Nanoarchitected Mechanical Metamaterials and Applications in Prosthetics.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Evolution and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, emerging from the convergence of nanotechnology, mechanical engineering, and materials design. These engineered structures, with precisely controlled geometries at the nanoscale, exhibit extraordinary mechanical properties that transcend those of conventional materials. The evolution of this field traces back to the early 2000s when researchers began exploring how structural arrangement at microscopic levels could fundamentally alter material behavior.

The journey of nanoarchitected metamaterials has been marked by several pivotal developments. Initially, research focused on theoretical modeling of these structures, with limited fabrication capabilities. By 2010, advancements in nanofabrication techniques, particularly two-photon lithography and atomic layer deposition, enabled the creation of increasingly complex three-dimensional architectures at the nanoscale. This technological leap allowed researchers to translate theoretical designs into physical reality.

Between 2015 and 2020, the field witnessed exponential growth as researchers demonstrated metamaterials with unprecedented combinations of properties—materials with high strength yet ultralow density, exceptional energy absorption capabilities, and programmable mechanical responses. These developments have fundamentally challenged traditional material property trade-offs, opening new design spaces previously considered impossible.

In the prosthetics domain, nanoarchitected metamaterials present transformative potential. Traditional prosthetic materials face inherent limitations in simultaneously achieving biocompatibility, durability, lightweight construction, and biomimetic mechanical behavior. The objective of current research is to leverage nanoarchitected metamaterials to overcome these constraints by developing prosthetic components that more accurately replicate the mechanical behavior of natural biological tissues.

Key technical objectives include developing metamaterial architectures that mimic the hierarchical structure and non-linear mechanical response of human tissues, particularly bone, cartilage, and muscle. Researchers aim to create prosthetic interfaces with mechanical gradients that reduce stress concentration at the tissue-prosthetic boundary, potentially extending device lifespan and improving patient comfort.

Another critical goal is establishing scalable manufacturing processes that can translate laboratory-scale demonstrations to clinically relevant dimensions while maintaining precise control over nanoscale features. This includes developing hybrid fabrication approaches that combine additive manufacturing with self-assembly techniques to achieve multi-scale control.

The field is now moving toward responsive and adaptive nanoarchitected metamaterials that can dynamically adjust their mechanical properties in response to environmental stimuli, potentially enabling prosthetics that adapt to different activity levels and physiological states of the user, representing the next frontier in this rapidly evolving technological landscape.

The journey of nanoarchitected metamaterials has been marked by several pivotal developments. Initially, research focused on theoretical modeling of these structures, with limited fabrication capabilities. By 2010, advancements in nanofabrication techniques, particularly two-photon lithography and atomic layer deposition, enabled the creation of increasingly complex three-dimensional architectures at the nanoscale. This technological leap allowed researchers to translate theoretical designs into physical reality.

Between 2015 and 2020, the field witnessed exponential growth as researchers demonstrated metamaterials with unprecedented combinations of properties—materials with high strength yet ultralow density, exceptional energy absorption capabilities, and programmable mechanical responses. These developments have fundamentally challenged traditional material property trade-offs, opening new design spaces previously considered impossible.

In the prosthetics domain, nanoarchitected metamaterials present transformative potential. Traditional prosthetic materials face inherent limitations in simultaneously achieving biocompatibility, durability, lightweight construction, and biomimetic mechanical behavior. The objective of current research is to leverage nanoarchitected metamaterials to overcome these constraints by developing prosthetic components that more accurately replicate the mechanical behavior of natural biological tissues.

Key technical objectives include developing metamaterial architectures that mimic the hierarchical structure and non-linear mechanical response of human tissues, particularly bone, cartilage, and muscle. Researchers aim to create prosthetic interfaces with mechanical gradients that reduce stress concentration at the tissue-prosthetic boundary, potentially extending device lifespan and improving patient comfort.

Another critical goal is establishing scalable manufacturing processes that can translate laboratory-scale demonstrations to clinically relevant dimensions while maintaining precise control over nanoscale features. This includes developing hybrid fabrication approaches that combine additive manufacturing with self-assembly techniques to achieve multi-scale control.

The field is now moving toward responsive and adaptive nanoarchitected metamaterials that can dynamically adjust their mechanical properties in response to environmental stimuli, potentially enabling prosthetics that adapt to different activity levels and physiological states of the user, representing the next frontier in this rapidly evolving technological landscape.

Market Analysis for Advanced Prosthetic Solutions

The global prosthetics market is experiencing significant growth, driven by technological advancements and increasing prevalence of limb loss due to various factors including vascular diseases, diabetes, trauma, and congenital disorders. Currently valued at approximately $2.3 billion, the advanced prosthetics segment is projected to grow at a CAGR of 9.8% through 2028, with particularly strong expansion in regions with aging populations and high rates of diabetes.

The market for nanoarchitected mechanical metamaterial-based prosthetics represents an emerging high-value segment within this broader landscape. While traditional prosthetics continue to dominate market share, advanced solutions incorporating lightweight, high-strength metamaterials are gaining traction, particularly in premium segments where performance advantages justify higher costs.

