Acrylic Resin vs Styrene Copolymers: Brittleness vs Flexibility

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Science Background and Research Objectives

Polymer science has evolved significantly over the past century, with synthetic polymers becoming integral to countless industrial applications and consumer products. The development of acrylic resins and styrene copolymers represents two major milestones in this evolution, each offering distinct mechanical properties that serve different functional needs. Acrylic resins, first commercialized in the 1930s, have developed into versatile materials known for their optical clarity and weatherability. Meanwhile, styrene copolymers, which gained prominence in the mid-20th century, have established themselves as cost-effective solutions across various sectors.

The mechanical properties of polymers, particularly the balance between brittleness and flexibility, are fundamentally determined by their molecular structure, chain length, degree of cross-linking, and intermolecular forces. These characteristics directly influence glass transition temperature (Tg), which serves as a critical indicator of a polymer's behavior under various temperature conditions. Understanding these structure-property relationships is essential for predicting performance and tailoring materials for specific applications.

Recent technological advancements have enabled more precise control over polymer architecture, allowing for customized mechanical properties through techniques such as controlled radical polymerization and the incorporation of specific functional groups. These innovations have expanded the application range for both acrylic resins and styrene copolymers, while simultaneously blurring the traditional boundaries between brittle and flexible materials.

Market trends indicate growing demand for polymers that combine seemingly contradictory properties – materials that exhibit both impact resistance and dimensional stability, or flexibility without sacrificing tensile strength. This has accelerated research into hybrid systems and composite materials that leverage the complementary properties of acrylic and styrene-based polymers.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of acrylic resins versus styrene copolymers, with specific focus on their brittleness and flexibility characteristics. We aim to establish quantitative relationships between molecular structure and mechanical performance, identify the key factors that influence these properties, and explore potential modification strategies to optimize performance for targeted applications.

Secondary objectives include mapping the temperature-dependent behavior of these polymer systems, evaluating their long-term performance under various environmental conditions, and assessing the feasibility of developing hybrid materials that combine the advantageous properties of both polymer families. This research will provide valuable insights for product development teams seeking to make informed material selection decisions based on specific performance requirements.

The mechanical properties of polymers, particularly the balance between brittleness and flexibility, are fundamentally determined by their molecular structure, chain length, degree of cross-linking, and intermolecular forces. These characteristics directly influence glass transition temperature (Tg), which serves as a critical indicator of a polymer's behavior under various temperature conditions. Understanding these structure-property relationships is essential for predicting performance and tailoring materials for specific applications.

Recent technological advancements have enabled more precise control over polymer architecture, allowing for customized mechanical properties through techniques such as controlled radical polymerization and the incorporation of specific functional groups. These innovations have expanded the application range for both acrylic resins and styrene copolymers, while simultaneously blurring the traditional boundaries between brittle and flexible materials.

Market trends indicate growing demand for polymers that combine seemingly contradictory properties – materials that exhibit both impact resistance and dimensional stability, or flexibility without sacrificing tensile strength. This has accelerated research into hybrid systems and composite materials that leverage the complementary properties of acrylic and styrene-based polymers.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of acrylic resins versus styrene copolymers, with specific focus on their brittleness and flexibility characteristics. We aim to establish quantitative relationships between molecular structure and mechanical performance, identify the key factors that influence these properties, and explore potential modification strategies to optimize performance for targeted applications.

Secondary objectives include mapping the temperature-dependent behavior of these polymer systems, evaluating their long-term performance under various environmental conditions, and assessing the feasibility of developing hybrid materials that combine the advantageous properties of both polymer families. This research will provide valuable insights for product development teams seeking to make informed material selection decisions based on specific performance requirements.

Market Applications and Demand Analysis

The global market for polymers with specific brittleness and flexibility properties has shown significant growth in recent years, driven by increasing demand across multiple industries. Acrylic resins and styrene copolymers represent two major polymer categories that serve distinct market segments based on their mechanical properties, particularly their brittleness versus flexibility characteristics.

In the automotive sector, there is a growing demand for materials that can provide both durability and weight reduction. Styrene copolymers, particularly ABS (Acrylonitrile Butadiene Styrene) and SBS (Styrene Butadiene Styrene), have captured approximately 35% of the polymer market share in this sector due to their superior impact resistance and flexibility. Meanwhile, acrylic resins maintain a strong presence in automotive lighting and display components where optical clarity and weather resistance are prioritized over flexibility.

