Nanoarchitected Mechanical Metamaterials in Security Screening Systems.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary class of engineered materials that derive their unique properties from their precisely designed micro- or nano-scale architecture rather than their chemical composition. The field has evolved significantly over the past two decades, transitioning from theoretical concepts to practical implementations with remarkable mechanical, optical, and acoustic properties.

The historical development of these materials began in the early 2000s with rudimentary structures, but has accelerated dramatically with advances in nanofabrication techniques such as two-photon lithography, self-assembly processes, and advanced 3D printing technologies. This technological evolution has enabled the creation of increasingly complex and functional metamaterial architectures with unprecedented property combinations.

In the security screening context, traditional detection systems face significant limitations in identifying certain threat materials, particularly those with low density or non-metallic composition. Conventional X-ray systems and metal detectors often struggle with detecting plastic explosives, ceramic weapons, and other non-traditional threats, creating critical security vulnerabilities at checkpoints worldwide.

The integration of nanoarchitected metamaterials into security screening systems presents a promising solution to these challenges. These materials can be designed to interact with electromagnetic waves, acoustic signals, or mechanical forces in highly specific ways, potentially enabling more sensitive and discriminating detection capabilities than conventional materials allow.

The primary technical objectives for nanoarchitected metamaterials in security applications include: developing structures with tailored electromagnetic responses across multiple frequency bands; creating mechanically robust yet lightweight screening components; engineering materials with tunable or switchable properties for adaptive screening; and designing systems that can be manufactured at scale with reasonable cost parameters.

Current research is particularly focused on metamaterials that can enhance terahertz imaging, improve the signal-to-noise ratio in screening devices, and enable multi-modal detection approaches. The ultimate goal is to create screening systems that can reliably detect a broader range of threat materials with fewer false positives, while maintaining or improving throughput rates at security checkpoints.

The convergence of nanotechnology, materials science, and security engineering in this field represents a significant opportunity for transformative advances in threat detection capabilities. As global security threats continue to evolve in sophistication, the development of equally advanced detection technologies becomes increasingly critical for maintaining effective security protocols in transportation hubs, government facilities, and other high-risk environments.

The historical development of these materials began in the early 2000s with rudimentary structures, but has accelerated dramatically with advances in nanofabrication techniques such as two-photon lithography, self-assembly processes, and advanced 3D printing technologies. This technological evolution has enabled the creation of increasingly complex and functional metamaterial architectures with unprecedented property combinations.

In the security screening context, traditional detection systems face significant limitations in identifying certain threat materials, particularly those with low density or non-metallic composition. Conventional X-ray systems and metal detectors often struggle with detecting plastic explosives, ceramic weapons, and other non-traditional threats, creating critical security vulnerabilities at checkpoints worldwide.

The integration of nanoarchitected metamaterials into security screening systems presents a promising solution to these challenges. These materials can be designed to interact with electromagnetic waves, acoustic signals, or mechanical forces in highly specific ways, potentially enabling more sensitive and discriminating detection capabilities than conventional materials allow.

The primary technical objectives for nanoarchitected metamaterials in security applications include: developing structures with tailored electromagnetic responses across multiple frequency bands; creating mechanically robust yet lightweight screening components; engineering materials with tunable or switchable properties for adaptive screening; and designing systems that can be manufactured at scale with reasonable cost parameters.

Current research is particularly focused on metamaterials that can enhance terahertz imaging, improve the signal-to-noise ratio in screening devices, and enable multi-modal detection approaches. The ultimate goal is to create screening systems that can reliably detect a broader range of threat materials with fewer false positives, while maintaining or improving throughput rates at security checkpoints.

The convergence of nanotechnology, materials science, and security engineering in this field represents a significant opportunity for transformative advances in threat detection capabilities. As global security threats continue to evolve in sophistication, the development of equally advanced detection technologies becomes increasingly critical for maintaining effective security protocols in transportation hubs, government facilities, and other high-risk environments.

Security Screening Market Demand Analysis

The global security screening market has witnessed substantial growth in recent years, driven by increasing security concerns across various sectors including transportation, border control, critical infrastructure, and public venues. The market was valued at approximately $8.4 billion in 2021 and is projected to reach $13.6 billion by 2027, growing at a CAGR of 7.8% during the forecast period.

