Impact of Nanoarchitected Mechanical Metamaterials on Aviation Safety.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, emerging from the convergence of nanotechnology, mechanical engineering, and materials design. These engineered structures possess unique mechanical properties that transcend those of conventional materials, achieved through precise control of their architecture at the nanoscale. The development trajectory of these materials spans several decades, beginning with theoretical frameworks in the 1980s and accelerating rapidly with advancements in nanofabrication techniques in the early 2000s.

The evolution of nanoarchitected metamaterials has been marked by significant breakthroughs in fabrication methods, including two-photon lithography, self-assembly processes, and additive manufacturing techniques. These advancements have enabled increasingly complex and precise control over material structures at previously unattainable scales, allowing for the creation of materials with programmable mechanical responses.

Aviation safety represents a critical application domain for these innovative materials, where traditional materials often face limitations in extreme operating conditions. The aviation industry continually seeks materials that offer superior strength-to-weight ratios, enhanced impact resistance, and adaptive responses to mechanical stresses—all characteristics that nanoarchitected metamaterials can potentially deliver.

The primary technical objectives for implementing nanoarchitected metamaterials in aviation safety applications include developing ultra-lightweight structural components with exceptional mechanical strength, creating energy-absorbing materials for crash protection, designing self-healing structures for damage mitigation, and engineering smart materials capable of responding adaptively to environmental changes or mechanical stresses.

Current research focuses on scaling production methods to meet industrial demands while maintaining nanoscale precision, addressing durability concerns in extreme aviation environments, and developing computational models that accurately predict mechanical behavior across multiple scales. These objectives align with broader aviation industry goals of improving fuel efficiency through weight reduction while simultaneously enhancing safety parameters.

The integration of nanoarchitected metamaterials into aviation safety systems represents a paradigm shift in how aircraft structures are conceptualized and designed. Rather than relying solely on material composition for desired properties, this approach leverages geometric arrangement at the nanoscale to achieve unprecedented mechanical performance. This fundamental shift promises to overcome longstanding engineering trade-offs between strength, weight, and functionality.

Looking forward, the technical trajectory points toward increasingly sophisticated multi-functional metamaterials that simultaneously address multiple aviation safety challenges, from impact resistance to thermal management and electromagnetic shielding, all within unified structural components.

The evolution of nanoarchitected metamaterials has been marked by significant breakthroughs in fabrication methods, including two-photon lithography, self-assembly processes, and additive manufacturing techniques. These advancements have enabled increasingly complex and precise control over material structures at previously unattainable scales, allowing for the creation of materials with programmable mechanical responses.

Aviation safety represents a critical application domain for these innovative materials, where traditional materials often face limitations in extreme operating conditions. The aviation industry continually seeks materials that offer superior strength-to-weight ratios, enhanced impact resistance, and adaptive responses to mechanical stresses—all characteristics that nanoarchitected metamaterials can potentially deliver.

The primary technical objectives for implementing nanoarchitected metamaterials in aviation safety applications include developing ultra-lightweight structural components with exceptional mechanical strength, creating energy-absorbing materials for crash protection, designing self-healing structures for damage mitigation, and engineering smart materials capable of responding adaptively to environmental changes or mechanical stresses.

Current research focuses on scaling production methods to meet industrial demands while maintaining nanoscale precision, addressing durability concerns in extreme aviation environments, and developing computational models that accurately predict mechanical behavior across multiple scales. These objectives align with broader aviation industry goals of improving fuel efficiency through weight reduction while simultaneously enhancing safety parameters.

The integration of nanoarchitected metamaterials into aviation safety systems represents a paradigm shift in how aircraft structures are conceptualized and designed. Rather than relying solely on material composition for desired properties, this approach leverages geometric arrangement at the nanoscale to achieve unprecedented mechanical performance. This fundamental shift promises to overcome longstanding engineering trade-offs between strength, weight, and functionality.

Looking forward, the technical trajectory points toward increasingly sophisticated multi-functional metamaterials that simultaneously address multiple aviation safety challenges, from impact resistance to thermal management and electromagnetic shielding, all within unified structural components.

Aviation Safety Market Demand Analysis

The aviation safety market is experiencing significant growth driven by increasing air traffic volumes and heightened safety regulations worldwide. According to recent industry analyses, the global aviation safety market was valued at approximately $2.5 billion in 2022 and is projected to reach $4.1 billion by 2028, representing a compound annual growth rate of 8.6%. This growth trajectory underscores the critical importance of continuous innovation in safety technologies and materials.

