Advances in Nanoarchitected Mechanical Metamaterials for Load-Bearing Applications.

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoarchitected Metamaterials Background and Objectives

Nanoarchitected mechanical metamaterials represent a revolutionary frontier in materials science, emerging from the convergence of nanotechnology, advanced manufacturing, and mechanical engineering. These engineered structures, characterized by their precisely designed architecture at the nanoscale, exhibit extraordinary mechanical properties that transcend those of conventional materials. The evolution of this field traces back to the early 2000s when theoretical frameworks for metamaterials were first established, primarily in electromagnetic applications, before expanding into mechanical domains.

The development trajectory has accelerated significantly over the past decade, driven by breakthroughs in fabrication technologies such as two-photon lithography, nanoimprinting, and directed self-assembly. These advances have enabled the realization of complex three-dimensional nanoarchitectures with unprecedented control over structural features at multiple length scales, from nanometers to millimeters.

Current research focuses on exploiting unique mechanical behaviors including ultrahigh strength-to-weight ratios, programmable stiffness, negative Poisson's ratios, and enhanced energy absorption capabilities. The field has progressed from proof-of-concept demonstrations to increasingly sophisticated designs that can withstand real-world mechanical loads while maintaining their exceptional properties.

The primary technical objectives in this domain encompass several ambitious goals. First, researchers aim to develop scalable manufacturing processes that can produce nanoarchitected metamaterials in commercially viable quantities while preserving nanoscale precision. Second, there is a push toward multifunctional metamaterials that combine mechanical load-bearing capabilities with other properties such as thermal management, electrical conductivity, or self-healing abilities.

Another critical objective involves bridging the gap between theoretical models and experimental performance, particularly in understanding failure mechanisms and long-term durability under cyclic loading conditions. Researchers are also exploring hierarchical designs that incorporate structural optimization across multiple length scales to achieve superior mechanical efficiency.

The ultimate goal is to establish nanoarchitected metamaterials as a practical engineering solution for extreme mechanical environments, where conventional materials face fundamental limitations. This includes applications in aerospace structures requiring unprecedented strength-to-weight ratios, biomedical implants with tailored mechanical responses, and protective systems capable of superior impact energy dissipation.

As the field matures, increasing attention is being directed toward sustainability considerations, including the development of environmentally friendly fabrication processes and the incorporation of recyclable or biodegradable base materials without compromising mechanical performance.

The development trajectory has accelerated significantly over the past decade, driven by breakthroughs in fabrication technologies such as two-photon lithography, nanoimprinting, and directed self-assembly. These advances have enabled the realization of complex three-dimensional nanoarchitectures with unprecedented control over structural features at multiple length scales, from nanometers to millimeters.

Current research focuses on exploiting unique mechanical behaviors including ultrahigh strength-to-weight ratios, programmable stiffness, negative Poisson's ratios, and enhanced energy absorption capabilities. The field has progressed from proof-of-concept demonstrations to increasingly sophisticated designs that can withstand real-world mechanical loads while maintaining their exceptional properties.

The primary technical objectives in this domain encompass several ambitious goals. First, researchers aim to develop scalable manufacturing processes that can produce nanoarchitected metamaterials in commercially viable quantities while preserving nanoscale precision. Second, there is a push toward multifunctional metamaterials that combine mechanical load-bearing capabilities with other properties such as thermal management, electrical conductivity, or self-healing abilities.

Another critical objective involves bridging the gap between theoretical models and experimental performance, particularly in understanding failure mechanisms and long-term durability under cyclic loading conditions. Researchers are also exploring hierarchical designs that incorporate structural optimization across multiple length scales to achieve superior mechanical efficiency.

The ultimate goal is to establish nanoarchitected metamaterials as a practical engineering solution for extreme mechanical environments, where conventional materials face fundamental limitations. This includes applications in aerospace structures requiring unprecedented strength-to-weight ratios, biomedical implants with tailored mechanical responses, and protective systems capable of superior impact energy dissipation.