The integration of nanoarchitected mechanical metamaterials into security screening systems represents a significant technological advancement with considerable market potential. Traditional security screening technologies face limitations in detection accuracy, throughput capacity, and false alarm rates. Market research indicates that approximately 30% of security breaches occur due to limitations in conventional screening technologies, creating a strong demand for innovative solutions.

Transportation security, particularly in aviation, remains the largest market segment, accounting for nearly 40% of the total security screening market. Airport authorities worldwide are actively seeking advanced materials and technologies that can enhance detection capabilities while reducing screening time. The International Air Transport Association (IATA) reports that passenger numbers are expected to reach 8.2 billion by 2037, intensifying the need for more efficient security screening solutions.

Border security represents another significant market segment with growing demand for advanced screening technologies. Government agencies globally are increasing investments in border security infrastructure, with spending expected to reach $168 billion by 2025. The ability of nanoarchitected metamaterials to detect concealed threats with higher precision addresses a critical need in this sector.

Critical infrastructure protection, including government buildings, energy facilities, and financial institutions, constitutes approximately 25% of the security screening market. These facilities require sophisticated screening systems capable of detecting increasingly complex threats. The market demand in this segment is growing at 9.2% annually, faster than the overall market average.

Commercial applications, including retail environments and entertainment venues, are emerging as significant growth areas for security screening technologies. These environments require unobtrusive screening solutions that maintain high throughput while ensuring effective threat detection. This segment is expected to grow at 10.5% annually through 2027.

Regional analysis reveals North America as the dominant market for security screening technologies, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.7% annually, driven by increasing security investments in China, India, and Southeast Asian countries.

Customer requirements are evolving toward multi-threat detection capabilities, reduced false alarm rates, higher throughput, and non-invasive screening methods. Nanoarchitected mechanical metamaterials, with their unique properties and customizable characteristics, are well-positioned to address these evolving market demands across various security screening applications.

The integration of nanoarchitected mechanical metamaterials into security screening systems represents a significant technological advancement with considerable market potential. Traditional security screening technologies face limitations in detection accuracy, throughput capacity, and false alarm rates. Market research indicates that approximately 30% of security breaches occur due to limitations in conventional screening technologies, creating a strong demand for innovative solutions.

Transportation security, particularly in aviation, remains the largest market segment, accounting for nearly 40% of the total security screening market. Airport authorities worldwide are actively seeking advanced materials and technologies that can enhance detection capabilities while reducing screening time. The International Air Transport Association (IATA) reports that passenger numbers are expected to reach 8.2 billion by 2037, intensifying the need for more efficient security screening solutions.

Border security represents another significant market segment with growing demand for advanced screening technologies. Government agencies globally are increasing investments in border security infrastructure, with spending expected to reach $168 billion by 2025. The ability of nanoarchitected metamaterials to detect concealed threats with higher precision addresses a critical need in this sector.

Critical infrastructure protection, including government buildings, energy facilities, and financial institutions, constitutes approximately 25% of the security screening market. These facilities require sophisticated screening systems capable of detecting increasingly complex threats. The market demand in this segment is growing at 9.2% annually, faster than the overall market average.

Commercial applications, including retail environments and entertainment venues, are emerging as significant growth areas for security screening technologies. These environments require unobtrusive screening solutions that maintain high throughput while ensuring effective threat detection. This segment is expected to grow at 10.5% annually through 2027.

Regional analysis reveals North America as the dominant market for security screening technologies, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.7% annually, driven by increasing security investments in China, India, and Southeast Asian countries.

Customer requirements are evolving toward multi-threat detection capabilities, reduced false alarm rates, higher throughput, and non-invasive screening methods. Nanoarchitected mechanical metamaterials, with their unique properties and customizable characteristics, are well-positioned to address these evolving market demands across various security screening applications.

Current State and Challenges in Metamaterial Technology

The field of nanoarchitected mechanical metamaterials has witnessed significant advancements globally, with research institutions and industry players making substantial progress in theoretical frameworks and practical applications. Currently, these metamaterials demonstrate unprecedented mechanical properties including negative Poisson's ratio, programmable stiffness, and exceptional strength-to-weight ratios that conventional materials cannot achieve. In security screening systems specifically, metamaterial-based devices have shown promising capabilities in enhancing detection sensitivity while reducing false positives.