Commercial aviation's expansion, particularly in emerging economies across Asia-Pacific and Latin America, has intensified the demand for advanced safety solutions. The International Air Transport Association reports that passenger numbers are expected to double to 8.2 billion by 2037, creating unprecedented pressure on existing safety infrastructure and protocols.

Regulatory bodies including the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented increasingly stringent safety standards, compelling aircraft manufacturers and airlines to adopt cutting-edge materials and technologies. These regulations specifically target structural integrity, impact resistance, and fire safety—areas where nanoarchitected mechanical metamaterials show particular promise.

The industry's shift toward lightweight construction to improve fuel efficiency has created a significant market gap for materials that can maintain or enhance safety standards while reducing overall weight. Airlines face the dual challenge of meeting sustainability goals while ensuring passenger safety, creating a prime opportunity for innovative metamaterials that offer superior strength-to-weight ratios.

Risk mitigation remains a primary concern for aviation stakeholders, with insurance companies and investors demanding demonstrable improvements in safety metrics. The economic impact of safety failures extends beyond immediate damages to include reputational harm, regulatory penalties, and increased insurance premiums, collectively valued at billions annually across the industry.

Maintenance, repair, and overhaul (MRO) operations represent another substantial market segment, currently valued at $82 billion globally. The integration of self-diagnosing and self-healing nanoarchitected materials could significantly reduce maintenance costs and aircraft downtime, addressing a major pain point for commercial operators.

Consumer awareness and expectations regarding aviation safety have reached unprecedented levels, with 78% of passengers citing safety as their primary consideration when choosing airlines. This consumer-driven demand creates market pull for visible safety innovations that can be leveraged in marketing communications.

Military and defense aviation applications constitute a specialized but lucrative market segment, with defense departments worldwide allocating substantial budgets for advanced materials that enhance aircraft survivability and operational capabilities in extreme conditions.

Commercial aviation's expansion, particularly in emerging economies across Asia-Pacific and Latin America, has intensified the demand for advanced safety solutions. The International Air Transport Association reports that passenger numbers are expected to double to 8.2 billion by 2037, creating unprecedented pressure on existing safety infrastructure and protocols.

Regulatory bodies including the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented increasingly stringent safety standards, compelling aircraft manufacturers and airlines to adopt cutting-edge materials and technologies. These regulations specifically target structural integrity, impact resistance, and fire safety—areas where nanoarchitected mechanical metamaterials show particular promise.

The industry's shift toward lightweight construction to improve fuel efficiency has created a significant market gap for materials that can maintain or enhance safety standards while reducing overall weight. Airlines face the dual challenge of meeting sustainability goals while ensuring passenger safety, creating a prime opportunity for innovative metamaterials that offer superior strength-to-weight ratios.

Risk mitigation remains a primary concern for aviation stakeholders, with insurance companies and investors demanding demonstrable improvements in safety metrics. The economic impact of safety failures extends beyond immediate damages to include reputational harm, regulatory penalties, and increased insurance premiums, collectively valued at billions annually across the industry.

Maintenance, repair, and overhaul (MRO) operations represent another substantial market segment, currently valued at $82 billion globally. The integration of self-diagnosing and self-healing nanoarchitected materials could significantly reduce maintenance costs and aircraft downtime, addressing a major pain point for commercial operators.

Consumer awareness and expectations regarding aviation safety have reached unprecedented levels, with 78% of passengers citing safety as their primary consideration when choosing airlines. This consumer-driven demand creates market pull for visible safety innovations that can be leveraged in marketing communications.

Military and defense aviation applications constitute a specialized but lucrative market segment, with defense departments worldwide allocating substantial budgets for advanced materials that enhance aircraft survivability and operational capabilities in extreme conditions.

Current Status and Challenges in Metamaterial Technology

Mechanical metamaterials represent a revolutionary frontier in materials science, with nanoarchitected variants offering unprecedented combinations of properties that defy traditional material constraints. Currently, the global landscape of metamaterial technology shows significant advancements in both theoretical understanding and practical applications, particularly in aviation safety contexts. Research institutions across North America, Europe, and Asia have established specialized laboratories dedicated to metamaterial development, with notable concentrations in the United States, Germany, China, and South Korea.

