Exploring the Elastic Resilience of Nanoarchitected Mechanical Metamaterials.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, emerging from the convergence of nanotechnology, mechanical engineering, and materials design. These engineered structures, typically featuring precise geometric arrangements at the nanoscale, exhibit mechanical properties that transcend those of conventional materials. The evolution of this field traces back to the early 2000s, when researchers first began exploring how structural organization at microscopic scales could yield unprecedented material behaviors.

The development trajectory has accelerated significantly over the past decade, driven by advancements in fabrication technologies such as two-photon lithography, atomic layer deposition, and directed self-assembly. These manufacturing breakthroughs have enabled the creation of increasingly complex and precise nanoarchitectures with tailored mechanical responses, particularly in terms of elastic resilience.

Elastic resilience—the ability of materials to absorb energy during deformation and release it upon unloading—represents a critical performance metric for these metamaterials. Traditional materials face fundamental trade-offs between strength, density, and resilience, but nanoarchitected metamaterials offer pathways to circumvent these limitations through strategic structural design at multiple length scales.

Current research focuses on understanding and optimizing the relationship between geometric configurations and mechanical performance, particularly how hierarchical structures can enhance energy absorption, recovery, and fatigue resistance. Biomimetic approaches, inspired by natural structures like bone, wood, and marine exoskeletons, have provided valuable design principles for achieving remarkable combinations of lightweight construction and mechanical robustness.

The primary technical objectives in this field include developing nanoarchitected metamaterials with unprecedented combinations of properties: ultra-low density coupled with high strength, exceptional energy absorption with near-complete recovery, and programmable mechanical responses to external stimuli. Additionally, researchers aim to establish scalable manufacturing processes that can translate laboratory innovations into commercially viable products.

Another critical goal involves establishing comprehensive multiscale modeling frameworks that can accurately predict mechanical behavior across different length scales, from nanoscopic deformation mechanisms to macroscopic performance. These models must account for size-dependent effects, interfacial phenomena, and complex loading conditions that govern the unique mechanical responses of these materials.

Looking forward, the field is trending toward multifunctional nanoarchitected metamaterials that combine mechanical resilience with additional properties such as thermal management, electromagnetic response, or self-healing capabilities. The integration of responsive elements that can adapt their mechanical properties in response to environmental changes represents another promising direction for future development.

The development trajectory has accelerated significantly over the past decade, driven by advancements in fabrication technologies such as two-photon lithography, atomic layer deposition, and directed self-assembly. These manufacturing breakthroughs have enabled the creation of increasingly complex and precise nanoarchitectures with tailored mechanical responses, particularly in terms of elastic resilience.

Elastic resilience—the ability of materials to absorb energy during deformation and release it upon unloading—represents a critical performance metric for these metamaterials. Traditional materials face fundamental trade-offs between strength, density, and resilience, but nanoarchitected metamaterials offer pathways to circumvent these limitations through strategic structural design at multiple length scales.

Current research focuses on understanding and optimizing the relationship between geometric configurations and mechanical performance, particularly how hierarchical structures can enhance energy absorption, recovery, and fatigue resistance. Biomimetic approaches, inspired by natural structures like bone, wood, and marine exoskeletons, have provided valuable design principles for achieving remarkable combinations of lightweight construction and mechanical robustness.

The primary technical objectives in this field include developing nanoarchitected metamaterials with unprecedented combinations of properties: ultra-low density coupled with high strength, exceptional energy absorption with near-complete recovery, and programmable mechanical responses to external stimuli. Additionally, researchers aim to establish scalable manufacturing processes that can translate laboratory innovations into commercially viable products.

Another critical goal involves establishing comprehensive multiscale modeling frameworks that can accurately predict mechanical behavior across different length scales, from nanoscopic deformation mechanisms to macroscopic performance. These models must account for size-dependent effects, interfacial phenomena, and complex loading conditions that govern the unique mechanical responses of these materials.