The construction industry represents another significant market, valued at approximately $12.5 billion for these polymers. Here, the demand is bifurcated: acrylic resins dominate in exterior applications such as siding, roofing, and weatherproof coatings due to their UV stability and brittleness that provides dimensional stability. Conversely, styrene copolymers find applications in flexible sealing systems, insulation, and impact-resistant components.

Consumer electronics manufacturers have increasingly shifted toward styrene copolymers for device casings and components, with market growth rates of 7-9% annually. This trend is driven by the need for materials that can withstand drops and impacts while maintaining aesthetic appeal. Acrylic resins remain prevalent in display screens and optical components where brittleness is less problematic than the need for optical clarity.

The medical device industry presents a specialized market segment where material properties are critically important. Acrylic resins are preferred for rigid applications such as diagnostic equipment housings and laboratory ware, while styrene copolymers are increasingly used in flexible tubing, connectors, and ergonomic device components. This sector shows steady growth of 5-6% annually for these materials.

Regional market analysis reveals that Asia-Pacific dominates consumption of both polymer types, accounting for over 40% of global demand, followed by North America and Europe. Emerging economies show accelerated growth rates, particularly in construction and automotive applications, where the balance between brittleness and flexibility directly impacts product performance and longevity.

Market forecasts indicate that demand for styrene copolymers with enhanced flexibility will outpace traditional acrylic resins in most sectors, with a projected compound annual growth rate of 6.2% through 2027, compared to 4.8% for standard acrylic formulations. This trend reflects the broader industry movement toward materials that combine durability with impact resistance.

In the automotive sector, there is a growing demand for materials that can provide both durability and weight reduction. Styrene copolymers, particularly ABS (Acrylonitrile Butadiene Styrene) and SBS (Styrene Butadiene Styrene), have captured approximately 35% of the polymer market share in this sector due to their superior impact resistance and flexibility. Meanwhile, acrylic resins maintain a strong presence in automotive lighting and display components where optical clarity and weather resistance are prioritized over flexibility.

The construction industry represents another significant market, valued at approximately $12.5 billion for these polymers. Here, the demand is bifurcated: acrylic resins dominate in exterior applications such as siding, roofing, and weatherproof coatings due to their UV stability and brittleness that provides dimensional stability. Conversely, styrene copolymers find applications in flexible sealing systems, insulation, and impact-resistant components.

Consumer electronics manufacturers have increasingly shifted toward styrene copolymers for device casings and components, with market growth rates of 7-9% annually. This trend is driven by the need for materials that can withstand drops and impacts while maintaining aesthetic appeal. Acrylic resins remain prevalent in display screens and optical components where brittleness is less problematic than the need for optical clarity.

The medical device industry presents a specialized market segment where material properties are critically important. Acrylic resins are preferred for rigid applications such as diagnostic equipment housings and laboratory ware, while styrene copolymers are increasingly used in flexible tubing, connectors, and ergonomic device components. This sector shows steady growth of 5-6% annually for these materials.

Regional market analysis reveals that Asia-Pacific dominates consumption of both polymer types, accounting for over 40% of global demand, followed by North America and Europe. Emerging economies show accelerated growth rates, particularly in construction and automotive applications, where the balance between brittleness and flexibility directly impacts product performance and longevity.

Market forecasts indicate that demand for styrene copolymers with enhanced flexibility will outpace traditional acrylic resins in most sectors, with a projected compound annual growth rate of 6.2% through 2027, compared to 4.8% for standard acrylic formulations. This trend reflects the broader industry movement toward materials that combine durability with impact resistance.

Current Limitations and Technical Challenges

The current technical landscape reveals significant limitations in both acrylic resins and styrene copolymers when optimizing for the balance between brittleness and flexibility. Acrylic resins, particularly polymethyl methacrylate (PMMA), exhibit excellent optical clarity and weather resistance but suffer from inherent brittleness with impact strength typically ranging from 0.4-1.9 kJ/m². This brittleness becomes particularly problematic in applications requiring mechanical stress resistance or temperature fluctuations.

Styrene copolymers, while offering improved flexibility compared to pure polystyrene, still face challenges in achieving optimal mechanical properties. Acrylonitrile-butadiene-styrene (ABS) provides better impact resistance (15-40 kJ/m²) but experiences significant property degradation when exposed to UV radiation and certain chemical environments, limiting outdoor applications without additional protection.