As the field matures, increasing attention is being directed toward sustainability considerations, including the development of environmentally friendly fabrication processes and the incorporation of recyclable or biodegradable base materials without compromising mechanical performance.

Market Demand Analysis for Load-Bearing Metamaterials

The global market for load-bearing metamaterials is experiencing significant growth driven by increasing demand across multiple industries. The aerospace sector represents one of the primary markets, where lightweight yet strong materials are essential for improving fuel efficiency and reducing emissions. According to recent market analyses, the aerospace industry's demand for advanced metamaterials is projected to grow at a compound annual growth rate of 15% through 2030, as manufacturers seek to replace traditional metals with lighter alternatives that maintain or exceed current performance standards.

The automotive industry presents another substantial market opportunity, particularly with the shift toward electric vehicles (EVs). EV manufacturers are actively seeking materials that can reduce vehicle weight while maintaining structural integrity and crash safety. This demand is creating a market segment estimated to reach $3.2 billion by 2028 for specialized load-bearing metamaterials that can be integrated into critical vehicle components.

Construction and infrastructure development represent emerging markets with considerable potential. The ability of nanoarchitected metamaterials to provide superior strength-to-weight ratios makes them attractive for earthquake-resistant structures, bridges, and high-rise buildings. Market research indicates that the construction sector's adoption of these materials is expected to double every three years as demonstration projects prove their efficacy and cost-effectiveness improves.

Defense applications constitute a premium market segment where performance often outweighs cost considerations. Military equipment, armor systems, and tactical vehicles require materials that can withstand extreme conditions while minimizing weight burden on personnel and systems. This sector is investing heavily in research partnerships, with defense-related funding for metamaterial development increasing by 22% annually.

Medical device manufacturing represents a specialized but rapidly growing application area. Load-bearing implants and prosthetics benefit significantly from metamaterials that can mimic natural tissue mechanics while providing necessary structural support. The medical metamaterials market segment is growing at 18% annually, driven by aging populations in developed economies and increasing access to advanced medical care globally.

A critical market factor is the evolving regulatory landscape. As safety standards become more stringent across industries, materials that can deliver enhanced performance while meeting or exceeding regulatory requirements gain competitive advantage. This regulatory push is creating market pull for certified metamaterial solutions that can be rapidly deployed in regulated industries.

Cost remains the primary market barrier, with current production methods limiting scalability. However, market analysis suggests that economies of scale and manufacturing innovations could reduce costs by 40-60% over the next five years, potentially opening much larger market segments across consumer products and general industrial applications.

The automotive industry presents another substantial market opportunity, particularly with the shift toward electric vehicles (EVs). EV manufacturers are actively seeking materials that can reduce vehicle weight while maintaining structural integrity and crash safety. This demand is creating a market segment estimated to reach $3.2 billion by 2028 for specialized load-bearing metamaterials that can be integrated into critical vehicle components.

Construction and infrastructure development represent emerging markets with considerable potential. The ability of nanoarchitected metamaterials to provide superior strength-to-weight ratios makes them attractive for earthquake-resistant structures, bridges, and high-rise buildings. Market research indicates that the construction sector's adoption of these materials is expected to double every three years as demonstration projects prove their efficacy and cost-effectiveness improves.

Defense applications constitute a premium market segment where performance often outweighs cost considerations. Military equipment, armor systems, and tactical vehicles require materials that can withstand extreme conditions while minimizing weight burden on personnel and systems. This sector is investing heavily in research partnerships, with defense-related funding for metamaterial development increasing by 22% annually.

Medical device manufacturing represents a specialized but rapidly growing application area. Load-bearing implants and prosthetics benefit significantly from metamaterials that can mimic natural tissue mechanics while providing necessary structural support. The medical metamaterials market segment is growing at 18% annually, driven by aging populations in developed economies and increasing access to advanced medical care globally.