Demand patterns show distinct regional variations. North America leads the market with approximately 40% share, driven by strong healthcare infrastructure, favorable reimbursement policies, and high adoption rates of cutting-edge technologies. Europe follows at 30%, with particularly strong markets in Germany, the UK, and France. The Asia-Pacific region, while currently accounting for only 20% of the market, is expected to show the fastest growth rate over the next decade due to improving healthcare access, rising disposable incomes, and increasing awareness.

Consumer segmentation reveals three primary market tiers: high-end custom solutions for professional athletes and specialized applications (15% of market), mid-tier advanced prosthetics for everyday users seeking enhanced functionality (45%), and basic functional prosthetics (40%). The nanoarchitected metamaterial solutions primarily target the first two segments, where performance advantages in weight reduction, durability, and biomechanical efficiency justify premium pricing.

Key market drivers include the growing demand for prosthetics that more closely mimic natural limb functionality, increasing patient expectations regarding comfort and aesthetics, and healthcare systems' recognition of the long-term economic benefits of high-quality prosthetic solutions. The rising participation of amputees in sports and active lifestyles is creating demand for prosthetics that can withstand high-impact activities while maintaining comfort.

Market barriers include high development and manufacturing costs, regulatory hurdles for novel materials, limited reimbursement for advanced solutions in many markets, and the need for specialized expertise in fitting and maintaining these sophisticated devices. Additionally, the market faces challenges related to the scalability of production processes for nanoarchitected metamaterials, which currently involve complex and time-consuming manufacturing techniques.

The market for nanoarchitected mechanical metamaterial-based prosthetics represents an emerging high-value segment within this broader landscape. While traditional prosthetics continue to dominate market share, advanced solutions incorporating lightweight, high-strength metamaterials are gaining traction, particularly in premium segments where performance advantages justify higher costs.

Demand patterns show distinct regional variations. North America leads the market with approximately 40% share, driven by strong healthcare infrastructure, favorable reimbursement policies, and high adoption rates of cutting-edge technologies. Europe follows at 30%, with particularly strong markets in Germany, the UK, and France. The Asia-Pacific region, while currently accounting for only 20% of the market, is expected to show the fastest growth rate over the next decade due to improving healthcare access, rising disposable incomes, and increasing awareness.

Consumer segmentation reveals three primary market tiers: high-end custom solutions for professional athletes and specialized applications (15% of market), mid-tier advanced prosthetics for everyday users seeking enhanced functionality (45%), and basic functional prosthetics (40%). The nanoarchitected metamaterial solutions primarily target the first two segments, where performance advantages in weight reduction, durability, and biomechanical efficiency justify premium pricing.

Key market drivers include the growing demand for prosthetics that more closely mimic natural limb functionality, increasing patient expectations regarding comfort and aesthetics, and healthcare systems' recognition of the long-term economic benefits of high-quality prosthetic solutions. The rising participation of amputees in sports and active lifestyles is creating demand for prosthetics that can withstand high-impact activities while maintaining comfort.

Market barriers include high development and manufacturing costs, regulatory hurdles for novel materials, limited reimbursement for advanced solutions in many markets, and the need for specialized expertise in fitting and maintaining these sophisticated devices. Additionally, the market faces challenges related to the scalability of production processes for nanoarchitected metamaterials, which currently involve complex and time-consuming manufacturing techniques.

Current Challenges in Nanoarchitected Metamaterials

Despite significant advancements in nanoarchitected mechanical metamaterials, several critical challenges impede their widespread application in prosthetics and other fields. The primary obstacle remains scalable manufacturing. Current fabrication techniques such as two-photon lithography and projection micro-stereolithography offer exceptional precision but suffer from extremely low throughput, limiting production to laboratory-scale samples typically measuring only a few cubic millimeters. This fundamental limitation prevents industrial-scale implementation and clinical translation.

Material selection presents another significant hurdle. Many high-performance metamaterial architectures rely on specialized polymers, ceramics, or metals that may not meet the biocompatibility requirements essential for prosthetic applications. The trade-off between mechanical performance and biological compatibility often forces compromises that diminish the metamaterial's functional advantages.

Mechanical durability under physiological conditions represents a persistent challenge. While nanoarchitected metamaterials demonstrate impressive properties in controlled laboratory environments, their long-term performance under cyclic loading, varied temperature conditions, and exposure to bodily fluids remains largely uncharacterized. Fatigue resistance and structural integrity over millions of cycles—a requirement for prosthetic applications—has not been adequately demonstrated for most metamaterial designs.

The multiscale modeling of these complex structures presents computational challenges. Current simulation approaches struggle to bridge the gap between nanoscale material behavior and macroscale functional performance, making accurate prediction of in vivo behavior difficult. This modeling gap hinders efficient design optimization and slows innovation cycles.

Standardization and quality control methodologies remain underdeveloped. The lack of established testing protocols specifically designed for nanoarchitected metamaterials makes comparative analysis difficult and complicates regulatory approval pathways for medical applications. Without standardized characterization methods, translating laboratory success to clinical implementation becomes exceedingly difficult.

Integration challenges also persist at material interfaces. Creating robust connections between nanoarchitected metamaterials and conventional materials in prosthetic systems often results in stress concentration and potential failure points. These interface weaknesses can negate the mechanical advantages offered by the metamaterial components.

