Modeling Acrylic Resin Polymer Chain Dynamics

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Polymer Chain Dynamics Background and Objectives

Acrylic resins represent a significant class of polymeric materials that have transformed various industries since their development in the early 20th century. The study of polymer chain dynamics in acrylic resins has evolved from rudimentary observations to sophisticated computational modeling approaches that leverage quantum mechanics, molecular dynamics, and machine learning techniques. This technological progression has been driven by the increasing demand for materials with precisely tailored properties across applications ranging from coatings and adhesives to medical devices and optical components.

The fundamental understanding of acrylic polymer chain behavior began with the pioneering work of Otto Röhm in the 1920s, who developed the first commercial acrylic products. Subsequent decades saw theoretical frameworks emerge that attempted to explain the relationship between molecular structure and macroscopic properties. The introduction of the reptation theory by de Gennes in the 1970s marked a significant milestone, providing a mathematical model for polymer chain movement in entangled systems.

Recent technological advancements have shifted the focus toward multi-scale modeling approaches that bridge the gap between atomic-level interactions and bulk material properties. The integration of computational techniques with experimental validation has accelerated in the past decade, enabling more accurate predictions of how acrylic polymer chains respond to various environmental stimuli, including temperature fluctuations, mechanical stress, and chemical exposure.

Current research trends indicate a growing interest in understanding the non-linear viscoelastic behavior of acrylic resins under complex loading conditions. This includes investigations into strain-rate dependency, relaxation phenomena, and the influence of crosslinking density on dynamic mechanical properties. Additionally, there is increasing attention to the role of additives and co-polymers in modifying chain mobility and consequent material performance.

The primary objective of modeling acrylic resin polymer chain dynamics is to establish predictive frameworks that can accurately simulate material behavior across multiple time and length scales. This includes developing computational tools that can forecast aging mechanisms, failure modes, and performance limitations under various service conditions. Such models aim to reduce the empirical trial-and-error approach traditionally employed in material development.

Another critical goal is to enable rational design of novel acrylic formulations with enhanced properties such as improved thermal stability, mechanical strength, or environmental resistance. By understanding the fundamental relationships between molecular architecture and macroscopic behavior, researchers seek to create materials with precisely engineered characteristics for specific applications.

Furthermore, the modeling efforts aim to optimize processing parameters for acrylic resin manufacturing, potentially leading to more energy-efficient production methods, reduced waste, and improved quality control. This aligns with broader industry trends toward sustainable manufacturing practices and circular economy principles.

The fundamental understanding of acrylic polymer chain behavior began with the pioneering work of Otto Röhm in the 1920s, who developed the first commercial acrylic products. Subsequent decades saw theoretical frameworks emerge that attempted to explain the relationship between molecular structure and macroscopic properties. The introduction of the reptation theory by de Gennes in the 1970s marked a significant milestone, providing a mathematical model for polymer chain movement in entangled systems.

Recent technological advancements have shifted the focus toward multi-scale modeling approaches that bridge the gap between atomic-level interactions and bulk material properties. The integration of computational techniques with experimental validation has accelerated in the past decade, enabling more accurate predictions of how acrylic polymer chains respond to various environmental stimuli, including temperature fluctuations, mechanical stress, and chemical exposure.

Current research trends indicate a growing interest in understanding the non-linear viscoelastic behavior of acrylic resins under complex loading conditions. This includes investigations into strain-rate dependency, relaxation phenomena, and the influence of crosslinking density on dynamic mechanical properties. Additionally, there is increasing attention to the role of additives and co-polymers in modifying chain mobility and consequent material performance.

The primary objective of modeling acrylic resin polymer chain dynamics is to establish predictive frameworks that can accurately simulate material behavior across multiple time and length scales. This includes developing computational tools that can forecast aging mechanisms, failure modes, and performance limitations under various service conditions. Such models aim to reduce the empirical trial-and-error approach traditionally employed in material development.

Another critical goal is to enable rational design of novel acrylic formulations with enhanced properties such as improved thermal stability, mechanical strength, or environmental resistance. By understanding the fundamental relationships between molecular architecture and macroscopic behavior, researchers seek to create materials with precisely engineered characteristics for specific applications.

Furthermore, the modeling efforts aim to optimize processing parameters for acrylic resin manufacturing, potentially leading to more energy-efficient production methods, reduced waste, and improved quality control. This aligns with broader industry trends toward sustainable manufacturing practices and circular economy principles.

