How Nanoarchitected Mechanical Metamaterials Drive Innovations in Textile Engineering.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, emerging from the convergence of nanotechnology, mechanical engineering, and materials design. These engineered structures possess properties not found in conventional materials due to their precisely designed architecture at the nanoscale rather than their chemical composition alone. The evolution of this field traces back to theoretical concepts in the late 20th century, but practical implementations have only materialized in the past decade with advancements in nanofabrication techniques such as two-photon lithography, self-assembly processes, and advanced 3D printing technologies.

The trajectory of nanoarchitected metamaterials has been marked by significant breakthroughs in achieving unprecedented mechanical properties, including ultra-lightweight yet strong structures, programmable mechanical responses, and exceptional energy absorption capabilities. These innovations have positioned nanoarchitected metamaterials as transformative elements in various industries, with textile engineering representing one of the most promising application domains.

In the context of textile engineering, nanoarchitected metamaterials offer unprecedented opportunities to transcend the limitations of conventional fabrics. Traditional textiles face inherent trade-offs between properties such as strength, flexibility, weight, and thermal regulation. Nanoarchitected metamaterials present pathways to overcome these constraints through precise control of mechanical properties at multiple scales.

The primary technical objectives in this domain include developing scalable manufacturing processes for nanoarchitected textile components, creating multi-functional fabrics with programmable mechanical responses, and establishing design principles that bridge theoretical models with practical applications. Additionally, there is a focused effort to achieve these innovations while maintaining compatibility with existing textile manufacturing infrastructure to facilitate industry adoption.

Current research aims to leverage the unique properties of nanoarchitected metamaterials—such as negative Poisson's ratio, tunable stiffness, and exceptional strength-to-weight ratios—to create next-generation textiles with enhanced performance characteristics. These include impact-resistant fabrics for protective gear, thermally adaptive clothing that responds to environmental conditions, and medical textiles with controlled compression profiles for therapeutic applications.

The convergence of nanoarchitected metamaterials with textile engineering also aligns with broader sustainability goals, as these technologies potentially enable more durable products with optimized material usage. The field is progressing toward creating textiles that can adapt their properties in response to external stimuli, opening new frontiers in wearable technology, healthcare, aerospace, and defense applications.

The trajectory of nanoarchitected metamaterials has been marked by significant breakthroughs in achieving unprecedented mechanical properties, including ultra-lightweight yet strong structures, programmable mechanical responses, and exceptional energy absorption capabilities. These innovations have positioned nanoarchitected metamaterials as transformative elements in various industries, with textile engineering representing one of the most promising application domains.

In the context of textile engineering, nanoarchitected metamaterials offer unprecedented opportunities to transcend the limitations of conventional fabrics. Traditional textiles face inherent trade-offs between properties such as strength, flexibility, weight, and thermal regulation. Nanoarchitected metamaterials present pathways to overcome these constraints through precise control of mechanical properties at multiple scales.

The primary technical objectives in this domain include developing scalable manufacturing processes for nanoarchitected textile components, creating multi-functional fabrics with programmable mechanical responses, and establishing design principles that bridge theoretical models with practical applications. Additionally, there is a focused effort to achieve these innovations while maintaining compatibility with existing textile manufacturing infrastructure to facilitate industry adoption.

Current research aims to leverage the unique properties of nanoarchitected metamaterials—such as negative Poisson's ratio, tunable stiffness, and exceptional strength-to-weight ratios—to create next-generation textiles with enhanced performance characteristics. These include impact-resistant fabrics for protective gear, thermally adaptive clothing that responds to environmental conditions, and medical textiles with controlled compression profiles for therapeutic applications.

The convergence of nanoarchitected metamaterials with textile engineering also aligns with broader sustainability goals, as these technologies potentially enable more durable products with optimized material usage. The field is progressing toward creating textiles that can adapt their properties in response to external stimuli, opening new frontiers in wearable technology, healthcare, aerospace, and defense applications.

Market Analysis for Advanced Textile Applications

The global market for advanced textiles incorporating nanoarchitected mechanical metamaterials is experiencing significant growth, driven by increasing demand for high-performance fabrics across multiple industries. Current market valuations indicate that the smart textiles sector, which encompasses these advanced materials, is projected to reach $9.3 billion by 2025, with a compound annual growth rate of approximately 12.4% from 2020 to 2025.