Finally, cost-effectiveness remains a significant barrier. The current high production costs and specialized equipment requirements place nanoarchitected metamaterials beyond practical implementation in mainstream prosthetic applications, particularly in resource-limited settings where prosthetic solutions are most needed.

Material selection presents another significant hurdle. Many high-performance metamaterial architectures rely on specialized polymers, ceramics, or metals that may not meet the biocompatibility requirements essential for prosthetic applications. The trade-off between mechanical performance and biological compatibility often forces compromises that diminish the metamaterial's functional advantages.

Mechanical durability under physiological conditions represents a persistent challenge. While nanoarchitected metamaterials demonstrate impressive properties in controlled laboratory environments, their long-term performance under cyclic loading, varied temperature conditions, and exposure to bodily fluids remains largely uncharacterized. Fatigue resistance and structural integrity over millions of cycles—a requirement for prosthetic applications—has not been adequately demonstrated for most metamaterial designs.

The multiscale modeling of these complex structures presents computational challenges. Current simulation approaches struggle to bridge the gap between nanoscale material behavior and macroscale functional performance, making accurate prediction of in vivo behavior difficult. This modeling gap hinders efficient design optimization and slows innovation cycles.

Standardization and quality control methodologies remain underdeveloped. The lack of established testing protocols specifically designed for nanoarchitected metamaterials makes comparative analysis difficult and complicates regulatory approval pathways for medical applications. Without standardized characterization methods, translating laboratory success to clinical implementation becomes exceedingly difficult.

Integration challenges also persist at material interfaces. Creating robust connections between nanoarchitected metamaterials and conventional materials in prosthetic systems often results in stress concentration and potential failure points. These interface weaknesses can negate the mechanical advantages offered by the metamaterial components.

Finally, cost-effectiveness remains a significant barrier. The current high production costs and specialized equipment requirements place nanoarchitected metamaterials beyond practical implementation in mainstream prosthetic applications, particularly in resource-limited settings where prosthetic solutions are most needed.

Current Nanoarchitected Solutions for Prosthetics

01 Nanoarchitected metamaterials with unique mechanical properties

Nanoarchitected mechanical metamaterials are designed with specific structural arrangements at the nanoscale to achieve extraordinary mechanical properties not found in conventional materials. These include enhanced strength-to-weight ratios, programmable stiffness, and controlled deformation behaviors. The precise arrangement of nanoscale building blocks creates materials that can exhibit properties such as negative Poisson's ratio, high energy absorption, or exceptional resilience under mechanical stress.- Nanoarchitected metamaterials with unique mechanical properties: Nanoarchitected mechanical metamaterials are engineered structures with precisely designed geometries at the nanoscale that exhibit extraordinary mechanical properties not found in conventional materials. These materials feature controlled architectures that enable properties such as ultra-high strength-to-weight ratios, programmable stiffness, and enhanced energy absorption capabilities. The nanoscale architecture allows for unprecedented control over mechanical behavior, including compression resistance, elasticity, and deformation characteristics.

- Fabrication techniques for nanoarchitected metamaterials: Various advanced manufacturing techniques are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These include two-photon lithography, 3D printing at nanoscale, self-assembly processes, and template-assisted fabrication. These techniques enable the creation of complex lattice structures, hierarchical architectures, and other geometrical configurations that would be impossible to achieve through conventional manufacturing methods, allowing for tailored mechanical responses.

- Applications in energy absorption and impact resistance: Nanoarchitected mechanical metamaterials offer exceptional capabilities for energy absorption and impact resistance applications. Their unique structural designs enable efficient dissipation of kinetic energy through controlled deformation mechanisms. These materials can be engineered to absorb impacts while maintaining structural integrity, making them valuable for protective equipment, automotive safety components, aerospace structures, and defense applications where lightweight yet highly protective materials are required.

- Electromagnetic and acoustic properties of mechanical metamaterials: Beyond purely mechanical characteristics, nanoarchitected metamaterials can be designed to exhibit unique electromagnetic and acoustic properties. These materials can manipulate electromagnetic waves and sound waves in unprecedented ways, enabling applications such as wave guiding, filtering, and cloaking. The integration of mechanical and electromagnetic/acoustic functionalities allows for multifunctional materials that can simultaneously provide structural support while controlling wave propagation.

- Responsive and programmable metamaterials: Advanced nanoarchitected mechanical metamaterials can be designed to respond dynamically to external stimuli, exhibiting programmable behavior. These materials can change their mechanical properties in response to temperature, electric fields, magnetic fields, or mechanical stress. Such responsive behavior enables applications in soft robotics, adaptive structures, and smart materials that can self-regulate their properties based on environmental conditions or user requirements.