Market Applications and Demand Analysis for Acrylic Resins

The global acrylic resin market demonstrates robust growth driven by diverse industrial applications across multiple sectors. Current market analysis indicates significant demand in construction, automotive, electronics, and consumer goods industries, with the construction sector representing the largest market share due to acrylic resins' exceptional weatherability and durability properties.

The automotive industry represents a rapidly expanding application segment, where acrylic resins are increasingly utilized in exterior and interior components due to their lightweight properties, contributing to fuel efficiency while maintaining structural integrity. This trend aligns with the automotive industry's shift toward more sustainable and efficient vehicle designs.

Electronics manufacturers are incorporating acrylic resins into device components, displays, and protective coatings due to their optical clarity, electrical insulation properties, and resistance to environmental degradation. The miniaturization trend in electronics has further accelerated demand for high-performance acrylic formulations capable of maintaining stability at microscopic scales.

The medical sector presents an emerging high-value application area, with acrylic resins being utilized in medical devices, implants, and drug delivery systems. The biocompatibility of certain acrylic formulations, combined with their mechanical properties, makes them particularly valuable in this sector where material performance directly impacts patient outcomes.

Market research indicates a growing consumer preference for environmentally sustainable materials, creating demand for bio-based and recyclable acrylic resin formulations. This sustainability trend is reshaping product development strategies across the industry, with manufacturers investing in research to develop acrylic resins with reduced environmental footprints without compromising performance characteristics.

Regional market analysis reveals Asia-Pacific as the fastest-growing market for acrylic resins, driven by rapid industrialization, construction booms, and expanding manufacturing bases in China, India, and Southeast Asian countries. North America and Europe maintain significant market shares, with demand increasingly focused on specialty and high-performance acrylic formulations for advanced applications.

Understanding polymer chain dynamics has become a critical factor in developing next-generation acrylic resins with enhanced performance profiles. Market feedback indicates growing demand for acrylic formulations with precisely engineered properties such as controlled degradation rates, specific mechanical responses, and tailored surface interactions. These advanced requirements necessitate sophisticated modeling approaches to predict and control polymer behavior at the molecular level.

The automotive industry represents a rapidly expanding application segment, where acrylic resins are increasingly utilized in exterior and interior components due to their lightweight properties, contributing to fuel efficiency while maintaining structural integrity. This trend aligns with the automotive industry's shift toward more sustainable and efficient vehicle designs.

Electronics manufacturers are incorporating acrylic resins into device components, displays, and protective coatings due to their optical clarity, electrical insulation properties, and resistance to environmental degradation. The miniaturization trend in electronics has further accelerated demand for high-performance acrylic formulations capable of maintaining stability at microscopic scales.

The medical sector presents an emerging high-value application area, with acrylic resins being utilized in medical devices, implants, and drug delivery systems. The biocompatibility of certain acrylic formulations, combined with their mechanical properties, makes them particularly valuable in this sector where material performance directly impacts patient outcomes.

Market research indicates a growing consumer preference for environmentally sustainable materials, creating demand for bio-based and recyclable acrylic resin formulations. This sustainability trend is reshaping product development strategies across the industry, with manufacturers investing in research to develop acrylic resins with reduced environmental footprints without compromising performance characteristics.

Regional market analysis reveals Asia-Pacific as the fastest-growing market for acrylic resins, driven by rapid industrialization, construction booms, and expanding manufacturing bases in China, India, and Southeast Asian countries. North America and Europe maintain significant market shares, with demand increasingly focused on specialty and high-performance acrylic formulations for advanced applications.

Understanding polymer chain dynamics has become a critical factor in developing next-generation acrylic resins with enhanced performance profiles. Market feedback indicates growing demand for acrylic formulations with precisely engineered properties such as controlled degradation rates, specific mechanical responses, and tailored surface interactions. These advanced requirements necessitate sophisticated modeling approaches to predict and control polymer behavior at the molecular level.

Current Modeling Approaches and Technical Challenges

The modeling of acrylic resin polymer chain dynamics currently employs several sophisticated approaches, each with distinct advantages and limitations. Molecular Dynamics (MD) simulations represent the most comprehensive method, allowing researchers to track atomic-level movements and interactions within polymer systems. These simulations can accurately capture the viscoelastic behavior of acrylic resins by incorporating detailed force fields that account for bond stretching, angle bending, and non-bonded interactions.