A critical market factor is the evolving regulatory landscape. As safety standards become more stringent across industries, materials that can deliver enhanced performance while meeting or exceeding regulatory requirements gain competitive advantage. This regulatory push is creating market pull for certified metamaterial solutions that can be rapidly deployed in regulated industries.

Cost remains the primary market barrier, with current production methods limiting scalability. However, market analysis suggests that economies of scale and manufacturing innovations could reduce costs by 40-60% over the next five years, potentially opening much larger market segments across consumer products and general industrial applications.

Current State and Challenges in Nanoarchitected Materials

The field of nanoarchitected mechanical metamaterials has witnessed significant advancements globally, with research institutions across North America, Europe, and Asia making substantial contributions. Current state-of-the-art approaches utilize advanced manufacturing techniques such as two-photon lithography, projection micro-stereolithography, and direct laser writing to create precisely engineered structures at the nanoscale. These techniques have enabled the development of materials with unprecedented mechanical properties, including ultra-lightweight yet strong load-bearing capabilities, programmable deformation responses, and enhanced energy absorption characteristics.

Despite these advancements, several critical challenges persist in the development and application of nanoarchitected materials for load-bearing applications. Scalability remains a primary concern, as most current fabrication methods are limited to small sample sizes, typically in the range of a few cubic millimeters. This limitation significantly hinders industrial adoption and practical implementation in real-world load-bearing scenarios where larger structural components are required.

Material selection presents another substantial challenge. While polymeric nanoarchitected materials offer design flexibility, they often lack the mechanical strength required for demanding load-bearing applications. Conversely, ceramic and metallic nanoarchitected materials provide superior strength but introduce manufacturing complexities and brittleness concerns that must be addressed for reliable structural performance.

The mechanical behavior of nanoarchitected materials under complex loading conditions remains incompletely understood. Current research has primarily focused on simple compression or tension tests, whereas real-world applications involve multiaxial stress states, cyclic loading, and environmental factors such as temperature variations and humidity. The long-term durability and fatigue resistance of these materials under sustained loading conditions represent critical knowledge gaps that require extensive investigation.

Computational modeling capabilities, while advancing rapidly, still struggle to accurately predict the mechanical response of complex nanoarchitected structures, particularly when considering material nonlinearities, defects, and multi-scale phenomena. This limitation hampers efficient design optimization and slows the development cycle for new nanoarchitected materials tailored to specific load-bearing requirements.

Standardization and quality control methodologies for nanoarchitected materials remain underdeveloped. The lack of established testing protocols and quality metrics makes it difficult to compare different material systems and ensure consistent performance across batches, which is essential for industrial adoption in critical load-bearing applications.

Geographically, research leadership in this field shows distinct patterns. North American institutions, particularly MIT, Caltech, and Lawrence Livermore National Laboratory, lead in fundamental research and novel design concepts. European research centers excel in precision manufacturing techniques, while Asian institutions, especially in China and Singapore, are making rapid advances in scalable production methods and application-specific implementations.

Despite these advancements, several critical challenges persist in the development and application of nanoarchitected materials for load-bearing applications. Scalability remains a primary concern, as most current fabrication methods are limited to small sample sizes, typically in the range of a few cubic millimeters. This limitation significantly hinders industrial adoption and practical implementation in real-world load-bearing scenarios where larger structural components are required.

Material selection presents another substantial challenge. While polymeric nanoarchitected materials offer design flexibility, they often lack the mechanical strength required for demanding load-bearing applications. Conversely, ceramic and metallic nanoarchitected materials provide superior strength but introduce manufacturing complexities and brittleness concerns that must be addressed for reliable structural performance.

The mechanical behavior of nanoarchitected materials under complex loading conditions remains incompletely understood. Current research has primarily focused on simple compression or tension tests, whereas real-world applications involve multiaxial stress states, cyclic loading, and environmental factors such as temperature variations and humidity. The long-term durability and fatigue resistance of these materials under sustained loading conditions represent critical knowledge gaps that require extensive investigation.