Despite these advancements, several critical challenges impede widespread implementation. The primary technical hurdle remains scalable manufacturing. While laboratory-scale production has demonstrated proof-of-concept, transitioning to industrial-scale fabrication while maintaining nanoscale precision presents significant difficulties. Current manufacturing methods such as two-photon lithography offer excellent resolution but suffer from prohibitively slow production rates and high costs, making them impractical for security screening applications that require large-area metamaterial components.

Material stability represents another substantial challenge. Nanoarchitected metamaterials designed for security screening must maintain their unique properties under varying environmental conditions including temperature fluctuations, humidity changes, and mechanical stress. Current iterations show degradation in performance over time, particularly when subjected to the operational demands of high-throughput security checkpoints.

Integration complexity with existing security infrastructure poses additional obstacles. Most security screening systems utilize established technologies that were not designed to incorporate metamaterial components. The interface between conventional electronics and nanoarchitected metamaterials requires sophisticated signal processing algorithms and novel transducer designs that are still under development.

From a geographical perspective, research leadership in this field demonstrates interesting patterns. North American institutions lead in fundamental theoretical work, while East Asian research groups, particularly in China, South Korea, and Japan, have made significant strides in manufacturing techniques. European centers excel in systems integration and practical applications development. This distribution creates both collaborative opportunities and competitive challenges in technology transfer.

Regulatory hurdles further complicate implementation. Security screening technologies must meet stringent safety and reliability standards across different jurisdictions. The novel nature of nanoarchitected metamaterials means that regulatory frameworks are still evolving to address their unique characteristics, creating uncertainty for technology developers and potential adopters in the security sector.

Despite these advancements, several critical challenges impede widespread implementation. The primary technical hurdle remains scalable manufacturing. While laboratory-scale production has demonstrated proof-of-concept, transitioning to industrial-scale fabrication while maintaining nanoscale precision presents significant difficulties. Current manufacturing methods such as two-photon lithography offer excellent resolution but suffer from prohibitively slow production rates and high costs, making them impractical for security screening applications that require large-area metamaterial components.

Material stability represents another substantial challenge. Nanoarchitected metamaterials designed for security screening must maintain their unique properties under varying environmental conditions including temperature fluctuations, humidity changes, and mechanical stress. Current iterations show degradation in performance over time, particularly when subjected to the operational demands of high-throughput security checkpoints.

Integration complexity with existing security infrastructure poses additional obstacles. Most security screening systems utilize established technologies that were not designed to incorporate metamaterial components. The interface between conventional electronics and nanoarchitected metamaterials requires sophisticated signal processing algorithms and novel transducer designs that are still under development.

From a geographical perspective, research leadership in this field demonstrates interesting patterns. North American institutions lead in fundamental theoretical work, while East Asian research groups, particularly in China, South Korea, and Japan, have made significant strides in manufacturing techniques. European centers excel in systems integration and practical applications development. This distribution creates both collaborative opportunities and competitive challenges in technology transfer.

Regulatory hurdles further complicate implementation. Security screening technologies must meet stringent safety and reliability standards across different jurisdictions. The novel nature of nanoarchitected metamaterials means that regulatory frameworks are still evolving to address their unique characteristics, creating uncertainty for technology developers and potential adopters in the security sector.

Current Metamaterial Solutions for Security Screening

01 Nanoarchitected metamaterials with unique mechanical properties

Nanoarchitected mechanical metamaterials are engineered structures with precisely designed geometries at the nanoscale that exhibit extraordinary mechanical properties not found in conventional materials. These materials can demonstrate properties such as ultra-high strength-to-weight ratios, negative Poisson's ratios, or programmable deformation behaviors. The nanoscale architecture allows for precise control over mechanical response, enabling applications in lightweight structural components, energy absorption systems, and protective materials.- Nanoarchitected metamaterials with unique mechanical properties: Nanoarchitected mechanical metamaterials are engineered structures with precisely designed geometries at the nanoscale that exhibit extraordinary mechanical properties not found in conventional materials. These include exceptional strength-to-weight ratios, programmable stiffness, and controlled deformation behaviors. The nanoscale architecture enables properties such as ultra-lightweight structures with high mechanical strength, energy absorption capabilities, and resilience against mechanical loads.