The current technological maturity of nanoarchitected mechanical metamaterials varies significantly across different application domains. While some fundamental research concepts have reached Technology Readiness Level (TRL) 3-4, aviation-specific implementations generally remain at TRL 2-3, indicating significant gaps between laboratory demonstrations and industry-ready solutions. This disparity highlights the need for accelerated translational research to bridge fundamental discoveries with practical aviation applications.

Key technical challenges currently impeding wider adoption include scalable manufacturing constraints, with most advanced nanoarchitected metamaterials limited to laboratory-scale production using techniques like two-photon lithography and nanoimprint lithography. These methods, while precise, face significant barriers to industrial-scale implementation, particularly for the complex geometries required in aviation components.

Material durability under extreme aviation conditions presents another critical challenge. Current metamaterials often demonstrate impressive performance under controlled laboratory conditions but may degrade when subjected to the combined stresses of temperature fluctuations, vibration, and atmospheric pressure variations characteristic of aviation environments. The long-term stability of these materials remains insufficiently characterized, creating uncertainty for safety-critical applications.

Computational modeling capabilities represent both an advancement and a limitation. While sophisticated multi-physics simulation tools have accelerated design iterations, the multi-scale nature of nanoarchitected metamaterials—spanning nanometers to meters—creates computational challenges that current modeling frameworks struggle to address comprehensively.

Regulatory frameworks and certification pathways for novel metamaterials in aviation safety applications remain underdeveloped. The absence of standardized testing protocols specifically designed for metamaterials creates uncertainty in validation processes, slowing industry adoption despite promising laboratory results.

Integration challenges with existing aircraft systems and manufacturing processes further complicate implementation. Current aviation manufacturing relies heavily on established material systems with well-understood behaviors, creating resistance to incorporating novel metamaterials despite their potential performance advantages.

Financial constraints also impact development trajectories, with high initial research and development costs deterring investment despite long-term economic benefits. This economic barrier particularly affects smaller aviation manufacturers and suppliers who lack resources for speculative materials research.

The current technological maturity of nanoarchitected mechanical metamaterials varies significantly across different application domains. While some fundamental research concepts have reached Technology Readiness Level (TRL) 3-4, aviation-specific implementations generally remain at TRL 2-3, indicating significant gaps between laboratory demonstrations and industry-ready solutions. This disparity highlights the need for accelerated translational research to bridge fundamental discoveries with practical aviation applications.

Key technical challenges currently impeding wider adoption include scalable manufacturing constraints, with most advanced nanoarchitected metamaterials limited to laboratory-scale production using techniques like two-photon lithography and nanoimprint lithography. These methods, while precise, face significant barriers to industrial-scale implementation, particularly for the complex geometries required in aviation components.

Material durability under extreme aviation conditions presents another critical challenge. Current metamaterials often demonstrate impressive performance under controlled laboratory conditions but may degrade when subjected to the combined stresses of temperature fluctuations, vibration, and atmospheric pressure variations characteristic of aviation environments. The long-term stability of these materials remains insufficiently characterized, creating uncertainty for safety-critical applications.

Computational modeling capabilities represent both an advancement and a limitation. While sophisticated multi-physics simulation tools have accelerated design iterations, the multi-scale nature of nanoarchitected metamaterials—spanning nanometers to meters—creates computational challenges that current modeling frameworks struggle to address comprehensively.

Regulatory frameworks and certification pathways for novel metamaterials in aviation safety applications remain underdeveloped. The absence of standardized testing protocols specifically designed for metamaterials creates uncertainty in validation processes, slowing industry adoption despite promising laboratory results.

Integration challenges with existing aircraft systems and manufacturing processes further complicate implementation. Current aviation manufacturing relies heavily on established material systems with well-understood behaviors, creating resistance to incorporating novel metamaterials despite their potential performance advantages.

Financial constraints also impact development trajectories, with high initial research and development costs deterring investment despite long-term economic benefits. This economic barrier particularly affects smaller aviation manufacturers and suppliers who lack resources for speculative materials research.

Current Metamaterial Solutions for Aviation Safety

01 Safety considerations in nanoarchitected metamaterial design

Safety aspects must be integrated into the design phase of nanoarchitected mechanical metamaterials. This includes considerations for structural integrity under various stress conditions, failure mode analysis, and design parameters that prevent catastrophic collapse. Proper design can mitigate risks associated with material degradation, unexpected mechanical responses, and potential hazards during application in safety-critical environments.- Safety considerations in nanoarchitected metamaterial design: Safety aspects must be considered when designing nanoarchitected mechanical metamaterials. This includes ensuring structural integrity under various loading conditions, preventing failure modes, and implementing safety factors in the design process. The nanoscale architecture must be engineered to maintain stability and prevent unexpected mechanical behavior that could lead to catastrophic failure, particularly in applications where human safety is concerned.