Monte Carlo (MC) methods offer a complementary approach, particularly useful for exploring configurational space and equilibrium properties. While less detailed in temporal evolution than MD, MC techniques excel at sampling diverse polymer conformations, making them valuable for understanding the thermodynamic properties of acrylic resin systems.

Coarse-grained modeling has emerged as a powerful intermediate approach, bridging the gap between atomistic detail and computational efficiency. By representing groups of atoms as single interaction sites, these models can simulate larger polymer systems over extended timescales, capturing mesoscale phenomena crucial for understanding bulk material properties.

Despite these advances, significant technical challenges persist in accurately modeling acrylic resin dynamics. The multi-scale nature of polymer behavior presents a fundamental difficulty, as relevant phenomena span from picosecond local motions to macroscopic relaxations occurring over seconds or longer. Current models struggle to bridge these disparate timescales efficiently.

Parameterization remains another critical challenge, with force fields requiring extensive calibration against experimental data to ensure accuracy. For acrylic resins specifically, capturing the complex interactions between pendant groups and the influence of tacticity on chain mobility demands highly specialized parameters that are not universally available.

Computational resource limitations continue to constrain simulation capabilities, particularly for industrially relevant molecular weights and complex formulations. Even with modern high-performance computing, fully atomistic simulations of commercial acrylic systems remain prohibitively expensive for routine analysis.

The accurate representation of crosslinking processes and network formation presents additional modeling difficulties. Current approaches often employ simplified reaction schemes that fail to capture the heterogeneity and kinetic complexity of actual polymerization processes, leading to idealized network structures that may not reflect real material properties.

Environmental factors such as solvent interactions, temperature effects, and mechanical deformation add further complexity to modeling efforts. Incorporating these external influences while maintaining computational tractability represents an ongoing challenge for researchers in this field.

Monte Carlo (MC) methods offer a complementary approach, particularly useful for exploring configurational space and equilibrium properties. While less detailed in temporal evolution than MD, MC techniques excel at sampling diverse polymer conformations, making them valuable for understanding the thermodynamic properties of acrylic resin systems.

Coarse-grained modeling has emerged as a powerful intermediate approach, bridging the gap between atomistic detail and computational efficiency. By representing groups of atoms as single interaction sites, these models can simulate larger polymer systems over extended timescales, capturing mesoscale phenomena crucial for understanding bulk material properties.

Despite these advances, significant technical challenges persist in accurately modeling acrylic resin dynamics. The multi-scale nature of polymer behavior presents a fundamental difficulty, as relevant phenomena span from picosecond local motions to macroscopic relaxations occurring over seconds or longer. Current models struggle to bridge these disparate timescales efficiently.

Parameterization remains another critical challenge, with force fields requiring extensive calibration against experimental data to ensure accuracy. For acrylic resins specifically, capturing the complex interactions between pendant groups and the influence of tacticity on chain mobility demands highly specialized parameters that are not universally available.

Computational resource limitations continue to constrain simulation capabilities, particularly for industrially relevant molecular weights and complex formulations. Even with modern high-performance computing, fully atomistic simulations of commercial acrylic systems remain prohibitively expensive for routine analysis.

The accurate representation of crosslinking processes and network formation presents additional modeling difficulties. Current approaches often employ simplified reaction schemes that fail to capture the heterogeneity and kinetic complexity of actual polymerization processes, leading to idealized network structures that may not reflect real material properties.

Environmental factors such as solvent interactions, temperature effects, and mechanical deformation add further complexity to modeling efforts. Incorporating these external influences while maintaining computational tractability represents an ongoing challenge for researchers in this field.

State-of-the-Art Simulation Methods for Polymer Dynamics

01 Molecular structure and chain mobility in acrylic resins

The molecular structure of acrylic resins significantly influences their chain dynamics. Factors such as molecular weight, chain length, and branching affect the mobility of polymer chains. Higher molecular weight typically results in reduced chain mobility, while branching can create steric hindrance that affects dynamic behavior. Understanding these structural characteristics is essential for predicting and controlling the physical properties of acrylic resin polymers in various applications.- Molecular structure and chain mobility in acrylic resins: The molecular structure of acrylic resins significantly influences their chain dynamics. Factors such as molecular weight, chain length, and branching affect the mobility of polymer chains. Higher molecular weight typically results in reduced chain mobility, while branching can create steric hindrance that impacts chain movement. Understanding these structural characteristics is essential for predicting and controlling the physical properties of acrylic resin polymers, including their glass transition temperature and mechanical behavior.