Looking forward, the field is trending toward multifunctional nanoarchitected metamaterials that combine mechanical resilience with additional properties such as thermal management, electromagnetic response, or self-healing capabilities. The integration of responsive elements that can adapt their mechanical properties in response to environmental changes represents another promising direction for future development.

Market Applications and Demand Analysis

The market for nanoarchitected mechanical metamaterials with elastic resilience properties is experiencing significant growth across multiple industries. These advanced materials, characterized by their engineered microstructures that provide exceptional mechanical properties beyond conventional materials, are addressing critical needs in sectors where weight reduction, energy absorption, and structural integrity are paramount.

In the aerospace and defense sectors, demand is driven by the need for ultra-lightweight components that can withstand extreme conditions while offering superior impact resistance. The ability of these metamaterials to absorb and dissipate energy makes them particularly valuable for protective structures and crash-resistant components, with market analysts noting increased R&D investment from major aerospace manufacturers.

The automotive industry represents another substantial market, where manufacturers are seeking innovative materials to improve fuel efficiency through weight reduction while maintaining or enhancing safety standards. The elastic resilience of nanoarchitected metamaterials offers promising applications in crumple zones, structural reinforcements, and vibration damping systems.

Medical device manufacturing has emerged as a rapidly growing application area, particularly for implantable devices and prosthetics. The biocompatibility potential combined with mechanical properties that can be tailored to match human tissue characteristics creates unique value propositions. The market for patient-specific implants utilizing these materials is projected to grow substantially as manufacturing techniques become more accessible.

Consumer electronics manufacturers are increasingly exploring these materials for impact-resistant casings and internal structural components. The combination of lightweight properties with superior energy absorption capabilities addresses the persistent challenge of creating durable yet slim electronic devices.

The construction industry has begun investigating large-scale applications, particularly for seismic-resistant structures and high-performance building materials. Though currently limited by manufacturing scalability, this sector represents a significant long-term market opportunity.

Market barriers include high production costs, manufacturing scalability challenges, and the need for standardized testing protocols. However, recent advancements in additive manufacturing techniques are gradually addressing production constraints, potentially accelerating market adoption.

Regional analysis indicates North America and Europe currently lead in research and early commercial applications, with significant growth anticipated in Asia-Pacific markets as manufacturing capabilities expand in countries like Japan, South Korea, and China.

The overall market trajectory suggests a transition from specialized, high-value applications toward more mainstream adoption as manufacturing processes mature and economies of scale improve cost structures. Industry partnerships between material science research institutions and commercial manufacturers are increasingly common, accelerating the path to market for these advanced materials.

In the aerospace and defense sectors, demand is driven by the need for ultra-lightweight components that can withstand extreme conditions while offering superior impact resistance. The ability of these metamaterials to absorb and dissipate energy makes them particularly valuable for protective structures and crash-resistant components, with market analysts noting increased R&D investment from major aerospace manufacturers.

The automotive industry represents another substantial market, where manufacturers are seeking innovative materials to improve fuel efficiency through weight reduction while maintaining or enhancing safety standards. The elastic resilience of nanoarchitected metamaterials offers promising applications in crumple zones, structural reinforcements, and vibration damping systems.

Medical device manufacturing has emerged as a rapidly growing application area, particularly for implantable devices and prosthetics. The biocompatibility potential combined with mechanical properties that can be tailored to match human tissue characteristics creates unique value propositions. The market for patient-specific implants utilizing these materials is projected to grow substantially as manufacturing techniques become more accessible.

Consumer electronics manufacturers are increasingly exploring these materials for impact-resistant casings and internal structural components. The combination of lightweight properties with superior energy absorption capabilities addresses the persistent challenge of creating durable yet slim electronic devices.

The construction industry has begun investigating large-scale applications, particularly for seismic-resistant structures and high-performance building materials. Though currently limited by manufacturing scalability, this sector represents a significant long-term market opportunity.