A critical technical challenge lies in the glass transition temperature (Tg) manipulation. Acrylic resins typically have Tg values between 85-165°C, while styrene copolymers range from 85-125°C depending on composition. Lowering Tg improves flexibility but compromises dimensional stability and heat resistance, creating an engineering trade-off that remains difficult to optimize for diverse application requirements.

Molecular weight distribution control presents another significant challenge. Both material families exhibit property variations based on molecular weight distributions, with higher molecular weights generally improving mechanical properties but simultaneously increasing processing difficulties. Current polymerization technologies struggle to achieve precise control over polydispersity indices, resulting in batch-to-batch variations that affect end-product consistency.

Plasticizer migration represents a persistent issue, particularly in applications requiring long-term flexibility. External plasticizers commonly used to enhance flexibility tend to migrate over time, leading to embrittlement and potential environmental concerns. Internal plasticization through copolymerization offers a partial solution but often compromises other desirable properties.

Cross-linking density optimization remains technically challenging, especially when balancing flexibility with chemical resistance. Higher cross-linking improves chemical resistance but reduces flexibility, while lower cross-linking enhances flexibility but compromises dimensional stability and solvent resistance.

Processing limitations further complicate material optimization. Acrylic resins require careful drying to prevent hydrolysis during processing, while styrene copolymers are sensitive to processing temperatures, with narrow processing windows that can lead to thermal degradation or insufficient polymer flow. These processing challenges often necessitate specialized equipment and expertise, increasing production costs and limiting widespread adoption in certain applications.

Styrene copolymers, while offering improved flexibility compared to pure polystyrene, still face challenges in achieving optimal mechanical properties. Acrylonitrile-butadiene-styrene (ABS) provides better impact resistance (15-40 kJ/m²) but experiences significant property degradation when exposed to UV radiation and certain chemical environments, limiting outdoor applications without additional protection.

A critical technical challenge lies in the glass transition temperature (Tg) manipulation. Acrylic resins typically have Tg values between 85-165°C, while styrene copolymers range from 85-125°C depending on composition. Lowering Tg improves flexibility but compromises dimensional stability and heat resistance, creating an engineering trade-off that remains difficult to optimize for diverse application requirements.

Molecular weight distribution control presents another significant challenge. Both material families exhibit property variations based on molecular weight distributions, with higher molecular weights generally improving mechanical properties but simultaneously increasing processing difficulties. Current polymerization technologies struggle to achieve precise control over polydispersity indices, resulting in batch-to-batch variations that affect end-product consistency.

Plasticizer migration represents a persistent issue, particularly in applications requiring long-term flexibility. External plasticizers commonly used to enhance flexibility tend to migrate over time, leading to embrittlement and potential environmental concerns. Internal plasticization through copolymerization offers a partial solution but often compromises other desirable properties.

Cross-linking density optimization remains technically challenging, especially when balancing flexibility with chemical resistance. Higher cross-linking improves chemical resistance but reduces flexibility, while lower cross-linking enhances flexibility but compromises dimensional stability and solvent resistance.

Processing limitations further complicate material optimization. Acrylic resins require careful drying to prevent hydrolysis during processing, while styrene copolymers are sensitive to processing temperatures, with narrow processing windows that can lead to thermal degradation or insufficient polymer flow. These processing challenges often necessitate specialized equipment and expertise, increasing production costs and limiting widespread adoption in certain applications.

Current Formulation Approaches and Solutions

01 Plasticizers and impact modifiers for improving flexibility

Various plasticizers and impact modifiers can be incorporated into acrylic resin and styrene copolymer formulations to reduce brittleness and enhance flexibility. These additives work by increasing the free volume between polymer chains, lowering the glass transition temperature, and improving impact resistance. Common plasticizers include phthalates, adipates, and citrates, while impact modifiers often consist of elastomeric particles that can absorb and dissipate energy upon impact.- Plasticizers and additives for improving flexibility: Various plasticizers and additives can be incorporated into acrylic resin and styrene copolymer formulations to reduce brittleness and enhance flexibility. These additives work by increasing the free volume between polymer chains, lowering the glass transition temperature, and improving chain mobility. Common plasticizers include phthalates, adipates, and specialized compounds that can be selected based on compatibility with the specific copolymer system.