- Temperature effects on acrylic polymer chain dynamics: Temperature plays a crucial role in acrylic resin polymer chain dynamics. As temperature increases, polymer chains gain kinetic energy, leading to enhanced mobility and flexibility. This temperature-dependent behavior affects properties such as viscosity, elasticity, and processability. The glass transition temperature (Tg) marks a critical point where chain dynamics change dramatically, transitioning from a rigid glassy state to a more mobile rubbery state. Controlling temperature during processing and application is therefore essential for achieving desired performance characteristics.

- Modification of acrylic polymer chain dynamics through copolymerization: Copolymerization strategies can be employed to modify and control acrylic polymer chain dynamics. By incorporating different monomers into the polymer backbone, properties such as flexibility, rigidity, and thermal behavior can be tailored. The introduction of specific functional groups through copolymerization can alter inter-chain interactions, affecting overall chain mobility. This approach allows for the design of acrylic resins with customized dynamic properties suitable for specific applications, from coatings to adhesives.

- Influence of additives and plasticizers on chain mobility: Additives and plasticizers significantly impact the chain dynamics of acrylic resin polymers. These compounds can intercalate between polymer chains, reducing intermolecular forces and enhancing chain mobility. The type and concentration of additives determine their effect on properties such as flexibility, processability, and glass transition temperature. Plasticizers particularly influence the free volume within the polymer matrix, facilitating chain movement and improving flow characteristics. Careful selection of additives enables fine-tuning of dynamic mechanical properties for specific applications.

- Characterization techniques for studying acrylic polymer chain dynamics: Various analytical techniques are employed to study and characterize acrylic resin polymer chain dynamics. Dynamic mechanical analysis (DMA) measures viscoelastic properties as a function of temperature, frequency, or time. Nuclear magnetic resonance (NMR) spectroscopy provides insights into local chain movements and relaxation processes. Differential scanning calorimetry (DSC) helps identify thermal transitions related to chain mobility. Additionally, rheological measurements offer valuable information about flow behavior and chain entanglements. These characterization methods are essential for understanding structure-property relationships and optimizing acrylic polymers for specific applications.

02 Temperature effects on acrylic polymer chain dynamics

Temperature plays a crucial role in acrylic resin polymer chain dynamics. As temperature increases, polymer chains gain kinetic energy, leading to enhanced mobility and flexibility. This temperature-dependent behavior affects properties such as glass transition temperature, viscoelasticity, and flow characteristics. By controlling temperature conditions during processing and application, manufacturers can optimize the performance characteristics of acrylic resin polymers for specific end-use requirements.Expand Specific Solutions03 Modification of acrylic polymers to control chain dynamics

Various modification techniques can be employed to control the chain dynamics of acrylic resin polymers. These include copolymerization with different monomers, incorporation of functional groups, and addition of plasticizers or other additives. Such modifications can alter the intermolecular forces between polymer chains, affecting their mobility and dynamic behavior. These approaches enable the tailoring of acrylic resins with specific chain dynamics for targeted applications.Expand Specific Solutions04 Crosslinking effects on acrylic polymer chain mobility

Crosslinking significantly impacts the chain dynamics of acrylic resin polymers by creating covalent bonds between polymer chains. This restricts chain mobility and increases rigidity of the polymer network. The degree of crosslinking can be controlled to achieve desired mechanical properties, thermal stability, and solvent resistance. Understanding the relationship between crosslinking density and chain dynamics is crucial for developing acrylic resins with specific performance characteristics.Expand Specific Solutions05 Advanced characterization techniques for studying acrylic polymer chain dynamics

Various analytical techniques are employed to study the chain dynamics of acrylic resin polymers. These include dynamic mechanical analysis (DMA), nuclear magnetic resonance (NMR) spectroscopy, rheological measurements, and computational modeling. These techniques provide insights into relaxation processes, segmental motion, and other dynamic behaviors of polymer chains. The data obtained helps in understanding structure-property relationships and guides the development of acrylic resins with optimized performance characteristics.Expand Specific Solutions