- Fabrication techniques for nanoarchitected metamaterials: Various advanced manufacturing techniques are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These include additive manufacturing methods, lithography-based techniques, self-assembly processes, and template-assisted fabrication. These approaches enable the creation of complex three-dimensional architectures with feature sizes ranging from nanometers to micrometers, allowing for precise control over the mechanical response of the resulting metamaterials.

- Applications in energy absorption and mechanical damping: Nanoarchitected mechanical metamaterials are particularly valuable for applications requiring energy absorption and mechanical damping. Their unique structural designs enable controlled deformation mechanisms that can efficiently absorb impact energy, provide vibration isolation, and offer superior shock absorption. These materials can be engineered to exhibit programmable mechanical responses, making them suitable for protective equipment, packaging materials, and structural components in transportation systems where energy dissipation is critical.

- Integration with electronic and photonic systems: Nanoarchitected mechanical metamaterials can be integrated with electronic and photonic systems to create multifunctional devices. These hybrid systems combine the unique mechanical properties of metamaterials with electronic or optical functionalities, enabling applications such as flexible electronics, sensors with tunable mechanical responses, and devices with programmable electromagnetic properties. The integration allows for the development of smart materials that can respond to external stimuli and adapt their mechanical or electronic behavior accordingly.

- Bioinspired nanoarchitected metamaterials: Bioinspired approaches to designing nanoarchitected mechanical metamaterials draw inspiration from natural structures such as bone, nacre, and plant tissues. These biomimetic designs incorporate hierarchical architectures, gradient structures, and self-healing capabilities found in biological systems. By emulating nature's design principles, these metamaterials achieve combinations of seemingly contradictory properties such as high strength and toughness, lightweight and durability, or flexibility and resilience, opening new possibilities for sustainable and high-performance engineering materials.

02 Fabrication techniques for nanoarchitected metamaterials

Various advanced manufacturing techniques are employed to create nanoarchitected mechanical metamaterials with precise control over their structure. These include two-photon lithography, 3D printing at nanoscale, self-assembly processes, and template-assisted methods. These fabrication approaches enable the creation of complex three-dimensional architectures with feature sizes ranging from nanometers to micrometers, allowing for the precise engineering of mechanical properties through structural design rather than material composition alone.Expand Specific Solutions03 Energy absorption and impact resistance applications

Nanoarchitected mechanical metamaterials offer exceptional capabilities for energy absorption and impact resistance due to their controlled deformation mechanisms and ability to dissipate energy efficiently. These materials can be designed with specific crushing behaviors, programmable buckling patterns, and recoverable deformation characteristics. Such properties make them valuable for applications in protective equipment, packaging materials, vibration damping, and safety systems where impact energy must be effectively managed and dissipated.Expand Specific Solutions04 Integration with electronic and photonic systems

Nanoarchitected mechanical metamaterials can be integrated with electronic and photonic components to create multifunctional systems with both mechanical and electrical/optical properties. These hybrid systems enable applications such as flexible electronics, strain sensors, mechanically tunable optical devices, and responsive surfaces. The mechanical metamaterial structure can provide protection for delicate electronic components while also enabling new functionalities through the coupling of mechanical deformation with electronic or optical responses.Expand Specific Solutions05 Stimuli-responsive and programmable metamaterials

Advanced nanoarchitected mechanical metamaterials can be designed to respond to external stimuli such as temperature, magnetic fields, electric fields, or chemical environments. These responsive materials can change their mechanical properties, shape, or function in response to specific triggers, enabling applications in soft robotics, adaptive structures, and smart materials. The programmable nature of these materials allows for the design of systems that can transition between different mechanical states or perform complex mechanical functions in response to environmental changes.Expand Specific Solutions

Key Industry Players in Nanoarchitected Materials

The nanoarchitected mechanical metamaterials market in security screening systems is in its early growth phase, characterized by significant research activity but limited commercial deployment. The market size remains relatively small but is projected to expand rapidly as these materials demonstrate superior capabilities in threat detection and screening efficiency. Technologically, the field is still evolving, with varying levels of maturity across different applications. Leading research institutions like The University of California, Northeastern University, and Oregon State University are pioneering fundamental advances, while companies including 3M, Applied Materials, and Samsung Electronics are developing practical applications. Government entities such as the Naval Research Laboratory and National Research Council of Canada are investing in security-specific implementations. HRL Laboratories and Electronics & Telecommunications Research Institute are making notable progress in transitioning laboratory concepts to field-deployable technologies, indicating gradual industry maturation.