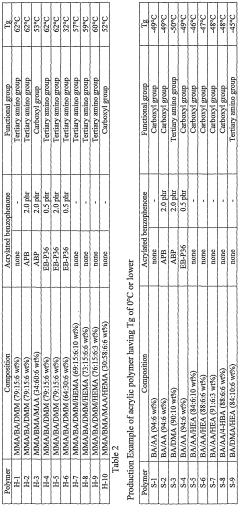

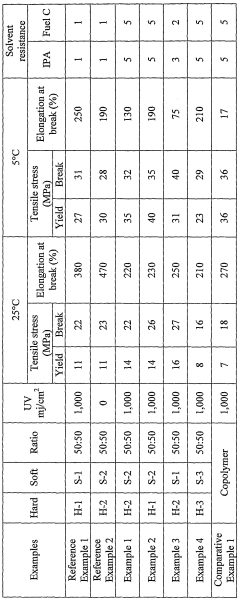

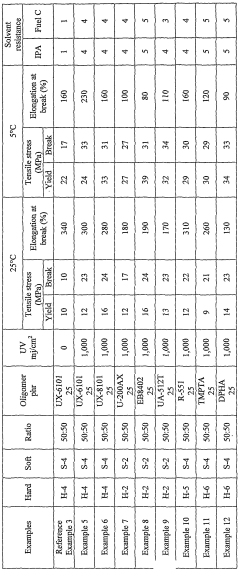

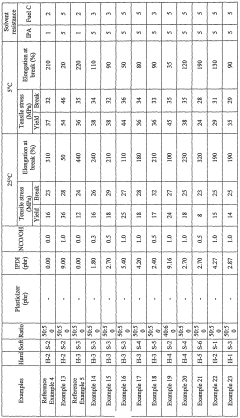

- Copolymer composition optimization: The brittleness and flexibility of acrylic resin and styrene copolymers can be controlled by adjusting the ratio of monomers in the copolymer composition. Increasing the proportion of softer monomers (such as butyl acrylate or 2-ethylhexyl acrylate) relative to harder monomers (like methyl methacrylate or styrene) results in more flexible materials with lower glass transition temperatures. The molecular weight and molecular weight distribution also significantly impact the mechanical properties.

- Impact modifiers and elastomeric additives: Impact modifiers and elastomeric additives can be blended with acrylic resin and styrene copolymers to improve toughness and flexibility. These modifiers typically consist of core-shell particles with a rubbery core and a compatible shell, or block copolymers that can absorb impact energy and prevent crack propagation. The elastomeric components create a separate phase that can deform under stress, enhancing the overall flexibility of the material.

- Cross-linking and network structure control: The brittleness and flexibility of acrylic resin and styrene copolymers can be modified through controlled cross-linking and network structure formation. Introducing specific cross-linking agents at optimal concentrations creates a balance between rigidity and flexibility. Too much cross-linking increases brittleness, while controlled cross-linking can enhance both strength and flexibility. Multifunctional monomers or post-polymerization treatments can be used to achieve the desired network structure.

- Processing conditions and thermal history: The processing conditions and thermal history significantly affect the brittleness and flexibility of acrylic resin and styrene copolymers. Factors such as processing temperature, cooling rate, and annealing treatments influence the molecular orientation, crystallinity, and residual stresses in the final product. Optimized processing conditions can reduce internal stresses and improve flexibility without changing the chemical composition of the material.

02 Copolymer composition optimization for balanced properties

The ratio and arrangement of acrylic and styrene monomers in copolymers significantly affect the balance between brittleness and flexibility. By adjusting the monomer ratios, molecular weight distribution, and polymerization conditions, manufacturers can tailor the mechanical properties of the resulting copolymers. Higher acrylic content typically increases flexibility, while higher styrene content tends to increase hardness but may contribute to brittleness.Expand Specific Solutions03 Cross-linking agents and network structure control

The degree and type of cross-linking in acrylic-styrene copolymers significantly influence their mechanical properties. Controlled cross-linking can improve tensile strength while maintaining adequate flexibility. Various cross-linking agents and techniques can be employed to create optimal network structures that balance rigidity and flexibility. The cross-link density and distribution throughout the polymer matrix are critical factors in determining the final mechanical properties.Expand Specific Solutions04 Core-shell polymer structures for improved impact resistance

Core-shell polymer architectures, where a flexible elastomeric core is surrounded by a more rigid shell, can significantly enhance the impact resistance of acrylic-styrene systems without compromising other desirable properties. This structural approach allows for the incorporation of flexibility-enhancing components while maintaining the overall integrity and performance of the material. The core typically consists of rubbery polymers that absorb impact energy, while the shell provides compatibility with the matrix.Expand Specific Solutions05 Functional additives and processing conditions

