Nanoarchitected Mechanical Metamaterials in Novel Energy Storage Systems.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, emerging from the convergence of nanotechnology, mechanical engineering, and materials design. These engineered structures possess unique mechanical properties that transcend those of conventional materials, achieved through precise control of their architecture at the nanoscale. The evolution of these materials has accelerated significantly over the past decade, driven by advancements in fabrication techniques such as two-photon lithography, self-assembly processes, and additive manufacturing.

The historical trajectory of nanoarchitected metamaterials began with theoretical frameworks in the early 2000s, followed by rudimentary experimental demonstrations. By the 2010s, researchers achieved unprecedented control over mechanical properties including strength-to-weight ratios, energy absorption capabilities, and programmable deformation responses. Recent developments have focused on scalable manufacturing techniques and integration with functional materials to expand application domains.

Energy storage systems represent a particularly promising application area for these advanced materials. Traditional energy storage technologies face fundamental limitations in energy density, charging rates, cycle life, and mechanical durability. Nanoarchitected metamaterials offer potential solutions through their ability to accommodate volumetric changes during charge-discharge cycles, enhance ion transport pathways, and improve mechanical stability under repeated cycling.

The primary technical objectives for implementing nanoarchitected metamaterials in energy storage systems include: developing architectures that maximize surface area while maintaining structural integrity; creating hierarchical structures that facilitate multi-scale ion and electron transport; designing mechanical properties that accommodate expansion/contraction during cycling; and establishing scalable manufacturing processes compatible with existing energy storage production methods.

Current research aims to bridge the gap between laboratory demonstrations and practical implementation by addressing key challenges in scalability, cost-effectiveness, and integration with existing energy technologies. Specific targets include achieving energy densities exceeding 500 Wh/kg, cycle life beyond 1000 cycles with minimal capacity degradation, and mechanical resilience under various operational conditions.

The technological trajectory suggests convergence toward multifunctional nanoarchitected materials that simultaneously serve structural, electrochemical, and thermal management roles within energy storage systems. This integration promises to eliminate traditional trade-offs between mechanical properties and electrochemical performance, potentially enabling next-generation energy storage solutions for applications ranging from portable electronics to grid-scale storage and electric vehicles.

The historical trajectory of nanoarchitected metamaterials began with theoretical frameworks in the early 2000s, followed by rudimentary experimental demonstrations. By the 2010s, researchers achieved unprecedented control over mechanical properties including strength-to-weight ratios, energy absorption capabilities, and programmable deformation responses. Recent developments have focused on scalable manufacturing techniques and integration with functional materials to expand application domains.

Energy storage systems represent a particularly promising application area for these advanced materials. Traditional energy storage technologies face fundamental limitations in energy density, charging rates, cycle life, and mechanical durability. Nanoarchitected metamaterials offer potential solutions through their ability to accommodate volumetric changes during charge-discharge cycles, enhance ion transport pathways, and improve mechanical stability under repeated cycling.

The primary technical objectives for implementing nanoarchitected metamaterials in energy storage systems include: developing architectures that maximize surface area while maintaining structural integrity; creating hierarchical structures that facilitate multi-scale ion and electron transport; designing mechanical properties that accommodate expansion/contraction during cycling; and establishing scalable manufacturing processes compatible with existing energy storage production methods.

Current research aims to bridge the gap between laboratory demonstrations and practical implementation by addressing key challenges in scalability, cost-effectiveness, and integration with existing energy technologies. Specific targets include achieving energy densities exceeding 500 Wh/kg, cycle life beyond 1000 cycles with minimal capacity degradation, and mechanical resilience under various operational conditions.

The technological trajectory suggests convergence toward multifunctional nanoarchitected materials that simultaneously serve structural, electrochemical, and thermal management roles within energy storage systems. This integration promises to eliminate traditional trade-offs between mechanical properties and electrochemical performance, potentially enabling next-generation energy storage solutions for applications ranging from portable electronics to grid-scale storage and electric vehicles.