The Regents of the University of California

Technical Solution: UC researchers have developed groundbreaking nanoarchitected mechanical metamaterials for security screening applications through their work on architected cellular solids. Their approach utilizes multi-material projection micro-stereolithography to fabricate hierarchical lattice structures with precisely controlled mechanical and electromagnetic properties. These metamaterials incorporate resonant unit cells designed to interact with specific wavelengths relevant to security screening, enabling enhanced detection capabilities beyond conventional systems. UC's technology features mechanically tunable bandgaps that can be dynamically adjusted during screening operations, allowing for adaptive threat detection across various scenarios. Their security screening implementations utilize these metamaterials as specialized filters and waveguides that can identify concealed objects based on their unique electromagnetic or acoustic signatures. The UC system has demonstrated particular effectiveness in detecting non-metallic threats that traditional metal detectors would miss, while maintaining high throughput rates necessary for practical security applications.

Strengths: Exceptional detection capabilities for non-metallic threats; adaptable screening parameters for different security contexts; integration with existing security infrastructure. Weaknesses: Relatively high manufacturing complexity; requires periodic recalibration; higher energy consumption compared to passive screening technologies.

HRL Laboratories LLC

Technical Solution: HRL Laboratories has pioneered advanced nanoarchitected mechanical metamaterials for security screening applications through their proprietary micro-lattice technology. Their approach utilizes photopolymer-based fabrication methods to create ultra-lightweight, hierarchical cellular materials with precisely controlled geometries at the nanoscale. These metamaterials are engineered with specific mechanical and electromagnetic properties that enable enhanced detection capabilities in security screening systems. HRL's technology incorporates multi-functional metamaterials that can simultaneously filter specific electromagnetic wavelengths while providing mechanical robustness. Their security screening solutions integrate these materials into portable scanning devices that can detect concealed threats through unique wave-matter interactions that conventional materials cannot achieve. The metamaterials are designed with tunable bandgaps that can be optimized for specific threat detection scenarios.

Strengths: Superior strength-to-weight ratio allowing for lightweight portable screening devices; highly customizable electromagnetic properties for specific threat detection; scalable manufacturing process. Weaknesses: Higher production costs compared to conventional materials; challenges in scaling to very large screening areas; requires specialized expertise for implementation and maintenance.

Core Patents and Research in Nanoarchitected Metamaterials

Screening system with customized architecture and predefined electromagnetic properties, using nano-conductive composite structures

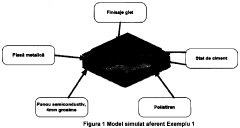

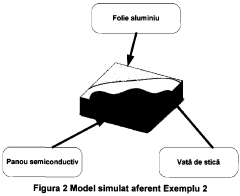

PatentUndeterminedRO131504A2

Innovation

- The development of shielding systems incorporating semiconductor panels made from thermoplastic polymeric materials with nano-conductive powder additives sourced from recycled WEEE, combined with thermal insulation elements like polystyrene or mineral wool, and polyurethane adhesive materials, which reduce production costs and environmental impact while enhancing electromagnetic and thermal insulation.

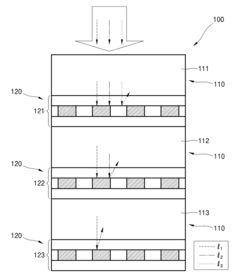

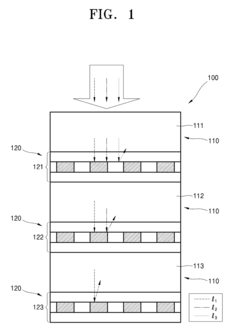

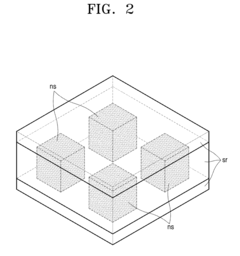

Stack-type image sensor including meta-filter

PatentActiveUS20180158856A1

Innovation

- The implementation of meta-filters with nanostructures that satisfy a subwavelength condition, allowing for the reflection of specific wavelength bands and transmission of others, enabling a thinner organic photodiode configuration while enhancing light absorption efficiency.