02 Fabrication techniques for nanoarchitected metamaterials

Advanced manufacturing methods are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These techniques include two-photon lithography, 3D printing at the nanoscale, self-assembly processes, and template-assisted fabrication. These methods enable the creation of complex three-dimensional architectures with feature sizes ranging from nanometers to micrometers, allowing for unprecedented control over mechanical behavior through structural design rather than material composition.Expand Specific Solutions03 Electronic and electromagnetic applications of nanoarchitected metamaterials

Beyond purely mechanical applications, nanoarchitected metamaterials are being developed for electronic and electromagnetic functionalities. These include metamaterials with tailored electromagnetic wave interactions, phononic crystals for sound and vibration control, and materials with programmable electrical properties. The precise structural control at the nanoscale allows for the creation of materials with unusual electromagnetic responses, including negative refractive indices, electromagnetic cloaking capabilities, and enhanced sensing properties.Expand Specific Solutions04 Multifunctional nanoarchitected metamaterials

Researchers are developing nanoarchitected metamaterials that combine multiple functionalities in a single structure. These multifunctional materials can simultaneously exhibit tailored mechanical, thermal, optical, and electrical properties. By integrating different material compositions within precisely designed nanoarchitectures, these metamaterials can respond to multiple stimuli or perform several functions simultaneously, opening new possibilities for smart materials and adaptive structures.Expand Specific Solutions05 Energy absorption and impact resistance applications

Nanoarchitected mechanical metamaterials show exceptional capabilities for energy absorption and impact resistance. Their precisely designed structures can deform in controlled ways to dissipate energy efficiently during impact events. These materials are being developed for applications in protective equipment, packaging, vibration damping, and structural components that require high impact resistance with minimal weight. The hierarchical design of these materials allows for tailored mechanical responses across multiple length scales.Expand Specific Solutions

Leading Research Groups and Industry Players

Nanoarchitected mechanical metamaterials for prosthetics are currently in an early growth phase, with the market expected to expand significantly as technology matures. The global market is projected to reach substantial value due to increasing demand for advanced prosthetic solutions with enhanced functionality and biocompatibility. Technologically, academic institutions lead fundamental research, with MIT, Purdue Research Foundation, and University of California pioneering novel architectures and manufacturing methods. Commercial players like Straumann Holding, ConforMIS, and N2 Biomedical are advancing practical applications through surface treatments and biomaterial integration. The field is transitioning from laboratory research to clinical implementation, with collaborative efforts between universities and medical device companies accelerating development of lightweight, durable, and biocompatible prosthetic solutions with improved mechanical properties.

The Regents of the University of California

Technical Solution: The University of California has developed groundbreaking nanoarchitected metamaterials for prosthetic applications through their pioneering work in mechanical metamaterials with programmable properties. Their approach utilizes hierarchical lattice structures with precisely engineered geometries at the nanoscale to achieve unprecedented combinations of strength, flexibility, and weight reduction. UC researchers have created metamaterials that can withstand extreme deformation while maintaining structural integrity, a critical feature for prosthetic applications that experience cyclic loading. Their technology incorporates biocompatible materials structured at the nanoscale to mimic natural tissue mechanics while promoting cellular integration. A key innovation is their development of "mechanical cloaking" metamaterials that redistribute stress around prosthetic-tissue interfaces, reducing rejection risks and improving long-term stability. UC's fabrication techniques combine additive manufacturing with self-assembly processes to create complex hierarchical structures with feature sizes ranging from nanometers to centimeters, enabling multi-functional prosthetics with integrated sensing and actuation capabilities.

Strengths: Exceptional mechanical property combinations (high strength with low density) that closely mimic natural tissues; ability to create structures with spatially varying properties to match different tissue interfaces; advanced biocompatibility through both material selection and structural design. Weaknesses: Complex manufacturing processes that may limit scalability; challenges in quality control across large-scale production; potential regulatory hurdles due to novel material-structure combinations.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered nanoarchitected mechanical metamaterials through their innovative hierarchical design approach that spans multiple length scales. Their research focuses on creating lightweight yet ultra-strong structures by precisely controlling material architecture at the nanoscale. MIT's technology employs two-photon lithography and other advanced fabrication techniques to create complex 3D nano-lattices with unprecedented mechanical properties, including exceptional strength-to-weight ratios and energy absorption capabilities. Their prosthetic applications leverage these metamaterials to create implants that mimic natural bone's hierarchical structure while providing superior mechanical performance. MIT researchers have developed metamaterials with tunable stiffness that can be adjusted post-implantation to match surrounding tissue properties, reducing stress shielding effects common in traditional prosthetics. Their technology also incorporates bioactive surface treatments that promote osseointegration while maintaining the mechanical advantages of the nanoarchitected structure.

Strengths: Exceptional strength-to-weight ratio allowing for lighter prosthetics without compromising structural integrity; ability to create patient-specific designs with precisely tuned mechanical properties; superior energy absorption capabilities that reduce impact forces on surrounding tissues. Weaknesses: High manufacturing costs associated with precision nanofabrication techniques; challenges in scaling production to commercial levels; potential long-term durability concerns in dynamic loading environments.

Key Patents and Research in Metamaterial Prosthetics

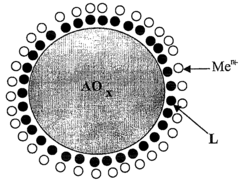

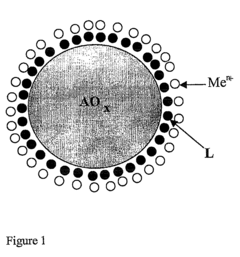

Use of nanomaterials based on titanium dioxide and zirconium diozide as coatings for osteointegrated biomedical prostheses, and osteointegrated biomedical prostheses prepared therewith

PatentInactiveUS20090270997A1

Innovation

- Development of coatings based on functionalized nanomaterials comprising titanium dioxide or zirconium dioxide with silver(I), zinc(II), and/or copper(II) ions, which exhibit bactericidal and virucidal activity without luminous irradiation, enhancing osteointegration and reducing inflammatory rejections.