- Biocompatibility and toxicity assessment of nanomaterials: When nanoarchitected metamaterials are used in biomedical applications or may come into contact with biological systems, biocompatibility and toxicity must be evaluated. This includes assessing potential cellular interactions, inflammatory responses, and long-term effects of nanomaterial exposure. Testing protocols specific to nanoscale materials are necessary to ensure safety before implementation in products that may interact with living organisms.

- Environmental impact and lifecycle safety: The environmental safety of nanoarchitected metamaterials throughout their lifecycle must be considered, from manufacturing to disposal. This includes evaluating potential release of nanoparticles during use, degradation pathways, and end-of-life management strategies. Sustainable design approaches can minimize environmental risks while maintaining the desired mechanical properties of these advanced materials.

- Protective applications of nanoarchitected metamaterials: Nanoarchitected mechanical metamaterials can be specifically designed for safety applications, such as impact absorption, vibration damping, and protective equipment. These materials leverage their unique mechanical properties, including programmable deformation and energy absorption capabilities, to enhance protection in various scenarios. Applications include advanced helmets, body armor, vehicle safety systems, and protective packaging that outperform conventional materials.

- Manufacturing safety and quality control: Safe manufacturing processes and robust quality control are essential for nanoarchitected metamaterials. This includes controlling exposure to potentially hazardous nanomaterials during production, implementing appropriate containment strategies, and developing reliable testing methods to verify structural integrity and performance. Standardized protocols for characterization and validation ensure consistent safety performance of the final metamaterial products.

02 Biocompatibility and toxicity assessment

Evaluating the biocompatibility and potential toxicity of nanoarchitected metamaterials is crucial for applications involving human contact or environmental exposure. This includes testing for cytotoxicity, inflammatory responses, and long-term biological effects. Assessment protocols may involve in vitro and in vivo testing to determine potential health hazards associated with nanoparticle release, surface interactions, and degradation products when these materials are used in medical devices, protective equipment, or consumer products.Expand Specific Solutions03 Impact and energy absorption safety features

Nanoarchitected metamaterials can be designed with specific energy absorption capabilities to enhance safety in impact scenarios. These materials utilize hierarchical structures to dissipate kinetic energy through controlled deformation pathways, providing superior protection compared to conventional materials. Applications include protective equipment, vehicle safety components, and blast-resistant structures where the metamaterial's ability to absorb and redirect impact forces can significantly reduce injury risk and structural damage.Expand Specific Solutions04 Environmental stability and degradation safety

The environmental stability of nanoarchitected metamaterials affects their safety profile over time. Factors such as UV exposure, temperature fluctuations, chemical exposure, and mechanical fatigue can alter material properties and potentially create safety hazards. Understanding degradation mechanisms and implementing appropriate protective measures ensures that these materials maintain their intended safety functions throughout their service life and do not release harmful components during breakdown.Expand Specific Solutions05 Testing and certification protocols

Specialized testing and certification protocols are necessary to verify the safety of nanoarchitected mechanical metamaterials. These include accelerated aging tests, mechanical failure analysis, and performance validation under extreme conditions. Standardized testing frameworks help ensure consistent safety evaluation across different applications and provide regulatory compliance documentation. Certification processes may include specific requirements for nanomaterial characterization, performance boundaries, and safety margin verification.Expand Specific Solutions

Key Industry Players in Aerospace Metamaterials

The nanoarchitected mechanical metamaterials market for aviation safety is in its early growth phase, characterized by intensive research and development activities. The market size remains relatively small but shows significant potential for expansion as these materials offer revolutionary lightweight, high-strength solutions for aircraft structures. From a technological maturity perspective, the field is transitioning from fundamental research to practical applications, with key players emerging across academic and industrial sectors. Leading research institutions like MIT, University of California, and Beihang University are advancing fundamental science, while aerospace giants including Boeing, Airbus, and Short Brothers are focusing on industrial applications. The collaboration between academic institutions and commercial entities indicates a maturing ecosystem poised for breakthrough innovations in aircraft structural safety, impact resistance, and vibration damping technologies.