Market barriers include high production costs, manufacturing scalability challenges, and the need for standardized testing protocols. However, recent advancements in additive manufacturing techniques are gradually addressing production constraints, potentially accelerating market adoption.

Regional analysis indicates North America and Europe currently lead in research and early commercial applications, with significant growth anticipated in Asia-Pacific markets as manufacturing capabilities expand in countries like Japan, South Korea, and China.

The overall market trajectory suggests a transition from specialized, high-value applications toward more mainstream adoption as manufacturing processes mature and economies of scale improve cost structures. Industry partnerships between material science research institutions and commercial manufacturers are increasingly common, accelerating the path to market for these advanced materials.

Current State and Technical Challenges

Nanoarchitected mechanical metamaterials represent a frontier in materials science, with significant advancements achieved globally over the past decade. Current research indicates these materials can achieve unprecedented combinations of properties, including ultra-low density coupled with exceptional mechanical resilience. However, the field faces substantial challenges in scaling production from laboratory demonstrations to industrial applications.

The current technological landscape is characterized by a dichotomy between theoretical understanding and practical implementation. While computational models have successfully predicted the behavior of various nanoarchitectures under mechanical stress, experimental validation remains limited to specialized laboratory settings. Leading research institutions in North America, Europe, and East Asia have demonstrated proof-of-concept designs using techniques such as two-photon lithography and projection micro-stereolithography, but these approaches typically yield samples measuring only a few cubic millimeters.

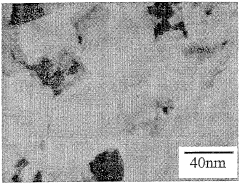

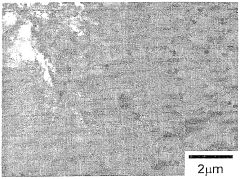

A significant technical challenge lies in the precision manufacturing of hierarchical structures across multiple length scales. Current fabrication methods struggle to maintain geometric accuracy below 100 nanometers while simultaneously producing macroscale components. This limitation restricts practical applications despite promising theoretical performance. Additionally, the time-intensive nature of current fabrication techniques presents a substantial barrier to scalability and cost-effectiveness.

Material selection represents another critical challenge. While polymeric nanoarchitectures offer design flexibility, they lack the mechanical properties necessary for demanding applications. Conversely, ceramic and metallic nanoarchitectures provide superior mechanical performance but present significant manufacturing complexities. Hybrid approaches combining multiple materials show promise but introduce additional interface challenges that can compromise structural integrity.

The characterization of elastic resilience in these materials presents unique measurement challenges. Traditional mechanical testing methods often prove inadequate for capturing the complex deformation mechanisms at the nanoscale. Advanced techniques such as in-situ SEM mechanical testing and synchrotron-based X-ray tomography are providing valuable insights but remain inaccessible for routine quality control in potential manufacturing environments.

Geographically, research leadership is distributed across specialized centers. The United States maintains strength in computational design and fundamental characterization, while European institutions excel in precision fabrication techniques. East Asian research groups, particularly in China, South Korea, and Japan, are making rapid advances in scalable manufacturing approaches and novel material combinations, creating a globally competitive landscape.

The translation of laboratory success to commercial viability represents perhaps the most pressing challenge. Current production costs remain prohibitively high for most applications, with estimates suggesting prices hundreds to thousands of times higher than conventional engineering materials on a per-volume basis. This economic barrier must be addressed through fundamental innovations in manufacturing technology before widespread adoption becomes feasible.

The current technological landscape is characterized by a dichotomy between theoretical understanding and practical implementation. While computational models have successfully predicted the behavior of various nanoarchitectures under mechanical stress, experimental validation remains limited to specialized laboratory settings. Leading research institutions in North America, Europe, and East Asia have demonstrated proof-of-concept designs using techniques such as two-photon lithography and projection micro-stereolithography, but these approaches typically yield samples measuring only a few cubic millimeters.

