Acrylic Resin vs Alkyd Resin: Weatherability in Outdoor Coatings

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coating Resin Technology Background and Objectives

Coating resins have evolved significantly over the past century, with acrylic and alkyd resins emerging as dominant technologies in the protective coatings industry. The development of these materials can be traced back to the early 20th century, with alkyds being introduced in the 1920s as one of the first synthetic resins for coatings. Acrylic resins followed later, gaining prominence in the 1950s and 1960s as the demand for more durable and environmentally friendly coating solutions increased.

The evolution of coating technology has been driven by several factors, including environmental regulations, performance requirements, and economic considerations. Traditional solvent-based alkyd systems dominated the market for decades due to their excellent application properties and relatively low cost. However, increasing concerns about volatile organic compounds (VOCs) and their environmental impact have pushed the industry toward water-based systems and higher-solid formulations.

Acrylic resins have gained significant market share in recent decades, particularly in exterior applications where weatherability is paramount. This shift represents a broader trend in the coatings industry toward more durable, sustainable, and environmentally compliant solutions. The technological trajectory clearly indicates a movement away from conventional solvent-based systems toward water-based, high-solid, and even powder coating technologies.

The primary technical objective in comparing acrylic and alkyd resins for outdoor applications is to establish quantifiable performance metrics related to weatherability. This includes resistance to UV degradation, moisture penetration, temperature fluctuations, and chemical exposure. Additionally, the investigation aims to identify the specific molecular and structural characteristics that contribute to superior weathering performance in each resin type.

Another critical objective is to understand the cost-performance relationship between these two resin technologies. While acrylics generally demonstrate superior weatherability, alkyds often present advantages in terms of cost, application properties, and certain performance characteristics such as adhesion and flexibility. Determining the optimal balance for specific applications represents a significant technical challenge.

Future technological developments are expected to focus on hybrid systems that combine the beneficial properties of both resin types. These may include acrylic-modified alkyds, alkyd-modified acrylics, and novel copolymer structures designed to maximize weatherability while maintaining other desirable coating properties. Additionally, research into bio-based alternatives for both resin types is gaining momentum as sustainability becomes increasingly important in coating formulations.

The evolution of coating technology has been driven by several factors, including environmental regulations, performance requirements, and economic considerations. Traditional solvent-based alkyd systems dominated the market for decades due to their excellent application properties and relatively low cost. However, increasing concerns about volatile organic compounds (VOCs) and their environmental impact have pushed the industry toward water-based systems and higher-solid formulations.

Acrylic resins have gained significant market share in recent decades, particularly in exterior applications where weatherability is paramount. This shift represents a broader trend in the coatings industry toward more durable, sustainable, and environmentally compliant solutions. The technological trajectory clearly indicates a movement away from conventional solvent-based systems toward water-based, high-solid, and even powder coating technologies.

The primary technical objective in comparing acrylic and alkyd resins for outdoor applications is to establish quantifiable performance metrics related to weatherability. This includes resistance to UV degradation, moisture penetration, temperature fluctuations, and chemical exposure. Additionally, the investigation aims to identify the specific molecular and structural characteristics that contribute to superior weathering performance in each resin type.

Another critical objective is to understand the cost-performance relationship between these two resin technologies. While acrylics generally demonstrate superior weatherability, alkyds often present advantages in terms of cost, application properties, and certain performance characteristics such as adhesion and flexibility. Determining the optimal balance for specific applications represents a significant technical challenge.

Future technological developments are expected to focus on hybrid systems that combine the beneficial properties of both resin types. These may include acrylic-modified alkyds, alkyd-modified acrylics, and novel copolymer structures designed to maximize weatherability while maintaining other desirable coating properties. Additionally, research into bio-based alternatives for both resin types is gaining momentum as sustainability becomes increasingly important in coating formulations.

Market Analysis for Outdoor Coating Resins

The global outdoor coatings market has been experiencing steady growth, with a market value reaching $19.8 billion in 2022 and projected to expand at a CAGR of 5.7% through 2030. This growth is primarily driven by increasing construction activities, infrastructure development, and rising awareness about the importance of protective coatings in extending asset lifespans.

