Application of Nanoarchitected Mechanical Metamaterials in Thermal Barriers.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary class of engineered materials that derive their exceptional properties from their precisely designed geometric structures rather than their chemical composition. The evolution of these materials can be traced back to the early 2000s when advances in nanofabrication techniques first enabled the creation of materials with controlled architectures at the nanoscale. Since then, the field has experienced exponential growth, driven by breakthroughs in additive manufacturing, lithography techniques, and computational design methods.

The technological trajectory of nanoarchitected metamaterials has been characterized by progressive miniaturization and increasing complexity of structural designs. Early metamaterials were limited to simple periodic structures, while contemporary designs incorporate hierarchical architectures spanning multiple length scales, from nanometers to centimeters, enabling unprecedented control over material properties.

In the context of thermal barriers, nanoarchitected metamaterials offer transformative potential by manipulating heat transfer mechanisms at the nanoscale. Traditional thermal barrier materials rely primarily on low thermal conductivity bulk properties, whereas nanoarchitected solutions can engineer phonon transport pathways, create thermal rectification effects, and establish thermal bandgaps that selectively block specific heat frequencies.

The primary objective of research in this domain is to develop nanoarchitected mechanical metamaterials that can withstand extreme thermal gradients while maintaining structural integrity and mechanical performance. This includes creating materials with programmable thermal expansion coefficients, directional heat flow control, and adaptive thermal response capabilities that can dynamically adjust to changing environmental conditions.

Additional technical goals include enhancing the scalability of fabrication processes to enable industrial-scale production, improving the durability of these materials under cyclic thermal loading, and developing multifunctional thermal barriers that simultaneously address mechanical, acoustic, and electromagnetic requirements alongside thermal management.

Recent advances in computational modeling have accelerated progress by enabling the prediction of thermal-mechanical coupling effects in complex nanoarchitectures before physical prototyping. Machine learning algorithms are increasingly being employed to explore vast design spaces and identify optimal geometries for specific thermal barrier applications.

The convergence of nanotechnology, materials science, and thermal engineering has positioned nanoarchitected mechanical metamaterials as a critical technology for next-generation thermal management solutions in aerospace, electronics, energy systems, and advanced manufacturing sectors where conventional materials approach their fundamental performance limits.

The technological trajectory of nanoarchitected metamaterials has been characterized by progressive miniaturization and increasing complexity of structural designs. Early metamaterials were limited to simple periodic structures, while contemporary designs incorporate hierarchical architectures spanning multiple length scales, from nanometers to centimeters, enabling unprecedented control over material properties.

In the context of thermal barriers, nanoarchitected metamaterials offer transformative potential by manipulating heat transfer mechanisms at the nanoscale. Traditional thermal barrier materials rely primarily on low thermal conductivity bulk properties, whereas nanoarchitected solutions can engineer phonon transport pathways, create thermal rectification effects, and establish thermal bandgaps that selectively block specific heat frequencies.

The primary objective of research in this domain is to develop nanoarchitected mechanical metamaterials that can withstand extreme thermal gradients while maintaining structural integrity and mechanical performance. This includes creating materials with programmable thermal expansion coefficients, directional heat flow control, and adaptive thermal response capabilities that can dynamically adjust to changing environmental conditions.

Additional technical goals include enhancing the scalability of fabrication processes to enable industrial-scale production, improving the durability of these materials under cyclic thermal loading, and developing multifunctional thermal barriers that simultaneously address mechanical, acoustic, and electromagnetic requirements alongside thermal management.

Recent advances in computational modeling have accelerated progress by enabling the prediction of thermal-mechanical coupling effects in complex nanoarchitectures before physical prototyping. Machine learning algorithms are increasingly being employed to explore vast design spaces and identify optimal geometries for specific thermal barrier applications.

The convergence of nanotechnology, materials science, and thermal engineering has positioned nanoarchitected mechanical metamaterials as a critical technology for next-generation thermal management solutions in aerospace, electronics, energy systems, and advanced manufacturing sectors where conventional materials approach their fundamental performance limits.

Thermal Barrier Market Demand Analysis

The thermal barrier market is experiencing significant growth driven by increasing demands across multiple industries. The global thermal barrier coatings market was valued at approximately $16.6 billion in 2020 and is projected to reach $24.8 billion by 2026, growing at a CAGR of around 6.9%. This growth is primarily fueled by the aerospace and automotive sectors, where high-temperature applications require advanced thermal protection solutions.