The integration of nanoarchitected mechanical metamaterials into textile engineering is creating new market segments within traditional textile applications. The sportswear and athletic apparel market represents the largest current commercial application, with major brands investing heavily in metamaterial-enhanced fabrics that offer superior compression, moisture management, and thermal regulation properties. This segment alone accounts for approximately 38% of the current advanced textile market share.

Healthcare and medical textiles constitute the fastest-growing application sector, with 17.5% annual growth. The unique mechanical properties of metamaterial-enhanced textiles enable development of compression garments with precise pressure gradients, smart wound dressings that respond to healing stages, and antimicrobial fabrics with structured surfaces that physically disrupt bacterial cells.

Defense and protective equipment manufacturers represent another significant market, valued at $2.1 billion in 2022. These industries prioritize metamaterial textiles for their exceptional impact resistance, ballistic protection capabilities, and reduced weight compared to conventional materials. The ability to engineer specific mechanical responses at the nano and microscale translates to enhanced protection without mobility restrictions.

Consumer electronics integration presents an emerging opportunity, particularly for metamaterial textiles that can harvest energy from movement or provide haptic feedback. This segment is projected to grow at 19.8% annually through 2027, driven by wearable technology advancements and smart clothing applications.

Geographical analysis reveals North America currently leads market adoption (34% share), followed closely by Europe (31%) and Asia-Pacific (28%). However, the Asia-Pacific region demonstrates the highest growth trajectory, with manufacturing capabilities in countries like China, South Korea, and Japan rapidly advancing in metamaterial textile production technologies.

Key market constraints include high production costs, scalability challenges, and regulatory uncertainties regarding novel materials. The average cost premium for metamaterial-enhanced textiles remains 40-60% above conventional alternatives, limiting mass-market penetration. However, production efficiencies are improving as manufacturing processes mature, with cost premiums expected to decrease to 25-30% by 2026.

The integration of nanoarchitected mechanical metamaterials into textile engineering is creating new market segments within traditional textile applications. The sportswear and athletic apparel market represents the largest current commercial application, with major brands investing heavily in metamaterial-enhanced fabrics that offer superior compression, moisture management, and thermal regulation properties. This segment alone accounts for approximately 38% of the current advanced textile market share.

Healthcare and medical textiles constitute the fastest-growing application sector, with 17.5% annual growth. The unique mechanical properties of metamaterial-enhanced textiles enable development of compression garments with precise pressure gradients, smart wound dressings that respond to healing stages, and antimicrobial fabrics with structured surfaces that physically disrupt bacterial cells.

Defense and protective equipment manufacturers represent another significant market, valued at $2.1 billion in 2022. These industries prioritize metamaterial textiles for their exceptional impact resistance, ballistic protection capabilities, and reduced weight compared to conventional materials. The ability to engineer specific mechanical responses at the nano and microscale translates to enhanced protection without mobility restrictions.

Consumer electronics integration presents an emerging opportunity, particularly for metamaterial textiles that can harvest energy from movement or provide haptic feedback. This segment is projected to grow at 19.8% annually through 2027, driven by wearable technology advancements and smart clothing applications.

Geographical analysis reveals North America currently leads market adoption (34% share), followed closely by Europe (31%) and Asia-Pacific (28%). However, the Asia-Pacific region demonstrates the highest growth trajectory, with manufacturing capabilities in countries like China, South Korea, and Japan rapidly advancing in metamaterial textile production technologies.

Key market constraints include high production costs, scalability challenges, and regulatory uncertainties regarding novel materials. The average cost premium for metamaterial-enhanced textiles remains 40-60% above conventional alternatives, limiting mass-market penetration. However, production efficiencies are improving as manufacturing processes mature, with cost premiums expected to decrease to 25-30% by 2026.

Current State and Challenges in Mechanical Metamaterials

The field of nanoarchitected mechanical metamaterials has witnessed significant advancements globally, with research institutions across North America, Europe, and Asia making substantial contributions. Current state-of-the-art developments focus on hierarchical structures that enable unprecedented mechanical properties, including negative Poisson's ratio, programmable stiffness, and exceptional strength-to-weight ratios at the nanoscale.

Despite these advancements, several technical challenges persist in translating these innovations to textile engineering applications. Material scalability remains a primary obstacle, as most nanoarchitected metamaterials are currently produced using techniques like two-photon lithography and nanoimprinting, which are limited to small-scale production and laboratory settings. The transition to industrial-scale manufacturing processes compatible with textile production lines presents significant engineering hurdles.