Within this market, resin selection represents a critical decision factor for manufacturers, with acrylic and alkyd resins dominating the outdoor coating segment. Acrylic resins currently hold approximately 38% market share in outdoor applications, while alkyd resins maintain about 27% of the market. The remaining portion is distributed among polyurethane, epoxy, and other specialty resins.

Regional analysis reveals distinct preferences and growth patterns. North America and Europe demonstrate stronger adoption of acrylic-based coatings due to stricter VOC regulations and greater environmental consciousness. The Asia-Pacific region, particularly China and India, shows robust growth for both resin types, with alkyd maintaining stronger positions in developing markets where cost considerations often outweigh performance factors.

Consumer trends indicate a growing preference for high-performance, long-lasting coatings with enhanced weatherability. Market research shows that end-users are increasingly willing to pay premium prices for coatings that demonstrate superior UV resistance, color retention, and reduced maintenance requirements. This shift has accelerated the transition toward acrylic formulations in premium segments.

Price sensitivity analysis reveals that while acrylic resins typically command a 15-30% price premium over alkyd counterparts, the total cost of ownership calculation increasingly favors acrylics when factoring in longer recoating intervals and reduced maintenance costs. However, alkyd resins maintain strong market presence in price-sensitive segments and applications where initial cost outweighs lifecycle considerations.

Distribution channels for outdoor coating resins have evolved significantly, with direct-to-consumer and professional contractor channels showing the strongest growth. Retail channels account for approximately 45% of sales volume, while professional and industrial channels represent 55%. E-commerce platforms have emerged as the fastest-growing distribution segment, expanding at nearly twice the rate of traditional channels.

Future market projections indicate continued growth for both resin types, with acrylics expected to gain additional market share due to their superior weatherability profile and ongoing regulatory pressure against solvent-based systems. However, innovations in alkyd technology, particularly water-based and high-solid formulations, may help maintain their market relevance in specific application niches.

Within this market, resin selection represents a critical decision factor for manufacturers, with acrylic and alkyd resins dominating the outdoor coating segment. Acrylic resins currently hold approximately 38% market share in outdoor applications, while alkyd resins maintain about 27% of the market. The remaining portion is distributed among polyurethane, epoxy, and other specialty resins.

Regional analysis reveals distinct preferences and growth patterns. North America and Europe demonstrate stronger adoption of acrylic-based coatings due to stricter VOC regulations and greater environmental consciousness. The Asia-Pacific region, particularly China and India, shows robust growth for both resin types, with alkyd maintaining stronger positions in developing markets where cost considerations often outweigh performance factors.

Consumer trends indicate a growing preference for high-performance, long-lasting coatings with enhanced weatherability. Market research shows that end-users are increasingly willing to pay premium prices for coatings that demonstrate superior UV resistance, color retention, and reduced maintenance requirements. This shift has accelerated the transition toward acrylic formulations in premium segments.

Price sensitivity analysis reveals that while acrylic resins typically command a 15-30% price premium over alkyd counterparts, the total cost of ownership calculation increasingly favors acrylics when factoring in longer recoating intervals and reduced maintenance costs. However, alkyd resins maintain strong market presence in price-sensitive segments and applications where initial cost outweighs lifecycle considerations.

Distribution channels for outdoor coating resins have evolved significantly, with direct-to-consumer and professional contractor channels showing the strongest growth. Retail channels account for approximately 45% of sales volume, while professional and industrial channels represent 55%. E-commerce platforms have emerged as the fastest-growing distribution segment, expanding at nearly twice the rate of traditional channels.

Future market projections indicate continued growth for both resin types, with acrylics expected to gain additional market share due to their superior weatherability profile and ongoing regulatory pressure against solvent-based systems. However, innovations in alkyd technology, particularly water-based and high-solid formulations, may help maintain their market relevance in specific application niches.

Current Weatherability Challenges in Resin Technology

The outdoor coatings industry faces significant weatherability challenges as environmental conditions become increasingly extreme and unpredictable. Both acrylic and alkyd resins, while offering distinct performance profiles, struggle with specific degradation mechanisms when exposed to outdoor elements. UV radiation represents the primary challenge, causing photodegradation that manifests as color fading, chalking, and loss of gloss in both resin types, though through different chemical pathways.