In aerospace, the push for more fuel-efficient engines operating at higher temperatures has created substantial demand for innovative thermal barrier technologies. Modern jet engines operate at temperatures exceeding 1600°C, necessitating materials that can withstand extreme thermal conditions while maintaining structural integrity. The aerospace industry accounts for nearly 40% of the thermal barrier market, with defense applications contributing an additional 15%.

The automotive sector represents another significant market segment, particularly with the growing emphasis on reducing emissions and improving engine efficiency. Thermal barriers in exhaust systems, cylinder heads, and pistons help manage heat distribution, leading to better fuel economy and reduced emissions. This sector is expected to grow at 7.5% annually through 2028.

Energy generation, particularly in gas turbines and power plants, constitutes approximately 20% of the market. As renewable energy sources gain prominence, there is increasing demand for thermal management solutions in concentrated solar power systems and geothermal applications, creating new market opportunities for advanced thermal barriers.

Consumer electronics represents an emerging application area with substantial growth potential. As devices become more powerful and compact, thermal management becomes increasingly critical. The miniaturization trend in electronics has created demand for microscale and nanoscale thermal barrier solutions that can be integrated into small form factors.

Market analysis indicates a significant shift toward nanoarchitected materials due to their superior performance characteristics. Traditional thermal barriers face limitations in terms of weight, durability, and thermal efficiency. Nanoarchitected mechanical metamaterials offer the potential to overcome these limitations by providing unprecedented combinations of low thermal conductivity, mechanical strength, and reduced weight.

Regional analysis shows North America and Europe leading the market with approximately 30% and 28% market share respectively, while Asia-Pacific represents the fastest-growing region with an annual growth rate of 8.2%, driven by rapid industrialization in China and India. The increasing focus on energy efficiency and stringent environmental regulations worldwide are expected to further accelerate market growth for advanced thermal barrier solutions.

In aerospace, the push for more fuel-efficient engines operating at higher temperatures has created substantial demand for innovative thermal barrier technologies. Modern jet engines operate at temperatures exceeding 1600°C, necessitating materials that can withstand extreme thermal conditions while maintaining structural integrity. The aerospace industry accounts for nearly 40% of the thermal barrier market, with defense applications contributing an additional 15%.

The automotive sector represents another significant market segment, particularly with the growing emphasis on reducing emissions and improving engine efficiency. Thermal barriers in exhaust systems, cylinder heads, and pistons help manage heat distribution, leading to better fuel economy and reduced emissions. This sector is expected to grow at 7.5% annually through 2028.

Energy generation, particularly in gas turbines and power plants, constitutes approximately 20% of the market. As renewable energy sources gain prominence, there is increasing demand for thermal management solutions in concentrated solar power systems and geothermal applications, creating new market opportunities for advanced thermal barriers.

Consumer electronics represents an emerging application area with substantial growth potential. As devices become more powerful and compact, thermal management becomes increasingly critical. The miniaturization trend in electronics has created demand for microscale and nanoscale thermal barrier solutions that can be integrated into small form factors.

Market analysis indicates a significant shift toward nanoarchitected materials due to their superior performance characteristics. Traditional thermal barriers face limitations in terms of weight, durability, and thermal efficiency. Nanoarchitected mechanical metamaterials offer the potential to overcome these limitations by providing unprecedented combinations of low thermal conductivity, mechanical strength, and reduced weight.

Regional analysis shows North America and Europe leading the market with approximately 30% and 28% market share respectively, while Asia-Pacific represents the fastest-growing region with an annual growth rate of 8.2%, driven by rapid industrialization in China and India. The increasing focus on energy efficiency and stringent environmental regulations worldwide are expected to further accelerate market growth for advanced thermal barrier solutions.

Current State and Challenges in Nanoarchitected Thermal Barriers

The field of nanoarchitected mechanical metamaterials for thermal barrier applications has witnessed significant advancements globally, yet continues to face substantial technical challenges. Current research indicates that these materials have reached Technology Readiness Level (TRL) 4-5, with laboratory demonstrations showing promising results but limited commercial deployment. The primary advantage of these materials—their ability to combine ultralow thermal conductivity with mechanical robustness—represents a paradigm shift from conventional thermal barriers that typically sacrifice mechanical integrity for thermal performance.