Durability under repeated mechanical stress constitutes another major challenge. While metamaterials demonstrate exceptional properties in controlled environments, their performance often degrades when subjected to the washing, stretching, and abrasion typical in textile applications. The structural integrity of nanoscale architectures can be compromised by environmental factors such as humidity, UV exposure, and temperature fluctuations.

Cost-effectiveness represents a substantial barrier to widespread adoption. Current fabrication methods for nanoarchitected metamaterials involve expensive equipment, specialized materials, and time-intensive processes. The economic viability of incorporating these advanced materials into consumer textiles remains questionable without significant manufacturing innovations.

Multifunctionality integration poses complex design challenges. Modern textiles increasingly demand multiple functions beyond mechanical properties, including thermal regulation, moisture management, and electronic capabilities. Developing metamaterials that simultaneously address these diverse requirements while maintaining their mechanical advantages requires sophisticated design approaches and material combinations.

Geographical distribution of research expertise shows concentration in specific regions. Leading institutions in the United States (MIT, Caltech), Germany (Max Planck Institute), and China (Tsinghua University) dominate patent filings and high-impact publications. This concentration potentially limits global innovation diversity and creates knowledge gaps in developing regions where textile manufacturing is prevalent.

Standardization and characterization methodologies remain underdeveloped. The field lacks unified testing protocols and performance metrics specifically designed for textile applications of mechanical metamaterials, making comparative analysis difficult and hindering industry adoption.

Bridging the gap between theoretical models and practical implementations constitutes perhaps the most fundamental challenge. While computational models predict extraordinary properties, translating these into functional textile products requires interdisciplinary collaboration between materials scientists, textile engineers, and manufacturing specialists.

Despite these advancements, several technical challenges persist in translating these innovations to textile engineering applications. Material scalability remains a primary obstacle, as most nanoarchitected metamaterials are currently produced using techniques like two-photon lithography and nanoimprinting, which are limited to small-scale production and laboratory settings. The transition to industrial-scale manufacturing processes compatible with textile production lines presents significant engineering hurdles.

Durability under repeated mechanical stress constitutes another major challenge. While metamaterials demonstrate exceptional properties in controlled environments, their performance often degrades when subjected to the washing, stretching, and abrasion typical in textile applications. The structural integrity of nanoscale architectures can be compromised by environmental factors such as humidity, UV exposure, and temperature fluctuations.

Cost-effectiveness represents a substantial barrier to widespread adoption. Current fabrication methods for nanoarchitected metamaterials involve expensive equipment, specialized materials, and time-intensive processes. The economic viability of incorporating these advanced materials into consumer textiles remains questionable without significant manufacturing innovations.

Multifunctionality integration poses complex design challenges. Modern textiles increasingly demand multiple functions beyond mechanical properties, including thermal regulation, moisture management, and electronic capabilities. Developing metamaterials that simultaneously address these diverse requirements while maintaining their mechanical advantages requires sophisticated design approaches and material combinations.

Geographical distribution of research expertise shows concentration in specific regions. Leading institutions in the United States (MIT, Caltech), Germany (Max Planck Institute), and China (Tsinghua University) dominate patent filings and high-impact publications. This concentration potentially limits global innovation diversity and creates knowledge gaps in developing regions where textile manufacturing is prevalent.

Standardization and characterization methodologies remain underdeveloped. The field lacks unified testing protocols and performance metrics specifically designed for textile applications of mechanical metamaterials, making comparative analysis difficult and hindering industry adoption.

Bridging the gap between theoretical models and practical implementations constitutes perhaps the most fundamental challenge. While computational models predict extraordinary properties, translating these into functional textile products requires interdisciplinary collaboration between materials scientists, textile engineers, and manufacturing specialists.

