Incorporating Nanoarchitected Mechanical Metamaterials in Drug Delivery Systems.

Nanoarchitected Metamaterials in Drug Delivery: Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, emerging from the convergence of nanotechnology, mechanical engineering, and materials design. These engineered structures possess unique mechanical properties that transcend those of conventional materials, including exceptional strength-to-weight ratios, programmable deformation behaviors, and tunable mechanical responses. The evolution of this field traces back to early theoretical work in the 1990s on photonic crystals and negative refractive index materials, which laid the groundwork for mechanical metamaterials.

Over the past decade, significant advancements in fabrication techniques such as two-photon lithography, direct laser writing, and self-assembly methods have enabled the precise construction of these complex nanoarchitectures with feature sizes ranging from nanometers to micrometers. This technological progression has transformed theoretical concepts into tangible structures with real-world applications, particularly in biomedical engineering.

The integration of nanoarchitected mechanical metamaterials into drug delivery systems represents a paradigm shift in pharmaceutical technology. Traditional drug delivery faces persistent challenges including poor bioavailability, uncontrolled release kinetics, and limited targeting capabilities. Nanoarchitected metamaterials offer promising solutions through their precisely engineered mechanical responses, which can be harnessed for controlled drug release mechanisms.

The primary technical objectives for incorporating these materials into drug delivery systems include: developing stimuli-responsive release mechanisms that can be triggered by specific physiological conditions; creating hierarchical structures capable of carrying multiple therapeutic agents with independent release profiles; engineering biodegradable metamaterials with predictable degradation timelines aligned with therapeutic windows; and designing systems with mechanical properties that facilitate targeted delivery to specific tissues while minimizing systemic exposure.

Current research trends indicate growing interest in mechanically actuated drug delivery systems that respond to ultrasound, magnetic fields, or mechanical strain within the body. Additionally, there is significant focus on developing metamaterials that can navigate biological barriers such as the blood-brain barrier or tumor microenvironments through their unique mechanical properties.

The ultimate goal of this technological integration is to create "smart" drug delivery platforms that combine the precision engineering of nanoarchitected metamaterials with the therapeutic efficacy of pharmaceutical compounds. Such systems would enable unprecedented control over drug pharmacokinetics, potentially revolutionizing treatment approaches for conditions ranging from cancer to chronic inflammatory diseases by maximizing therapeutic efficacy while minimizing adverse effects.

Market Analysis for Advanced Drug Delivery Systems

The global advanced drug delivery systems market is experiencing robust growth, valued at approximately $231 billion in 2022 and projected to reach $320 billion by 2027, representing a compound annual growth rate (CAGR) of 6.8%. This growth is primarily driven by increasing prevalence of chronic diseases, rising demand for targeted drug delivery, and technological advancements in nanomedicine.

Nanoarchitected mechanical metamaterials represent a revolutionary approach within this market, offering unprecedented control over drug release kinetics and targeting capabilities. The segment focusing on these advanced materials is currently small but growing at an accelerated rate of nearly 12% annually, significantly outpacing the broader market.

North America dominates the advanced drug delivery systems market with approximately 42% market share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is witnessing the fastest growth due to increasing healthcare expenditure, growing research activities, and improving regulatory frameworks in countries like China, Japan, and India.

Oncology applications currently represent the largest application segment for advanced drug delivery systems, accounting for 31% of the market. This is followed by cardiovascular diseases (18%), neurological disorders (14%), and infectious diseases (12%). The integration of nanoarchitected mechanical metamaterials is particularly promising in oncology, where precise drug delivery can significantly reduce systemic toxicity while enhancing therapeutic efficacy.

Key market drivers include the growing demand for minimally invasive drug delivery methods, increasing research funding in nanomedicine, and rising patient preference for self-administration devices. The shift toward personalized medicine is also creating significant opportunities for tailored drug delivery systems incorporating smart materials that respond to patient-specific physiological conditions.

Market challenges include high development costs, complex regulatory approval processes, and technical difficulties in scaling up production of nanoarchitected materials. The average development timeline for bringing a new advanced drug delivery system to market ranges from 5-7 years, with costs often exceeding $50 million.

Consumer willingness to pay premium prices for advanced drug delivery systems varies by region and application, with oncology patients showing the highest acceptance of price premiums (up to 40% over conventional therapies) for solutions that offer improved efficacy and reduced side effects.