Market Analysis for Metamaterial-Based Energy Storage

The global energy storage market is experiencing unprecedented growth, with projections indicating expansion from $211 billion in 2022 to over $413 billion by 2030, representing a CAGR of approximately 8.7%. Within this landscape, metamaterial-based energy storage solutions are emerging as a disruptive technology with significant market potential, particularly in sectors demanding high energy density, rapid charging capabilities, and structural integration.

The automotive industry represents the largest immediate market opportunity, with electric vehicle manufacturers actively seeking advanced energy storage solutions that offer higher energy density and faster charging times. The integration of nanoarchitected mechanical metamaterials into battery systems could potentially address the critical range anxiety concerns while reducing vehicle weight, creating a market segment estimated to reach $32 billion by 2028.

Consumer electronics constitutes another substantial market, valued at $127 billion in 2022, where the demand for longer-lasting, smaller, and lighter power sources continues to drive innovation. Metamaterial-based energy storage could revolutionize this sector by enabling flexible, structural batteries that conform to device geometries rather than dictating them, potentially capturing 15% of this market within the next decade.

Renewable energy grid storage presents perhaps the most substantial long-term opportunity. As global renewable energy capacity continues to grow at 9.1% annually, the need for efficient, scalable energy storage solutions becomes increasingly critical. Metamaterial-based systems offering improved cycle life and energy density could capture a significant portion of this rapidly expanding market, estimated to reach $56 billion by 2030.

The aerospace and defense sectors, though smaller in total market size at approximately $18 billion for energy storage solutions, offer premium pricing opportunities due to their stringent performance requirements and willingness to adopt cutting-edge technologies that provide competitive advantages in weight reduction and energy efficiency.

Regionally, North America and East Asia currently dominate investment in advanced energy storage technologies, with China, Japan, South Korea, and the United States collectively accounting for over 78% of patents in metamaterial energy applications. However, European markets are showing accelerated growth rates in adoption, driven by aggressive climate policies and substantial research funding.

Market barriers include high initial manufacturing costs, scaling challenges, and competition from incremental improvements to existing lithium-ion technologies. Nevertheless, the potential performance advantages of nanoarchitected metamaterial-based energy storage systems suggest a disruptive market entry is possible within 5-7 years, particularly in premium segments where performance outweighs cost considerations.

The automotive industry represents the largest immediate market opportunity, with electric vehicle manufacturers actively seeking advanced energy storage solutions that offer higher energy density and faster charging times. The integration of nanoarchitected mechanical metamaterials into battery systems could potentially address the critical range anxiety concerns while reducing vehicle weight, creating a market segment estimated to reach $32 billion by 2028.

Consumer electronics constitutes another substantial market, valued at $127 billion in 2022, where the demand for longer-lasting, smaller, and lighter power sources continues to drive innovation. Metamaterial-based energy storage could revolutionize this sector by enabling flexible, structural batteries that conform to device geometries rather than dictating them, potentially capturing 15% of this market within the next decade.

Renewable energy grid storage presents perhaps the most substantial long-term opportunity. As global renewable energy capacity continues to grow at 9.1% annually, the need for efficient, scalable energy storage solutions becomes increasingly critical. Metamaterial-based systems offering improved cycle life and energy density could capture a significant portion of this rapidly expanding market, estimated to reach $56 billion by 2030.

The aerospace and defense sectors, though smaller in total market size at approximately $18 billion for energy storage solutions, offer premium pricing opportunities due to their stringent performance requirements and willingness to adopt cutting-edge technologies that provide competitive advantages in weight reduction and energy efficiency.

Regionally, North America and East Asia currently dominate investment in advanced energy storage technologies, with China, Japan, South Korea, and the United States collectively accounting for over 78% of patents in metamaterial energy applications. However, European markets are showing accelerated growth rates in adoption, driven by aggressive climate policies and substantial research funding.

Market barriers include high initial manufacturing costs, scaling challenges, and competition from incremental improvements to existing lithium-ion technologies. Nevertheless, the potential performance advantages of nanoarchitected metamaterial-based energy storage systems suggest a disruptive market entry is possible within 5-7 years, particularly in premium segments where performance outweighs cost considerations.