Leading Research Groups and Industrial Players

The acrylic resin polymer chain dynamics market is currently in a growth phase, with increasing applications across automotive, construction, electronics, and medical sectors. The global market size is estimated to reach $11.5 billion by 2027, growing at a CAGR of 5.8%. Technologically, the field shows moderate maturity with ongoing innovations in modeling techniques. Leading players like Nippon Shokubai, Sumitomo Chemical, and LG Chem have established strong R&D capabilities in polymer chain simulation, while Mitsubishi Gas Chemical, Kaneka, and Kuraray focus on specialized applications. Companies including Toray Industries and DIC Corp are advancing computational modeling approaches to optimize resin performance characteristics, creating a competitive landscape where Asian manufacturers, particularly Japanese firms, maintain technological leadership.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has developed a comprehensive modeling platform called ACRY-SIM for simulating acrylic resin polymer chain dynamics. Their approach combines quantum mechanical calculations with coarse-grained molecular dynamics to efficiently model large-scale polymer systems. The company has created proprietary force fields specifically optimized for various acrylic monomers and their copolymers, enabling accurate prediction of physical properties including glass transition temperature, mechanical strength, and rheological behavior[5]. Their methodology incorporates reaction kinetics models to simulate polymerization processes under various conditions, allowing optimization of synthesis parameters. Nippon Shokubai's platform features a unique capability to model water absorption and diffusion in acrylic resins, critical for predicting performance in high-humidity environments. The company has validated their models against extensive experimental data from their superabsorbent polymer production, demonstrating prediction accuracy within 5-10% for key material properties[7].

Strengths: Exceptional expertise in modeling water-polymer interactions; highly optimized force fields for acrylic systems; strong integration with industrial manufacturing processes. Weaknesses: Models show limitations in predicting behavior of highly crosslinked systems; computational demands restrict real-time application in production environments.

Mitsubishi Rayon Co Ltd

Technical Solution: Mitsubishi Rayon has developed the ACRYDYN simulation framework for modeling acrylic resin polymer chain dynamics across multiple time and length scales. Their approach integrates atomistic molecular dynamics with mesoscale dissipative particle dynamics to capture both local chain motions and large-scale polymer relaxations. The company employs machine learning algorithms to establish quantitative structure-property relationships, enabling rapid screening of potential monomer combinations and processing conditions[6]. Their methodology incorporates specialized modules for simulating photo-polymerization kinetics and thermomechanical behavior during processing. Mitsubishi Rayon has implemented a hybrid Monte Carlo/molecular dynamics approach to efficiently sample conformational space of high molecular weight acrylic polymers. The company has successfully applied these models to optimize their PMMA production processes, resulting in materials with enhanced optical clarity and mechanical durability. Their simulation platform includes capabilities for predicting aging behavior and environmental stress cracking resistance, critical for automotive and architectural applications[8].

Strengths: Excellent prediction of optical properties and aging behavior; efficient sampling algorithms for high molecular weight systems; strong correlation with manufacturing parameters. Weaknesses: Models require extensive parameterization for new monomer systems; limited accuracy in predicting behavior under extreme processing conditions.

Key Theoretical Frameworks and Computational Algorithms

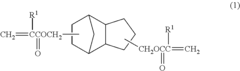

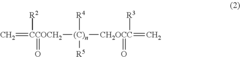

Highly processable multi-stage flexible acrylic resins and process for making same

PatentActiveUS11814512B2

Innovation

- A multi-stage flexible acrylic resin composition comprising a crosslinked core, intermediate layers with compositional gradients, outer layers derived from alkyl (meth)acrylate and styrenic monomers, and a branched polymer layer to reduce viscosity and enhance tensile properties, formed through sequential emulsion polymerization.

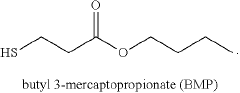

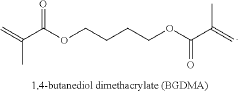

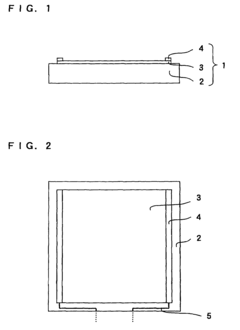

Acrylic resin, resin boards, transparent electrode boards for touch panels, touch panels, and processes for production of them

PatentInactiveUS8231981B2

Innovation

- A method involving the addition of specific compounds like cyclohexadiene derivatives and terpenoid-based compounds to a mixture of mono-ethylenically unsaturated monomers and poly-functional (meth)acrylates, along with a polymerization initiator, to create a polymerizable mixture that is then hardened, resulting in an acrylic resin plate with improved heat resistance, appearance, and shape stability, suitable for use in transparent electrode plates for touch panels.