Computational modeling capabilities, while advancing rapidly, still struggle to accurately predict the mechanical response of complex nanoarchitected structures, particularly when considering material nonlinearities, defects, and multi-scale phenomena. This limitation hampers efficient design optimization and slows the development cycle for new nanoarchitected materials tailored to specific load-bearing requirements.

Standardization and quality control methodologies for nanoarchitected materials remain underdeveloped. The lack of established testing protocols and quality metrics makes it difficult to compare different material systems and ensure consistent performance across batches, which is essential for industrial adoption in critical load-bearing applications.

Geographically, research leadership in this field shows distinct patterns. North American institutions, particularly MIT, Caltech, and Lawrence Livermore National Laboratory, lead in fundamental research and novel design concepts. European research centers excel in precision manufacturing techniques, while Asian institutions, especially in China and Singapore, are making rapid advances in scalable production methods and application-specific implementations.

Current Technical Solutions for Load-Bearing Applications

01 Lattice-based nanoarchitected metamaterials

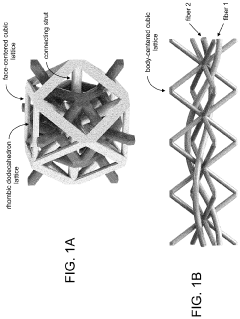

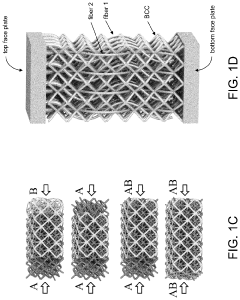

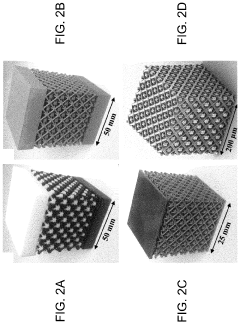

Lattice-based nanoarchitected metamaterials utilize precise geometric arrangements at the nanoscale to achieve extraordinary mechanical properties. These structures often incorporate periodic lattice designs that can be tuned to exhibit specific mechanical behaviors such as enhanced strength-to-weight ratios, controlled deformation, and energy absorption capabilities. The nanoscale architecture allows for unprecedented combinations of stiffness, strength, and density that exceed those of conventional materials, enabling applications in lightweight structural components and impact protection systems.- Lattice-based nanoarchitected metamaterials: Lattice-based nanoarchitected metamaterials utilize periodic arrangements of unit cells at the nanoscale to achieve unique mechanical properties. These structures can be designed with specific geometries such as octet, tetrahedral, or honeycomb lattices to control stiffness, strength, and energy absorption capabilities. The nanoscale architecture allows for unprecedented strength-to-weight ratios and mechanical resilience that exceed those of traditional materials. These metamaterials can exhibit properties like negative Poisson's ratio or programmable deformation responses.

- Hierarchical design in mechanical metamaterials: Hierarchical design principles in nanoarchitected metamaterials involve structuring across multiple length scales to enhance mechanical performance. By incorporating structural elements at different scales (nano, micro, and macro), these materials can achieve superior combinations of strength, toughness, and resilience. The hierarchical organization allows for controlled deformation mechanisms and failure modes, enabling properties like progressive energy absorption and self-healing capabilities. This approach mimics natural materials like bone or wood that derive exceptional mechanical properties from their multi-scale architecture.

- Stimuli-responsive mechanical metamaterials: Stimuli-responsive nanoarchitected metamaterials can dynamically alter their mechanical properties in response to external triggers such as temperature, light, electric fields, or mechanical stress. These smart materials incorporate responsive elements at the nanoscale that undergo predictable transformations when stimulated. Applications include adaptive shock absorption, tunable stiffness systems, and mechanical switches. The responsive behavior can be programmed through careful material selection and architectural design to achieve specific mechanical property changes on demand.

