Nanoarchitected Mechanical Metamaterials for Noise Reduction in Urban Settings.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, emerging from the convergence of nanotechnology, mechanical engineering, and acoustic physics. These engineered structures possess unique properties that transcend those of conventional materials, particularly in manipulating sound waves. The evolution of these metamaterials can be traced back to the early 2000s, when researchers first began exploring artificial structures with properties not found in nature. Over the past decade, significant advancements in nanofabrication techniques have accelerated development, enabling precise control over material architecture at the nanoscale.

The technological trajectory of nanoarchitected metamaterials has been marked by progressive refinement in design methodologies, fabrication precision, and theoretical understanding. Initial research focused primarily on electromagnetic applications, but attention has increasingly shifted toward acoustic and mechanical properties, particularly for noise reduction purposes. Recent breakthroughs in computational modeling have further enhanced our ability to predict and optimize metamaterial performance before physical fabrication.

Urban noise pollution represents one of the most pervasive environmental challenges of modern cities, with documented impacts on public health, cognitive function, and quality of life. Traditional noise reduction solutions often involve bulky barriers, expensive sound-absorbing materials, or limited-effectiveness active cancellation systems. Nanoarchitected metamaterials offer a paradigm shift in addressing this challenge through their ability to manipulate acoustic waves with unprecedented precision.

The primary technical objectives for nanoarchitected metamaterials in urban noise reduction include developing structures capable of attenuating specific frequency ranges most prevalent in urban environments (particularly low-frequency noise from transportation and construction), creating lightweight and thin materials that can be integrated into existing infrastructure, and ensuring durability under varied environmental conditions. Additionally, scalable and cost-effective fabrication methods must be established to transition from laboratory prototypes to commercial applications.

A critical goal is achieving broadband noise reduction across the human auditory range (20Hz-20kHz) while maintaining structural integrity and aesthetic compatibility with urban architecture. This requires innovative approaches to metamaterial design that balance acoustic performance with practical considerations such as weatherability, maintenance requirements, and installation complexity.

The long-term technological vision extends beyond passive noise reduction to include adaptive metamaterials capable of responding dynamically to changing acoustic environments, potentially incorporating smart materials and sensors to optimize performance in real-time. Such systems could revolutionize urban soundscapes, transforming noise management from mitigation to deliberate acoustic design of public spaces.

The technological trajectory of nanoarchitected metamaterials has been marked by progressive refinement in design methodologies, fabrication precision, and theoretical understanding. Initial research focused primarily on electromagnetic applications, but attention has increasingly shifted toward acoustic and mechanical properties, particularly for noise reduction purposes. Recent breakthroughs in computational modeling have further enhanced our ability to predict and optimize metamaterial performance before physical fabrication.

Urban noise pollution represents one of the most pervasive environmental challenges of modern cities, with documented impacts on public health, cognitive function, and quality of life. Traditional noise reduction solutions often involve bulky barriers, expensive sound-absorbing materials, or limited-effectiveness active cancellation systems. Nanoarchitected metamaterials offer a paradigm shift in addressing this challenge through their ability to manipulate acoustic waves with unprecedented precision.

The primary technical objectives for nanoarchitected metamaterials in urban noise reduction include developing structures capable of attenuating specific frequency ranges most prevalent in urban environments (particularly low-frequency noise from transportation and construction), creating lightweight and thin materials that can be integrated into existing infrastructure, and ensuring durability under varied environmental conditions. Additionally, scalable and cost-effective fabrication methods must be established to transition from laboratory prototypes to commercial applications.

A critical goal is achieving broadband noise reduction across the human auditory range (20Hz-20kHz) while maintaining structural integrity and aesthetic compatibility with urban architecture. This requires innovative approaches to metamaterial design that balance acoustic performance with practical considerations such as weatherability, maintenance requirements, and installation complexity.

The long-term technological vision extends beyond passive noise reduction to include adaptive metamaterials capable of responding dynamically to changing acoustic environments, potentially incorporating smart materials and sensors to optimize performance in real-time. Such systems could revolutionize urban soundscapes, transforming noise management from mitigation to deliberate acoustic design of public spaces.

Urban Noise Reduction Market Analysis

The global urban noise reduction market is experiencing significant growth, driven by increasing urbanization and rising awareness of noise pollution's negative health impacts. Currently valued at approximately 6.2 billion USD, the market is projected to reach 8.5 billion USD by 2027, representing a compound annual growth rate of 6.4%. This growth trajectory is particularly pronounced in densely populated urban centers across North America, Europe, and rapidly developing Asian metropolitan areas.