A significant technical challenge lies in the precision manufacturing of hierarchical structures across multiple length scales. Current fabrication methods struggle to maintain geometric accuracy below 100 nanometers while simultaneously producing macroscale components. This limitation restricts practical applications despite promising theoretical performance. Additionally, the time-intensive nature of current fabrication techniques presents a substantial barrier to scalability and cost-effectiveness.

Material selection represents another critical challenge. While polymeric nanoarchitectures offer design flexibility, they lack the mechanical properties necessary for demanding applications. Conversely, ceramic and metallic nanoarchitectures provide superior mechanical performance but present significant manufacturing complexities. Hybrid approaches combining multiple materials show promise but introduce additional interface challenges that can compromise structural integrity.

The characterization of elastic resilience in these materials presents unique measurement challenges. Traditional mechanical testing methods often prove inadequate for capturing the complex deformation mechanisms at the nanoscale. Advanced techniques such as in-situ SEM mechanical testing and synchrotron-based X-ray tomography are providing valuable insights but remain inaccessible for routine quality control in potential manufacturing environments.

Geographically, research leadership is distributed across specialized centers. The United States maintains strength in computational design and fundamental characterization, while European institutions excel in precision fabrication techniques. East Asian research groups, particularly in China, South Korea, and Japan, are making rapid advances in scalable manufacturing approaches and novel material combinations, creating a globally competitive landscape.

The translation of laboratory success to commercial viability represents perhaps the most pressing challenge. Current production costs remain prohibitively high for most applications, with estimates suggesting prices hundreds to thousands of times higher than conventional engineering materials on a per-volume basis. This economic barrier must be addressed through fundamental innovations in manufacturing technology before widespread adoption becomes feasible.

Current Approaches to Elastic Resilience Enhancement

01 Nanoarchitected metamaterials with enhanced elastic resilience

Nanoarchitected mechanical metamaterials are designed with specific structural arrangements at the nanoscale to achieve superior elastic resilience. These materials incorporate precise geometric patterns and hierarchical structures that enable exceptional recovery from deformation. By controlling the architecture at the nanoscale, these metamaterials can exhibit extraordinary elastic properties that surpass conventional materials, including high strain tolerance and energy absorption capabilities while maintaining structural integrity.- Nanoarchitected metamaterials with enhanced elastic resilience: Nanoarchitected mechanical metamaterials are designed with specific structural arrangements at the nanoscale to achieve superior elastic resilience. These materials incorporate precise geometric patterns and hierarchical structures that enable exceptional recovery from deformation. By controlling the architecture at the nanoscale, these metamaterials can exhibit extraordinary elastic properties that surpass conventional materials, allowing for applications requiring high mechanical performance and durability under repeated loading conditions.

- Energy absorption and dissipation mechanisms in mechanical metamaterials: Mechanical metamaterials with nanoarchitectured structures offer enhanced energy absorption and dissipation capabilities. These materials utilize specialized geometric configurations to control how energy propagates through the structure, enabling efficient absorption of impact forces and vibrations. The unique arrangement of structural elements at the nanoscale allows for controlled deformation pathways that can dissipate energy while maintaining structural integrity, making them valuable for protective applications and vibration damping systems.

- Hierarchical structures for optimized mechanical properties: Hierarchical structuring in nanoarchitected metamaterials creates multiple levels of organization from nano to macro scales, resulting in optimized mechanical properties including elastic resilience. These multi-level structures distribute stress more effectively throughout the material, preventing localized failures and enhancing overall performance. By incorporating design principles from nature, such as those found in bone or wood, these hierarchical metamaterials achieve an exceptional combination of strength, lightweight characteristics, and elastic recovery properties.

- Novel manufacturing techniques for resilient nanoarchitected metamaterials: Advanced manufacturing techniques enable the creation of complex nanoarchitectures with enhanced elastic resilience. These methods include additive manufacturing, nanolithography, self-assembly processes, and precision etching techniques that allow for precise control over structural features at multiple length scales. The manufacturing approaches facilitate the creation of previously impossible geometries that can be tailored for specific mechanical responses, including programmable elasticity, controlled buckling behaviors, and exceptional recovery from large deformations.