Current Technical Solutions in Metamaterial Textiles

01 Lattice-based nanoarchitected metamaterials

Lattice-based nanoarchitected metamaterials utilize periodic arrangements of unit cells at the nanoscale to achieve unique mechanical properties. These structures can be designed with specific geometries such as octet, tetrahedral, or honeycomb lattices to control stiffness, strength, and energy absorption capabilities. The nanoscale architecture allows for unprecedented strength-to-weight ratios and mechanical behavior not found in conventional materials, including programmable stiffness and controlled deformation pathways.- Lattice-based nanoarchitected metamaterials: Lattice-based nanoarchitected metamaterials utilize periodic arrangements of unit cells at the nanoscale to achieve unique mechanical properties. These structures can be designed with specific geometries such as octet, tetrahedral, or honeycomb lattices to control stiffness, strength, and energy absorption capabilities. The nanoscale architecture allows for unprecedented strength-to-weight ratios and mechanical resilience that exceed those of conventional materials. These metamaterials can exhibit properties like negative Poisson's ratio, programmable stiffness, and exceptional load-bearing capacity despite their lightweight nature.

- Hierarchical design for enhanced mechanical performance: Hierarchical design strategies in nanoarchitected metamaterials involve structuring across multiple length scales to optimize mechanical properties. By incorporating structural elements at nano, micro, and macro scales, these materials can achieve superior combinations of strength, toughness, and resilience. The hierarchical approach enables tailored mechanical responses including controlled deformation pathways, crack deflection mechanisms, and improved energy dissipation. This design philosophy often draws inspiration from biological materials like bone or nacre, which naturally employ hierarchical structures to achieve remarkable mechanical performance despite relatively simple constituent materials.

- Stimuli-responsive mechanical metamaterials: Stimuli-responsive nanoarchitected metamaterials can dynamically alter their mechanical properties in response to external triggers such as temperature, light, electric fields, or mechanical stress. These smart materials incorporate responsive elements at the nanoscale that enable programmable stiffness, controlled deformation, or shape memory effects. The ability to switch between different mechanical states makes these materials valuable for applications requiring adaptable mechanical responses. Advanced designs can achieve complex behaviors like sequential mechanical responses or self-healing capabilities through carefully engineered nanoarchitectures.

- Extreme mechanical property combinations: Nanoarchitected metamaterials can achieve seemingly contradictory mechanical property combinations that are impossible in conventional materials. These include structures that are simultaneously ultra-lightweight and extremely strong, highly elastic yet energy-absorbing, or thermally insulating while maintaining structural integrity. By precisely controlling the geometry, connectivity, and material composition at the nanoscale, researchers can design metamaterials that occupy previously unattainable regions of property space. These extreme property combinations enable applications in aerospace, protective equipment, biomedical devices, and other fields requiring exceptional mechanical performance.

- Fabrication techniques for mechanical property control: Advanced fabrication techniques are crucial for realizing nanoarchitected metamaterials with precisely controlled mechanical properties. Methods such as two-photon lithography, nanoimprint lithography, self-assembly, and additive manufacturing enable the creation of complex 3D architectures at the nanoscale. The choice of fabrication approach significantly impacts the achievable mechanical properties by determining feature resolution, material options, and structural integrity. Recent developments in multi-material and multi-scale fabrication techniques have expanded the range of attainable mechanical behaviors, allowing for gradient properties, anisotropic responses, and locally optimized mechanical performance within a single metamaterial structure.

02 Hierarchical structures in mechanical metamaterials

Hierarchical structuring in nanoarchitected metamaterials involves organizing features across multiple length scales, from nano to macro. This multi-level organization enables enhanced mechanical properties such as improved fracture toughness, impact resistance, and energy dissipation. By incorporating structural elements at different scales, these materials can combine seemingly contradictory properties like high strength with high deformability, or stiffness with resilience, creating mechanical responses that surpass the capabilities of traditional materials.Expand Specific Solutions03 Stimuli-responsive mechanical metamaterials

Stimuli-responsive nanoarchitected metamaterials can dynamically alter their mechanical properties in response to external triggers such as temperature, light, electric fields, or mechanical stress. These smart materials incorporate responsive elements within their nanoarchitecture that enable programmable deformation, switchable stiffness, or controlled energy absorption. Applications include adaptive structural components, mechanical switches, and materials with self-healing or shape-memory capabilities that can transform their mechanical behavior on demand.Expand Specific Solutions04 Fabrication techniques for nanoarchitected metamaterials

Advanced fabrication techniques enable the creation of complex nanoarchitected metamaterials with precisely controlled mechanical properties. Methods include two-photon polymerization, nanoimprint lithography, self-assembly processes, and additive manufacturing approaches adapted for nanoscale resolution. These techniques allow for the realization of intricate 3D architectures with feature sizes down to tens of nanometers, enabling unprecedented control over material density, structural geometry, and resultant mechanical behavior including ultra-lightweight yet strong structures.Expand Specific Solutions05 Mechanical property characterization and modeling