Consumer demand for noise reduction solutions has evolved beyond traditional applications in industrial settings to encompass residential, commercial, and public infrastructure sectors. Market research indicates that approximately 68% of urban residents consider noise pollution a significant factor affecting their quality of life, with 42% willing to pay premium prices for effective noise reduction solutions in their living environments.

The regulatory landscape is increasingly favorable for noise reduction technologies, with many municipalities implementing stricter noise ordinances and building codes. The European Union's Environmental Noise Directive and similar regulations in North America and Asia have established maximum permissible noise levels in urban areas, creating substantial market pull for innovative noise reduction solutions.

Market segmentation reveals distinct customer profiles: municipal governments seeking infrastructure-scale solutions (representing 35% of the market), commercial property developers (28%), residential consumers (22%), and industrial applications (15%). The highest growth segment is currently in smart city infrastructure projects, where noise reduction is integrated with other urban planning objectives.

Competitive analysis shows the market is fragmented with traditional acoustic material manufacturers holding approximately 45% market share, while specialized architectural solution providers control 30%. The remaining 25% is divided among emerging technology companies, including those developing metamaterial-based solutions. This fragmentation presents significant opportunities for disruptive technologies like nanoarchitected mechanical metamaterials.

Price sensitivity varies by segment, with infrastructure projects demonstrating greater willingness to invest in high-performance solutions with proven longevity, while residential applications remain more cost-conscious. The average implementation cost for noise reduction solutions ranges from 85-350 USD per square meter, depending on performance requirements and application complexity.

Distribution channels are evolving from traditional construction supply chains to include direct-to-consumer options for modular solutions and specialized consulting services for custom implementations. This evolution is creating new market entry points for innovative technologies that can demonstrate clear performance advantages over conventional solutions.

Consumer demand for noise reduction solutions has evolved beyond traditional applications in industrial settings to encompass residential, commercial, and public infrastructure sectors. Market research indicates that approximately 68% of urban residents consider noise pollution a significant factor affecting their quality of life, with 42% willing to pay premium prices for effective noise reduction solutions in their living environments.

The regulatory landscape is increasingly favorable for noise reduction technologies, with many municipalities implementing stricter noise ordinances and building codes. The European Union's Environmental Noise Directive and similar regulations in North America and Asia have established maximum permissible noise levels in urban areas, creating substantial market pull for innovative noise reduction solutions.

Market segmentation reveals distinct customer profiles: municipal governments seeking infrastructure-scale solutions (representing 35% of the market), commercial property developers (28%), residential consumers (22%), and industrial applications (15%). The highest growth segment is currently in smart city infrastructure projects, where noise reduction is integrated with other urban planning objectives.

Competitive analysis shows the market is fragmented with traditional acoustic material manufacturers holding approximately 45% market share, while specialized architectural solution providers control 30%. The remaining 25% is divided among emerging technology companies, including those developing metamaterial-based solutions. This fragmentation presents significant opportunities for disruptive technologies like nanoarchitected mechanical metamaterials.

Price sensitivity varies by segment, with infrastructure projects demonstrating greater willingness to invest in high-performance solutions with proven longevity, while residential applications remain more cost-conscious. The average implementation cost for noise reduction solutions ranges from 85-350 USD per square meter, depending on performance requirements and application complexity.

Distribution channels are evolving from traditional construction supply chains to include direct-to-consumer options for modular solutions and specialized consulting services for custom implementations. This evolution is creating new market entry points for innovative technologies that can demonstrate clear performance advantages over conventional solutions.

Current Challenges in Acoustic Metamaterials Development

Despite significant advancements in acoustic metamaterials research, several critical challenges continue to impede the widespread implementation of nanoarchitected mechanical metamaterials for urban noise reduction. The miniaturization of acoustic metamaterial structures to the nanoscale presents formidable fabrication difficulties. Current manufacturing techniques such as two-photon lithography and nanoimprint lithography offer high precision but suffer from low throughput and high costs, making mass production for urban applications economically unfeasible.