Environmental Impact and Sustainability Considerations

The environmental impact of acrylic resin polymer systems extends far beyond their production phase, encompassing their entire lifecycle from raw material extraction to end-of-life disposal. Traditional acrylic resin manufacturing processes involve petroleum-derived monomers and energy-intensive polymerization reactions that release significant greenhouse gas emissions. Recent lifecycle assessments indicate that the production of one metric ton of acrylic resin generates approximately 2-3 tons of CO2 equivalent emissions, positioning it as a moderate carbon footprint material within the polymer industry.

Water consumption and pollution represent another critical environmental concern. Polymerization processes typically require substantial water volumes for cooling and washing operations, with potential for contamination by unreacted monomers, catalysts, and additives. Advanced modeling of polymer chain dynamics has enabled the development of more efficient reaction pathways that reduce both water requirements and pollutant generation by optimizing reaction conditions and minimizing waste byproducts.

Biodegradability remains a significant challenge for acrylic resins due to their synthetic carbon-carbon backbone structure, which resists natural decomposition processes. Current research utilizing molecular dynamics simulations is exploring the incorporation of biodegradable linkages within the polymer architecture without compromising performance characteristics. These computational approaches have identified promising candidates that could reduce environmental persistence while maintaining essential material properties.

Recycling opportunities for acrylic resins are expanding through improved understanding of chain dynamics during reprocessing. Molecular modeling has revealed how thermal and mechanical stresses during recycling affect chain scission and recombination, enabling the development of more recyclable formulations. Chemical recycling technologies that depolymerize acrylic resins back to their monomer constituents show particular promise, with recent models predicting recovery efficiencies exceeding 85% under optimized conditions.

Energy efficiency improvements in manufacturing processes have been achieved through computational modeling of reaction kinetics and heat transfer dynamics. These models have led to process innovations that reduce energy consumption by 15-30% compared to conventional methods. Additionally, bio-based alternatives derived from renewable resources are emerging as sustainable substitutes for petroleum-based acrylic monomers, with molecular dynamics simulations confirming comparable chain mobility and material performance characteristics.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of polymeric materials, with particular focus on microplastic generation from acrylic products. Understanding polymer chain degradation mechanisms through advanced modeling is essential for designing more environmentally compatible materials that meet evolving compliance requirements while satisfying technical performance specifications.

Water consumption and pollution represent another critical environmental concern. Polymerization processes typically require substantial water volumes for cooling and washing operations, with potential for contamination by unreacted monomers, catalysts, and additives. Advanced modeling of polymer chain dynamics has enabled the development of more efficient reaction pathways that reduce both water requirements and pollutant generation by optimizing reaction conditions and minimizing waste byproducts.

Biodegradability remains a significant challenge for acrylic resins due to their synthetic carbon-carbon backbone structure, which resists natural decomposition processes. Current research utilizing molecular dynamics simulations is exploring the incorporation of biodegradable linkages within the polymer architecture without compromising performance characteristics. These computational approaches have identified promising candidates that could reduce environmental persistence while maintaining essential material properties.

Recycling opportunities for acrylic resins are expanding through improved understanding of chain dynamics during reprocessing. Molecular modeling has revealed how thermal and mechanical stresses during recycling affect chain scission and recombination, enabling the development of more recyclable formulations. Chemical recycling technologies that depolymerize acrylic resins back to their monomer constituents show particular promise, with recent models predicting recovery efficiencies exceeding 85% under optimized conditions.

Energy efficiency improvements in manufacturing processes have been achieved through computational modeling of reaction kinetics and heat transfer dynamics. These models have led to process innovations that reduce energy consumption by 15-30% compared to conventional methods. Additionally, bio-based alternatives derived from renewable resources are emerging as sustainable substitutes for petroleum-based acrylic monomers, with molecular dynamics simulations confirming comparable chain mobility and material performance characteristics.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of polymeric materials, with particular focus on microplastic generation from acrylic products. Understanding polymer chain degradation mechanisms through advanced modeling is essential for designing more environmentally compatible materials that meet evolving compliance requirements while satisfying technical performance specifications.