In the United States, research institutions like MIT, Caltech, and Lawrence Livermore National Laboratory lead development efforts, while in Europe, ETH Zurich and Imperial College London have established strong research programs. Asian contributions come primarily from research groups in China, Japan, and Singapore, creating a globally distributed but somewhat fragmented research landscape.

The fabrication of nanoarchitected thermal barriers presents a significant challenge, with current methods including two-photon lithography, direct ink writing, and self-assembly techniques. While these approaches enable precise control over architecture, they suffer from limited scalability and high production costs. Two-photon lithography, though offering nanometer precision, remains prohibitively expensive and slow for industrial applications. Direct ink writing offers better scalability but sacrifices some precision in structural control.

Material selection represents another critical challenge. Current nanoarchitected thermal barriers primarily utilize ceramics, polymers, and ceramic-polymer composites. Each material class presents trade-offs between thermal performance, mechanical robustness, and high-temperature stability. Ceramic-based metamaterials offer excellent thermal resistance but suffer from inherent brittleness, while polymer-based structures provide design flexibility but limited temperature range.

Performance consistency across operating conditions remains problematic. Many nanoarchitected thermal barriers demonstrate excellent performance under laboratory conditions but experience significant degradation when subjected to thermal cycling, mechanical vibration, or environmental factors like humidity and oxidation. This performance gap between controlled laboratory settings and real-world applications represents a major hurdle for commercial adoption.

Computational modeling and simulation tools, while advancing rapidly, still struggle to accurately predict the complex thermal-mechanical coupling behaviors in these multiscale structures. The disconnect between simulation predictions and experimental results creates uncertainty in design optimization processes and slows development cycles.

Standardization and testing methodologies specific to nanoarchitected thermal barriers remain underdeveloped. The lack of industry-wide standards for characterizing these materials' performance creates barriers to comparative analysis and technology transfer from research to industry. This standardization gap impedes commercial adoption despite promising laboratory results.

In the United States, research institutions like MIT, Caltech, and Lawrence Livermore National Laboratory lead development efforts, while in Europe, ETH Zurich and Imperial College London have established strong research programs. Asian contributions come primarily from research groups in China, Japan, and Singapore, creating a globally distributed but somewhat fragmented research landscape.

The fabrication of nanoarchitected thermal barriers presents a significant challenge, with current methods including two-photon lithography, direct ink writing, and self-assembly techniques. While these approaches enable precise control over architecture, they suffer from limited scalability and high production costs. Two-photon lithography, though offering nanometer precision, remains prohibitively expensive and slow for industrial applications. Direct ink writing offers better scalability but sacrifices some precision in structural control.

Material selection represents another critical challenge. Current nanoarchitected thermal barriers primarily utilize ceramics, polymers, and ceramic-polymer composites. Each material class presents trade-offs between thermal performance, mechanical robustness, and high-temperature stability. Ceramic-based metamaterials offer excellent thermal resistance but suffer from inherent brittleness, while polymer-based structures provide design flexibility but limited temperature range.

Performance consistency across operating conditions remains problematic. Many nanoarchitected thermal barriers demonstrate excellent performance under laboratory conditions but experience significant degradation when subjected to thermal cycling, mechanical vibration, or environmental factors like humidity and oxidation. This performance gap between controlled laboratory settings and real-world applications represents a major hurdle for commercial adoption.

Computational modeling and simulation tools, while advancing rapidly, still struggle to accurately predict the complex thermal-mechanical coupling behaviors in these multiscale structures. The disconnect between simulation predictions and experimental results creates uncertainty in design optimization processes and slows development cycles.

Standardization and testing methodologies specific to nanoarchitected thermal barriers remain underdeveloped. The lack of industry-wide standards for characterizing these materials' performance creates barriers to comparative analysis and technology transfer from research to industry. This standardization gap impedes commercial adoption despite promising laboratory results.

Current Technical Solutions for Metamaterial Thermal Barriers

01 Nanostructured thermal barrier coatings

Thermal barrier coatings with nanostructured architectures provide enhanced thermal insulation properties. These coatings typically consist of ceramic materials with engineered nanoscale features that reduce thermal conductivity while maintaining mechanical stability. The nanostructured design creates numerous interfaces that scatter phonons and impede heat transfer, making these materials effective for high-temperature applications such as gas turbines and aerospace components.- Nanostructured thermal barrier coatings: Thermal barrier coatings with nanoarchitected structures provide enhanced thermal insulation properties. These coatings typically consist of ceramic materials with engineered nanoscale features that reduce thermal conductivity while maintaining mechanical stability. The nanostructured design creates numerous interfaces that scatter phonons, effectively blocking heat transfer while providing resistance to thermal cycling and mechanical stresses.