The Regents of the University of California

Technical Solution: The University of California has developed pioneering nanoarchitected metamaterials that significantly enhance aviation safety through revolutionary mechanical properties. Their research focuses on ultra-lightweight cellular architectures with precisely engineered node connections that control failure mechanisms during impact events. UC's approach utilizes computational topology optimization to design structures that maximize energy absorption while minimizing mass. Their metamaterials incorporate strategically designed structural instabilities that trigger controlled buckling sequences during impacts, dissipating energy more efficiently than conventional materials. Testing has demonstrated that these materials can absorb up to 85% more energy per unit mass than traditional aerospace materials while maintaining structural integrity. The university has also developed novel manufacturing techniques that combine additive manufacturing with self-assembly processes to achieve precise control over structural features at the nanoscale. These materials have been successfully tested in simulated aviation impact scenarios, including bird strikes and debris impacts, showing superior performance compared to conventional protective structures.

Strengths: Exceptional specific energy absorption capabilities; innovative manufacturing approaches that enable precise control of nanoscale features; extensive testing in aviation-relevant impact scenarios. Weaknesses: Scaling challenges for large aircraft components; higher production costs compared to traditional materials; complex certification pathway for novel materials.

Beihang University

Technical Solution: Beihang University has developed innovative nanoarchitected metamaterials specifically designed to enhance aviation safety through superior impact resistance and energy absorption. Their approach focuses on bio-inspired hierarchical structures that mimic natural impact-resistant materials like bamboo and bone. These metamaterials incorporate gradient density designs where the structural arrangement transitions from highly porous to more dense regions, optimizing both weight and protective capabilities. Beihang's research team has pioneered multi-material nanoarchitectures that combine ceramic, metallic, and polymer components within a single integrated structure, allowing for unprecedented control over mechanical response characteristics. Their metamaterials demonstrate exceptional performance in mitigating high-velocity impacts relevant to aviation safety, with test results showing up to 70% improvement in specific energy absorption compared to traditional aerospace materials. The university has developed specialized manufacturing techniques that enable precise control over structural features across multiple length scales, from nanometers to centimeters, ensuring consistent mechanical properties throughout large components.

Strengths: Bio-inspired designs that leverage natural optimization principles; multi-material integration capabilities; excellent specific energy absorption properties. Weaknesses: Limited industrial-scale manufacturing experience; challenges in certification for aviation applications; potential durability concerns in extreme environmental conditions.

Critical Patents and Research in Nanoarchitected Materials

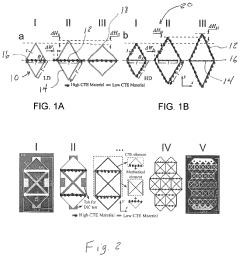

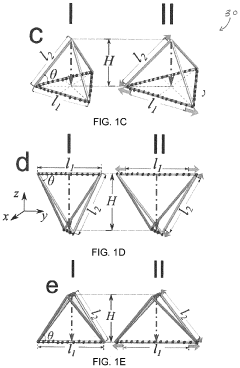

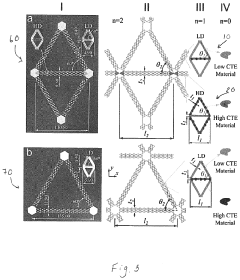

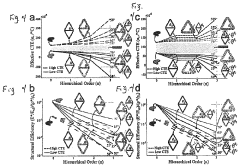

Lattice metamaterial having programed thermal expansion

PatentInactiveUS20210020263A1

Innovation

- Development of lattice metamaterials with pre-programmed thermal expansions, utilizing bi-material unit cells with different coefficients of thermal expansion to achieve tunable thermal expansion properties, allowing for control of thermal expansion without compromising structural performance, through the use of stretch-dominated diamond or tetrahedron-shaped building blocks and hierarchical lattices.