Moisture exposure presents another critical challenge, with hydrolysis affecting alkyd resins particularly severely due to their ester linkages. This vulnerability leads to film breakdown and reduced coating integrity over time. Acrylic resins demonstrate superior hydrolytic stability but still face challenges with water absorption that can compromise adhesion to substrates.

Temperature fluctuations induce thermal expansion and contraction cycles that stress coating films, creating microcracks that accelerate degradation. Alkyd resins typically exhibit greater brittleness at low temperatures, while acrylics maintain flexibility across a wider temperature range but may soften excessively at elevated temperatures.

Biological degradation from mold, mildew, and algae represents an emerging concern, particularly in humid environments. Alkyd resins, containing natural oil components, provide nutrients for microorganisms, making them more susceptible to biodeterioration than acrylics. However, both resin types require effective biocide packages to ensure long-term performance.

Atmospheric pollutants, including acid rain, industrial emissions, and particulate matter, create chemical attack vectors that accelerate coating degradation. Alkyd resins show particular vulnerability to alkaline conditions, while acrylics demonstrate better chemical resistance but may still degrade when exposed to specific industrial pollutants.

The industry faces significant formulation challenges in addressing these weatherability issues. Balancing UV stabilizers, antioxidants, and other additives without compromising other coating properties remains difficult. Additionally, as environmental regulations increasingly restrict certain additives traditionally used to enhance weatherability, formulators must develop alternative solutions that maintain performance while meeting compliance requirements.

Testing methodologies present another challenge, as accelerated weathering tests often fail to accurately predict real-world performance. The correlation between laboratory results and actual field performance remains imperfect, creating uncertainty in product development and performance claims. This disconnect is particularly problematic when comparing different resin technologies with distinct degradation mechanisms.

Moisture exposure presents another critical challenge, with hydrolysis affecting alkyd resins particularly severely due to their ester linkages. This vulnerability leads to film breakdown and reduced coating integrity over time. Acrylic resins demonstrate superior hydrolytic stability but still face challenges with water absorption that can compromise adhesion to substrates.

Temperature fluctuations induce thermal expansion and contraction cycles that stress coating films, creating microcracks that accelerate degradation. Alkyd resins typically exhibit greater brittleness at low temperatures, while acrylics maintain flexibility across a wider temperature range but may soften excessively at elevated temperatures.

Biological degradation from mold, mildew, and algae represents an emerging concern, particularly in humid environments. Alkyd resins, containing natural oil components, provide nutrients for microorganisms, making them more susceptible to biodeterioration than acrylics. However, both resin types require effective biocide packages to ensure long-term performance.

Atmospheric pollutants, including acid rain, industrial emissions, and particulate matter, create chemical attack vectors that accelerate coating degradation. Alkyd resins show particular vulnerability to alkaline conditions, while acrylics demonstrate better chemical resistance but may still degrade when exposed to specific industrial pollutants.

The industry faces significant formulation challenges in addressing these weatherability issues. Balancing UV stabilizers, antioxidants, and other additives without compromising other coating properties remains difficult. Additionally, as environmental regulations increasingly restrict certain additives traditionally used to enhance weatherability, formulators must develop alternative solutions that maintain performance while meeting compliance requirements.

Testing methodologies present another challenge, as accelerated weathering tests often fail to accurately predict real-world performance. The correlation between laboratory results and actual field performance remains imperfect, creating uncertainty in product development and performance claims. This disconnect is particularly problematic when comparing different resin technologies with distinct degradation mechanisms.

Comparative Analysis of Acrylic vs Alkyd Performance

01 Modification of acrylic resins for improved weatherability

Acrylic resins can be modified with specific functional groups or additives to enhance their weatherability. These modifications include incorporating UV absorbers, HALS (Hindered Amine Light Stabilizers), and other stabilizing compounds directly into the polymer structure. The modified acrylic resins show improved resistance to yellowing, chalking, and degradation when exposed to outdoor conditions, making them suitable for exterior coatings and applications requiring long-term durability.- Modification of acrylic resins for improved weatherability: Acrylic resins can be modified with specific functional groups or additives to enhance their weatherability. These modifications include incorporating UV stabilizers, antioxidants, or specific monomers that improve resistance to degradation from sunlight and environmental factors. The modified acrylic resins show improved color retention, gloss retention, and overall durability when exposed to outdoor conditions.

