Enhancing Acrylic Resin’s Recyclability Without Property Loss

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Recyclability Background and Objectives

Acrylic resin, predominantly composed of polymethyl methacrylate (PMMA), has established itself as a versatile material across numerous industries since its commercial introduction in the 1930s. The evolution of acrylic resin technology has been marked by continuous improvements in manufacturing processes, formulation techniques, and application methodologies. Initially valued for its optical clarity and weather resistance, acrylic resins have expanded their utility into automotive components, medical devices, construction materials, and consumer electronics.

The global acrylic resin market has experienced steady growth, with projections indicating a compound annual growth rate of approximately 6% through 2028. This growth trajectory underscores the material's enduring relevance in modern manufacturing and design applications. However, this expansion has simultaneously amplified concerns regarding end-of-life management and environmental impact, particularly as regulatory frameworks worldwide increasingly emphasize circular economy principles.

Traditional acrylic resin recycling has been limited by significant challenges, primarily the degradation of mechanical and optical properties during reprocessing cycles. Conventional recycling methods, including mechanical grinding and thermal depolymerization, typically result in 15-30% reduction in tensile strength and impact resistance after a single recycling iteration. This property deterioration has historically relegated recycled acrylic to lower-value applications, creating a downcycling pattern rather than true circularity.

The technical objective of this research initiative is to develop innovative methodologies for enhancing acrylic resin recyclability while maintaining its premium material properties through multiple life cycles. Specifically, we aim to achieve less than 5% degradation in critical performance metrics including tensile strength, impact resistance, and optical clarity after three complete recycling iterations. This ambitious target necessitates fundamental advancements in polymer stabilization, processing technologies, and additive formulations.

Secondary objectives include reducing the energy intensity of the recycling process by at least 25% compared to virgin material production, developing sorting and identification protocols for different acrylic formulations, and establishing quality assurance methodologies for recycled acrylic materials. These complementary goals address the full spectrum of technical challenges in creating a closed-loop system for acrylic resin utilization.

The technological evolution in this field is trending toward chemical recycling approaches, particularly depolymerization techniques that recover monomer units for subsequent repolymerization. Parallel developments in compatibilizers, chain extenders, and reactive extrusion processes offer promising pathways for property preservation during mechanical recycling. These emerging technologies represent the foundation upon which our research objectives will build.

The global acrylic resin market has experienced steady growth, with projections indicating a compound annual growth rate of approximately 6% through 2028. This growth trajectory underscores the material's enduring relevance in modern manufacturing and design applications. However, this expansion has simultaneously amplified concerns regarding end-of-life management and environmental impact, particularly as regulatory frameworks worldwide increasingly emphasize circular economy principles.

Traditional acrylic resin recycling has been limited by significant challenges, primarily the degradation of mechanical and optical properties during reprocessing cycles. Conventional recycling methods, including mechanical grinding and thermal depolymerization, typically result in 15-30% reduction in tensile strength and impact resistance after a single recycling iteration. This property deterioration has historically relegated recycled acrylic to lower-value applications, creating a downcycling pattern rather than true circularity.

The technical objective of this research initiative is to develop innovative methodologies for enhancing acrylic resin recyclability while maintaining its premium material properties through multiple life cycles. Specifically, we aim to achieve less than 5% degradation in critical performance metrics including tensile strength, impact resistance, and optical clarity after three complete recycling iterations. This ambitious target necessitates fundamental advancements in polymer stabilization, processing technologies, and additive formulations.

Secondary objectives include reducing the energy intensity of the recycling process by at least 25% compared to virgin material production, developing sorting and identification protocols for different acrylic formulations, and establishing quality assurance methodologies for recycled acrylic materials. These complementary goals address the full spectrum of technical challenges in creating a closed-loop system for acrylic resin utilization.

The technological evolution in this field is trending toward chemical recycling approaches, particularly depolymerization techniques that recover monomer units for subsequent repolymerization. Parallel developments in compatibilizers, chain extenders, and reactive extrusion processes offer promising pathways for property preservation during mechanical recycling. These emerging technologies represent the foundation upon which our research objectives will build.

Market Demand for Sustainable Acrylic Materials

The global market for sustainable acrylic materials has witnessed significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. Acrylic resins, widely used in various industries including automotive, construction, and consumer goods, have traditionally posed recycling challenges due to their thermosetting nature. This has created a substantial demand for innovations that enhance recyclability without compromising performance properties.

Consumer awareness regarding environmental sustainability has dramatically shifted purchasing behaviors, with 73% of global consumers willing to pay premium prices for sustainable products according to recent market surveys. This trend is particularly pronounced in developed markets across North America and Europe, where regulatory frameworks increasingly mandate extended producer responsibility and circular economy principles.