- Metamaterial structures for thermal management: Mechanical metamaterials with engineered geometries can manipulate heat flow pathways. These structures utilize periodic arrangements of materials with contrasting thermal properties to create thermal bandgaps, similar to photonic crystals for light. The precise architecture controls thermal energy propagation, enabling directional heat flow, thermal cloaking, or insulation properties that exceed conventional materials while maintaining lightweight characteristics.

- Hierarchical cellular metamaterials: Hierarchical cellular structures with multiple scale levels provide exceptional thermal insulation combined with mechanical strength. These materials feature engineered porosity at nano, micro, and macro scales, creating trapped air pockets that minimize conductive heat transfer. The multi-level architecture allows for optimization of both thermal and mechanical properties, making them suitable for applications requiring both thermal barriers and load-bearing capabilities.

- Phase-change metamaterials for adaptive thermal control: Advanced thermal barrier systems incorporating phase-change materials within nanoarchitected frameworks provide adaptive thermal management. These systems can absorb or release thermal energy in response to temperature fluctuations, effectively regulating heat flow. The metamaterial structure enhances the performance of the phase-change component while providing mechanical stability and protection against degradation during thermal cycling.

- Ceramic-based nanoarchitected thermal barriers: Ceramic-based nanoarchitected materials offer superior high-temperature thermal barrier properties. These materials combine the inherent thermal resistance of ceramics with engineered nanostructures to further reduce thermal conductivity. The precise control of porosity, grain boundaries, and interfaces at the nanoscale enhances phonon scattering while maintaining oxidation resistance and structural integrity at elevated temperatures, making them ideal for extreme thermal environments.

02 Metamaterial structures for thermal management

Mechanical metamaterials with engineered geometries can control thermal energy flow. These structures utilize periodic arrangements of unit cells with specific architectures to create unusual thermal properties not found in conventional materials. By manipulating the material geometry at micro and nanoscales, these metamaterials can direct, focus, or block heat transfer pathways, enabling advanced thermal management solutions for electronics, energy systems, and building applications.Expand Specific Solutions03 Nanoporous materials for thermal insulation

Nanoporous materials with controlled void structures offer exceptional thermal barrier properties. These materials contain engineered nanoscale pores that trap air or gas, significantly reducing thermal conductivity through the material. The nanoporous architecture limits convective heat transfer while the small pore size minimizes radiative heat transfer, resulting in highly efficient thermal insulation. Applications include aerospace thermal protection systems, building insulation, and energy storage.Expand Specific Solutions04 Nanocomposite thermal barrier materials

Nanocomposites combining different materials at the nanoscale create advanced thermal barriers with multifunctional properties. These materials typically incorporate nanoparticles, nanofibers, or nanolayers within a matrix to enhance thermal resistance while maintaining or improving mechanical properties. The interfaces between nanoscale components scatter phonons and impede heat flow, while the composite nature allows for customization of properties such as strength, weight, and durability for specific applications.Expand Specific Solutions05 Hierarchical metamaterial structures for thermal protection

Hierarchical metamaterials with multi-scale architectural features provide superior thermal protection. These materials incorporate structural elements across multiple length scales, from nano to macro, creating a hierarchical system that can effectively manage thermal energy. The multi-scale architecture enables simultaneous optimization of mechanical strength, thermal resistance, and weight, making these materials particularly valuable for extreme thermal environments such as spacecraft reentry shields and high-temperature industrial applications.Expand Specific Solutions