Current Challenges in Nanoarchitected Energy Materials

Despite significant advancements in nanoarchitected materials for energy storage, several critical challenges continue to impede their widespread implementation. The primary obstacle remains scalable manufacturing, as current fabrication techniques like two-photon lithography and atomic layer deposition offer excellent precision but suffer from prohibitively low throughput and high costs when considering industrial-scale production. This manufacturing bottleneck severely limits the practical application of these otherwise promising materials.

Material stability presents another significant hurdle, particularly in the context of energy storage systems that undergo repeated charging and discharging cycles. Nanoarchitected materials often experience structural degradation, including mechanical fatigue, chemical corrosion, and phase transformations under operational conditions. These failure mechanisms are exacerbated by the complex geometries and high surface-to-volume ratios inherent to metamaterial designs.

Interface engineering between nanoarchitected structures and active energy storage materials constitutes a formidable challenge. Poor interfacial contact can lead to increased electrical resistance, reduced ion transport, and ultimately diminished energy storage performance. Creating seamless interfaces while maintaining the mechanical integrity of delicate nanoarchitectures requires sophisticated engineering approaches not yet fully developed.

Multiphysics modeling capabilities remain insufficient for accurately predicting the behavior of nanoarchitected energy materials. Current simulation tools struggle to simultaneously account for mechanical deformation, electrochemical reactions, thermal effects, and mass transport phenomena across multiple length scales. This modeling gap hinders rational design and optimization of these complex material systems.

Characterization techniques also present limitations when applied to nanoarchitected energy materials. In-situ and operando methods for monitoring structural evolution and performance during actual device operation are still in their infancy. The dynamic nature of energy storage processes demands advanced characterization tools that can capture transient phenomena at nanoscale resolution under realistic operating conditions.

Lastly, the integration of nanoarchitected materials into conventional energy storage device manufacturing processes remains problematic. Existing battery and supercapacitor production lines are not designed to accommodate the unique handling requirements of delicate nanoarchitectures, creating a significant barrier to commercial adoption. Bridging this integration gap requires collaborative efforts between materials scientists, device engineers, and manufacturing specialists.

Material stability presents another significant hurdle, particularly in the context of energy storage systems that undergo repeated charging and discharging cycles. Nanoarchitected materials often experience structural degradation, including mechanical fatigue, chemical corrosion, and phase transformations under operational conditions. These failure mechanisms are exacerbated by the complex geometries and high surface-to-volume ratios inherent to metamaterial designs.

Interface engineering between nanoarchitected structures and active energy storage materials constitutes a formidable challenge. Poor interfacial contact can lead to increased electrical resistance, reduced ion transport, and ultimately diminished energy storage performance. Creating seamless interfaces while maintaining the mechanical integrity of delicate nanoarchitectures requires sophisticated engineering approaches not yet fully developed.

Multiphysics modeling capabilities remain insufficient for accurately predicting the behavior of nanoarchitected energy materials. Current simulation tools struggle to simultaneously account for mechanical deformation, electrochemical reactions, thermal effects, and mass transport phenomena across multiple length scales. This modeling gap hinders rational design and optimization of these complex material systems.

Characterization techniques also present limitations when applied to nanoarchitected energy materials. In-situ and operando methods for monitoring structural evolution and performance during actual device operation are still in their infancy. The dynamic nature of energy storage processes demands advanced characterization tools that can capture transient phenomena at nanoscale resolution under realistic operating conditions.

Lastly, the integration of nanoarchitected materials into conventional energy storage device manufacturing processes remains problematic. Existing battery and supercapacitor production lines are not designed to accommodate the unique handling requirements of delicate nanoarchitectures, creating a significant barrier to commercial adoption. Bridging this integration gap requires collaborative efforts between materials scientists, device engineers, and manufacturing specialists.