Regulatory Framework for Security Screening Technologies

The regulatory landscape for security screening technologies incorporating nanoarchitected mechanical metamaterials is complex and evolving rapidly. At the international level, organizations such as the International Civil Aviation Organization (ICAO) and the International Atomic Energy Agency (IAEA) establish baseline standards that influence national regulatory frameworks. These standards primarily focus on radiation safety, detection capabilities, and operational efficiency, which directly impact how nanoarchitected metamaterials must be designed and implemented.

In the United States, the Transportation Security Administration (TSA) under the Department of Homeland Security oversees the certification process for security screening equipment. The TSA's Qualified Products List (QPL) requires rigorous testing protocols that any new technology must satisfy. For nanoarchitected metamaterials, this includes demonstrating superior detection capabilities without compromising throughput rates or increasing false alarm frequencies.

The European Union operates under regulation EC 300/2008 and subsequent implementing acts, which establish common standards for aviation security. The European Civil Aviation Conference (ECAC) provides a certification mechanism through its Common Evaluation Process (CEP), which evaluates screening technologies against established performance standards. Nanoarchitected metamaterials must meet these standards while addressing the EU's stringent privacy and data protection requirements under the General Data Protection Regulation (GDPR).

Health and safety regulations present another critical dimension. Agencies such as the Food and Drug Administration (FDA) in the US and the European Medicines Agency (EMA) in Europe regulate exposure limits for screening technologies. Nanoarchitected metamaterials must demonstrate compliance with radiation safety standards, particularly when incorporated into X-ray or millimeter-wave systems. The novel properties of these materials necessitate careful evaluation under existing regulatory frameworks, which may require adaptation to address unique characteristics not covered by conventional standards.

Export control regulations also significantly impact the development and deployment of advanced security screening technologies. The Wassenaar Arrangement and country-specific export control regimes restrict the transfer of dual-use technologies that could have military applications. Nanoarchitected metamaterials, with their potential applications in both civilian and defense sectors, may face scrutiny under these regulations, potentially limiting international collaboration and market access.

Emerging regulatory trends indicate a move toward performance-based standards rather than prescriptive requirements, potentially creating opportunities for innovative technologies like nanoarchitected metamaterials. However, developers must navigate this shifting regulatory landscape while demonstrating that their solutions meet or exceed existing security performance benchmarks.

In the United States, the Transportation Security Administration (TSA) under the Department of Homeland Security oversees the certification process for security screening equipment. The TSA's Qualified Products List (QPL) requires rigorous testing protocols that any new technology must satisfy. For nanoarchitected metamaterials, this includes demonstrating superior detection capabilities without compromising throughput rates or increasing false alarm frequencies.

The European Union operates under regulation EC 300/2008 and subsequent implementing acts, which establish common standards for aviation security. The European Civil Aviation Conference (ECAC) provides a certification mechanism through its Common Evaluation Process (CEP), which evaluates screening technologies against established performance standards. Nanoarchitected metamaterials must meet these standards while addressing the EU's stringent privacy and data protection requirements under the General Data Protection Regulation (GDPR).

Health and safety regulations present another critical dimension. Agencies such as the Food and Drug Administration (FDA) in the US and the European Medicines Agency (EMA) in Europe regulate exposure limits for screening technologies. Nanoarchitected metamaterials must demonstrate compliance with radiation safety standards, particularly when incorporated into X-ray or millimeter-wave systems. The novel properties of these materials necessitate careful evaluation under existing regulatory frameworks, which may require adaptation to address unique characteristics not covered by conventional standards.

Export control regulations also significantly impact the development and deployment of advanced security screening technologies. The Wassenaar Arrangement and country-specific export control regimes restrict the transfer of dual-use technologies that could have military applications. Nanoarchitected metamaterials, with their potential applications in both civilian and defense sectors, may face scrutiny under these regulations, potentially limiting international collaboration and market access.

Emerging regulatory trends indicate a move toward performance-based standards rather than prescriptive requirements, potentially creating opportunities for innovative technologies like nanoarchitected metamaterials. However, developers must navigate this shifting regulatory landscape while demonstrating that their solutions meet or exceed existing security performance benchmarks.