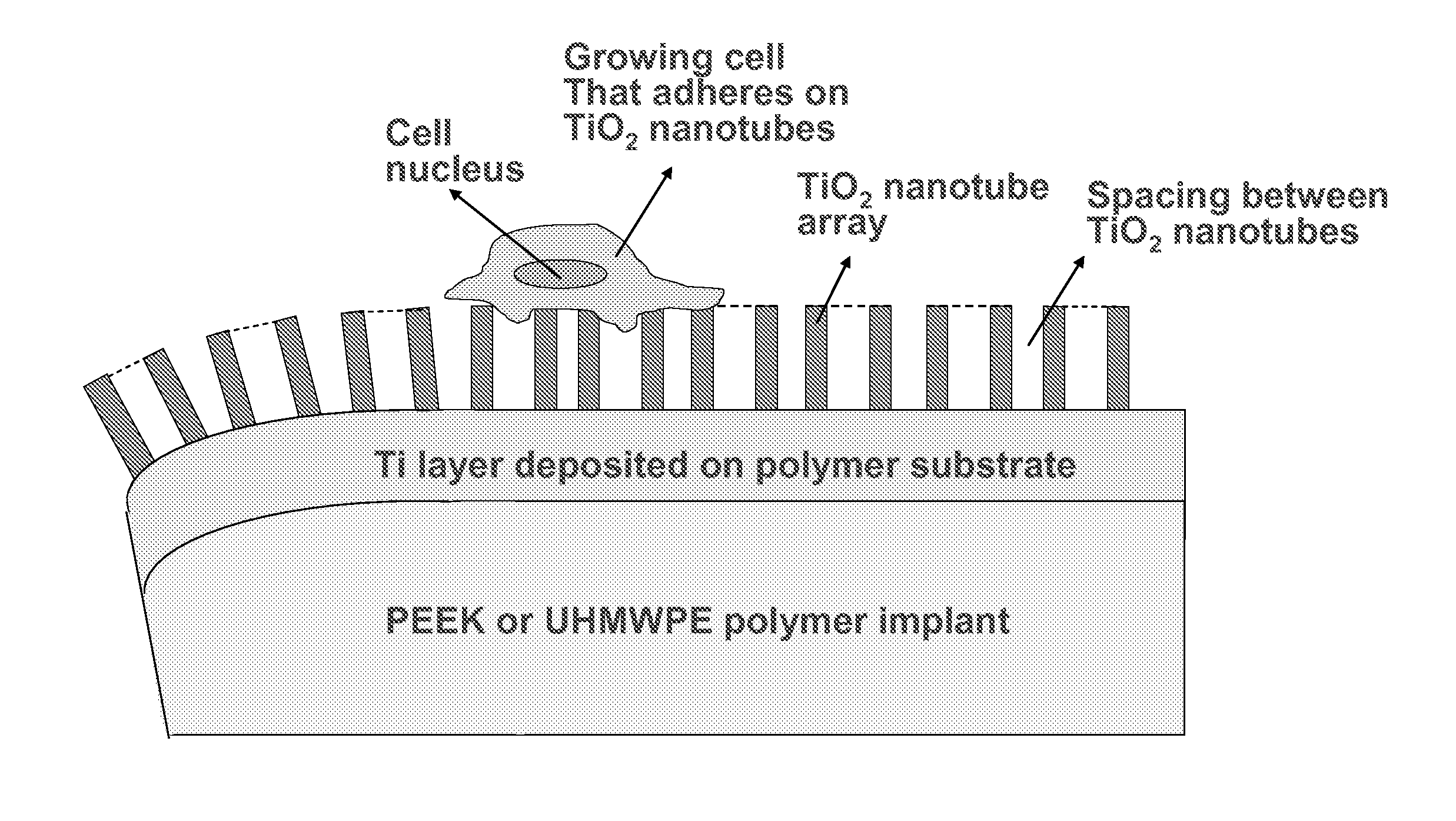

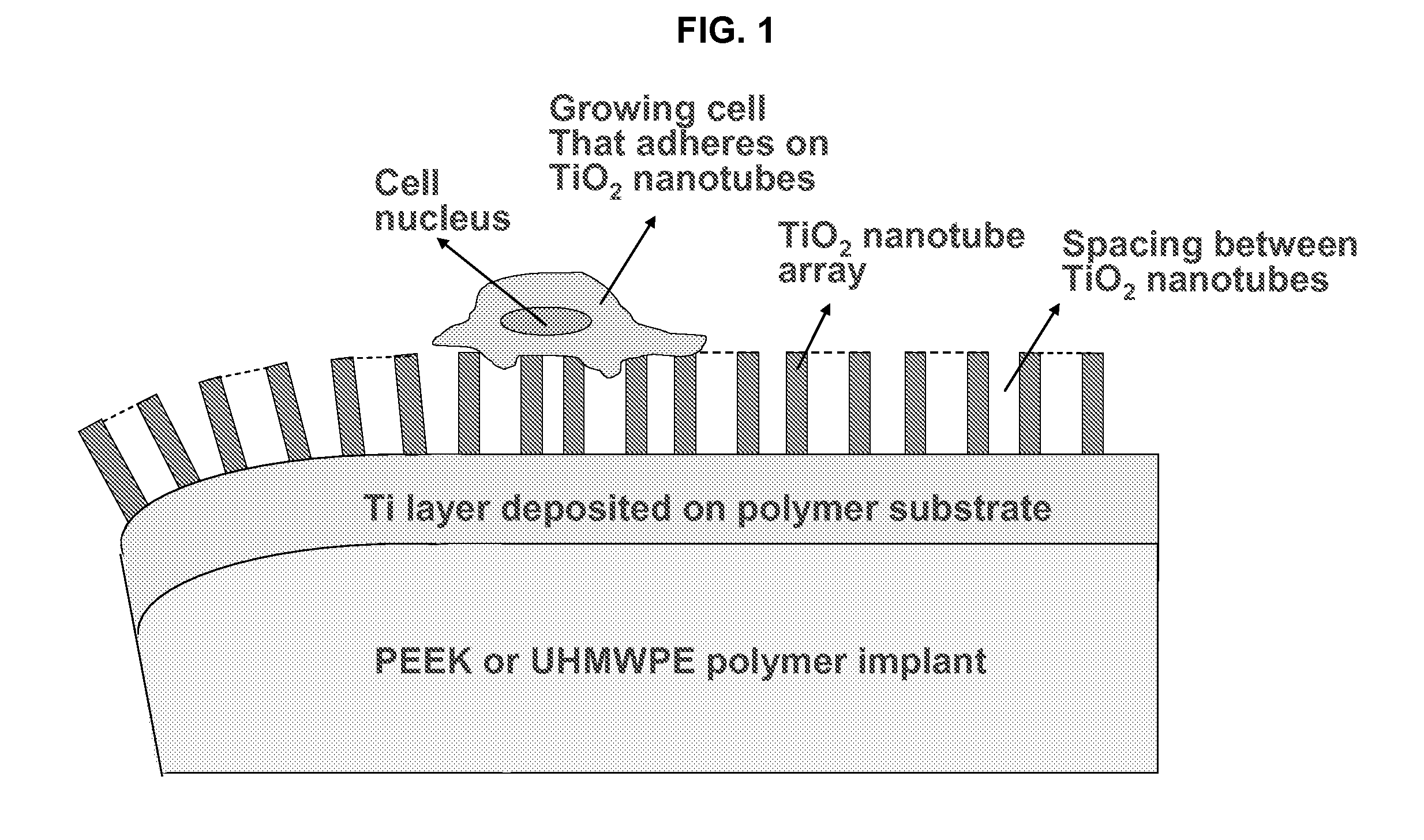

Inorganically surface-modified polymers and methods for making and using them

PatentActiveUS20120010599A1

Innovation

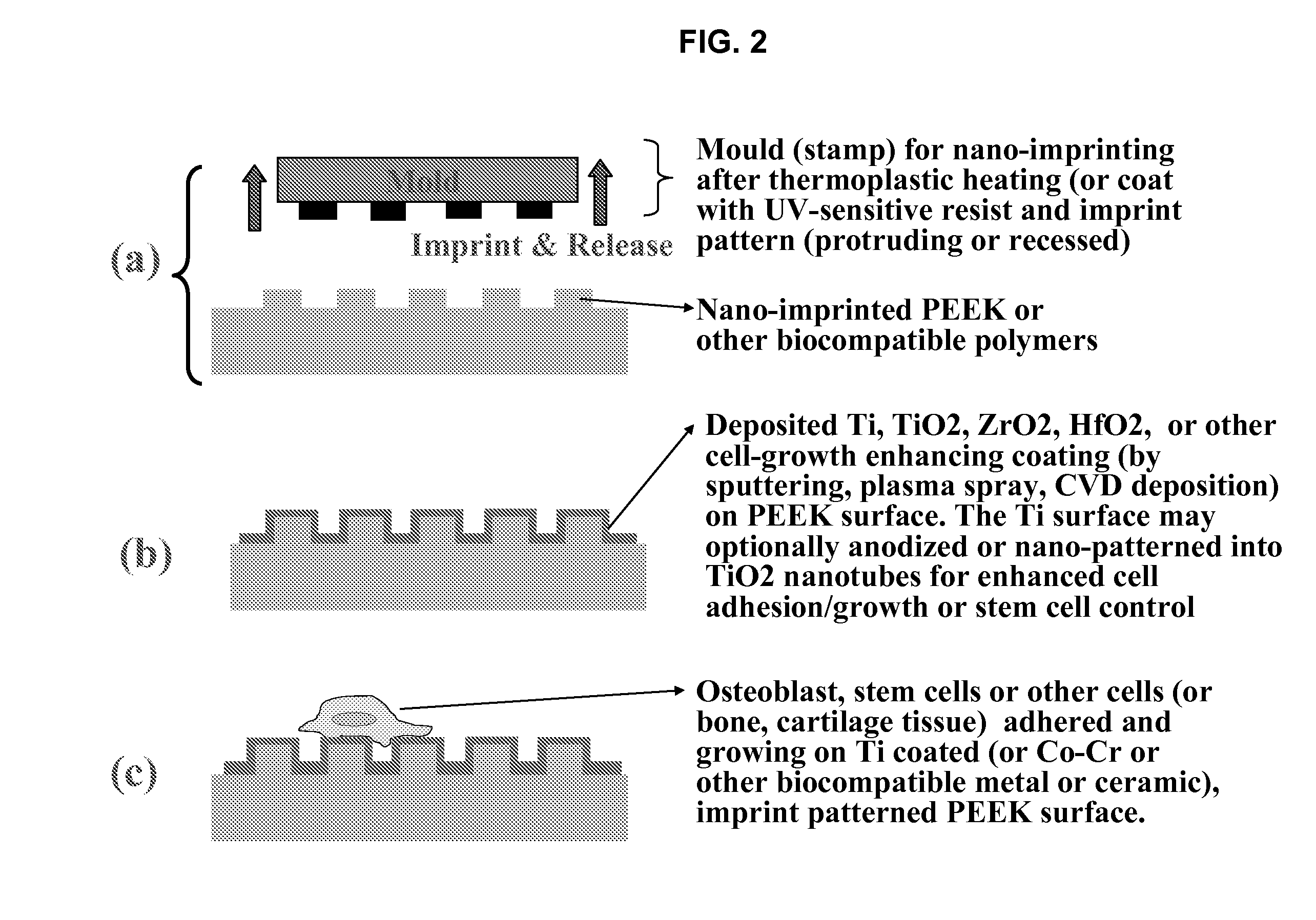

- Surface-nanopatterned PEEK or ultra-high-molecular-weight polyethylene (UHMWPE) with nanostructured coatings such as Ti or TiO2 nanotubes, nanowires, and nano-grooves to enhance osseointegration and bone bonding, using techniques like anodization and patterned chemical etching.

Biocompatibility and Safety Considerations

The integration of nanoarchitected mechanical metamaterials into prosthetic applications necessitates rigorous assessment of biocompatibility and safety considerations. These advanced materials, while offering unprecedented mechanical properties, must meet stringent biological safety standards before clinical implementation.

Material selection represents the first critical consideration, as direct contact with human tissue demands biocompatible constituents. Titanium alloys, medical-grade polymers, and certain ceramics have demonstrated promising compatibility profiles when structured at the nanoscale. However, the novel geometrical arrangements in metamaterials may alter cellular responses even when using established biocompatible materials, requiring comprehensive biocompatibility testing beyond standard protocols.