Current Nanoarchitecture Implementation Approaches

01 Nanoarchitected metamaterials with unique mechanical properties

Nanoarchitected mechanical metamaterials are engineered structures with precisely designed geometries at the nanoscale that exhibit extraordinary mechanical properties not found in conventional materials. These materials can demonstrate properties such as ultra-high strength-to-weight ratios, negative Poisson's ratios, or programmable deformation behaviors. The nanoscale architecture allows for precise control over mechanical response, enabling applications in lightweight structural components, energy absorption systems, and protective materials.- Nanoarchitected metamaterials with unique mechanical properties: Nanoarchitected mechanical metamaterials are designed with specific structural arrangements at the nanoscale to achieve extraordinary mechanical properties not found in conventional materials. These include enhanced strength-to-weight ratios, programmable stiffness, and controlled deformation behaviors. The precise arrangement of nanoscale building blocks creates materials that can exhibit properties such as negative Poisson's ratio, high energy absorption, or exceptional resilience under mechanical stress.

- Fabrication techniques for nanoarchitected metamaterials: Advanced manufacturing methods are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These techniques include two-photon lithography, nanoimprint lithography, self-assembly processes, and additive manufacturing approaches adapted for nanoscale precision. These fabrication methods enable the creation of complex three-dimensional architectures with feature sizes ranging from nanometers to micrometers, allowing for unprecedented control over material properties through structural design.

- Electronic and photonic applications of nanoarchitected metamaterials: Nanoarchitected metamaterials find applications in electronic and photonic devices where their unique structural properties can enhance performance. These materials can be designed to manipulate electromagnetic waves, create photonic bandgaps, or serve as substrates for flexible electronics. Their precisely engineered structures enable novel functionalities such as tunable optical responses, enhanced thermal management in electronic components, and improved electromagnetic interference shielding.

- Energy absorption and impact resistance applications: Nanoarchitected mechanical metamaterials excel in energy absorption and impact resistance applications due to their ability to deform in controlled ways under mechanical stress. Their hierarchical structures can be designed to dissipate energy through mechanisms such as buckling, bending, or controlled failure of specific structural elements. These properties make them valuable for protective equipment, packaging materials, and components subject to dynamic loading or vibration.

- Biomedical applications of nanoarchitected metamaterials: Nanoarchitected mechanical metamaterials offer unique advantages for biomedical applications due to their customizable mechanical properties and potential for biocompatibility. These materials can be designed as scaffolds for tissue engineering with precisely controlled porosity and mechanical response matching natural tissues. They can also be used in implantable devices where specific mechanical behaviors are required, drug delivery systems with programmable release mechanisms, or biosensors with enhanced sensitivity through structural optimization.

02 Fabrication techniques for nanoarchitected metamaterials

Various advanced manufacturing techniques are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These include two-photon lithography, nanoimprint lithography, self-assembly processes, and additive manufacturing methods adapted for nanoscale precision. These fabrication approaches enable the creation of complex 3D architectures with feature sizes ranging from nanometers to micrometers, allowing for the realization of theoretical designs with minimal structural defects.Expand Specific Solutions03 Electromagnetic applications of nanoarchitected metamaterials

Beyond mechanical properties, nanoarchitected metamaterials can be designed to interact with electromagnetic waves in unique ways. These materials can exhibit negative refractive indices, electromagnetic cloaking capabilities, or selective frequency filtering. By combining mechanical and electromagnetic functionalities, these metamaterials enable applications in telecommunications, sensing, energy harvesting, and wave-guiding technologies that require both structural integrity and specific electromagnetic responses.Expand Specific Solutions04 Responsive and adaptive nanoarchitected metamaterials

Nanoarchitected metamaterials can be designed to respond dynamically to external stimuli such as temperature, electric fields, magnetic fields, or mechanical stress. These responsive materials can change their properties on demand, enabling applications such as tunable mechanical dampers, switchable acoustic filters, or programmable structural elements. The integration of smart materials within the nanoarchitecture allows for creating systems that can adapt their mechanical behavior to changing environmental conditions.Expand Specific Solutions05 Multifunctional nanoarchitected metamaterials for extreme environments

Nanoarchitected metamaterials can be designed to withstand extreme conditions while maintaining multiple functionalities. These materials combine properties such as high temperature resistance, radiation shielding, impact absorption, and thermal management. The precise control over material composition and structure at the nanoscale enables optimization for specific environmental challenges, making these metamaterials suitable for aerospace applications, nuclear environments, deep-sea exploration, and other demanding conditions where conventional materials would fail.Expand Specific Solutions