Reimbursement policies significantly impact market adoption, with favorable coverage in North America and Western Europe accelerating uptake, while limited reimbursement in emerging markets remains a barrier to widespread adoption despite growing demand.

Current Status and Challenges in Nanoarchitected Drug Delivery

The integration of nanoarchitected mechanical metamaterials into drug delivery systems represents a frontier area in nanomedicine, with significant progress made globally over the past decade. Currently, several research institutions across North America, Europe, and Asia are actively developing these advanced systems, though commercial applications remain limited. The field has evolved from simple nanoparticle-based delivery to sophisticated architectures with programmable mechanical properties that respond to specific biological stimuli.

Despite promising advancements, numerous technical challenges persist. Precise control over the mechanical properties of nanomaterials at biologically relevant scales remains difficult, particularly when designing structures that must navigate complex biological barriers while maintaining structural integrity. The translation of laboratory-scale fabrication techniques to scalable manufacturing processes presents significant hurdles, limiting widespread clinical adoption.

Biocompatibility and biodegradation represent critical challenges, as these materials must function effectively within biological environments without triggering adverse immune responses. Current research indicates that while many nanoarchitected materials show promising in vitro results, their in vivo performance often falls short of expectations due to unforeseen biological interactions and mechanical failures under physiological conditions.

Regulatory frameworks worldwide are struggling to keep pace with these technological innovations. The FDA in the United States and the EMA in Europe have established preliminary guidelines for nanomedicine evaluation, but specific protocols for mechanical metamaterial-based drug delivery systems remain underdeveloped, creating uncertainty for researchers and companies pursuing commercialization.

Geographic distribution of research expertise shows concentration in specific regions. The United States leads in fundamental research through institutions like MIT, Stanford, and Harvard, while China has rapidly expanded its capabilities, particularly in scalable manufacturing techniques. European contributions are notable in the areas of biocompatibility assessment and regulatory science, with strong programs in Germany, Switzerland, and the United Kingdom.

Funding patterns reveal increasing investment in this field, with approximately $2.3 billion allocated globally in 2022, representing a 15% increase from the previous year. However, the capital-intensive nature of development and extended timelines for regulatory approval create significant barriers for startups and smaller research entities.

Technical limitations in characterization methods also impede progress. Current imaging and testing technologies struggle to simultaneously capture the mechanical behavior and drug release kinetics of these complex systems in real-time within biological environments, necessitating the development of new analytical approaches.

Current Technical Approaches to Nanoarchitected Drug Delivery

01 Nanoarchitected metamaterials with unique mechanical properties

Nanoarchitected mechanical metamaterials are designed with specific structural arrangements at the nanoscale to achieve extraordinary mechanical properties not found in conventional materials. These include enhanced strength-to-weight ratios, programmable stiffness, and controlled deformation behaviors. The precise arrangement of nanoscale building blocks creates materials that can exhibit properties such as negative Poisson's ratio, high energy absorption, or exceptional resilience under mechanical stress.- Nanoarchitected metamaterials with unique mechanical properties: Nanoarchitected mechanical metamaterials are engineered structures with precisely designed geometries at the nanoscale that exhibit extraordinary mechanical properties not found in conventional materials. These materials can demonstrate properties such as ultra-high strength-to-weight ratios, negative Poisson's ratios, or programmable deformation behaviors. The nanoscale architecture allows for precise control over mechanical response, enabling applications in lightweight structural components, energy absorption systems, and protective materials.

- Fabrication methods for nanoarchitected metamaterials: Various advanced manufacturing techniques are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These methods include two-photon lithography, nanoimprint lithography, self-assembly processes, and additive manufacturing techniques adapted for nanoscale precision. These fabrication approaches enable the creation of complex three-dimensional architectures with feature sizes ranging from nanometers to micrometers, allowing for unprecedented control over material properties through structural design rather than chemical composition.

- Electronic and photonic applications of nanoarchitected metamaterials: Beyond mechanical properties, nanoarchitected metamaterials can be designed to exhibit unique electronic and photonic behaviors. These materials can be engineered to manipulate electromagnetic waves, create photonic bandgaps, or enhance electronic properties through structural design. Applications include advanced sensors, electromagnetic shielding, optical filters, and components for telecommunications. The ability to precisely control both mechanical and electronic/photonic properties makes these materials particularly valuable for multifunctional devices.