- Hybrid acrylic-alkyd resin systems: Hybrid systems combining acrylic and alkyd resins can achieve superior weatherability compared to either resin type alone. These hybrid systems leverage the fast-drying and UV resistance properties of acrylics with the flexibility and adhesion properties of alkyds. The resulting coatings exhibit enhanced resistance to chalking, cracking, and fading when exposed to outdoor conditions, while maintaining good application properties.

- UV stabilizers and additives for resin weatherability: Incorporating specific UV stabilizers, HALS (Hindered Amine Light Stabilizers), and other additives into acrylic and alkyd resin formulations significantly improves their weatherability. These additives work by absorbing harmful UV radiation, scavenging free radicals, or providing a physical barrier against environmental factors. The proper selection and concentration of these additives can dramatically extend the service life of coatings based on these resins.

- Silicone-modified acrylic and alkyd resins: Incorporating silicone components into acrylic and alkyd resin systems significantly enhances their weatherability. The silicone modification improves water repellency, UV resistance, and thermal stability of the coating systems. These modified resins maintain flexibility and adhesion while providing superior resistance to chalking, cracking, and color fading under prolonged outdoor exposure conditions.

- Comparative weatherability testing methods: Various testing methods are employed to evaluate and compare the weatherability of acrylic and alkyd resins. These include accelerated weathering tests using QUV chambers, xenon arc exposure, and natural outdoor exposure testing. The tests measure parameters such as gloss retention, color change, chalking resistance, and mechanical property retention over time. These standardized testing protocols help in formulating resins with improved weatherability for specific application environments.

02 Hybrid acrylic-alkyd resin systems

Hybrid systems combining acrylic and alkyd resins leverage the advantages of both materials. These hybrid formulations typically feature the fast-drying and durability properties of acrylics with the excellent adhesion and flexibility of alkyds. The resulting coatings demonstrate superior weatherability compared to traditional alkyd resins alone, with improved resistance to UV degradation, better color retention, and enhanced gloss retention over extended outdoor exposure periods.Expand Specific Solutions03 UV-resistant additives and stabilizers for resin formulations

Various additives and stabilizers can be incorporated into acrylic and alkyd resin formulations to enhance their weatherability. These include nanomaterials like titanium dioxide, zinc oxide, and cerium oxide, as well as specialized UV absorbers, antioxidants, and radical scavengers. When properly dispersed in the resin matrix, these additives significantly improve the coating's resistance to photodegradation, extending service life and maintaining aesthetic properties under harsh environmental conditions.Expand Specific Solutions04 Silicone-modified acrylic and alkyd resins

Incorporating silicone components into acrylic and alkyd resin systems significantly enhances their weatherability. The silicone modification provides improved water repellency, UV resistance, and thermal stability. These modified resins demonstrate superior resistance to chalking, cracking, and color fading when exposed to outdoor conditions. The silicone components create a protective barrier that prevents moisture penetration while maintaining flexibility, making these resins particularly suitable for exterior architectural coatings and industrial applications.Expand Specific Solutions05 Waterborne acrylic and alkyd resin formulations with enhanced durability

Environmentally friendly waterborne acrylic and alkyd resin formulations have been developed with enhanced weatherability characteristics. These water-based systems utilize specialized emulsion technologies, crosslinking mechanisms, and stabilizing additives to achieve performance comparable to solvent-based systems. The formulations feature improved UV resistance, water resistance, and adhesion properties while reducing VOC emissions. Advanced waterborne technologies include self-crosslinking mechanisms that activate after application, forming durable films with excellent outdoor durability and resistance to environmental stressors.Expand Specific Solutions

Leading Manufacturers and Market Competition

The weatherability competition between acrylic and alkyd resins in outdoor coatings is currently in a mature growth phase, with the global market valued at approximately $30 billion. Acrylic resins are gaining market share due to superior UV resistance and color retention properties. Key industry players demonstrate varying technological maturity: LG Chem, Arkema, and Eastman Chemical lead with advanced acrylic formulations, while Allnex, Kansai Paint, and Nippon Paint have developed hybrid technologies combining benefits of both resin types. Asian manufacturers like Asian Paints and Jiangsu companies are rapidly advancing their weatherable coating portfolios, while established players such as 3M and Momentive focus on premium specialty applications with enhanced durability characteristics.