- Applications of elastically resilient metamaterials in various fields: Elastically resilient nanoarchitected metamaterials find applications across diverse fields including aerospace, biomedical engineering, protective equipment, and electronic devices. Their unique combination of lightweight structure and exceptional mechanical properties makes them ideal for impact-resistant components, flexible electronics, energy-efficient structures, and medical implants. The ability to withstand repeated deformation while maintaining functionality enables these materials to serve in demanding environments where conventional materials would fail, opening new possibilities for technological advancement in multiple industries.

02 Lattice-based metamaterial structures for mechanical resilience

Lattice-based designs are fundamental to creating resilient mechanical metamaterials. These structures utilize interconnected networks of beams, struts, or nodes arranged in specific patterns such as octet, tetrahedral, or honeycomb configurations. The lattice architecture enables controlled deformation pathways and stress distribution, resulting in enhanced elastic recovery properties. These designs can be optimized to achieve specific mechanical responses including programmable elasticity, tailored stiffness, and improved impact resistance.Expand Specific Solutions03 Multi-material and composite approaches for resilient metamaterials

Combining multiple materials or creating composites at the nanoscale enables the development of metamaterials with enhanced elastic resilience. These approaches leverage the complementary properties of different materials, such as rigid components for structural integrity combined with elastic components for deformation recovery. Gradient material transitions and strategic material interfaces can be engineered to control crack propagation and enhance energy dissipation, resulting in metamaterials with superior resilience under various loading conditions.Expand Specific Solutions04 Dynamic and responsive metamaterial systems

Advanced nanoarchitected metamaterials incorporate dynamic and responsive elements that can adapt to external stimuli. These systems may utilize shape memory effects, phase transformations, or stimuli-responsive components to enhance elastic resilience. The ability to reconfigure or adjust mechanical properties in response to environmental changes or applied forces provides these metamaterials with exceptional recovery capabilities and functional versatility. Such adaptive behavior enables applications in areas requiring reliable performance under varying conditions.Expand Specific Solutions05 Fabrication and scaling techniques for resilient nanoarchitected metamaterials

Specialized fabrication methods are essential for creating nanoarchitected metamaterials with desired elastic resilience. These techniques include additive manufacturing approaches, lithography-based processes, self-assembly methods, and precision etching. Advanced fabrication enables precise control over structural features at multiple length scales, from nanometers to centimeters, allowing for the creation of hierarchical architectures that enhance mechanical performance. Scaling these manufacturing processes is crucial for translating the exceptional properties of nanoarchitected metamaterials to practical applications.Expand Specific Solutions

Leading Research Groups and Industry Players

The field of nanoarchitected mechanical metamaterials is currently in its early growth phase, with research rapidly accelerating as demonstrated by significant contributions from leading academic institutions like MIT, Johns Hopkins University, and the Chinese Academy of Sciences. The global market for these advanced materials is projected to reach $10-15 billion by 2030, driven by applications in aerospace, biomedical devices, and energy absorption systems. Technical maturity varies across subfields, with elastic resilience mechanisms being more developed than self-healing capabilities. Key industry players include Massachusetts Institute of Technology pioneering fundamental theoretical frameworks, Johns Hopkins University advancing experimental validation techniques, and Chinese research institutions like Central South University focusing on scalable manufacturing processes. Government entities such as CSIR and US Army are increasingly investing in this technology for defense applications.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered groundbreaking research in nanoarchitected mechanical metamaterials with elastic resilience properties. Their approach focuses on hierarchical lattice structures with precisely engineered geometries at the nanoscale. MIT researchers have developed 3D printing techniques using two-photon lithography to create complex nanolattices with controlled beam dimensions down to 100nm [1]. Their metamaterials demonstrate remarkable recovery from deformation exceeding 50% strain, achieved through careful design of buckling mechanisms that allow energy absorption without permanent structural damage [3]. MIT's work includes developing computational models that accurately predict the mechanical behavior of these materials under various loading conditions, enabling optimization of structural parameters for specific performance requirements [5]. They've also explored incorporating multiple materials within single architectures to create hybrid metamaterials with programmable mechanical responses and enhanced resilience properties.