- Energy absorption and damping in nanoarchitected metamaterials: Nanoarchitected mechanical metamaterials can be designed with specific energy absorption and damping characteristics. These materials utilize their complex structural arrangements to dissipate energy through controlled deformation pathways, making them excellent for impact protection, vibration damping, and acoustic insulation. The hierarchical structure allows for tailored mechanical responses across multiple length scales, enabling progressive energy absorption that outperforms conventional materials in protective applications.

- Responsive and programmable nanoarchitected metamaterials: Advanced nanoarchitected metamaterials can be designed to respond to external stimuli or exhibit programmable behaviors. These materials can change their properties in response to temperature, light, electric fields, or mechanical forces. Some designs incorporate shape memory effects or bistable elements that allow for programmable shape changes or mechanical logic operations. These responsive behaviors enable applications in soft robotics, adaptive structures, and smart materials that can autonomously adjust their properties based on environmental conditions.

02 Fabrication techniques for nanoarchitected metamaterials

Advanced manufacturing methods are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These techniques include two-photon lithography, nanoimprint lithography, self-assembly processes, and additive manufacturing approaches adapted for nanoscale precision. These fabrication methods enable the creation of complex 3D architectures with feature sizes ranging from nanometers to micrometers, allowing for the precise engineering of mechanical responses through structural design.Expand Specific Solutions03 Electronic and photonic applications of nanoarchitected metamaterials

Beyond purely mechanical applications, nanoarchitected metamaterials are being developed for electronic and photonic devices. These materials can be designed to manipulate electromagnetic waves, create photonic bandgaps, or serve as components in microelectronic systems. The ability to precisely control both the mechanical and electromagnetic properties makes these materials valuable for applications in sensors, actuators, and communication devices where mechanical stability and electronic functionality must be integrated.Expand Specific Solutions04 Energy absorption and impact resistance applications

Nanoarchitected metamaterials are designed to provide superior energy absorption and impact resistance properties. Their carefully engineered structures can dissipate kinetic energy through controlled deformation mechanisms, making them ideal for protective applications. These materials can be tailored to absorb specific frequencies of vibration or impact forces, offering advantages in applications ranging from personal protective equipment to vehicle safety systems and aerospace components subjected to extreme mechanical stresses.Expand Specific Solutions05 Responsive and programmable mechanical metamaterials

Advanced nanoarchitected metamaterials are being developed with responsive and programmable mechanical behaviors. These materials can change their properties in response to external stimuli such as temperature, electric fields, or mechanical stress. Some designs incorporate shape memory effects or bistable mechanisms that allow for programmable deformation pathways. This adaptability enables applications in soft robotics, deployable structures, and medical devices where controlled mechanical responses to environmental changes are required.Expand Specific Solutions

Key Industry Players in Nanomedicine and Metamaterials

The field of nanoarchitected mechanical metamaterials in drug delivery systems is currently in an early growth phase, with significant research momentum but limited commercial applications. The market is projected to reach $5-7 billion by 2028, driven by precision medicine demands. Academic institutions lead fundamental research, with the University of California and Tsinghua University pioneering novel architectures. Research hospitals like Memorial Sloan Kettering and commercial entities such as Pfizer and Beam Therapeutics are bridging the gap between research and clinical applications. The technology remains at TRL 4-6, with challenges in scalable manufacturing and regulatory approval pathways. International collaboration between academic institutions (CNRS, Université d'Aix-Marseille) and industry partners is accelerating development toward clinical translation.

The Regents of the University of California

Tsinghua University

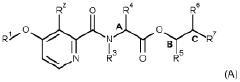

Critical Patents and Research in Mechanical Metamaterial Drug Carriers

- A metamaterial plate with subwavelength thickness is used to create a space of invisibility by radiating its bottom surface, forming a secondary radiation space above, where any object within this space becomes invisible to devices above the plate, and the metamaterial plate itself becomes invisible under primary and secondary radiations.

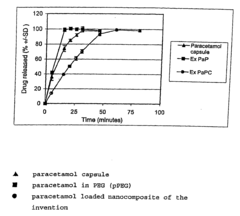

- The use of nanocomposite materials, specifically polymer-clay nanocomposites, which enhance mechanical strength and control release rates by dispersing active ingredients within a biologically inert matrix, allowing for tailored mechanical properties and degradation profiles.

Biocompatibility and Safety Considerations

The integration of nanoarchitected mechanical metamaterials into drug delivery systems necessitates rigorous evaluation of biocompatibility and safety profiles. These advanced materials, while offering unprecedented control over drug release kinetics and targeting capabilities, introduce novel biological interactions that must be thoroughly characterized before clinical translation.