Various functional additives and optimized processing conditions can significantly improve the flexibility and reduce brittleness of acrylic-styrene copolymers. These include chain transfer agents to control molecular weight, thermal stabilizers to prevent degradation during processing, and processing aids that enhance flow characteristics. Additionally, processing parameters such as temperature profiles, cooling rates, and annealing conditions can be adjusted to optimize the morphology and mechanical properties of the final product.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The acrylic resin versus styrene copolymers market is in a mature growth phase, with global demand driven by automotive, construction, and electronics industries. The market size is estimated at $25-30 billion annually, with steady 4-5% growth. Technologically, both materials have established manufacturing processes, but innovation continues in enhancing flexibility-brittleness balance. Key players like LG Chem, Lotte Advanced Materials, and Kuraray lead in acrylic resin development, while companies such as PS Japan, UMG ABS, and Techno-UMG dominate styrene copolymer technologies. Asian manufacturers, particularly from Japan and South Korea, hold significant market share, with companies like Toray Industries and Asahi Kasei advancing hybrid formulations that combine the transparency of acrylics with the impact resistance of styrene-based materials.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced acrylic resin formulations with enhanced impact modifiers that address the inherent brittleness of traditional acrylic materials. Their proprietary ABS-modified acrylic compounds incorporate elastomeric components that create microphase separation within the polymer matrix, resulting in improved flexibility while maintaining optical clarity. The company's LUPOY® series specifically targets applications requiring both transparency and impact resistance by utilizing a core-shell rubber particle structure dispersed throughout the acrylic matrix. This technology allows for energy absorption during impact events, preventing crack propagation. LG Chem has also pioneered weatherable acrylic-styrene copolymer blends that maintain flexibility across a wide temperature range (-30°C to 80°C) while offering superior UV resistance compared to conventional styrene-based materials.

Strengths: Superior weatherability and UV resistance; excellent optical clarity even with flexibility modifications; good chemical resistance. Weaknesses: Higher production costs compared to standard styrene copolymers; slightly lower heat resistance than some competing materials; requires specialized processing conditions.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed a proprietary technology called "Controlled Polymerization" for creating acrylic-styrene hybrid materials with precisely engineered molecular architectures. Their TENAC™ acrylic resin incorporates specially designed cross-linking agents that create a semi-interpenetrating network structure, allowing for improved flexibility without sacrificing dimensional stability. The company utilizes a multi-stage polymerization process where elastomeric domains are strategically distributed within a rigid matrix, creating materials with balanced mechanical properties. Asahi Kasei's approach includes the incorporation of functional monomers with pendant groups that disrupt crystallinity, reducing brittleness while maintaining thermal performance. Their materials demonstrate a flexural modulus reduction of approximately 15-20% compared to conventional acrylics while achieving impact strength improvements of over 200% in some formulations.

Strengths: Excellent balance of rigidity and impact resistance; superior processing characteristics with lower molding shrinkage; good colorability and surface quality. Weaknesses: Higher cost structure than commodity styrene copolymers; more complex processing requirements; slightly lower chemical resistance to certain solvents.

Critical Patents and Technical Literature Review

(METH)acrylic film, and marking film and receptor sheet using the same

PatentWO2006094177A1

Innovation

- A (meth)acrylic film is developed by copolymerizing acidic and basic group-containing (meth)acrylic polymers with radical generating groups, which are crosslinked using ultraviolet light or heating, incorporating a polyisocyanate for enhanced solvent resistance and miscibility, resulting in a film with improved tensile strength and elongation characteristics.

Styrenic resin composition

PatentWO2004067628A1

Innovation

- A styrene copolymer composition comprising a styrene monomer, butyl acrylate, and methyl methacrylate, combined with a block copolymer of styrene and conjugated diene-based monomers, forming a multilayer structure with a specific mass ratio of conjugated diene-based monomers (9-25%) to enhance both rigidity and impact strength.

Environmental Impact and Sustainability Considerations

The environmental impact of polymer materials has become a critical consideration in material selection processes across industries. When comparing acrylic resins and styrene copolymers, their environmental footprints differ significantly throughout their lifecycle stages, from production to disposal.