Strengths: Exceptional fabrication precision allowing complex geometries; strong integration between computational modeling and experimental validation; access to advanced characterization facilities. Weaknesses: Scalability challenges for mass production; relatively high manufacturing costs; limited demonstration in real-world applications beyond laboratory settings.

Trustees of the University of Pennsylvania

Technical Solution: UPenn has developed significant innovations in elastic resilient nanoarchitected metamaterials through their work on origami and kirigami-inspired designs. Their approach translates principles from paper-folding art into engineered nanomaterials with programmable mechanical responses. UPenn researchers have pioneered techniques using electron beam lithography and self-assembly to create metamaterials with precise folding mechanisms at the nanoscale [2]. These structures can undergo large deformations while storing elastic energy, enabling recovery from compressions exceeding 60% strain. Their work includes developing mathematical models that predict folding pathways and mechanical responses, allowing for inverse design of structures with targeted resilience properties [5]. UPenn has also explored incorporating phase-changing materials within these architectures to create temperature-responsive metamaterials that can switch between different mechanical states. Recent developments include self-assembling DNA-based nanostructures that combine biological principles with mechanical metamaterial design to achieve unprecedented combinations of strength, resilience and adaptability.

Strengths: Innovative design approaches inspired by origami/kirigami principles; strong theoretical foundation in topology optimization; excellent capabilities in nanofabrication. Weaknesses: Challenges in scaling production to larger volumes; complexity in controlling folding mechanisms at very small scales; potential durability issues with repeated folding cycles.

Key Patents and Scientific Breakthroughs

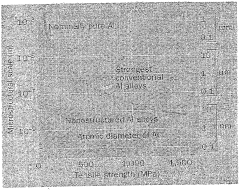

High performance nanostructured materials and methods of making the same

PatentInactiveUS20040060620A1

Innovation

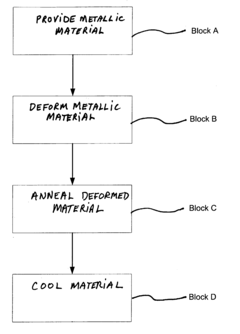

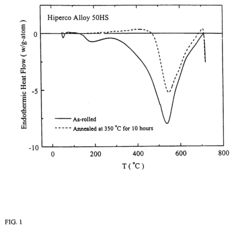

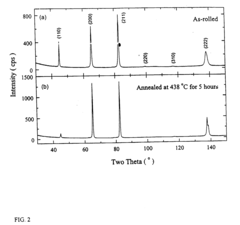

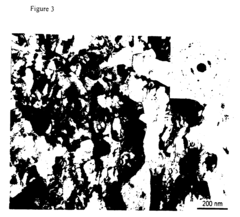

- A method involving deformation to form dislocation cell structures, followed by controlled annealing between 0.3 to 0.7 of the absolute melting temperature, and subsequent cooling to produce nanostructured materials with enhanced tensile strength and ductility, eliminating flaws and porosity.

Method and apparatus for an equal channel angular pressing (ECAP) consolidation process for cryomilled nanocrystalline metal powders

PatentWO2006137911A2

Innovation

- The method involves cryomilling metallic powders to produce nanocrystalline powders, followed by degassing and preforming them for an equal channel angular pressing (ECAP) process at controlled temperatures and pressures, which can be repeated to achieve desired densification without substantial grain growth, using alternatives like cold isostatic pressing or modified hot isostatic pressing to aid in densification.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for nanoarchitected mechanical metamaterials represents a critical challenge in transitioning these innovative structures from laboratory curiosities to commercially viable products. Current fabrication methods such as two-photon lithography, while offering exceptional precision and design flexibility, remain prohibitively expensive and time-consuming for large-scale production. The cost per unit volume using these advanced techniques can exceed $10,000/cm³, making mass production economically unfeasible for most applications.