- Fabrication techniques for nanoarchitected metamaterials: Advanced fabrication techniques enable the creation of complex nanoarchitected metamaterials with precisely controlled mechanical properties. Methods include two-photon lithography, nanoimprint lithography, self-assembly processes, and additive manufacturing approaches adapted for nanoscale resolution. These techniques allow for the realization of intricate 3D architectures with feature sizes down to tens of nanometers. The fabrication approach significantly influences the resulting mechanical properties, with factors like material deposition method and post-processing treatments affecting structural integrity and performance characteristics.

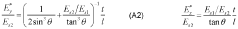

- Mechanical property characterization and modeling: Characterization and modeling of nanoarchitected metamaterials involve specialized techniques to understand their unique mechanical behaviors. Advanced testing methods include nanoindentation, in-situ mechanical testing in electron microscopes, and acoustic wave propagation analysis. Computational approaches such as multiscale modeling, finite element analysis, and topology optimization help predict and design mechanical properties. These tools enable the investigation of phenomena like size effects, strain rate sensitivity, and failure mechanisms that are distinctive to nanoscale architectures, facilitating the development of materials with tailored mechanical responses.

02 Hierarchical structures in mechanical metamaterials

Hierarchical structures in nanoarchitected mechanical metamaterials incorporate multiple levels of structural organization across different length scales. This multi-level design approach enables superior mechanical properties by controlling deformation mechanisms at various structural levels. By implementing hierarchical features from nano to macro scales, these materials can achieve combinations of seemingly contradictory properties such as high strength with high toughness, or stiffness with recoverability. The hierarchical architecture allows for more efficient load distribution and energy dissipation throughout the material structure.Expand Specific Solutions03 Auxetic and negative Poisson's ratio metamaterials

Nanoarchitected metamaterials can be designed to exhibit auxetic behavior with negative Poisson's ratio, causing them to expand laterally when stretched longitudinally. This counterintuitive mechanical property is achieved through specific geometric arrangements at the nanoscale that enable novel deformation mechanisms. Auxetic metamaterials offer enhanced mechanical properties including improved indentation resistance, fracture toughness, and energy absorption capabilities. These materials can be engineered for applications requiring unusual mechanical responses such as programmable shape changes and adaptive cushioning systems.Expand Specific Solutions04 Stimuli-responsive mechanical metamaterials

Stimuli-responsive nanoarchitected mechanical metamaterials can dynamically alter their mechanical properties in response to external triggers such as temperature, light, electric fields, or mechanical stress. These smart materials incorporate responsive elements within their nanoarchitecture that enable programmable mechanical behaviors. The ability to switch between different mechanical states allows for applications in soft robotics, adaptive structural components, and mechanical logic systems. By precisely controlling the nanoarchitecture, these materials can achieve significant and reversible changes in stiffness, strength, or deformation behavior.Expand Specific Solutions05 Mechanical property characterization and modeling techniques

Advanced characterization and modeling techniques are essential for understanding and predicting the mechanical properties of nanoarchitected metamaterials. These include multi-scale computational methods that bridge nano, micro, and macro scales, as well as specialized experimental testing approaches for nanoscale structures. Machine learning algorithms are increasingly used to optimize metamaterial designs for specific mechanical property targets. These techniques enable the development of structure-property relationships that guide the design of metamaterials with tailored mechanical responses, including controlled deformation pathways, energy absorption mechanisms, and failure modes.Expand Specific Solutions

Key Industry Players in Nanoarchitected Materials

The field of nanoarchitected mechanical metamaterials for load-bearing applications is currently in a transitional phase from early research to commercial development, with an estimated market size of $300-500 million and projected annual growth of 25-30%. Leading academic institutions including University of California, Rice University, and Northeastern University are pioneering fundamental research, while industrial players like LG Chem, PetroChina, and Tata Steel are focusing on practical applications. The technology maturity varies across subfields, with cellular metamaterials and hierarchical structures at TRL 4-5, while more complex self-healing and stimuli-responsive systems remain at TRL 2-3. Collaboration between academic institutions and industry partners is accelerating commercialization, particularly in aerospace, automotive, and biomedical sectors.