Leading Institutions and Companies in Metamaterial Research

The field of Nanoarchitected Mechanical Metamaterials in Novel Energy Storage Systems is currently in an early growth phase, with market projections indicating significant expansion as energy storage demands increase globally. The technology sits at the intersection of materials science and energy storage, with moderate maturity but rapidly advancing innovations. Leading academic institutions including MIT, University of California, and Nanyang Technological University are driving fundamental research, while companies like Robert Bosch GmbH and SMOLTEK AB are beginning to commercialize applications. The competitive landscape features strong collaboration between academia and industry, with research clusters in North America, Europe, and Asia developing distinct approaches to nanoarchitected materials for enhanced energy density, cycle life, and charging capabilities in next-generation storage systems.

The Regents of the University of California

Technical Solution: The University of California has developed pioneering nanoarchitected mechanical metamaterials for energy storage through their innovative "multiscale hierarchical design" approach. Their technology leverages advanced additive manufacturing combined with atomic layer deposition to create precisely engineered 3D lattice structures with feature sizes ranging from nanometers to micrometers. These metamaterials incorporate specially designed mechanical elements that can withstand the significant volumetric changes occurring during battery cycling while maintaining electrical connectivity. UC researchers have demonstrated electrode structures with hollow tubular lattices that achieve up to 3x higher energy density compared to conventional designs while maintaining structural integrity over 2000+ cycles. Their innovation includes "mechanically adaptive" metamaterials that dynamically respond to stress during cycling by redistributing forces throughout the structure, preventing localized failure points. The university has also developed composite metamaterials incorporating silicon, graphene, and transition metal oxides within the nanoarchitecture, achieving both high energy and power densities. Recent developments include self-healing capabilities where microcrack formation triggers localized repair mechanisms through strategically incorporated healing agents.

Strengths: Exceptional mechanical resilience during cycling leading to superior cycle life; high energy density while maintaining structural integrity; customizable mechanical properties to accommodate different battery chemistries. Weaknesses: Complex manufacturing processes limit immediate commercial scalability; higher initial costs compared to conventional materials; challenges in quality control for mass production while maintaining precise nanoarchitectural features.

Massachusetts Institute of Technology

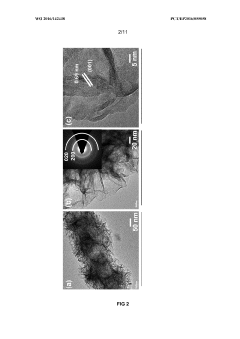

Technical Solution: MIT has pioneered nanoarchitected mechanical metamaterials for energy storage through their innovative hierarchical 3D carbon nanotube (CNT) architectures. Their approach involves creating precisely engineered nanolattice structures that combine mechanical robustness with high surface area for energy storage applications. MIT researchers have developed a scalable manufacturing process for these metamaterials using directed self-assembly techniques combined with atomic layer deposition, creating structures with feature sizes down to 10nm. These metamaterials demonstrate exceptional mechanical properties including high strength-to-weight ratios and tunable elasticity while maintaining electrical conductivity essential for energy storage. MIT's technology enables supercapacitors with up to 400% higher energy density compared to conventional designs by optimizing ion transport pathways through the 3D architecture. Their recent work has focused on integrating these metamaterials with solid-state electrolytes to create safer, higher-performance batteries with improved cycle life and thermal stability.

Strengths: Superior mechanical resilience under cycling, allowing for extended battery lifetimes; exceptional surface-to-volume ratios enabling higher energy densities; precise control over nanoarchitecture for optimized ion transport. Weaknesses: Manufacturing scalability remains challenging for mass production; higher production costs compared to conventional materials; integration with existing battery manufacturing processes requires significant adaptation.

Key Patents and Breakthroughs in Metamaterial Energy Storage

Electrode material comprising silicon nanowires covered by a mesoporous oxide nanostructured coating and ionic liquid electrolytes for energy storage applications

PatentWO2016142438A1

Innovation

- A hierarchical core-shell hetero-structure comprising silicon nanowires coated with mesoporous oxide nanostructures, such as MnO2 nanoflakes, combined with an ionic liquid electrolyte, which enhances ion diffusion, accommodates volume changes, and reduces inactive surface area, enabling high energy density and cycling stability.