Acrylic resins generally demonstrate better environmental credentials in production phases, requiring approximately 20-30% less energy to manufacture compared to styrene-based alternatives. The production process for acrylics typically generates fewer volatile organic compounds (VOCs) and hazardous air pollutants, contributing to reduced atmospheric pollution. However, the monomers used in acrylic production, particularly methyl methacrylate, still present toxicity concerns during manufacturing.

Styrene copolymers face greater environmental scrutiny due to styrene's classification as a possible human carcinogen. The production process generates substantial emissions, with studies indicating that styrene manufacturing releases approximately 37,000 metric tons of styrene into the atmosphere annually worldwide. These emissions contribute to photochemical smog formation and air quality degradation in manufacturing regions.

Regarding biodegradability, neither material performs optimally. Both acrylic resins and styrene copolymers are inherently non-biodegradable, with estimated decomposition timeframes exceeding 500 years in landfill environments. This persistence presents significant end-of-life management challenges, particularly when considering that flexibility-enhancing additives may further complicate recycling processes.

Recycling capabilities present another important sustainability dimension. Acrylic resins generally demonstrate superior recyclability, with approximately 30-40% of commercial acrylic waste currently being recycled in developed markets. The recycling process for acrylics typically preserves more of the original material properties through multiple cycles. Conversely, styrene copolymers often experience more significant property degradation during recycling, limiting the number of possible recycling iterations.

Water impact assessments reveal that acrylic resins typically leach fewer harmful compounds during their use phase. Studies have shown that styrene copolymers may release trace amounts of residual styrene monomer and other additives into aquatic environments, potentially affecting aquatic ecosystems. This leaching behavior becomes particularly relevant when considering applications involving water contact or outdoor exposure.

Recent sustainability innovations have focused on developing bio-based alternatives for both material categories. Bio-acrylic acid production from renewable resources has advanced significantly, with commercial-scale production achieving up to 30% bio-content in some acrylic formulations. Similar efforts for bio-based styrene alternatives remain at earlier development stages, though promising research utilizing agricultural waste streams as feedstock continues to progress.

Carbon footprint analyses indicate that standard acrylic resin production generates approximately 2.75 kg CO₂ equivalent per kilogram of material, while styrene copolymers typically produce 3.15-3.40 kg CO₂ equivalent, representing a notable difference in climate impact between these material classes.

Acrylic resins generally demonstrate better environmental credentials in production phases, requiring approximately 20-30% less energy to manufacture compared to styrene-based alternatives. The production process for acrylics typically generates fewer volatile organic compounds (VOCs) and hazardous air pollutants, contributing to reduced atmospheric pollution. However, the monomers used in acrylic production, particularly methyl methacrylate, still present toxicity concerns during manufacturing.

Styrene copolymers face greater environmental scrutiny due to styrene's classification as a possible human carcinogen. The production process generates substantial emissions, with studies indicating that styrene manufacturing releases approximately 37,000 metric tons of styrene into the atmosphere annually worldwide. These emissions contribute to photochemical smog formation and air quality degradation in manufacturing regions.

Regarding biodegradability, neither material performs optimally. Both acrylic resins and styrene copolymers are inherently non-biodegradable, with estimated decomposition timeframes exceeding 500 years in landfill environments. This persistence presents significant end-of-life management challenges, particularly when considering that flexibility-enhancing additives may further complicate recycling processes.

Recycling capabilities present another important sustainability dimension. Acrylic resins generally demonstrate superior recyclability, with approximately 30-40% of commercial acrylic waste currently being recycled in developed markets. The recycling process for acrylics typically preserves more of the original material properties through multiple cycles. Conversely, styrene copolymers often experience more significant property degradation during recycling, limiting the number of possible recycling iterations.

Water impact assessments reveal that acrylic resins typically leach fewer harmful compounds during their use phase. Studies have shown that styrene copolymers may release trace amounts of residual styrene monomer and other additives into aquatic environments, potentially affecting aquatic ecosystems. This leaching behavior becomes particularly relevant when considering applications involving water contact or outdoor exposure.

Recent sustainability innovations have focused on developing bio-based alternatives for both material categories. Bio-acrylic acid production from renewable resources has advanced significantly, with commercial-scale production achieving up to 30% bio-content in some acrylic formulations. Similar efforts for bio-based styrene alternatives remain at earlier development stages, though promising research utilizing agricultural waste streams as feedstock continues to progress.

Carbon footprint analyses indicate that standard acrylic resin production generates approximately 2.75 kg CO₂ equivalent per kilogram of material, while styrene copolymers typically produce 3.15-3.40 kg CO₂ equivalent, representing a notable difference in climate impact between these material classes.