Key Industry Players in Nanoarchitected Materials

The nanoarchitected mechanical metamaterials for thermal barriers market is currently in an early growth phase, characterized by intensive R&D activities and emerging commercial applications. The global market size is estimated at approximately $350-450 million, with projected annual growth of 15-20% through 2030. From a technological maturity perspective, the field shows varying development levels across key players. Research institutions like CNRS, McGill University, and Rice University are pioneering fundamental innovations, while industrial leaders including Honeywell International, Toyota, Siemens, and Saint-Gobain are advancing application-specific solutions. Government laboratories such as Lawrence Livermore National Security and Japan Science & Technology Agency are bridging fundamental research with practical applications. The competitive landscape features strong collaboration between academic institutions and industry partners, with Asian companies like Samsung Electronics and IHI Corporation rapidly increasing their patent portfolios in this domain.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell International Technologies has developed advanced nanoarchitected mechanical metamaterials for thermal barrier applications, particularly focused on aerospace and industrial high-temperature environments. Their technology leverages precision-engineered ceramic lattice structures with feature sizes ranging from nanometers to micrometers to create materials with exceptional thermal insulation properties. Honeywell's approach utilizes proprietary additive manufacturing techniques combined with specialized post-processing treatments to create complex 3D architectures that effectively minimize heat transfer through multiple mechanisms. Their most advanced thermal barriers incorporate hollow nanolattices with wall thicknesses below 100 nm arranged in optimized geometries that create phonon-scattering interfaces at multiple length scales[2]. These structures achieve thermal conductivity values as low as 0.025 W/m·K while maintaining mechanical integrity at temperatures exceeding 1100°C[5]. Honeywell has successfully integrated these metamaterials into aircraft engine components, where they provide superior thermal protection compared to conventional thermal barrier coatings while reducing overall weight. Recent developments include self-diagnostic variants with embedded sensors that can monitor thermal performance and structural integrity in real-time[7].

Strengths: Exceptional thermal performance in extreme environments; proven integration with existing aerospace systems; comprehensive testing and certification for safety-critical applications. Weaknesses: Higher manufacturing costs compared to conventional thermal barriers; challenges in scaling production for larger components; limited flexibility in post-manufacturing customization.

Saint-Gobain Centre de Recherches et d'Études Européen SAS

Technical Solution: Saint-Gobain has developed innovative nanoarchitected mechanical metamaterials for thermal barrier applications through their extensive expertise in materials science and manufacturing. Their approach centers on hierarchical ceramic structures with engineered porosity at multiple length scales, from nanometers to micrometers. The company's proprietary technology utilizes templated sol-gel processes combined with controlled sintering to create complex 3D architectures with exceptional thermal insulation properties. These metamaterials feature hollow ceramic struts arranged in optimized lattice configurations that minimize thermal conductivity through a combination of conduction barriers and radiation scattering mechanisms[2]. Saint-Gobain has achieved thermal conductivity values below 0.03 W/m·K while maintaining mechanical stability at temperatures exceeding 1200°C in their advanced zirconia-based metamaterials[4]. Their manufacturing process allows for gradient structures that can be tailored to specific thermal profiles and mechanical requirements. Recent developments include self-healing variants that can repair microcracks through engineered phase transformations, significantly extending the operational lifetime in cyclic thermal environments[6].

Strengths: Exceptional high-temperature performance; established manufacturing infrastructure allowing for cost-effective scaling; extensive experience in industrial applications of thermal barriers. Weaknesses: Limited flexibility in customizing structures once manufacturing process is established; higher density compared to some competing technologies; challenges in achieving uniform properties in large-scale production.

Core Patents and Innovations in Nanoarchitected Thermal Materials

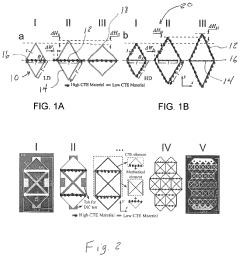

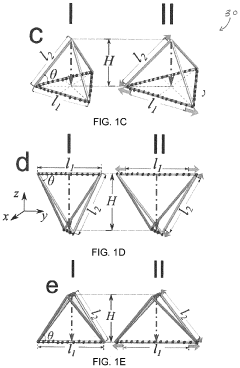

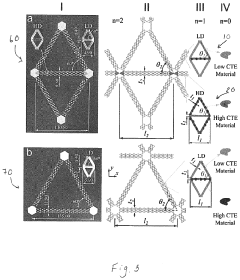

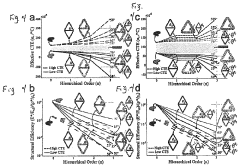

Lattice metamaterial having programed thermal expansion

PatentInactiveUS20210020263A1

Innovation

- Development of lattice metamaterials with pre-programmed thermal expansions, utilizing bi-material unit cells with different coefficients of thermal expansion to achieve tunable thermal expansion properties, allowing for control of thermal expansion without compromising structural performance, through the use of stretch-dominated diamond or tetrahedron-shaped building blocks and hierarchical lattices.