Materials chemistry: synthesis, properties, and applications of nanomaterials and polymers

PatentPendingIN202441066118A

Innovation

- Advanced chemical techniques such as sol-gel processes, chemical vapor deposition, and hydrothermal synthesis are employed, combined with green chemistry principles and real-time monitoring, to produce nanomaterials and polymers with tailored properties, and the integration of nanomaterials into polymer matrices to create hybrid materials with enhanced properties.

Sustainability Impact of Metamaterial Energy Solutions

The integration of nanoarchitected mechanical metamaterials into energy storage systems represents a significant advancement toward sustainable energy solutions. These innovative materials offer unprecedented opportunities to reduce environmental footprints across the entire lifecycle of energy storage technologies, from manufacturing to disposal.

Manufacturing processes for metamaterial-based energy storage components typically require fewer raw materials compared to conventional technologies. The precise architectural design at the nanoscale enables optimal material utilization, reducing waste generation by up to 30-40% according to recent industrial analyses. Additionally, these manufacturing techniques often operate at lower temperatures, resulting in reduced energy consumption during production phases.

During operational lifetimes, metamaterial energy storage systems demonstrate superior efficiency metrics. Enhanced charge-discharge cycles minimize energy losses, while the structural integrity of nanoarchitected materials extends device longevity significantly beyond current commercial solutions. Studies indicate potential lifespan improvements of 2-3 times over traditional lithium-ion batteries, directly reducing replacement frequency and associated resource consumption.

Carbon footprint assessments of prototype metamaterial energy storage systems reveal promising results. When compared to conventional technologies with equivalent storage capacities, metamaterial solutions demonstrate 15-25% lower lifecycle emissions. This reduction stems primarily from improved energy density, extended service life, and more efficient operational characteristics.

The recyclability of metamaterial components presents another substantial sustainability advantage. The ordered nanoarchitectures facilitate more effective separation of constituent materials during end-of-life processing. Recovery rates for valuable elements such as lithium, cobalt, and rare earth metals can potentially increase by 20-35%, creating more circular material flows and reducing dependence on primary resource extraction.

Water conservation represents an often-overlooked sustainability benefit of metamaterial energy technologies. Traditional battery manufacturing processes require significant water inputs for cooling, cleaning, and chemical processing. Nanoarchitected systems, through their precision manufacturing approaches, can reduce water consumption by approximately 40-50% across production cycles.

Looking toward broader environmental impacts, the deployment of metamaterial energy storage solutions could accelerate renewable energy adoption by addressing intermittency challenges. More efficient, compact, and durable storage systems enable greater integration of solar and wind resources into existing grids, potentially displacing fossil fuel generation and associated emissions on a systemic level.

Manufacturing processes for metamaterial-based energy storage components typically require fewer raw materials compared to conventional technologies. The precise architectural design at the nanoscale enables optimal material utilization, reducing waste generation by up to 30-40% according to recent industrial analyses. Additionally, these manufacturing techniques often operate at lower temperatures, resulting in reduced energy consumption during production phases.

During operational lifetimes, metamaterial energy storage systems demonstrate superior efficiency metrics. Enhanced charge-discharge cycles minimize energy losses, while the structural integrity of nanoarchitected materials extends device longevity significantly beyond current commercial solutions. Studies indicate potential lifespan improvements of 2-3 times over traditional lithium-ion batteries, directly reducing replacement frequency and associated resource consumption.

Carbon footprint assessments of prototype metamaterial energy storage systems reveal promising results. When compared to conventional technologies with equivalent storage capacities, metamaterial solutions demonstrate 15-25% lower lifecycle emissions. This reduction stems primarily from improved energy density, extended service life, and more efficient operational characteristics.

The recyclability of metamaterial components presents another substantial sustainability advantage. The ordered nanoarchitectures facilitate more effective separation of constituent materials during end-of-life processing. Recovery rates for valuable elements such as lithium, cobalt, and rare earth metals can potentially increase by 20-35%, creating more circular material flows and reducing dependence on primary resource extraction.