Material limitations constitute another significant barrier. Many theoretical designs require materials with specific mechanical properties that are difficult to achieve in practice. The ideal materials must simultaneously possess appropriate density, stiffness, and damping characteristics while remaining durable enough to withstand environmental exposure in urban settings. The development of composite nanomaterials that meet these conflicting requirements remains an ongoing challenge.

Broadband effectiveness represents perhaps the most significant technical hurdle. Urban noise pollution spans a wide frequency spectrum (20 Hz to 20 kHz), yet most current metamaterial designs are effective only within narrow frequency bands. Creating structures that can simultaneously attenuate multiple frequency ranges without compromising performance requires complex multi-scale architectures that are difficult to design and fabricate.

The scaling gap between laboratory prototypes and real-world implementation presents additional complications. Most successful demonstrations have been conducted on small samples under controlled laboratory conditions. Scaling these solutions to cover large urban surfaces while maintaining acoustic performance integrity has proven problematic, with issues of structural consistency and performance degradation at larger scales.

Environmental durability poses another critical challenge. Urban acoustic metamaterials must withstand temperature fluctuations, moisture, pollution, and mechanical wear. Current nanomaterials often degrade rapidly under such conditions, compromising their long-term acoustic performance. Developing protective coatings or self-healing capabilities without affecting acoustic properties remains an unsolved problem.

Computational limitations also hinder progress. The multi-physics modeling required to accurately predict acoustic behavior of complex nanoarchitectures demands enormous computational resources. Current simulation tools struggle to bridge the gap between nano-scale material properties and macro-scale acoustic performance, making design optimization inefficient and time-consuming.

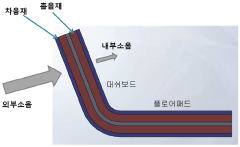

Finally, integration challenges with existing urban infrastructure cannot be overlooked. Retrofitting buildings, transportation systems, and public spaces with nanoarchitected metamaterials requires solutions that are not only acoustically effective but also compatible with diverse architectural styles, building codes, and installation methods.

Material limitations constitute another significant barrier. Many theoretical designs require materials with specific mechanical properties that are difficult to achieve in practice. The ideal materials must simultaneously possess appropriate density, stiffness, and damping characteristics while remaining durable enough to withstand environmental exposure in urban settings. The development of composite nanomaterials that meet these conflicting requirements remains an ongoing challenge.

Broadband effectiveness represents perhaps the most significant technical hurdle. Urban noise pollution spans a wide frequency spectrum (20 Hz to 20 kHz), yet most current metamaterial designs are effective only within narrow frequency bands. Creating structures that can simultaneously attenuate multiple frequency ranges without compromising performance requires complex multi-scale architectures that are difficult to design and fabricate.

The scaling gap between laboratory prototypes and real-world implementation presents additional complications. Most successful demonstrations have been conducted on small samples under controlled laboratory conditions. Scaling these solutions to cover large urban surfaces while maintaining acoustic performance integrity has proven problematic, with issues of structural consistency and performance degradation at larger scales.

Environmental durability poses another critical challenge. Urban acoustic metamaterials must withstand temperature fluctuations, moisture, pollution, and mechanical wear. Current nanomaterials often degrade rapidly under such conditions, compromising their long-term acoustic performance. Developing protective coatings or self-healing capabilities without affecting acoustic properties remains an unsolved problem.

Computational limitations also hinder progress. The multi-physics modeling required to accurately predict acoustic behavior of complex nanoarchitectures demands enormous computational resources. Current simulation tools struggle to bridge the gap between nano-scale material properties and macro-scale acoustic performance, making design optimization inefficient and time-consuming.

Finally, integration challenges with existing urban infrastructure cannot be overlooked. Retrofitting buildings, transportation systems, and public spaces with nanoarchitected metamaterials requires solutions that are not only acoustically effective but also compatible with diverse architectural styles, building codes, and installation methods.