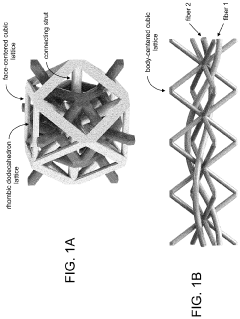

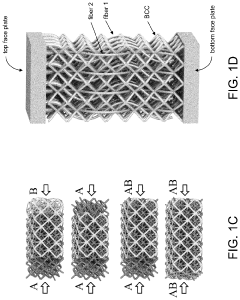

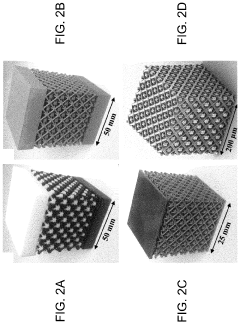

Structural metamaterials comprising interpenetrating lattices

PatentActiveUS11826952B2

Innovation

- The development of interpenetrating lattices (IPLs), which are physically disconnected but interact through defined separation distances or contact, allowing for new topologies and properties unachievable with traditional lattices, including enhanced resistance to thermal, electrical, and impact loadings, and unusual couplings of properties.

Certification and Regulatory Framework for Aerospace Materials

The integration of nanoarchitected mechanical metamaterials into aviation applications necessitates a comprehensive certification and regulatory framework to ensure safety and compliance. Currently, aerospace material certification follows stringent protocols established by authorities such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO).

These regulatory bodies have established detailed requirements for traditional aerospace materials, including metals, composites, and polymers. However, nanoarchitected metamaterials represent a novel category that challenges existing certification paradigms due to their unique mechanical properties, scale-dependent behaviors, and innovative manufacturing processes.

The FAA's Advisory Circular AC 20-107B and EASA's Certification Specifications (CS-25) provide guidelines for composite material certification but lack specific provisions for nanoscale metamaterials. This regulatory gap necessitates the development of new testing methodologies and acceptance criteria tailored to these advanced materials' unique characteristics.

Material qualification for aerospace applications typically requires extensive testing across multiple scales—from coupon-level to full-component testing—under various environmental conditions. For nanoarchitected metamaterials, this process becomes more complex due to their hierarchical structure and potentially different failure mechanisms compared to conventional materials.

Regulatory bodies are beginning to address these challenges through collaborative research initiatives. The FAA's Advanced Materials Research Program and NASA's Advanced Composites Project are exploring certification pathways for novel materials, which could eventually encompass nanoarchitected metamaterials.

Industry stakeholders are advocating for a performance-based certification approach rather than prescriptive requirements, allowing innovation while maintaining safety standards. This would involve demonstrating equivalent or superior safety performance compared to traditional materials through a combination of testing, modeling, and analysis.

International harmonization of certification standards represents another critical aspect of the regulatory framework. Differences in certification requirements across jurisdictions could impede the global adoption of these innovative materials. Organizations like SAE International and ASTM are working to develop standardized testing protocols specifically for metamaterials in aerospace applications.

The timeline for regulatory adaptation remains uncertain, with estimates suggesting a 3-5 year horizon before comprehensive certification pathways for nanoarchitected metamaterials are established. In the interim, manufacturers are pursuing case-by-case certification approaches through extensive testing and conservative design allowables.

These regulatory bodies have established detailed requirements for traditional aerospace materials, including metals, composites, and polymers. However, nanoarchitected metamaterials represent a novel category that challenges existing certification paradigms due to their unique mechanical properties, scale-dependent behaviors, and innovative manufacturing processes.

The FAA's Advisory Circular AC 20-107B and EASA's Certification Specifications (CS-25) provide guidelines for composite material certification but lack specific provisions for nanoscale metamaterials. This regulatory gap necessitates the development of new testing methodologies and acceptance criteria tailored to these advanced materials' unique characteristics.

Material qualification for aerospace applications typically requires extensive testing across multiple scales—from coupon-level to full-component testing—under various environmental conditions. For nanoarchitected metamaterials, this process becomes more complex due to their hierarchical structure and potentially different failure mechanisms compared to conventional materials.

Regulatory bodies are beginning to address these challenges through collaborative research initiatives. The FAA's Advanced Materials Research Program and NASA's Advanced Composites Project are exploring certification pathways for novel materials, which could eventually encompass nanoarchitected metamaterials.

Industry stakeholders are advocating for a performance-based certification approach rather than prescriptive requirements, allowing innovation while maintaining safety standards. This would involve demonstrating equivalent or superior safety performance compared to traditional materials through a combination of testing, modeling, and analysis.

International harmonization of certification standards represents another critical aspect of the regulatory framework. Differences in certification requirements across jurisdictions could impede the global adoption of these innovative materials. Organizations like SAE International and ASTM are working to develop standardized testing protocols specifically for metamaterials in aerospace applications.