Allnex Belgium SA

Technical Solution: Allnex has pioneered innovative acrylic resin technologies specifically designed for superior weatherability in outdoor applications. Their UCECOAT® and EBECRYL® product lines feature radiation-curable acrylic resins that form highly crosslinked networks upon exposure to UV light, creating exceptionally durable coatings. For challenging outdoor environments, Allnex has developed their MACRYNAL® acrylic polyols that can be combined with polyisocyanates to create two-component polyurethane coatings with outstanding weatherability. Their acrylic resins incorporate advanced stabilization packages including UV absorbers, radical scavengers, and antioxidants that work synergistically to prevent polymer degradation. Allnex's water-based acrylic dispersions utilize core-shell technology to optimize film formation and mechanical properties while maintaining excellent resistance to hydrolysis. Comparative testing has demonstrated that their premium acrylic systems retain up to 95% of their original gloss and color after 3000 hours of QUV accelerated weathering, significantly outperforming traditional alkyd systems in outdoor durability.

Strengths: Exceptional UV and weather resistance; versatile product range covering solvent-based, water-based, and radiation-curable systems; excellent color and gloss retention in outdoor exposure. Weaknesses: Higher cost compared to conventional alkyd systems; some formulations require specialized application equipment; certain high-performance products may have more limited shelf life.

Kansai Paint Co., Ltd.

Technical Solution: Kansai Paint has developed proprietary acrylic resin technologies specifically engineered for extreme weatherability in outdoor coatings. Their ALMATEX™ line features self-crosslinking acrylic emulsions that form highly durable films with exceptional resistance to UV degradation and hydrolysis. For premium exterior applications, Kansai utilizes core-shell acrylic polymer architectures where the core provides hardness and the shell enables flexibility and adhesion. Their acrylic formulations incorporate synergistic combinations of UV absorbers, HALS (Hindered Amine Light Stabilizers), and antioxidants that significantly extend coating lifespans. Kansai's research has demonstrated that their advanced acrylic systems maintain color stability and gloss retention even after 7-10 years of outdoor exposure in harsh tropical environments. For industrial applications, they've developed silicone-modified acrylic resins that combine the weatherability of acrylics with the heat resistance of silicones. Their comparative testing shows acrylic-based coatings maintaining approximately 85% gloss retention after 3000 hours of accelerated weathering, while comparable alkyd systems typically retain only 40-50% gloss under identical conditions.

Strengths: Exceptional long-term UV and weather resistance; excellent color stability and chalk resistance; versatile application methods including spray, brush, and roll. Weaknesses: Generally higher cost than conventional alkyd systems; some premium formulations require longer curing times to achieve optimal performance; may require specific surface preparation for maximum adhesion.

Key Patents and Research in Weatherable Coatings

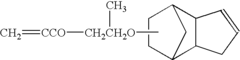

Acrylic resin composition, acrylic resin film, and molded body

PatentWO2015156323A1

Innovation

- A rubber-containing multistage polymer-based acrylic resin composition with a specific formulation, including a high content of elastic polymer and a hard polymer, is developed, which involves heating and melting the composition under pressure, followed by cooling and stretching to achieve desired properties such as high tensile elongation, low haze, and high flexural modulus.

Cold setting coating composition

PatentInactiveUS7084211B2

Innovation

- A cold setting coating composition utilizing an oxidatively curable urethane-modified vinyl resin, produced by reacting an epoxy group-containing vinyl copolymer with a fatty acid component and an isocyanate group-possessing compound, along with a polymer dispersion, to enhance film-forming properties and resistance.

Environmental Regulations Impacting Resin Selection

Environmental regulations have become increasingly stringent worldwide, significantly influencing the selection of resin systems for outdoor coating applications. The volatile organic compound (VOC) regulations represent one of the most impactful frameworks affecting the choice between acrylic and alkyd resins. Traditional solvent-based alkyd coatings typically contain 40-60% VOCs, making them increasingly problematic under current regulatory frameworks such as the EU's Paints Directive 2004/42/EC and the U.S. EPA's Architectural Coatings Rule.