Existing Noise Reduction Metamaterial Solutions

01 Metamaterial acoustic structures for noise reduction

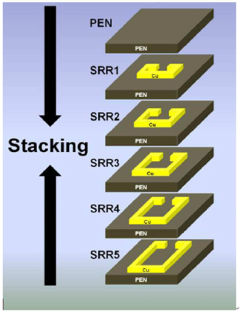

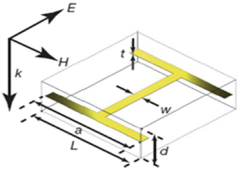

Nanoarchitected metamaterials can be designed with specific acoustic properties to absorb, redirect, or cancel sound waves. These structures typically feature periodic arrangements of resonators or cavities at the nanoscale that interact with sound waves in ways that natural materials cannot. By carefully engineering the geometry and composition of these metamaterials, they can target specific frequency ranges for noise reduction, creating effective sound barriers or absorbers with minimal material thickness.- Metamaterial acoustic structures for noise reduction: Nanoarchitected metamaterials can be designed with specific acoustic properties to absorb, redirect, or cancel sound waves. These structures typically feature periodic arrangements of resonators and waveguides at the nanoscale that interact with sound waves in ways conventional materials cannot. By carefully engineering the geometry and composition of these metamaterials, they can target specific frequency ranges for noise reduction, creating effective sound barriers with minimal material thickness.

- Vibration damping through nanoarchitected lattice structures: Mechanical metamaterials with hierarchical lattice structures at the nanoscale can effectively dampen vibrations that contribute to noise. These structures work by converting vibrational energy into heat through internal friction mechanisms or by trapping the energy within the structure through designed resonance effects. The precise arrangement of struts, nodes, and voids in these lattices determines their frequency-dependent damping characteristics, allowing them to be tailored for specific noise reduction applications.

- Adaptive and tunable metamaterials for dynamic noise control: Advanced nanoarchitected metamaterials can be designed with tunable properties that respond to external stimuli, allowing for dynamic noise reduction capabilities. These smart materials can adjust their mechanical or acoustic properties in real-time through electrical, magnetic, or thermal inputs, enabling them to adapt to changing noise environments. This adaptability makes them particularly valuable in applications where noise characteristics vary over time or where different frequency ranges need to be targeted at different moments.

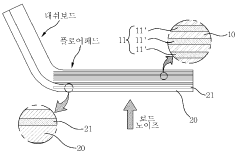

- Integration of metamaterials in electronic devices for noise reduction: Nanoarchitected metamaterials can be integrated into electronic devices to reduce operational noise and improve audio quality. These materials can be strategically placed around speakers, microphones, or mechanical components to absorb unwanted vibrations and acoustic emissions. The nanoscale precision of these metamaterials allows them to be incorporated into compact electronic designs without significantly increasing device dimensions, while still providing effective noise isolation and acoustic enhancement.

- Multi-functional metamaterials combining noise reduction with other properties: Advanced nanoarchitected metamaterials can be designed to simultaneously provide noise reduction alongside other beneficial properties such as thermal insulation, electromagnetic shielding, or structural support. These multi-functional materials optimize space and weight in applications where multiple performance criteria must be met. By carefully engineering the composition and geometry at the nanoscale, these materials can address multiple challenges simultaneously, making them particularly valuable in aerospace, automotive, and construction applications where space and weight constraints are significant.

02 Vibration damping through nanoarchitected lattice structures

Mechanical metamaterials with hierarchical lattice structures at the nanoscale can effectively dampen vibrations that contribute to noise. These structures work by creating phononic bandgaps that prevent certain frequencies of mechanical waves from propagating through the material. The engineered lattices can convert vibrational energy into heat through internal friction mechanisms, providing superior damping performance compared to conventional materials while maintaining lightweight properties.Expand Specific Solutions03 Active noise cancellation using smart metamaterials

Advanced nanoarchitected metamaterials can incorporate active elements that dynamically respond to incoming sound waves. These smart structures can detect acoustic signals and generate counter-waves that cancel out unwanted noise through destructive interference. By integrating sensors, actuators, and control systems within the metamaterial architecture, these systems can adapt to changing noise environments in real-time, providing superior noise reduction across a broad frequency spectrum.Expand Specific Solutions04 Tunable acoustic properties through reconfigurable nanostructures

Mechanical metamaterials can be designed with reconfigurable nanostructures that allow their acoustic properties to be tuned on demand. These materials incorporate mechanisms that can change their geometry, stiffness, or damping characteristics in response to external stimuli such as electrical signals, temperature changes, or mechanical forces. This tunability enables adaptive noise reduction solutions that can optimize performance for different acoustic environments or target specific noise frequencies as needed.Expand Specific Solutions05 Multi-functional metamaterials combining noise reduction with other properties