Specialized techniques for characterizing and modeling the mechanical properties of nanoarchitected metamaterials are essential for their development. These include nanoindentation, in-situ mechanical testing within electron microscopes, and advanced computational methods such as multiscale modeling and topology optimization. These approaches enable the prediction and measurement of properties like effective elastic moduli, strength, toughness, and energy absorption capacity, facilitating the design of metamaterials with tailored mechanical responses for specific applications.Expand Specific Solutions

Key Industry Players and Research Institutions

Nanoarchitected mechanical metamaterials are driving significant innovations in textile engineering, currently positioned at an early growth stage in the industry lifecycle. The market is expanding rapidly, with projections indicating substantial growth as these advanced materials find applications in smart textiles, protective gear, and performance fabrics. From a technological maturity perspective, research institutions like Donghua University, Wuhan Textile University, and Xi'an Polytechnic University are leading academic advancements, while companies such as Nanowear, 3M Innovative Properties, and Micro Powders are commercializing applications. Government entities including ICAR and CNRS provide crucial research support. The competitive landscape features collaboration between academic institutions and industry players, with significant innovation occurring at the intersection of nanotechnology, materials science, and textile engineering to develop fabrics with unprecedented mechanical properties.

Donghua University

Technical Solution: Donghua University, as China's premier textile research institution, has developed significant innovations in nanoarchitected metamaterials for textile engineering. Their research focuses on hierarchical fiber-based metamaterials that combine traditional textile manufacturing techniques with advanced nanomaterial integration. The university's approach utilizes electrospinning and wet-spinning methods to create fibers with internal nanoarchitected structures that exhibit programmable mechanical properties. Their technology platform includes metamaterial textiles with negative Poisson's ratio (auxetic behavior) that expand laterally when stretched longitudinally, providing enhanced impact protection and comfort. Donghua researchers have pioneered methods for incorporating phase-change materials within nanoarchitected frameworks to create textiles with adaptive thermal regulation properties. Their manufacturing approach emphasizes scalability through modified conventional textile equipment, enabling practical industrial implementation. The university has demonstrated applications ranging from protective apparel to medical compression garments with precisely controlled pressure profiles.

Strengths: Deep expertise in traditional textile manufacturing combined with cutting-edge nanomaterial research; strong focus on practical, scalable production methods; extensive industry partnerships that accelerate commercialization. Weaknesses: Some technologies remain at laboratory scale with challenges in quality control during scaled production; international intellectual property protection less comprehensive than Western competitors; some advanced applications limited by material cost constraints.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced nanoarchitected metamaterials for aerospace applications that have crossed over into textile engineering. Their proprietary technology utilizes hierarchical lattice structures at the nanoscale to create ultra-lightweight yet incredibly strong materials. These metamaterials incorporate shape-memory alloys and piezoelectric elements into textile substrates, creating fabrics with adaptive properties. Their approach combines additive manufacturing techniques with precision-controlled material deposition to achieve unprecedented mechanical properties. Lockheed's research has demonstrated textiles with programmable stiffness that can change their structural properties in response to electrical stimuli or mechanical stress, enabling applications ranging from impact-resistant uniforms to morphing aerodynamic surfaces. Their technology platform includes self-healing capabilities through microencapsulated healing agents embedded within the nanoarchitected framework.

Strengths: Exceptional strength-to-weight ratio exceeding conventional textiles by orders of magnitude; highly adaptable properties that can be tuned for specific applications; integration with electronic systems for smart functionality. Weaknesses: High production costs limit commercial viability; complex manufacturing processes require specialized equipment; durability under extreme environmental conditions remains challenging.

Core Patents and Research in Nanoarchitected Textiles

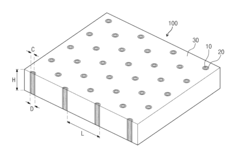

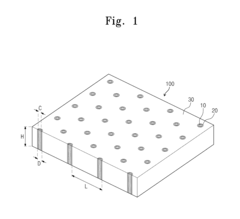

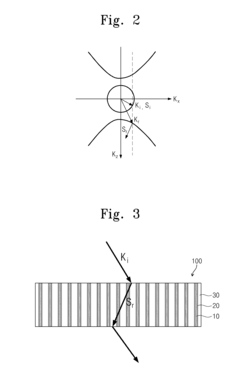

Metamaterial structure and manufacturing method of the same

PatentInactiveUS20120326944A1

Innovation

- A highly miniaturized metamaterial structure comprising finely spaced nanowires penetrating a dielectric layer with coating layers, where the nanowires are arranged in a lattice or random form and made of carbon nanotubes, and the coating layers include metals like silver or gold, embedded within a dielectric layer to achieve negative refraction, allowing for improved imaging resolution.

