialized training programs for NDT technicians and engineers will be essential to build the workforce capabilities needed to effectively deploy these advanced materials in industrial settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!