Regulatory Framework for Polymer Applications

The regulatory landscape governing polymer applications, particularly for acrylic resins and styrene copolymers, has evolved significantly in response to growing environmental and health concerns. These regulations directly impact material selection decisions when considering brittleness versus flexibility properties in various applications.

In the United States, the Food and Drug Administration (FDA) maintains strict guidelines for polymers used in food contact applications through 21 CFR 177.1010 for acrylic resins and 21 CFR 177.1640 for styrene copolymers. These regulations establish specific migration limits and physical property requirements that influence formulation choices, particularly regarding flexibility additives that might potentially leach into food products.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes comprehensive testing requirements for both polymer types. Notably, styrene monomers face stricter scrutiny due to their classification as substances of very high concern (SVHC), which has accelerated industry movement toward acrylic alternatives in certain applications where flexibility is less critical than regulatory compliance.

Environmental regulations increasingly influence polymer selection decisions. The EU's Single-Use Plastics Directive and similar legislation worldwide have created pressure to develop more environmentally sustainable polymer formulations. This regulatory pressure has spurred innovation in biodegradable acrylic variants, though these often exhibit different brittleness profiles compared to traditional formulations.

Building codes and safety standards represent another significant regulatory consideration. UL 94 flammability standards and ASTM D256 impact resistance requirements often necessitate specific brittleness-to-flexibility ratios that must be achieved while maintaining compliance with chemical composition regulations. Styrene copolymers typically offer superior impact resistance in these applications but may require flame retardant additives that further complicate regulatory compliance.

Medical device regulations, including ISO 10993 biocompatibility standards, impose additional requirements for polymers in healthcare applications. Acrylic resins generally face fewer regulatory hurdles in this sector due to their established safety profile, despite potential brittleness limitations compared to certain styrene copolymer formulations.

Regional variations in regulatory frameworks create significant complexity for global manufacturers. Japan's Positive List System and China's GB standards impose different requirements for polymer composition and physical properties than Western regulations, necessitating formulation adjustments that may alter brittleness-flexibility characteristics to maintain compliance across markets.

Looking forward, emerging regulations focused on microplastics and end-of-life product management will likely reshape polymer formulation priorities, potentially favoring materials with specific degradation profiles that balance environmental concerns with performance requirements including flexibility and impact resistance.

In the United States, the Food and Drug Administration (FDA) maintains strict guidelines for polymers used in food contact applications through 21 CFR 177.1010 for acrylic resins and 21 CFR 177.1640 for styrene copolymers. These regulations establish specific migration limits and physical property requirements that influence formulation choices, particularly regarding flexibility additives that might potentially leach into food products.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes comprehensive testing requirements for both polymer types. Notably, styrene monomers face stricter scrutiny due to their classification as substances of very high concern (SVHC), which has accelerated industry movement toward acrylic alternatives in certain applications where flexibility is less critical than regulatory compliance.

Environmental regulations increasingly influence polymer selection decisions. The EU's Single-Use Plastics Directive and similar legislation worldwide have created pressure to develop more environmentally sustainable polymer formulations. This regulatory pressure has spurred innovation in biodegradable acrylic variants, though these often exhibit different brittleness profiles compared to traditional formulations.

Building codes and safety standards represent another significant regulatory consideration. UL 94 flammability standards and ASTM D256 impact resistance requirements often necessitate specific brittleness-to-flexibility ratios that must be achieved while maintaining compliance with chemical composition regulations. Styrene copolymers typically offer superior impact resistance in these applications but may require flame retardant additives that further complicate regulatory compliance.

Medical device regulations, including ISO 10993 biocompatibility standards, impose additional requirements for polymers in healthcare applications. Acrylic resins generally face fewer regulatory hurdles in this sector due to their established safety profile, despite potential brittleness limitations compared to certain styrene copolymer formulations.

Regional variations in regulatory frameworks create significant complexity for global manufacturers. Japan's Positive List System and China's GB standards impose different requirements for polymer composition and physical properties than Western regulations, necessitating formulation adjustments that may alter brittleness-flexibility characteristics to maintain compliance across markets.

Looking forward, emerging regulations focused on microplastics and end-of-life product management will likely reshape polymer formulation priorities, potentially favoring materials with specific degradation profiles that balance environmental concerns with performance requirements including flexibility and impact resistance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!