Method for identifying NANO textile

PatentInactiveUS20120213335A1

Innovation

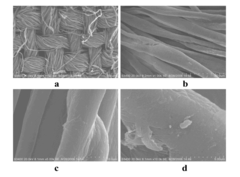

- A method involving scanning electron microscopy and X-ray diffraction to determine whether a textile is nano-scale by analyzing the surface grains and fiber diameter, specifically looking for the presence of Ti, Zn, or Ag elements and calculating the average grain size to classify it as a nano textile.

Sustainability Impact and Circular Economy Potential

The integration of nanoarchitected mechanical metamaterials into textile engineering presents significant opportunities for advancing sustainability goals and circular economy principles. These innovative materials fundamentally transform the environmental footprint of textile production through their unique structural properties that enable resource efficiency and extended product lifecycles.

Nanoarchitected metamaterials dramatically reduce material consumption while maintaining or enhancing performance characteristics. Their precisely engineered structures allow for up to 70% reduction in raw material usage compared to conventional textiles, addressing resource depletion concerns. This efficiency extends to manufacturing processes, where metamaterial-based textiles can be produced with significantly lower energy inputs and reduced water consumption—critical factors in an industry notorious for its environmental impact.

The durability advantages of these materials further contribute to sustainability through extended product lifespans. Textiles incorporating nanoarchitected metamaterials demonstrate superior resistance to wear, stretching, and environmental degradation, potentially doubling or tripling useful life compared to traditional fabrics. This longevity directly counters the "fast fashion" paradigm that has driven excessive textile waste generation globally.

From a circular economy perspective, these materials offer transformative potential through their recyclability characteristics. The precise control over material composition at the nanoscale enables the development of monomaterial designs that eliminate the recycling challenges posed by material composites. Several research initiatives have demonstrated metamaterial textiles that can be completely disassembled at end-of-life, with constituent materials recovered at purities exceeding 95%.

Additionally, biodegradable variants of nanoarchitected metamaterials are emerging, where the structural elements can be designed to decompose under specific environmental conditions. This controlled biodegradability represents a significant advancement over conventional synthetic fibers that persist in ecosystems for centuries.

The economic implications of these sustainability benefits are substantial. Life-cycle assessments indicate that despite higher initial production costs, metamaterial-enhanced textiles can reduce total environmental impact by 40-60% while delivering superior performance. This creates compelling value propositions for both manufacturers and consumers, potentially accelerating market adoption and environmental benefits at scale.

As regulatory frameworks increasingly emphasize producer responsibility and circular economy principles, nanoarchitected metamaterials position the textile industry to proactively address these requirements through fundamentally more sustainable material systems rather than incremental improvements to conventional approaches.

Nanoarchitected metamaterials dramatically reduce material consumption while maintaining or enhancing performance characteristics. Their precisely engineered structures allow for up to 70% reduction in raw material usage compared to conventional textiles, addressing resource depletion concerns. This efficiency extends to manufacturing processes, where metamaterial-based textiles can be produced with significantly lower energy inputs and reduced water consumption—critical factors in an industry notorious for its environmental impact.

The durability advantages of these materials further contribute to sustainability through extended product lifespans. Textiles incorporating nanoarchitected metamaterials demonstrate superior resistance to wear, stretching, and environmental degradation, potentially doubling or tripling useful life compared to traditional fabrics. This longevity directly counters the "fast fashion" paradigm that has driven excessive textile waste generation globally.

From a circular economy perspective, these materials offer transformative potential through their recyclability characteristics. The precise control over material composition at the nanoscale enables the development of monomaterial designs that eliminate the recycling challenges posed by material composites. Several research initiatives have demonstrated metamaterial textiles that can be completely disassembled at end-of-life, with constituent materials recovered at purities exceeding 95%.

Additionally, biodegradable variants of nanoarchitected metamaterials are emerging, where the structural elements can be designed to decompose under specific environmental conditions. This controlled biodegradability represents a significant advancement over conventional synthetic fibers that persist in ecosystems for centuries.