Primary biocompatibility concerns include potential immunogenicity, where the unique structural features of metamaterials may trigger immune responses not observed with conventional delivery systems. Research indicates that surface chemistry modifications and protein corona formation significantly influence recognition by immune cells, with preliminary studies showing varied responses depending on metamaterial geometry and composition.

Cytotoxicity assessments reveal complex relationships between metamaterial architecture and cellular viability. Certain lattice configurations demonstrate minimal cytotoxicity in vitro, while others with similar chemical composition but different structural arrangements show increased cellular damage. This highlights the critical importance of structure-function relationships in biological environments beyond mere material selection.

Hemocompatibility represents another crucial consideration, as many drug delivery systems require intravenous administration. Current evidence suggests that metamaterial surface topography significantly influences platelet adhesion and activation, with hierarchical structures potentially offering improved hemocompatibility compared to conventional nanoparticles.

Biodegradation pathways of nanoarchitected metamaterials remain incompletely characterized, raising questions about long-term safety. Studies indicate that degradation kinetics can be engineered through strategic incorporation of biodegradable linkages within the metamaterial framework, though predicting in vivo degradation remains challenging due to the complex biological milieu.

Regulatory considerations present significant hurdles, as existing frameworks for nanomaterial safety assessment may inadequately address the unique properties of mechanical metamaterials. Current guidelines focus primarily on chemical composition rather than architectural features that may fundamentally alter biological interactions.

Standardized testing protocols specifically designed for metamaterial evaluation are urgently needed. Conventional assays may fail to capture the mechanical-biological interactions unique to these materials, potentially overlooking important safety signals. Multi-parametric approaches combining traditional toxicity assessments with advanced imaging and mechanical characterization offer more comprehensive safety profiles.

Risk mitigation strategies include rational design approaches that incorporate safety considerations from inception, such as selecting biocompatible building blocks and implementing architectures demonstrated to minimize adverse biological interactions. Computational modeling of metamaterial-biological interfaces shows promise for predicting potential safety concerns before physical synthesis, potentially accelerating development timelines while enhancing safety.

Scalability and Manufacturing Challenges

The scaling of nanoarchitected mechanical metamaterials for drug delivery systems represents a significant manufacturing challenge that currently limits widespread commercial adoption. Traditional fabrication methods such as two-photon lithography offer exceptional precision but operate at prohibitively slow production rates, making them suitable only for laboratory-scale prototyping rather than industrial manufacturing. This fundamental bottleneck restricts the translation of promising research into clinically viable products.

Recent advances in parallel processing techniques, including projection micro-stereolithography and high-resolution digital light processing (DLP), have demonstrated potential for increasing throughput by orders of magnitude. However, these methods still struggle with achieving the necessary sub-micron resolution while maintaining the complex geometrical features that give metamaterials their unique mechanical properties. The trade-off between resolution and production speed remains a central challenge.

Material selection compounds these difficulties, as biocompatible and biodegradable polymers often exhibit different processing characteristics than those typically used in metamaterial research. The rheological properties of these materials can limit their compatibility with high-resolution manufacturing techniques, necessitating extensive reformulation and process optimization. Additionally, post-processing steps such as development, washing, and sterilization must be carefully designed to preserve the delicate nanoarchitectures.

Quality control presents another significant hurdle, as conventional inspection methods lack the throughput needed to validate large quantities of nanoscale structures. Non-destructive testing approaches capable of rapidly assessing critical geometric parameters and mechanical properties are still in early development stages. Without reliable quality assurance protocols, regulatory approval for clinical applications remains challenging.

Cost considerations further complicate scalability, with current manufacturing approaches requiring specialized equipment and expertise that drive production expenses well beyond commercially viable thresholds. Economic analyses suggest that per-unit costs need to decrease by at least two orders of magnitude to compete with conventional drug delivery systems, necessitating fundamental innovations in manufacturing technology rather than incremental improvements.

Environmental and sustainability concerns also merit attention, as some nanofabrication processes involve hazardous chemicals or generate significant waste. Developing greener manufacturing protocols that minimize environmental impact while maintaining precision and throughput will be essential for responsible scaling of these technologies. This includes exploring bio-inspired fabrication routes that operate under ambient conditions with minimal energy requirements.