Nanoarchitected mechanical metamaterials can be designed to simultaneously provide noise reduction along with other beneficial properties such as thermal insulation, electromagnetic shielding, or structural support. These multi-functional materials optimize space and weight efficiency by integrating multiple performance characteristics into a single material system. The hierarchical design approach allows engineers to create materials that address multiple environmental challenges simultaneously without compromising on noise reduction capabilities.Expand Specific Solutions

Leading Organizations in Nanoarchitected Materials Research

Nanoarchitected mechanical metamaterials for noise reduction in urban settings are emerging as a promising solution to urban noise pollution. The market is in its early growth phase, with an estimated global value of $2-3 billion and projected annual growth of 15-20%. Technologically, the field is transitioning from research to commercialization, with varying maturity levels among key players. Research institutions like Northeastern University, University of Michigan, and National University of Defense Technology are pioneering fundamental research, while companies including Hyundai Motor, Kia, ThyssenKrupp, and Robert Bosch are developing practical applications. Fraunhofer-Gesellschaft and BASF are bridging the gap between academic research and industrial implementation, focusing on scalable manufacturing processes for these advanced acoustic metamaterials.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed innovative nanoarchitected metamaterials specifically designed to reduce vehicle-generated noise in urban environments. Their technology utilizes precisely engineered cellular structures with nanoscale features that create phononic bandgaps, effectively blocking sound transmission at targeted frequencies (particularly 500Hz-2kHz range common in traffic noise). Hyundai's approach combines computational acoustic modeling with advanced manufacturing techniques to create lightweight, thin metamaterial panels that can be integrated into urban infrastructure. Their solution incorporates gradient-index metamaterials that can guide sound waves away from sensitive areas, creating acoustic "quiet zones" in urban settings. The company has also developed adaptive metamaterials that can change their acoustic properties based on environmental conditions, optimizing noise reduction during peak traffic hours. These materials are designed for integration into sound barriers, building facades, and transportation infrastructure, with special attention to aesthetics and durability in urban environments.

Strengths: Deep understanding of vehicle noise profiles enables highly targeted solutions; integration with smart city technologies allows dynamic noise management. Weaknesses: Relatively new to metamaterial technology compared to research institutions; solutions may be optimized primarily for automotive-related noise sources.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed acoustic metamaterials with nanoscale precision that can selectively filter urban noise frequencies. Their technology utilizes periodic arrangements of resonant cells with tailored geometries at the nanoscale, creating phononic bandgaps that block specific sound frequencies. These metamaterials are designed as modular panels that can be integrated into building facades, traffic barriers, and urban infrastructure. Fraunhofer's approach combines computational modeling with advanced manufacturing techniques like nanoimprinting and 3D laser lithography to create hierarchical structures that can absorb low-frequency noise (20-200 Hz) typically challenging for conventional materials. Their solutions incorporate gradient-index metamaterials that can redirect sound waves away from protected areas, effectively creating acoustic "cloaks" around urban spaces requiring noise protection.

Strengths: Industry-leading manufacturing capabilities allow scaling from laboratory prototypes to commercial applications; extensive experience in technology transfer ensures practical implementation. Weaknesses: Higher production costs compared to conventional noise barriers; durability in outdoor urban environments still requires long-term validation studies.

Key Patents in Nanoarchitected Acoustic Materials

Device for reducing noise using sound meta-material

PatentPendingKR1020230035798A

Innovation

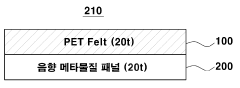

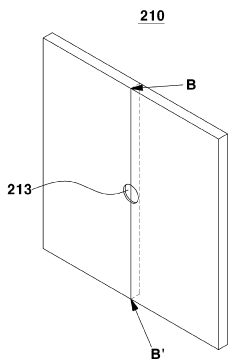

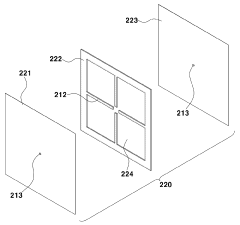

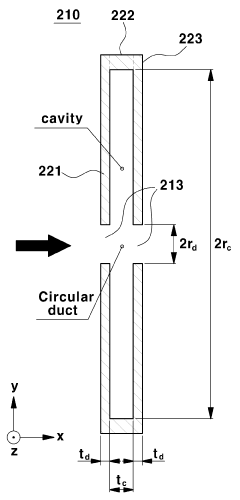

- A noise reduction device using acoustic metamaterials with a fastening structure that includes a metamaterial panel layer, sound absorbing layer, and reinforcing parts, configured to form a housing that can be easily fastened and tuned for specific frequency bands.