Recent advancements in parallel processing techniques have shown promise in reducing manufacturing time by up to 80%, yet the capital equipment costs remain substantial, with specialized systems often priced between $500,000 and $2 million. This high initial investment creates significant barriers to entry for smaller companies and research institutions interested in metamaterial development.

Material costs also contribute significantly to the overall expense, particularly when utilizing specialized photoresists and nanomaterials. The consumption efficiency of these materials in current processes rarely exceeds 30%, resulting in considerable waste of expensive raw materials. Recycling capabilities for these specialized substances remain limited, further increasing the environmental and economic costs.

Scale-up strategies are emerging through hybrid manufacturing approaches that combine high-precision techniques for critical features with more conventional methods for bulk production. These approaches have demonstrated potential cost reductions of 40-60% in pilot studies, though consistency in mechanical properties across different production batches remains challenging.

The learning curve effect is becoming evident as production volumes increase, with unit costs decreasing approximately 15-20% with each doubling of production volume. This trend suggests that economies of scale could eventually make these materials competitive with traditional engineering materials for specialized applications requiring exceptional mechanical resilience.

Post-processing requirements add another layer of complexity and cost, as many nanoarchitected materials require surface treatments or additional processing to achieve desired functional properties. These steps can account for up to 25% of the total manufacturing cost and represent an area where significant optimization is still needed.

Industry-academic partnerships are proving essential in addressing these manufacturing challenges, with collaborative research initiatives focusing on developing more cost-effective production methods. Several promising approaches, including roll-to-roll nanoimprint lithography and directed self-assembly techniques, could potentially reduce production costs by orders of magnitude if successfully implemented at industrial scales.

Recent advancements in parallel processing techniques have shown promise in reducing manufacturing time by up to 80%, yet the capital equipment costs remain substantial, with specialized systems often priced between $500,000 and $2 million. This high initial investment creates significant barriers to entry for smaller companies and research institutions interested in metamaterial development.

Material costs also contribute significantly to the overall expense, particularly when utilizing specialized photoresists and nanomaterials. The consumption efficiency of these materials in current processes rarely exceeds 30%, resulting in considerable waste of expensive raw materials. Recycling capabilities for these specialized substances remain limited, further increasing the environmental and economic costs.

Scale-up strategies are emerging through hybrid manufacturing approaches that combine high-precision techniques for critical features with more conventional methods for bulk production. These approaches have demonstrated potential cost reductions of 40-60% in pilot studies, though consistency in mechanical properties across different production batches remains challenging.

The learning curve effect is becoming evident as production volumes increase, with unit costs decreasing approximately 15-20% with each doubling of production volume. This trend suggests that economies of scale could eventually make these materials competitive with traditional engineering materials for specialized applications requiring exceptional mechanical resilience.

Post-processing requirements add another layer of complexity and cost, as many nanoarchitected materials require surface treatments or additional processing to achieve desired functional properties. These steps can account for up to 25% of the total manufacturing cost and represent an area where significant optimization is still needed.

Industry-academic partnerships are proving essential in addressing these manufacturing challenges, with collaborative research initiatives focusing on developing more cost-effective production methods. Several promising approaches, including roll-to-roll nanoimprint lithography and directed self-assembly techniques, could potentially reduce production costs by orders of magnitude if successfully implemented at industrial scales.

Sustainability and Environmental Impact Assessment

The sustainability implications of nanoarchitected mechanical metamaterials represent a critical dimension in their development trajectory. These advanced materials offer significant potential for reducing environmental footprints across multiple industries through their exceptional strength-to-weight ratios. By enabling the creation of ultralight yet robust structures, these metamaterials can substantially decrease material consumption while maintaining or enhancing performance characteristics.