Water-based acrylic resins have gained substantial market advantage due to their inherently lower VOC content, typically below 100 g/L compared to traditional alkyds that often exceed 350 g/L. This significant difference has accelerated the market transition toward acrylic systems, particularly in regions with the most stringent environmental controls such as California (CARB regulations) and the European Union.

The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in Europe has further complicated the landscape for alkyd resins. Several common components in alkyd formulations, including specific driers and additives containing heavy metals like cobalt and lead compounds, face increasing restrictions or outright bans. Acrylic systems generally require fewer regulated additives, providing manufacturers with greater formulation flexibility under these constraints.

Hazardous Air Pollutants (HAPs) regulations have also created challenges for traditional alkyd systems. The solvents commonly used in alkyd formulations, such as mineral spirits and xylene, are classified as HAPs under various regulatory frameworks. Manufacturers must implement costly control technologies or reformulate to maintain compliance, further eroding the cost advantage traditionally held by alkyd systems.

The global push toward circular economy principles is emerging as another regulatory factor. Extended Producer Responsibility (EPR) programs increasingly hold coating manufacturers accountable for end-of-life management of their products. Acrylic resins, which can be more easily recycled in some applications and generally produce fewer hazardous waste byproducts during disposal, may offer advantages under these emerging frameworks.

Carbon footprint regulations and carbon pricing mechanisms are beginning to influence resin selection decisions as well. Life Cycle Assessment (LCA) studies suggest that water-based acrylic systems typically have lower overall carbon footprints compared to solvent-based alkyd systems when considering the entire production, application, and disposal cycle, though this advantage narrows with the development of high-solid and water-dispersible alkyd technologies.

Regional regulatory variations create significant complexity for global coating manufacturers. While North America and Europe have led in environmental restrictions, emerging economies are rapidly adopting similar frameworks, creating a complex global compliance landscape that favors versatile resin systems with broad regulatory acceptance.

Water-based acrylic resins have gained substantial market advantage due to their inherently lower VOC content, typically below 100 g/L compared to traditional alkyds that often exceed 350 g/L. This significant difference has accelerated the market transition toward acrylic systems, particularly in regions with the most stringent environmental controls such as California (CARB regulations) and the European Union.

The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation in Europe has further complicated the landscape for alkyd resins. Several common components in alkyd formulations, including specific driers and additives containing heavy metals like cobalt and lead compounds, face increasing restrictions or outright bans. Acrylic systems generally require fewer regulated additives, providing manufacturers with greater formulation flexibility under these constraints.

Hazardous Air Pollutants (HAPs) regulations have also created challenges for traditional alkyd systems. The solvents commonly used in alkyd formulations, such as mineral spirits and xylene, are classified as HAPs under various regulatory frameworks. Manufacturers must implement costly control technologies or reformulate to maintain compliance, further eroding the cost advantage traditionally held by alkyd systems.

The global push toward circular economy principles is emerging as another regulatory factor. Extended Producer Responsibility (EPR) programs increasingly hold coating manufacturers accountable for end-of-life management of their products. Acrylic resins, which can be more easily recycled in some applications and generally produce fewer hazardous waste byproducts during disposal, may offer advantages under these emerging frameworks.

Carbon footprint regulations and carbon pricing mechanisms are beginning to influence resin selection decisions as well. Life Cycle Assessment (LCA) studies suggest that water-based acrylic systems typically have lower overall carbon footprints compared to solvent-based alkyd systems when considering the entire production, application, and disposal cycle, though this advantage narrows with the development of high-solid and water-dispersible alkyd technologies.

Regional regulatory variations create significant complexity for global coating manufacturers. While North America and Europe have led in environmental restrictions, emerging economies are rapidly adopting similar frameworks, creating a complex global compliance landscape that favors versatile resin systems with broad regulatory acceptance.

Accelerated Testing Methods for Weatherability

Accelerated testing methods are essential for evaluating the weatherability of coating systems, particularly when comparing acrylic and alkyd resins for outdoor applications. These methods simulate years of natural exposure in significantly reduced timeframes, allowing manufacturers and researchers to make informed decisions about coating formulations without waiting for real-time aging results.