Experimental Validation Techniques for Computational Models

Experimental validation is critical for ensuring the accuracy and reliability of computational models simulating acrylic resin polymer chain dynamics. Nuclear Magnetic Resonance (NMR) spectroscopy stands as a primary validation technique, offering detailed insights into local chain mobility and conformational changes. Both solid-state and solution NMR provide complementary data on polymer backbone flexibility and side-chain interactions, essential for validating computational predictions of molecular behavior under various conditions.

Rheological measurements serve as another fundamental validation approach, directly correlating with computational predictions of viscoelastic properties. Dynamic mechanical analysis (DMA) and oscillatory shear testing enable researchers to compare experimental stress-strain relationships with simulated mechanical responses across different temperatures and frequencies, providing crucial benchmarks for model accuracy.

Small-angle X-ray scattering (SAXS) and neutron scattering techniques offer valuable structural validation by revealing polymer chain organization at nanoscale dimensions. These methods provide statistical information about chain dimensions, persistence length, and radius of gyration—parameters directly comparable to those generated by molecular dynamics simulations of acrylic resin systems.

Differential scanning calorimetry (DSC) measurements validate thermodynamic aspects of computational models by determining glass transition temperatures, crystallization behavior, and heat capacity changes. These thermal properties reflect fundamental aspects of chain mobility and intermolecular interactions that sophisticated polymer models must accurately predict to be considered reliable.

Atomic force microscopy (AFM) and surface force apparatus (SFA) experiments provide direct measurements of interfacial phenomena and thin-film behavior of acrylic polymers. These techniques enable validation of computational predictions regarding surface interactions, adhesion properties, and confined chain dynamics—aspects particularly relevant for coating applications of acrylic resins.

Time-resolved spectroscopic techniques, including fluorescence correlation spectroscopy and dielectric spectroscopy, offer validation for dynamic aspects of polymer chain models. These methods capture relaxation processes across multiple timescales, from nanoseconds to seconds, allowing comprehensive comparison with time-dependent computational simulations of chain reorganization and response to external stimuli.

Multi-technique validation approaches have emerged as best practice, combining complementary experimental methods to provide comprehensive validation datasets. Statistical analysis frameworks for quantifying agreement between experimental and computational results have become increasingly sophisticated, employing metrics such as Bayesian inference and uncertainty quantification to establish confidence levels in model predictions.

Rheological measurements serve as another fundamental validation approach, directly correlating with computational predictions of viscoelastic properties. Dynamic mechanical analysis (DMA) and oscillatory shear testing enable researchers to compare experimental stress-strain relationships with simulated mechanical responses across different temperatures and frequencies, providing crucial benchmarks for model accuracy.

Small-angle X-ray scattering (SAXS) and neutron scattering techniques offer valuable structural validation by revealing polymer chain organization at nanoscale dimensions. These methods provide statistical information about chain dimensions, persistence length, and radius of gyration—parameters directly comparable to those generated by molecular dynamics simulations of acrylic resin systems.

Differential scanning calorimetry (DSC) measurements validate thermodynamic aspects of computational models by determining glass transition temperatures, crystallization behavior, and heat capacity changes. These thermal properties reflect fundamental aspects of chain mobility and intermolecular interactions that sophisticated polymer models must accurately predict to be considered reliable.

Atomic force microscopy (AFM) and surface force apparatus (SFA) experiments provide direct measurements of interfacial phenomena and thin-film behavior of acrylic polymers. These techniques enable validation of computational predictions regarding surface interactions, adhesion properties, and confined chain dynamics—aspects particularly relevant for coating applications of acrylic resins.

Time-resolved spectroscopic techniques, including fluorescence correlation spectroscopy and dielectric spectroscopy, offer validation for dynamic aspects of polymer chain models. These methods capture relaxation processes across multiple timescales, from nanoseconds to seconds, allowing comprehensive comparison with time-dependent computational simulations of chain reorganization and response to external stimuli.

Multi-technique validation approaches have emerged as best practice, combining complementary experimental methods to provide comprehensive validation datasets. Statistical analysis frameworks for quantifying agreement between experimental and computational results have become increasingly sophisticated, employing metrics such as Bayesian inference and uncertainty quantification to establish confidence levels in model predictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!