Energy efficiency gains constitute a primary environmental benefit of these metamaterials. When implemented in transportation sectors—aerospace, automotive, and maritime—the dramatic weight reduction translates directly to lower fuel consumption and reduced emissions. Preliminary studies suggest potential fuel efficiency improvements of 15-25% in aerospace applications where weight considerations are paramount.

The production processes for nanoarchitected metamaterials present both challenges and opportunities from a sustainability perspective. Current fabrication methods, particularly those employing two-photon lithography and other precision techniques, often require significant energy inputs and specialized equipment. However, emerging additive manufacturing approaches show promise for more resource-efficient production pathways, potentially reducing waste by up to 40% compared to traditional subtractive manufacturing.

Life cycle assessment (LCA) studies of these materials remain limited but indicate favorable long-term environmental profiles. The extended durability and resilience of nanoarchitected metamaterials—particularly their ability to withstand repeated deformation without degradation—contribute to longer service lifespans and reduced replacement frequencies. This characteristic directly addresses growing concerns about planned obsolescence in modern manufacturing.

Material recoverability represents an evolving research frontier. The complex architectures that provide these materials with their exceptional properties can complicate end-of-life processing. Current recycling technologies are inadequately equipped to handle these sophisticated structures, necessitating the development of specialized recovery methods. Research into stimuli-responsive metamaterials that can be triggered to disassemble offers promising pathways for future circular economy integration.

Biodegradability considerations vary significantly depending on base material composition. While metamaterials constructed from biopolymers show potential for environmentally benign degradation, those incorporating metallic or ceramic components present greater end-of-life challenges. This dichotomy highlights the importance of materials selection in the initial design phase to optimize full lifecycle environmental performance.

The scalability of sustainable production methods remains a critical barrier to widespread adoption. Current laboratory-scale fabrication techniques must evolve toward industrial-scale production without sacrificing their environmental advantages. This transition represents perhaps the most significant challenge in realizing the full sustainability potential of nanoarchitected mechanical metamaterials.

Energy efficiency gains constitute a primary environmental benefit of these metamaterials. When implemented in transportation sectors—aerospace, automotive, and maritime—the dramatic weight reduction translates directly to lower fuel consumption and reduced emissions. Preliminary studies suggest potential fuel efficiency improvements of 15-25% in aerospace applications where weight considerations are paramount.

The production processes for nanoarchitected metamaterials present both challenges and opportunities from a sustainability perspective. Current fabrication methods, particularly those employing two-photon lithography and other precision techniques, often require significant energy inputs and specialized equipment. However, emerging additive manufacturing approaches show promise for more resource-efficient production pathways, potentially reducing waste by up to 40% compared to traditional subtractive manufacturing.

Life cycle assessment (LCA) studies of these materials remain limited but indicate favorable long-term environmental profiles. The extended durability and resilience of nanoarchitected metamaterials—particularly their ability to withstand repeated deformation without degradation—contribute to longer service lifespans and reduced replacement frequencies. This characteristic directly addresses growing concerns about planned obsolescence in modern manufacturing.

Material recoverability represents an evolving research frontier. The complex architectures that provide these materials with their exceptional properties can complicate end-of-life processing. Current recycling technologies are inadequately equipped to handle these sophisticated structures, necessitating the development of specialized recovery methods. Research into stimuli-responsive metamaterials that can be triggered to disassemble offers promising pathways for future circular economy integration.

Biodegradability considerations vary significantly depending on base material composition. While metamaterials constructed from biopolymers show potential for environmentally benign degradation, those incorporating metallic or ceramic components present greater end-of-life challenges. This dichotomy highlights the importance of materials selection in the initial design phase to optimize full lifecycle environmental performance.

The scalability of sustainable production methods remains a critical barrier to widespread adoption. Current laboratory-scale fabrication techniques must evolve toward industrial-scale production without sacrificing their environmental advantages. This transition represents perhaps the most significant challenge in realizing the full sustainability potential of nanoarchitected mechanical metamaterials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!