Noise reduction material using acoustic meta-material

PatentInactiveKR1020130051696A

Innovation

- A noise reduction material using an acoustic meta-material lens with controlled refractive index, embedded in a base material, changes the direction of acoustic waves to reduce noise by altering their refractive index to a negative value, utilizing a filler with lower impedance to reflect or discharge noise outside.

Environmental Impact Assessment of Metamaterial Implementation

The implementation of nanoarchitected mechanical metamaterials for noise reduction in urban environments necessitates a comprehensive environmental impact assessment. These advanced materials, while promising significant acoustic benefits, may introduce both positive and negative environmental consequences throughout their lifecycle.

The primary environmental benefit of metamaterial implementation is the potential reduction in noise pollution, which is increasingly recognized as an environmental hazard affecting both human health and urban ecosystems. By effectively absorbing and redirecting sound waves, these materials could significantly decrease ambient noise levels in densely populated areas, potentially reducing stress-related health issues and improving quality of life for urban residents.

From a manufacturing perspective, the production of nanoarchitected metamaterials involves sophisticated processes that may require substantial energy inputs and specialized materials. The environmental footprint of these manufacturing processes must be carefully evaluated, particularly regarding energy consumption, greenhouse gas emissions, and the use of potentially hazardous nanomaterials. Current life cycle assessments suggest that the energy intensity of precision nanofabrication techniques may partially offset the environmental benefits unless powered by renewable energy sources.

Material composition presents another critical environmental consideration. Many metamaterial designs incorporate metals, polymers, or composite materials that may pose challenges for recycling or biodegradation. The potential for nanoparticle release during weathering or at end-of-life stages requires thorough investigation, as the ecological impacts of engineered nanomaterials remain incompletely understood. Recent research indicates that careful material selection can mitigate these risks, with some bioinspired metamaterial designs utilizing biodegradable polymers showing promising environmental profiles.

Long-term durability and maintenance requirements also factor into the environmental assessment. Materials that maintain acoustic performance over extended periods without requiring frequent replacement or energy-intensive maintenance would offer superior environmental benefits. Preliminary weathering studies suggest that properly engineered metamaterials can maintain structural integrity and functional properties under typical urban environmental conditions, though more extensive field testing is needed.

The scalability of metamaterial solutions presents both opportunities and challenges from an environmental perspective. While localized implementations may have minimal environmental impact, widespread deployment across urban infrastructure would amplify both benefits and potential risks. Modeling studies suggest that strategic implementation in urban acoustic hotspots could maximize noise reduction benefits while minimizing material usage and associated environmental impacts.

The primary environmental benefit of metamaterial implementation is the potential reduction in noise pollution, which is increasingly recognized as an environmental hazard affecting both human health and urban ecosystems. By effectively absorbing and redirecting sound waves, these materials could significantly decrease ambient noise levels in densely populated areas, potentially reducing stress-related health issues and improving quality of life for urban residents.

From a manufacturing perspective, the production of nanoarchitected metamaterials involves sophisticated processes that may require substantial energy inputs and specialized materials. The environmental footprint of these manufacturing processes must be carefully evaluated, particularly regarding energy consumption, greenhouse gas emissions, and the use of potentially hazardous nanomaterials. Current life cycle assessments suggest that the energy intensity of precision nanofabrication techniques may partially offset the environmental benefits unless powered by renewable energy sources.

Material composition presents another critical environmental consideration. Many metamaterial designs incorporate metals, polymers, or composite materials that may pose challenges for recycling or biodegradation. The potential for nanoparticle release during weathering or at end-of-life stages requires thorough investigation, as the ecological impacts of engineered nanomaterials remain incompletely understood. Recent research indicates that careful material selection can mitigate these risks, with some bioinspired metamaterial designs utilizing biodegradable polymers showing promising environmental profiles.

Long-term durability and maintenance requirements also factor into the environmental assessment. Materials that maintain acoustic performance over extended periods without requiring frequent replacement or energy-intensive maintenance would offer superior environmental benefits. Preliminary weathering studies suggest that properly engineered metamaterials can maintain structural integrity and functional properties under typical urban environmental conditions, though more extensive field testing is needed.