Cytotoxicity assessment of nanoarchitected metamaterials presents unique challenges due to their complex structures. Studies indicate that cell viability, proliferation, and differentiation can be significantly influenced by the specific architectural features at the micro and nanoscale. The three-dimensional nature of these structures creates microenvironments that may either promote or inhibit cellular functions depending on precise geometric parameters.

Inflammatory responses represent another critical safety consideration. Research has shown that certain nanoarchitectures may trigger unexpected immune reactions despite using materials that are individually biocompatible. The surface area-to-volume ratio, which is dramatically increased in these structures, can amplify potential inflammatory pathways through enhanced protein adsorption and subsequent immune cell activation.

Long-term stability within the biological environment poses additional concerns. Mechanical metamaterials must maintain their structural integrity and functional properties when exposed to physiological conditions. Degradation products from these complex structures may exhibit different toxicity profiles compared to bulk materials, necessitating thorough investigation of their long-term biological effects.

Sterilization compatibility represents a practical yet crucial consideration. Traditional sterilization methods such as autoclaving, gamma irradiation, or chemical treatments may compromise the intricate nanoarchitectures that provide the metamaterials' unique properties. Alternative sterilization approaches must be developed and validated specifically for these advanced structures.

Regulatory pathways for nanoarchitected metamaterial-based prosthetics remain challenging due to their novelty. Current frameworks for medical device approval may not adequately address the unique characteristics and potential risks associated with these materials. Collaborative efforts between researchers, industry, and regulatory bodies are essential to establish appropriate evaluation standards and approval processes.

Standardized testing protocols specifically designed for nanoarchitected metamaterials in prosthetic applications are currently lacking. The development of such protocols represents a critical step toward ensuring consistent safety evaluation across different research groups and manufacturers, ultimately facilitating clinical translation of these promising technologies.

Material selection represents the first critical consideration, as direct contact with human tissue demands biocompatible constituents. Titanium alloys, medical-grade polymers, and certain ceramics have demonstrated promising compatibility profiles when structured at the nanoscale. However, the novel geometrical arrangements in metamaterials may alter cellular responses even when using established biocompatible materials, requiring comprehensive biocompatibility testing beyond standard protocols.

Cytotoxicity assessment of nanoarchitected metamaterials presents unique challenges due to their complex structures. Studies indicate that cell viability, proliferation, and differentiation can be significantly influenced by the specific architectural features at the micro and nanoscale. The three-dimensional nature of these structures creates microenvironments that may either promote or inhibit cellular functions depending on precise geometric parameters.