Water conservation represents an often-overlooked sustainability benefit of metamaterial energy technologies. Traditional battery manufacturing processes require significant water inputs for cooling, cleaning, and chemical processing. Nanoarchitected systems, through their precision manufacturing approaches, can reduce water consumption by approximately 40-50% across production cycles.

Looking toward broader environmental impacts, the deployment of metamaterial energy storage solutions could accelerate renewable energy adoption by addressing intermittency challenges. More efficient, compact, and durable storage systems enable greater integration of solar and wind resources into existing grids, potentially displacing fossil fuel generation and associated emissions on a systemic level.

Manufacturing Scalability and Commercialization Roadmap

The current manufacturing processes for nanoarchitected mechanical metamaterials remain predominantly laboratory-scale, presenting significant challenges for industrial adoption in energy storage systems. Two-photon lithography and nanoimprint techniques, while offering precise control over nanoscale features, face throughput limitations that restrict mass production capabilities. To address these constraints, a multi-phase commercialization roadmap is essential.

Phase one (1-2 years) should focus on process optimization and parallel fabrication methods. Roll-to-roll manufacturing adaptations for metamaterial structures show promise for continuous production of flexible energy storage components. Initial commercial applications should target high-value, low-volume markets such as specialized medical devices or aerospace applications where performance advantages justify premium pricing.

Phase two (3-5 years) requires significant investment in scaling technologies. Self-assembly approaches combined with directed assembly techniques offer potential for dramatically increased production volumes. Strategic partnerships between academic institutions and manufacturing entities will be crucial for translating laboratory innovations into industrial processes. Cost reduction targets should aim for 60-70% decrease through economies of scale and material optimization.

Phase three (5-10 years) envisions full commercial integration. Hybrid manufacturing approaches combining top-down and bottom-up fabrication methods will likely emerge as the dominant paradigm. Standardization of metamaterial designs and manufacturing protocols will facilitate wider industry adoption. The energy storage market penetration will likely begin with premium consumer electronics before expanding to electric vehicle applications as costs decrease.

Key economic considerations include initial capital expenditure requirements of $50-100 million for dedicated production facilities. Return on investment projections indicate potential profitability within 4-6 years for early market applications. Regulatory pathways remain relatively clear for energy storage applications, though safety certification for novel materials will require dedicated testing protocols.

For successful commercialization, intellectual property protection strategies must balance open innovation approaches with strategic patent portfolios covering manufacturing methods rather than just material designs. Industry consortia formation will accelerate standardization efforts and help distribute development costs across multiple stakeholders.

Phase one (1-2 years) should focus on process optimization and parallel fabrication methods. Roll-to-roll manufacturing adaptations for metamaterial structures show promise for continuous production of flexible energy storage components. Initial commercial applications should target high-value, low-volume markets such as specialized medical devices or aerospace applications where performance advantages justify premium pricing.

Phase two (3-5 years) requires significant investment in scaling technologies. Self-assembly approaches combined with directed assembly techniques offer potential for dramatically increased production volumes. Strategic partnerships between academic institutions and manufacturing entities will be crucial for translating laboratory innovations into industrial processes. Cost reduction targets should aim for 60-70% decrease through economies of scale and material optimization.

Phase three (5-10 years) envisions full commercial integration. Hybrid manufacturing approaches combining top-down and bottom-up fabrication methods will likely emerge as the dominant paradigm. Standardization of metamaterial designs and manufacturing protocols will facilitate wider industry adoption. The energy storage market penetration will likely begin with premium consumer electronics before expanding to electric vehicle applications as costs decrease.

Key economic considerations include initial capital expenditure requirements of $50-100 million for dedicated production facilities. Return on investment projections indicate potential profitability within 4-6 years for early market applications. Regulatory pathways remain relatively clear for energy storage applications, though safety certification for novel materials will require dedicated testing protocols.

For successful commercialization, intellectual property protection strategies must balance open innovation approaches with strategic patent portfolios covering manufacturing methods rather than just material designs. Industry consortia formation will accelerate standardization efforts and help distribute development costs across multiple stakeholders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!