The construction sector represents the largest market segment for acrylic resins, accounting for approximately 35% of total consumption. This sector has shown growing interest in recyclable acrylic materials for applications in architectural panels, fixtures, and decorative elements. The automotive industry follows closely, seeking sustainable acrylic alternatives for interior components and lighting systems that maintain optical clarity and impact resistance while offering end-of-life recyclability.

Industrial forecasts project the sustainable acrylic materials market to grow at a compound annual growth rate of 7.2% through 2028, significantly outpacing the conventional acrylic market's growth rate of 3.5%. This accelerated growth trajectory reflects both regulatory push factors and market pull dynamics as manufacturers seek to differentiate their offerings through enhanced sustainability credentials.

Regional analysis reveals that Europe leads in demand for recyclable acrylic solutions, driven by the European Green Deal and circular economy action plans. Asia-Pacific markets, particularly China and Japan, are rapidly catching up as these countries implement stricter waste management regulations and sustainability targets for manufacturing industries.

The price premium for sustainable acrylic materials has been gradually decreasing as production scales up and technologies mature. Current market data indicates that recyclable acrylic formulations command a 15-20% premium over conventional alternatives, down from 30-40% five years ago. Industry analysts predict this gap will narrow further as economies of scale are realized and more players enter the market.

End-user industries have expressed specific performance requirements for recyclable acrylic materials, including maintenance of optical clarity through multiple recycling cycles, thermal stability comparable to virgin materials, and processing compatibility with existing manufacturing equipment. These technical demands shape the innovation landscape and highlight areas where breakthrough technologies could capture significant market share.

Consumer awareness regarding environmental sustainability has dramatically shifted purchasing behaviors, with 73% of global consumers willing to pay premium prices for sustainable products according to recent market surveys. This trend is particularly pronounced in developed markets across North America and Europe, where regulatory frameworks increasingly mandate extended producer responsibility and circular economy principles.

The construction sector represents the largest market segment for acrylic resins, accounting for approximately 35% of total consumption. This sector has shown growing interest in recyclable acrylic materials for applications in architectural panels, fixtures, and decorative elements. The automotive industry follows closely, seeking sustainable acrylic alternatives for interior components and lighting systems that maintain optical clarity and impact resistance while offering end-of-life recyclability.

Industrial forecasts project the sustainable acrylic materials market to grow at a compound annual growth rate of 7.2% through 2028, significantly outpacing the conventional acrylic market's growth rate of 3.5%. This accelerated growth trajectory reflects both regulatory push factors and market pull dynamics as manufacturers seek to differentiate their offerings through enhanced sustainability credentials.

Regional analysis reveals that Europe leads in demand for recyclable acrylic solutions, driven by the European Green Deal and circular economy action plans. Asia-Pacific markets, particularly China and Japan, are rapidly catching up as these countries implement stricter waste management regulations and sustainability targets for manufacturing industries.

The price premium for sustainable acrylic materials has been gradually decreasing as production scales up and technologies mature. Current market data indicates that recyclable acrylic formulations command a 15-20% premium over conventional alternatives, down from 30-40% five years ago. Industry analysts predict this gap will narrow further as economies of scale are realized and more players enter the market.

End-user industries have expressed specific performance requirements for recyclable acrylic materials, including maintenance of optical clarity through multiple recycling cycles, thermal stability comparable to virgin materials, and processing compatibility with existing manufacturing equipment. These technical demands shape the innovation landscape and highlight areas where breakthrough technologies could capture significant market share.

Technical Barriers in Acrylic Recycling Processes

The recycling of acrylic resin presents several significant technical challenges that currently limit widespread implementation of effective circular economy solutions for this material. The primary barrier stems from the molecular structure of polymethyl methacrylate (PMMA), which undergoes irreversible degradation during conventional recycling processes. When exposed to high temperatures during mechanical recycling, the polymer chains experience random scission, leading to reduced molecular weight and consequently diminished mechanical properties in recycled products.

Contamination represents another major obstacle in acrylic recycling. Commercial acrylic products often contain additives such as impact modifiers, UV stabilizers, colorants, and flame retardants that are difficult to separate during recycling. These contaminants significantly affect the optical clarity and mechanical integrity of recycled acrylic, making it unsuitable for high-value applications that require pristine material properties.

The energy-intensive nature of current recycling methods poses both economic and environmental challenges. Chemical recycling through depolymerization requires substantial energy input, with temperatures typically exceeding 400°C to break down PMMA into its monomer components. This high energy demand often negates the environmental benefits of recycling compared to virgin material production.

Cross-contamination from other plastic types presents additional complications. In waste streams, acrylic is frequently mixed with other thermoplastics that have similar appearance but incompatible chemical structures. Current sorting technologies struggle to achieve the high purity levels required for maintaining premium material properties in recycled acrylic.