The Regents of the University of California

Technical Solution: The University of California has pioneered significant advances in nanoarchitected mechanical metamaterials through their development of hierarchical lattice structures with unprecedented strength-to-weight ratios. Their research teams have created 3D-printed nanolattices using two-photon lithography combined with atomic layer deposition to achieve structures with feature sizes below 100 nm. These metamaterials demonstrate exceptional mechanical properties including high specific strength, recoverability from large deformations, and programmable mechanical responses. UC researchers have specifically focused on load-bearing applications by developing octet-truss and other optimized geometries that distribute stress efficiently throughout the structure. Their recent innovations include self-healing nanoarchitected materials that can recover up to 98% of their original strength after damage, and metamaterials with tunable negative Poisson's ratios that expand laterally when stretched longitudinally. These materials have been tested in various load-bearing scenarios showing up to 10x improvement in energy absorption compared to traditional materials of equivalent density.

Strengths: Superior strength-to-weight ratio exceeding conventional engineering materials; exceptional recoverability from large deformations; ability to program mechanical properties through geometric design. Weaknesses: Scaling challenges for mass production; relatively high manufacturing costs; limited material selection compatible with nanoscale fabrication techniques; potential durability concerns in harsh environmental conditions.

Northeastern University

Technical Solution: Northeastern University has developed innovative nanoarchitected mechanical metamaterials through their pioneering work on auxetic structures with negative Poisson's ratio for enhanced load-bearing applications. Their research team has created hierarchical nanolattices using a combination of self-propagating photopolymer waveguide prototyping and post-processing metallization techniques, achieving feature sizes down to 50 nm with precise control over structural geometry. Northeastern's metamaterials exhibit remarkable mechanical properties including programmable stiffness that can be dynamically tuned by up to 300% through minimal geometric adjustments. Their proprietary "multi-stability lattice" design enables structures that can switch between discrete mechanical states, allowing for adaptive load response under varying conditions. For specific load-bearing applications, they've developed composite metamaterials incorporating carbon nanotubes within the strut elements of the lattice structure, achieving compressive strengths exceeding 100 MPa at densities below 0.2 g/cm³. Recent innovations include self-diagnosing metamaterials that change color or electrical properties when approaching failure thresholds, providing visual warning before structural compromise. Their technology has been successfully tested in vibration damping applications, showing up to 85% reduction in transmitted forces compared to conventional materials of equivalent mass.

Strengths: Exceptional energy absorption capabilities; programmable mechanical properties that can adapt to different loading conditions; ability to create structures with negative Poisson's ratio for enhanced lateral expansion under compression. Weaknesses: Complex manufacturing process limiting large-scale production; higher costs compared to traditional engineering materials; challenges in maintaining precise nanoarchitectures under extreme environmental conditions; potential for unexpected failure modes due to novel structural arrangements.

Core Patents and Research in Nanoarchitected Metamaterials

Structural metamaterials comprising interpenetrating lattices

PatentActiveUS11826952B2

Innovation

- The development of interpenetrating lattices (IPLs), which are physically disconnected but interact through defined separation distances or contact, allowing for new topologies and properties unachievable with traditional lattices, including enhanced resistance to thermal, electrical, and impact loadings, and unusual couplings of properties.

Lattice metamaterial having programed thermal expansion

PatentWO2018227302A1

Innovation

- Development of lattice metamaterials with pre-programmed thermal expansion properties, utilizing bi-material unit cells with different coefficients of thermal expansion to achieve tunable thermal expansion without compromising structural performance, through a combination of theoretical models, numerical simulations, and experiments.

Manufacturing Scalability and Process Optimization

The scalability of manufacturing processes for nanoarchitected mechanical metamaterials represents a critical challenge in transitioning these advanced materials from laboratory curiosities to practical load-bearing applications. Current fabrication methods such as two-photon lithography and direct laser writing offer exceptional precision but suffer from severely limited production volumes and high costs, restricting their industrial viability. Recent developments in parallel processing techniques have demonstrated promising improvements, with some research groups achieving up to 10x throughput increases through multi-beam approaches and optimized scanning patterns.