The QUV accelerated weathering tester represents one of the most widely used methods in the industry, employing fluorescent UV lamps to simulate sunlight's damaging effects. For acrylic versus alkyd resin comparisons, the ASTM G154 protocol is commonly implemented, typically utilizing UVA-340 lamps that closely match the critical short-wavelength UV spectrum of natural sunlight. This test reveals acrylic resins' superior UV resistance compared to alkyds, which tend to show more rapid degradation under these conditions.

Xenon arc testing, governed by standards such as ASTM G155 and ISO 16474-2, provides a fuller spectrum simulation that more accurately reproduces both UV and visible light. This method is particularly valuable for evaluating color retention differences between acrylic and alkyd systems, with acrylics typically demonstrating superior performance in maintaining aesthetic properties over time.

Cyclic corrosion testing combines UV exposure with salt spray and humidity cycles, following standards like ASTM D5894. This approach is especially relevant for comparing how acrylic and alkyd resins perform in coastal environments or areas with high pollution levels. Results consistently show that properly formulated acrylic systems maintain better film integrity under these complex exposure conditions.

The EMMAQUA (Equatorial Mount with Mirrors for Acceleration with Water) test represents one of the most aggressive accelerated weathering methods, using concentrated natural sunlight to achieve acceleration factors of 5-10 times. This desert-based testing is particularly valuable for evaluating high-performance coating systems where acrylics' superior photostability becomes evident compared to alkyds' tendency toward chalking and film degradation.

Thermal cycling chambers subject coatings to rapid temperature fluctuations, often combined with UV exposure, to evaluate coating flexibility and adhesion over time. This testing reveals significant differences in how acrylic and alkyd resins respond to thermal stress, with acrylics generally maintaining better flexibility after aging due to their thermoplastic nature versus the increasingly brittle behavior of crosslinked alkyds.

Correlation between accelerated and natural weathering remains a critical consideration. While accelerated methods provide valuable comparative data, verification through natural exposure testing at standardized outdoor exposure sites in Florida, Arizona, or international locations helps validate findings and establish more accurate service life predictions for both resin systems.

The QUV accelerated weathering tester represents one of the most widely used methods in the industry, employing fluorescent UV lamps to simulate sunlight's damaging effects. For acrylic versus alkyd resin comparisons, the ASTM G154 protocol is commonly implemented, typically utilizing UVA-340 lamps that closely match the critical short-wavelength UV spectrum of natural sunlight. This test reveals acrylic resins' superior UV resistance compared to alkyds, which tend to show more rapid degradation under these conditions.

Xenon arc testing, governed by standards such as ASTM G155 and ISO 16474-2, provides a fuller spectrum simulation that more accurately reproduces both UV and visible light. This method is particularly valuable for evaluating color retention differences between acrylic and alkyd systems, with acrylics typically demonstrating superior performance in maintaining aesthetic properties over time.

Cyclic corrosion testing combines UV exposure with salt spray and humidity cycles, following standards like ASTM D5894. This approach is especially relevant for comparing how acrylic and alkyd resins perform in coastal environments or areas with high pollution levels. Results consistently show that properly formulated acrylic systems maintain better film integrity under these complex exposure conditions.

The EMMAQUA (Equatorial Mount with Mirrors for Acceleration with Water) test represents one of the most aggressive accelerated weathering methods, using concentrated natural sunlight to achieve acceleration factors of 5-10 times. This desert-based testing is particularly valuable for evaluating high-performance coating systems where acrylics' superior photostability becomes evident compared to alkyds' tendency toward chalking and film degradation.

Thermal cycling chambers subject coatings to rapid temperature fluctuations, often combined with UV exposure, to evaluate coating flexibility and adhesion over time. This testing reveals significant differences in how acrylic and alkyd resins respond to thermal stress, with acrylics generally maintaining better flexibility after aging due to their thermoplastic nature versus the increasingly brittle behavior of crosslinked alkyds.

Correlation between accelerated and natural weathering remains a critical consideration. While accelerated methods provide valuable comparative data, verification through natural exposure testing at standardized outdoor exposure sites in Florida, Arizona, or international locations helps validate findings and establish more accurate service life predictions for both resin systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!