Inflammatory responses represent another critical safety consideration. Research has shown that certain nanoarchitectures may trigger unexpected immune reactions despite using materials that are individually biocompatible. The surface area-to-volume ratio, which is dramatically increased in these structures, can amplify potential inflammatory pathways through enhanced protein adsorption and subsequent immune cell activation.

Long-term stability within the biological environment poses additional concerns. Mechanical metamaterials must maintain their structural integrity and functional properties when exposed to physiological conditions. Degradation products from these complex structures may exhibit different toxicity profiles compared to bulk materials, necessitating thorough investigation of their long-term biological effects.

Sterilization compatibility represents a practical yet crucial consideration. Traditional sterilization methods such as autoclaving, gamma irradiation, or chemical treatments may compromise the intricate nanoarchitectures that provide the metamaterials' unique properties. Alternative sterilization approaches must be developed and validated specifically for these advanced structures.

Regulatory pathways for nanoarchitected metamaterial-based prosthetics remain challenging due to their novelty. Current frameworks for medical device approval may not adequately address the unique characteristics and potential risks associated with these materials. Collaborative efforts between researchers, industry, and regulatory bodies are essential to establish appropriate evaluation standards and approval processes.

Standardized testing protocols specifically designed for nanoarchitected metamaterials in prosthetic applications are currently lacking. The development of such protocols represents a critical step toward ensuring consistent safety evaluation across different research groups and manufacturers, ultimately facilitating clinical translation of these promising technologies.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of nanoarchitected mechanical metamaterials represents a significant challenge in their transition from laboratory curiosities to practical prosthetic applications. Current fabrication methods such as two-photon lithography and direct laser writing offer exceptional precision but suffer from extremely low throughput, typically producing only a few cubic millimeters of material per day. This fundamental limitation has kept production costs prohibitively high, with estimates ranging from $10,000 to $100,000 per cubic centimeter, making widespread clinical adoption economically unfeasible.

Recent advances in parallel processing techniques show promising developments. Multi-beam interference lithography and high-speed projection micro-stereolithography have demonstrated potential for scaling production by orders of magnitude. These approaches can simultaneously pattern multiple areas, potentially increasing throughput by 10-100 times compared to traditional serial methods. However, these technologies remain in early development stages for metamaterial applications.

Material costs present another significant consideration. While base polymers used in many metamaterial structures are relatively inexpensive, specialized photoresists and nanomaterials required for advanced mechanical properties can cost $1,000-5,000 per liter. Post-processing treatments, including metal coating and surface functionalization necessary for biocompatibility, further increase production expenses by 30-50%.

Economic analysis indicates that achieving commercial viability requires reducing manufacturing costs by approximately 95% from current levels. Industry projections suggest this may be possible within 5-7 years through continued development of parallel processing technologies and economies of scale. The learning curve for manufacturing efficiency typically follows a 70-85% progress ratio, meaning costs decrease by 15-30% with each doubling of production volume.

For prosthetic applications specifically, the cost-benefit analysis must consider the enhanced functionality provided by metamaterial-based components. Preliminary studies suggest that metamaterial prosthetics could reduce secondary healthcare costs by 20-40% through improved comfort, reduced tissue damage, and extended device lifespan. This potential for downstream savings may justify higher initial manufacturing costs during early adoption phases.

Strategic partnerships between academic institutions, manufacturing technology companies, and medical device manufacturers represent the most promising pathway to overcome these economic barriers. Several collaborative initiatives have recently secured significant funding to develop scalable manufacturing platforms specifically for metamaterial-based medical applications, indicating growing recognition of both the challenges and potential in this field.

Recent advances in parallel processing techniques show promising developments. Multi-beam interference lithography and high-speed projection micro-stereolithography have demonstrated potential for scaling production by orders of magnitude. These approaches can simultaneously pattern multiple areas, potentially increasing throughput by 10-100 times compared to traditional serial methods. However, these technologies remain in early development stages for metamaterial applications.

Material costs present another significant consideration. While base polymers used in many metamaterial structures are relatively inexpensive, specialized photoresists and nanomaterials required for advanced mechanical properties can cost $1,000-5,000 per liter. Post-processing treatments, including metal coating and surface functionalization necessary for biocompatibility, further increase production expenses by 30-50%.

Economic analysis indicates that achieving commercial viability requires reducing manufacturing costs by approximately 95% from current levels. Industry projections suggest this may be possible within 5-7 years through continued development of parallel processing technologies and economies of scale. The learning curve for manufacturing efficiency typically follows a 70-85% progress ratio, meaning costs decrease by 15-30% with each doubling of production volume.

For prosthetic applications specifically, the cost-benefit analysis must consider the enhanced functionality provided by metamaterial-based components. Preliminary studies suggest that metamaterial prosthetics could reduce secondary healthcare costs by 20-40% through improved comfort, reduced tissue damage, and extended device lifespan. This potential for downstream savings may justify higher initial manufacturing costs during early adoption phases.

Strategic partnerships between academic institutions, manufacturing technology companies, and medical device manufacturers represent the most promising pathway to overcome these economic barriers. Several collaborative initiatives have recently secured significant funding to develop scalable manufacturing platforms specifically for metamaterial-based medical applications, indicating growing recognition of both the challenges and potential in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!