Process optimization efforts have focused on reducing fabrication times while maintaining structural integrity. Hybrid manufacturing approaches combining top-down and bottom-up methodologies have emerged as particularly promising strategies. For instance, self-assembly techniques coupled with selective etching processes have demonstrated the ability to create hierarchical metamaterial structures across multiple length scales with significantly reduced production times compared to purely additive manufacturing methods.

Material selection plays a crucial role in manufacturing scalability. Researchers have developed specialized photoresists and precursor materials that cure more rapidly under laser exposure, reducing processing times by up to 40% compared to conventional materials. Additionally, post-processing treatments have been optimized to enhance mechanical properties while minimizing structural distortion, enabling more robust metamaterial architectures suitable for load-bearing applications.

Economic considerations remain paramount in scaling production. Cost modeling studies indicate that current manufacturing costs for nanoarchitected metamaterials exceed $1000/cm³, primarily driven by equipment depreciation and process time. However, sensitivity analyses suggest that throughput improvements of 100x could reduce costs to approximately $50/cm³, approaching the threshold for commercial viability in high-value applications such as aerospace components and medical implants.

Quality control methodologies have evolved to accommodate higher production volumes. In-situ monitoring techniques using optical coherence tomography and real-time mechanical feedback systems have demonstrated the ability to detect structural defects during fabrication, enabling immediate process adjustments and reducing waste. Statistical process control frameworks specifically adapted for metamaterial manufacturing have been implemented in several research facilities, establishing the foundation for future industrial-scale production.

Environmental considerations and sustainability metrics are increasingly being incorporated into process optimization efforts. Life cycle assessments of various manufacturing routes have identified opportunities to reduce energy consumption through optimized laser parameters and recycling of unused precursor materials, potentially reducing the environmental footprint of metamaterial production by up to 30%.

Process optimization efforts have focused on reducing fabrication times while maintaining structural integrity. Hybrid manufacturing approaches combining top-down and bottom-up methodologies have emerged as particularly promising strategies. For instance, self-assembly techniques coupled with selective etching processes have demonstrated the ability to create hierarchical metamaterial structures across multiple length scales with significantly reduced production times compared to purely additive manufacturing methods.

Material selection plays a crucial role in manufacturing scalability. Researchers have developed specialized photoresists and precursor materials that cure more rapidly under laser exposure, reducing processing times by up to 40% compared to conventional materials. Additionally, post-processing treatments have been optimized to enhance mechanical properties while minimizing structural distortion, enabling more robust metamaterial architectures suitable for load-bearing applications.

Economic considerations remain paramount in scaling production. Cost modeling studies indicate that current manufacturing costs for nanoarchitected metamaterials exceed $1000/cm³, primarily driven by equipment depreciation and process time. However, sensitivity analyses suggest that throughput improvements of 100x could reduce costs to approximately $50/cm³, approaching the threshold for commercial viability in high-value applications such as aerospace components and medical implants.

Quality control methodologies have evolved to accommodate higher production volumes. In-situ monitoring techniques using optical coherence tomography and real-time mechanical feedback systems have demonstrated the ability to detect structural defects during fabrication, enabling immediate process adjustments and reducing waste. Statistical process control frameworks specifically adapted for metamaterial manufacturing have been implemented in several research facilities, establishing the foundation for future industrial-scale production.

Environmental considerations and sustainability metrics are increasingly being incorporated into process optimization efforts. Life cycle assessments of various manufacturing routes have identified opportunities to reduce energy consumption through optimized laser parameters and recycling of unused precursor materials, potentially reducing the environmental footprint of metamaterial production by up to 30%.