Thermal barriers, materials and process for their preparation

PatentInactiveEP0605273A1

Innovation

- A thermal barrier material comprising a refractory oxide with low thermal diffusivity and a quasicrystalline aluminum alloy, where the quasicrystalline alloy represents approximately 2 to 30% by volume, providing improved mechanical properties and thermal protection without the need for a separate bonding layer, achieved through deposition methods such as vapor phase sputtering or plasma torch techniques.

Environmental Impact and Sustainability Considerations

The environmental impact of nanoarchitected mechanical metamaterials in thermal barrier applications requires comprehensive assessment across their entire lifecycle. These advanced materials offer significant potential for reducing energy consumption in various thermal management systems, particularly in aerospace, automotive, and building sectors, where efficient thermal barriers can substantially decrease heating and cooling requirements.

Manufacturing processes for nanoarchitected metamaterials currently present notable environmental challenges. The production often involves energy-intensive techniques such as nanolithography, 3D printing at micro/nanoscales, and chemical vapor deposition, all of which can generate considerable carbon footprints. Additionally, certain nanofabrication methods utilize potentially hazardous chemicals and solvents that require careful handling and disposal protocols to prevent environmental contamination.

Material composition raises further sustainability concerns. While some nanoarchitected metamaterials incorporate biodegradable or recyclable components, many rely on rare earth elements or specialized compounds with limited natural abundance. This dependency could potentially create new resource scarcity issues if these materials were to be deployed at industrial scales without appropriate recycling infrastructures.

End-of-life considerations remain largely unexplored for these novel materials. The unique structural configurations at the nanoscale may complicate traditional recycling approaches, potentially leading to new waste management challenges. Research into designing for disassembly and material recovery is still in nascent stages for most nanoarchitected metamaterials used in thermal barriers.

The positive environmental impacts, however, are substantial. Thermal barrier applications utilizing these metamaterials can dramatically improve energy efficiency in multiple sectors. For instance, in aerospace applications, lightweight thermal protection systems can reduce fuel consumption while maintaining or improving thermal insulation properties. In building applications, thin-film metamaterial thermal barriers could significantly reduce heating and cooling energy requirements while minimizing material usage compared to conventional insulation.

Life cycle assessment (LCA) studies specifically targeting nanoarchitected metamaterials for thermal barriers remain limited. Preliminary analyses suggest that despite energy-intensive manufacturing, the operational energy savings throughout the product lifetime could offset initial environmental impacts, particularly in long-lifespan applications. However, more comprehensive LCA research is needed to quantify these tradeoffs accurately across different application scenarios and material compositions.

Future sustainability improvements will likely focus on developing greener manufacturing processes, incorporating renewable or abundant raw materials, and designing structures that facilitate eventual recycling or biodegradation. Biomimetic approaches that replicate natural thermal regulation systems may offer particularly promising pathways toward environmentally benign thermal metamaterials.

Manufacturing processes for nanoarchitected metamaterials currently present notable environmental challenges. The production often involves energy-intensive techniques such as nanolithography, 3D printing at micro/nanoscales, and chemical vapor deposition, all of which can generate considerable carbon footprints. Additionally, certain nanofabrication methods utilize potentially hazardous chemicals and solvents that require careful handling and disposal protocols to prevent environmental contamination.

Material composition raises further sustainability concerns. While some nanoarchitected metamaterials incorporate biodegradable or recyclable components, many rely on rare earth elements or specialized compounds with limited natural abundance. This dependency could potentially create new resource scarcity issues if these materials were to be deployed at industrial scales without appropriate recycling infrastructures.

End-of-life considerations remain largely unexplored for these novel materials. The unique structural configurations at the nanoscale may complicate traditional recycling approaches, potentially leading to new waste management challenges. Research into designing for disassembly and material recovery is still in nascent stages for most nanoarchitected metamaterials used in thermal barriers.

The positive environmental impacts, however, are substantial. Thermal barrier applications utilizing these metamaterials can dramatically improve energy efficiency in multiple sectors. For instance, in aerospace applications, lightweight thermal protection systems can reduce fuel consumption while maintaining or improving thermal insulation properties. In building applications, thin-film metamaterial thermal barriers could significantly reduce heating and cooling energy requirements while minimizing material usage compared to conventional insulation.