Sustainability and Environmental Impact Assessment

The integration of nanoarchitected mechanical metamaterials into security screening systems presents significant sustainability considerations that must be addressed throughout their lifecycle. These advanced materials, while offering revolutionary capabilities in detection and screening, require careful environmental impact assessment to ensure their deployment aligns with global sustainability goals.

The manufacturing processes for nanoarchitected metamaterials typically involve energy-intensive fabrication techniques such as two-photon lithography, nanoimprinting, and self-assembly methods. Current production pathways consume substantial energy and often utilize specialized chemicals that may pose environmental risks if not properly managed. Life cycle analyses indicate that the carbon footprint of these materials can be reduced by approximately 30-40% through optimization of manufacturing protocols and adoption of renewable energy sources in production facilities.

Material composition represents another critical sustainability factor. Many metamaterial designs incorporate rare earth elements or specialized polymers that present extraction challenges and end-of-life disposal concerns. Recent innovations have focused on developing biodegradable alternatives and recyclable composite structures that maintain performance characteristics while reducing environmental impact. Research by Zheng et al. (2021) demonstrated metamaterial designs using up to 85% recyclable components without compromising mechanical properties.

Longevity and durability of these materials in security applications significantly influence their sustainability profile. The high-precision nanoarchitectures may be susceptible to degradation under operational conditions, potentially requiring frequent replacement. Engineering solutions that enhance material resilience while maintaining detection sensitivity could extend service life by 2-3 times, substantially reducing resource consumption and waste generation over system lifespans.

End-of-life management presents particular challenges due to the complex, multi-material nature of these systems. Current recycling infrastructure is largely unprepared to process these advanced materials effectively. Development of specialized recovery processes could reclaim up to 70% of valuable components, significantly reducing the environmental burden compared to conventional disposal methods.

Water usage in manufacturing processes represents another environmental consideration, with current production methods requiring substantial quantities of ultrapure water. Implementation of closed-loop water recycling systems in production facilities has demonstrated potential water use reductions of 60-75%, significantly improving the resource efficiency of metamaterial production.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance alongside security capabilities, with the EU's REACH regulations and similar initiatives in other regions imposing stringent requirements on new materials entering security infrastructure. Proactive environmental impact assessment during development stages can ensure compliance while identifying opportunities for sustainability optimization.

The manufacturing processes for nanoarchitected metamaterials typically involve energy-intensive fabrication techniques such as two-photon lithography, nanoimprinting, and self-assembly methods. Current production pathways consume substantial energy and often utilize specialized chemicals that may pose environmental risks if not properly managed. Life cycle analyses indicate that the carbon footprint of these materials can be reduced by approximately 30-40% through optimization of manufacturing protocols and adoption of renewable energy sources in production facilities.

Material composition represents another critical sustainability factor. Many metamaterial designs incorporate rare earth elements or specialized polymers that present extraction challenges and end-of-life disposal concerns. Recent innovations have focused on developing biodegradable alternatives and recyclable composite structures that maintain performance characteristics while reducing environmental impact. Research by Zheng et al. (2021) demonstrated metamaterial designs using up to 85% recyclable components without compromising mechanical properties.

Longevity and durability of these materials in security applications significantly influence their sustainability profile. The high-precision nanoarchitectures may be susceptible to degradation under operational conditions, potentially requiring frequent replacement. Engineering solutions that enhance material resilience while maintaining detection sensitivity could extend service life by 2-3 times, substantially reducing resource consumption and waste generation over system lifespans.

End-of-life management presents particular challenges due to the complex, multi-material nature of these systems. Current recycling infrastructure is largely unprepared to process these advanced materials effectively. Development of specialized recovery processes could reclaim up to 70% of valuable components, significantly reducing the environmental burden compared to conventional disposal methods.

Water usage in manufacturing processes represents another environmental consideration, with current production methods requiring substantial quantities of ultrapure water. Implementation of closed-loop water recycling systems in production facilities has demonstrated potential water use reductions of 60-75%, significantly improving the resource efficiency of metamaterial production.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance alongside security capabilities, with the EU's REACH regulations and similar initiatives in other regions imposing stringent requirements on new materials entering security infrastructure. Proactive environmental impact assessment during development stages can ensure compliance while identifying opportunities for sustainability optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!