The scalability of metamaterial solutions presents both opportunities and challenges from an environmental perspective. While localized implementations may have minimal environmental impact, widespread deployment across urban infrastructure would amplify both benefits and potential risks. Modeling studies suggest that strategic implementation in urban acoustic hotspots could maximize noise reduction benefits while minimizing material usage and associated environmental impacts.

Scalability and Manufacturing Considerations

The scalability and manufacturing of nanoarchitected mechanical metamaterials present significant challenges that must be addressed for widespread urban noise reduction applications. Current fabrication methods such as two-photon lithography and direct laser writing offer exceptional precision but remain limited to laboratory-scale production. These techniques, while capable of creating intricate nanoscale structures with acoustic-dampening properties, typically produce samples measuring only a few cubic centimeters, insufficient for urban implementation.

Transitioning from laboratory prototypes to commercial-scale production requires substantial process optimization. Additive manufacturing technologies show promise, with recent advancements in micro-stereolithography and projection micro-stereolithography enabling faster production of metamaterial structures. However, these methods still face resolution limitations when attempting to maintain nanoscale features across larger volumes.

Roll-to-roll manufacturing represents a potential breakthrough for scaling production, particularly for metamaterial films and coatings that could be applied to urban infrastructure. This approach allows continuous fabrication of nanostructured materials on flexible substrates, though maintaining precise geometric control remains challenging. Self-assembly techniques utilizing block copolymers offer another avenue for large-scale production, where nanoscale patterns form spontaneously under controlled conditions.

Material selection significantly impacts both manufacturing feasibility and acoustic performance. While polymeric materials offer easier processing, their acoustic properties may be inferior to ceramic or metallic alternatives. Hybrid approaches using polymer templates subsequently converted to more robust materials through coating or infiltration processes show promise for balancing manufacturability with performance.

Cost considerations remain paramount for urban implementation. Current production costs for nanoarchitected metamaterials range from $1,000-10,000 per square meter, prohibitively expensive for large-scale urban deployment. Achieving economically viable solutions requires either dramatic cost reductions in existing methods or development of entirely new manufacturing paradigms.

Quality control presents another critical challenge, as acoustic performance depends on maintaining precise structural parameters across large areas. Defects or variations in the nanoscale architecture can significantly compromise noise reduction capabilities. Advanced in-line inspection techniques utilizing machine vision and AI-based defect detection will be essential for ensuring consistent performance in mass-produced metamaterials.

Environmental durability must also be addressed, as urban applications expose materials to weathering, pollution, and mechanical stress. Developing protective coatings or encapsulation methods that preserve acoustic properties while enhancing durability represents an important research direction for practical implementation.

Transitioning from laboratory prototypes to commercial-scale production requires substantial process optimization. Additive manufacturing technologies show promise, with recent advancements in micro-stereolithography and projection micro-stereolithography enabling faster production of metamaterial structures. However, these methods still face resolution limitations when attempting to maintain nanoscale features across larger volumes.

Roll-to-roll manufacturing represents a potential breakthrough for scaling production, particularly for metamaterial films and coatings that could be applied to urban infrastructure. This approach allows continuous fabrication of nanostructured materials on flexible substrates, though maintaining precise geometric control remains challenging. Self-assembly techniques utilizing block copolymers offer another avenue for large-scale production, where nanoscale patterns form spontaneously under controlled conditions.

Material selection significantly impacts both manufacturing feasibility and acoustic performance. While polymeric materials offer easier processing, their acoustic properties may be inferior to ceramic or metallic alternatives. Hybrid approaches using polymer templates subsequently converted to more robust materials through coating or infiltration processes show promise for balancing manufacturability with performance.

Cost considerations remain paramount for urban implementation. Current production costs for nanoarchitected metamaterials range from $1,000-10,000 per square meter, prohibitively expensive for large-scale urban deployment. Achieving economically viable solutions requires either dramatic cost reductions in existing methods or development of entirely new manufacturing paradigms.

Quality control presents another critical challenge, as acoustic performance depends on maintaining precise structural parameters across large areas. Defects or variations in the nanoscale architecture can significantly compromise noise reduction capabilities. Advanced in-line inspection techniques utilizing machine vision and AI-based defect detection will be essential for ensuring consistent performance in mass-produced metamaterials.

Environmental durability must also be addressed, as urban applications expose materials to weathering, pollution, and mechanical stress. Developing protective coatings or encapsulation methods that preserve acoustic properties while enhancing durability represents an important research direction for practical implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!