Life cycle assessment (LCA) studies specifically targeting nanoarchitected metamaterials for thermal barriers remain limited. Preliminary analyses suggest that despite energy-intensive manufacturing, the operational energy savings throughout the product lifetime could offset initial environmental impacts, particularly in long-lifespan applications. However, more comprehensive LCA research is needed to quantify these tradeoffs accurately across different application scenarios and material compositions.

Future sustainability improvements will likely focus on developing greener manufacturing processes, incorporating renewable or abundant raw materials, and designing structures that facilitate eventual recycling or biodegradation. Biomimetic approaches that replicate natural thermal regulation systems may offer particularly promising pathways toward environmentally benign thermal metamaterials.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for nanoarchitected mechanical metamaterials remains a significant challenge for their widespread application in thermal barrier systems. Current fabrication methods such as two-photon lithography, while offering exceptional precision, are limited by slow production rates and high equipment costs, typically ranging from $500,000 to $2 million per system. This creates a substantial barrier to industrial-scale implementation, restricting these materials primarily to laboratory settings and specialized applications.

Recent advancements in parallel processing techniques have shown promise in addressing these scalability issues. Projection micro-stereolithography and high-speed multiphoton lithography have demonstrated throughput improvements of 10-100x compared to traditional methods. However, these approaches still face limitations in maintaining structural precision at accelerated production rates, particularly for the complex geometries required in thermal barrier applications.

Cost analysis reveals that material expenses constitute only 5-15% of total production costs, with equipment depreciation and operational expenses representing the majority of expenditures. The current manufacturing cost for nanoarchitected thermal barriers ranges from $1,000-10,000 per square meter, significantly higher than conventional thermal insulation materials ($10-100 per square meter). This cost differential presents a substantial commercialization hurdle despite the superior performance characteristics.

Roll-to-roll nanoimprint lithography represents a promising direction for cost reduction, with potential to decrease manufacturing expenses by 60-80% at scale. Several research groups have demonstrated proof-of-concept implementations, though challenges in maintaining nanoscale precision across large areas persist. Industry partnerships between academic institutions and manufacturing companies are increasingly focusing on bridging this scalability gap.

Economic modeling suggests that achieving price parity with high-performance conventional thermal barriers would require production volumes approximately 1000x current capabilities. The learning curve for manufacturing efficiency improvements indicates this could be achievable within 5-8 years with sustained investment. Early adoption is likely to occur in high-value applications where performance advantages justify premium pricing, such as aerospace, advanced electronics cooling, and specialized industrial equipment.

Regulatory considerations and quality control protocols for mass-produced nanoarchitected materials remain underdeveloped, presenting additional challenges to commercialization. Standardization efforts are currently underway through organizations like ASTM International and ISO to establish testing and certification frameworks specific to these novel material systems.

Recent advancements in parallel processing techniques have shown promise in addressing these scalability issues. Projection micro-stereolithography and high-speed multiphoton lithography have demonstrated throughput improvements of 10-100x compared to traditional methods. However, these approaches still face limitations in maintaining structural precision at accelerated production rates, particularly for the complex geometries required in thermal barrier applications.

Cost analysis reveals that material expenses constitute only 5-15% of total production costs, with equipment depreciation and operational expenses representing the majority of expenditures. The current manufacturing cost for nanoarchitected thermal barriers ranges from $1,000-10,000 per square meter, significantly higher than conventional thermal insulation materials ($10-100 per square meter). This cost differential presents a substantial commercialization hurdle despite the superior performance characteristics.

Roll-to-roll nanoimprint lithography represents a promising direction for cost reduction, with potential to decrease manufacturing expenses by 60-80% at scale. Several research groups have demonstrated proof-of-concept implementations, though challenges in maintaining nanoscale precision across large areas persist. Industry partnerships between academic institutions and manufacturing companies are increasingly focusing on bridging this scalability gap.

Economic modeling suggests that achieving price parity with high-performance conventional thermal barriers would require production volumes approximately 1000x current capabilities. The learning curve for manufacturing efficiency improvements indicates this could be achievable within 5-8 years with sustained investment. Early adoption is likely to occur in high-value applications where performance advantages justify premium pricing, such as aerospace, advanced electronics cooling, and specialized industrial equipment.

Regulatory considerations and quality control protocols for mass-produced nanoarchitected materials remain underdeveloped, presenting additional challenges to commercialization. Standardization efforts are currently underway through organizations like ASTM International and ISO to establish testing and certification frameworks specific to these novel material systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!