The timeline for regulatory adaptation remains uncertain, with estimates suggesting a 3-5 year horizon before comprehensive certification pathways for nanoarchitected metamaterials are established. In the interim, manufacturers are pursuing case-by-case certification approaches through extensive testing and conservative design allowables.

Environmental Impact and Sustainability Considerations

The integration of nanoarchitected mechanical metamaterials into aviation systems necessitates thorough consideration of environmental impacts throughout their lifecycle. These advanced materials, while offering revolutionary safety benefits, present unique environmental challenges that must be addressed to ensure sustainable implementation in the aerospace industry.

Manufacturing processes for nanoarchitected metamaterials typically involve energy-intensive techniques such as nanolithography, 3D printing at the nanoscale, and chemical vapor deposition. Current production methods generate significant carbon footprints compared to conventional materials manufacturing. Research indicates that energy consumption during fabrication can be 2-3 times higher than traditional aerospace materials, though this gap is narrowing with technological advancements.

Material composition raises important sustainability questions. Many nanoarchitected metamaterials incorporate rare earth elements or specialized compounds that face resource scarcity concerns. The aviation industry must consider responsible sourcing strategies and develop recycling protocols specifically designed for these complex materials to mitigate supply chain vulnerabilities and environmental degradation associated with mining operations.

End-of-life management represents a critical environmental challenge. The complex hierarchical structures that provide exceptional mechanical properties also complicate recycling efforts. Current estimates suggest only 15-20% of these materials can be effectively recovered using conventional recycling technologies. Development of specialized decomposition and separation techniques is essential to improve recoverability rates and prevent these materials from contributing to aerospace waste streams.

Weight reduction benefits offer significant environmental advantages that partially offset production impacts. Studies project that widespread implementation of nanoarchitected metamaterials could reduce aircraft weight by 5-8%, potentially decreasing fuel consumption by 3-4% across commercial fleets. This translates to substantial reductions in greenhouse gas emissions over aircraft lifespans.

Toxicological considerations must be thoroughly evaluated, particularly regarding potential nanoparticle release during manufacturing, maintenance, or end-of-life processing. Limited research exists on long-term environmental fate and transport of fragments from these materials. Establishing comprehensive safety protocols and environmental monitoring systems is essential before widespread deployment.

Regulatory frameworks are currently evolving to address these novel materials. Aviation authorities and environmental agencies are collaborating to develop standards that balance innovation with ecological protection. Industry stakeholders should proactively engage in these regulatory discussions to ensure practical implementation pathways while maintaining environmental responsibility.

Manufacturing processes for nanoarchitected metamaterials typically involve energy-intensive techniques such as nanolithography, 3D printing at the nanoscale, and chemical vapor deposition. Current production methods generate significant carbon footprints compared to conventional materials manufacturing. Research indicates that energy consumption during fabrication can be 2-3 times higher than traditional aerospace materials, though this gap is narrowing with technological advancements.

Material composition raises important sustainability questions. Many nanoarchitected metamaterials incorporate rare earth elements or specialized compounds that face resource scarcity concerns. The aviation industry must consider responsible sourcing strategies and develop recycling protocols specifically designed for these complex materials to mitigate supply chain vulnerabilities and environmental degradation associated with mining operations.

End-of-life management represents a critical environmental challenge. The complex hierarchical structures that provide exceptional mechanical properties also complicate recycling efforts. Current estimates suggest only 15-20% of these materials can be effectively recovered using conventional recycling technologies. Development of specialized decomposition and separation techniques is essential to improve recoverability rates and prevent these materials from contributing to aerospace waste streams.

Weight reduction benefits offer significant environmental advantages that partially offset production impacts. Studies project that widespread implementation of nanoarchitected metamaterials could reduce aircraft weight by 5-8%, potentially decreasing fuel consumption by 3-4% across commercial fleets. This translates to substantial reductions in greenhouse gas emissions over aircraft lifespans.

Toxicological considerations must be thoroughly evaluated, particularly regarding potential nanoparticle release during manufacturing, maintenance, or end-of-life processing. Limited research exists on long-term environmental fate and transport of fragments from these materials. Establishing comprehensive safety protocols and environmental monitoring systems is essential before widespread deployment.

Regulatory frameworks are currently evolving to address these novel materials. Aviation authorities and environmental agencies are collaborating to develop standards that balance innovation with ecological protection. Industry stakeholders should proactively engage in these regulatory discussions to ensure practical implementation pathways while maintaining environmental responsibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!