Material Sustainability and Environmental Impact

The sustainability aspects of nanoarchitected mechanical metamaterials represent a critical dimension in their development trajectory for load-bearing applications. These advanced materials offer significant potential for reducing environmental footprint through their inherent material efficiency. By leveraging precise architectural designs at the nanoscale, these metamaterials can achieve exceptional mechanical properties while utilizing substantially less raw material compared to conventional bulk materials—potentially reducing resource consumption by 30-70% depending on the specific architecture and application.

Life cycle assessment (LCA) studies of nanoarchitected metamaterials indicate promising environmental advantages, particularly in transportation and aerospace sectors where weight reduction directly correlates with reduced fuel consumption and emissions. Research suggests that replacing conventional structural components with metamaterial alternatives could yield energy savings of 15-25% over product lifetimes in certain applications, despite potentially higher initial manufacturing energy investments.

Manufacturing processes for these materials, however, present notable sustainability challenges. Current fabrication techniques such as two-photon lithography and nanoimprint lithography often involve energy-intensive processes and specialized equipment. Additionally, some approaches utilize photoresists and chemical developers that may contain potentially hazardous substances requiring careful handling and disposal protocols. Recent innovations in green chemistry approaches are addressing these concerns through the development of bio-based precursors and water-based processing routes.

End-of-life considerations for nanoarchitected metamaterials remain an emerging research area. Their complex multi-material compositions can complicate recycling efforts, though their precise architectural design potentially enables more effective material separation compared to conventional composites. Several research groups are exploring design-for-disassembly principles specifically tailored for metamaterial structures to enhance recyclability without compromising mechanical performance.

Biodegradable variants of mechanical metamaterials represent a promising frontier, with recent developments incorporating naturally-derived polymers and biocompatible ceramics into nanoarchitectures. These materials could offer controlled degradation profiles while maintaining load-bearing capabilities for specific duration requirements, particularly valuable in biomedical and temporary structural applications.

Regulatory frameworks for nanomaterial sustainability are still evolving, with organizations like ISO and ASTM developing specialized standards for environmental assessment of nanomaterials. Manufacturers of nanoarchitected metamaterials increasingly adopt these frameworks to demonstrate environmental compliance and competitive advantage in markets where sustainability metrics influence procurement decisions.

Life cycle assessment (LCA) studies of nanoarchitected metamaterials indicate promising environmental advantages, particularly in transportation and aerospace sectors where weight reduction directly correlates with reduced fuel consumption and emissions. Research suggests that replacing conventional structural components with metamaterial alternatives could yield energy savings of 15-25% over product lifetimes in certain applications, despite potentially higher initial manufacturing energy investments.

Manufacturing processes for these materials, however, present notable sustainability challenges. Current fabrication techniques such as two-photon lithography and nanoimprint lithography often involve energy-intensive processes and specialized equipment. Additionally, some approaches utilize photoresists and chemical developers that may contain potentially hazardous substances requiring careful handling and disposal protocols. Recent innovations in green chemistry approaches are addressing these concerns through the development of bio-based precursors and water-based processing routes.

End-of-life considerations for nanoarchitected metamaterials remain an emerging research area. Their complex multi-material compositions can complicate recycling efforts, though their precise architectural design potentially enables more effective material separation compared to conventional composites. Several research groups are exploring design-for-disassembly principles specifically tailored for metamaterial structures to enhance recyclability without compromising mechanical performance.

Biodegradable variants of mechanical metamaterials represent a promising frontier, with recent developments incorporating naturally-derived polymers and biocompatible ceramics into nanoarchitectures. These materials could offer controlled degradation profiles while maintaining load-bearing capabilities for specific duration requirements, particularly valuable in biomedical and temporary structural applications.

Regulatory frameworks for nanomaterial sustainability are still evolving, with organizations like ISO and ASTM developing specialized standards for environmental assessment of nanomaterials. Manufacturers of nanoarchitected metamaterials increasingly adopt these frameworks to demonstrate environmental compliance and competitive advantage in markets where sustainability metrics influence procurement decisions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!