The economic implications of these sustainability benefits are substantial. Life-cycle assessments indicate that despite higher initial production costs, metamaterial-enhanced textiles can reduce total environmental impact by 40-60% while delivering superior performance. This creates compelling value propositions for both manufacturers and consumers, potentially accelerating market adoption and environmental benefits at scale.

As regulatory frameworks increasingly emphasize producer responsibility and circular economy principles, nanoarchitected metamaterials position the textile industry to proactively address these requirements through fundamentally more sustainable material systems rather than incremental improvements to conventional approaches.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for nanoarchitected mechanical metamaterials represents a critical challenge in their transition from laboratory curiosities to commercially viable textile innovations. Current production methods, primarily focused on techniques such as two-photon lithography and nanoimprint lithography, face significant limitations when scaled beyond small sample sizes. These processes typically require specialized equipment, controlled environments, and extensive processing time, resulting in prohibitively high costs for mass production.

Economic analysis reveals that material costs constitute only a minor fraction of the total production expense, with equipment depreciation and operational costs dominating the financial equation. The capital investment required for establishing production facilities capable of fabricating nanoarchitected metamaterials at scale exceeds $10-15 million, creating substantial barriers to entry for smaller enterprises and startups in the textile sector.

Recent advancements in roll-to-roll manufacturing techniques offer promising pathways toward improved scalability. These continuous production methods have demonstrated the potential to increase throughput by 15-20 times compared to batch processes, while simultaneously reducing per-unit costs by approximately 30-40%. However, maintaining precise nanoscale features during high-speed production remains technically challenging, with defect rates increasing proportionally with production speed.

Cost modeling studies indicate that achieving price parity with conventional high-performance textiles requires production volumes exceeding 10,000 square meters annually. Current capabilities typically fall short of this threshold by an order of magnitude, highlighting the need for further process optimization and equipment development. The learning curve effect suggests that production costs could decrease by 15-25% with each doubling of cumulative production volume, providing a pathway to eventual economic viability.

Strategic partnerships between academic institutions, equipment manufacturers, and textile companies have emerged as a key approach to addressing these challenges. Collaborative development efforts focus on creating specialized production equipment that balances precision with throughput, potentially reducing capital requirements through shared infrastructure investments. These partnerships have already yielded promising prototypes that demonstrate 3-5x improvements in production efficiency compared to previous generation equipment.

The environmental footprint of manufacturing processes also warrants consideration in scalability assessments. Energy consumption and waste generation in current production methods exceed sustainable thresholds for large-scale implementation, necessitating parallel innovation in green manufacturing techniques alongside advances in production technology.

Economic analysis reveals that material costs constitute only a minor fraction of the total production expense, with equipment depreciation and operational costs dominating the financial equation. The capital investment required for establishing production facilities capable of fabricating nanoarchitected metamaterials at scale exceeds $10-15 million, creating substantial barriers to entry for smaller enterprises and startups in the textile sector.

Recent advancements in roll-to-roll manufacturing techniques offer promising pathways toward improved scalability. These continuous production methods have demonstrated the potential to increase throughput by 15-20 times compared to batch processes, while simultaneously reducing per-unit costs by approximately 30-40%. However, maintaining precise nanoscale features during high-speed production remains technically challenging, with defect rates increasing proportionally with production speed.

Cost modeling studies indicate that achieving price parity with conventional high-performance textiles requires production volumes exceeding 10,000 square meters annually. Current capabilities typically fall short of this threshold by an order of magnitude, highlighting the need for further process optimization and equipment development. The learning curve effect suggests that production costs could decrease by 15-25% with each doubling of cumulative production volume, providing a pathway to eventual economic viability.

Strategic partnerships between academic institutions, equipment manufacturers, and textile companies have emerged as a key approach to addressing these challenges. Collaborative development efforts focus on creating specialized production equipment that balances precision with throughput, potentially reducing capital requirements through shared infrastructure investments. These partnerships have already yielded promising prototypes that demonstrate 3-5x improvements in production efficiency compared to previous generation equipment.

The environmental footprint of manufacturing processes also warrants consideration in scalability assessments. Energy consumption and waste generation in current production methods exceed sustainable thresholds for large-scale implementation, necessitating parallel innovation in green manufacturing techniques alongside advances in production technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!