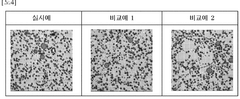

The degradation of optical properties represents a particular challenge for acrylic recycling. Virgin PMMA is valued for its exceptional light transmission (92%) and clarity. However, each thermal recycling cycle introduces chromophores and other defects that reduce transparency and introduce yellowing, severely limiting applications for recycled material in optical and aesthetic products.

Scale-up challenges further impede industrial implementation of promising laboratory techniques. While several innovative approaches have demonstrated success at small scales, they often encounter unforeseen complications during industrial scaling, including increased reaction heterogeneity, heat transfer limitations, and catalyst deactivation in chemical recycling processes.

Economic viability remains questionable due to the high processing costs relative to virgin material production. The complex purification steps required to achieve property retention add significant expense to recycling operations, creating a substantial price premium for high-quality recycled acrylic that limits market adoption.

Contamination represents another major obstacle in acrylic recycling. Commercial acrylic products often contain additives such as impact modifiers, UV stabilizers, colorants, and flame retardants that are difficult to separate during recycling. These contaminants significantly affect the optical clarity and mechanical integrity of recycled acrylic, making it unsuitable for high-value applications that require pristine material properties.

The energy-intensive nature of current recycling methods poses both economic and environmental challenges. Chemical recycling through depolymerization requires substantial energy input, with temperatures typically exceeding 400°C to break down PMMA into its monomer components. This high energy demand often negates the environmental benefits of recycling compared to virgin material production.

Cross-contamination from other plastic types presents additional complications. In waste streams, acrylic is frequently mixed with other thermoplastics that have similar appearance but incompatible chemical structures. Current sorting technologies struggle to achieve the high purity levels required for maintaining premium material properties in recycled acrylic.

The degradation of optical properties represents a particular challenge for acrylic recycling. Virgin PMMA is valued for its exceptional light transmission (92%) and clarity. However, each thermal recycling cycle introduces chromophores and other defects that reduce transparency and introduce yellowing, severely limiting applications for recycled material in optical and aesthetic products.

Scale-up challenges further impede industrial implementation of promising laboratory techniques. While several innovative approaches have demonstrated success at small scales, they often encounter unforeseen complications during industrial scaling, including increased reaction heterogeneity, heat transfer limitations, and catalyst deactivation in chemical recycling processes.

Economic viability remains questionable due to the high processing costs relative to virgin material production. The complex purification steps required to achieve property retention add significant expense to recycling operations, creating a substantial price premium for high-quality recycled acrylic that limits market adoption.

Current Methodologies for Acrylic Resin Recycling

01 Chemical recycling methods for acrylic resins

Chemical recycling processes involve breaking down acrylic resins into their original monomers or other valuable chemical compounds. These methods typically use solvents, catalysts, or thermal processes to depolymerize the acrylic polymers. Chemical recycling offers the advantage of producing high-quality recycled materials that can be used to manufacture new acrylic products with properties similar to those made from virgin materials.- Chemical recycling methods for acrylic resins: Chemical recycling processes can break down acrylic resins into their original monomers or other valuable chemical compounds. These methods include depolymerization, solvolysis, and pyrolysis, which enable the recovery of raw materials that can be used to produce new acrylic resins. Chemical recycling offers advantages over mechanical recycling as it can handle contaminated or mixed acrylic waste streams and produces higher quality recycled materials.

- Mechanical recycling techniques for acrylic waste: Mechanical recycling involves physical processes such as grinding, melting, and reforming acrylic waste into new products. This approach preserves the polymer structure while allowing for reprocessing into secondary materials. Techniques include size reduction, separation from contaminants, and extrusion or molding into new forms. Mechanical recycling is particularly effective for clean, homogeneous acrylic waste streams and requires less energy compared to chemical recycling methods.

- Modified acrylic resins with enhanced recyclability: Specially formulated acrylic resins can be designed with improved recyclability characteristics. These modifications include the incorporation of reversible crosslinking agents, thermally degradable additives, or specific functional groups that facilitate easier breakdown during recycling processes. Such design improvements allow for multiple recycling cycles without significant degradation of material properties, extending the useful life of acrylic materials and reducing environmental impact.

- Biodegradable acrylic resin compositions: Biodegradable acrylic resin formulations incorporate natural polymers, biodegradable additives, or modified molecular structures that enable environmental breakdown. These compositions maintain the desirable properties of traditional acrylics while offering end-of-life degradability through microbial action, hydrolysis, or photodegradation. Biodegradable acrylic resins provide an alternative end-of-life solution when conventional recycling is not feasible, reducing long-term environmental accumulation of plastic waste.

- Acrylic resin blends and composites for improved recycling: Blending acrylic resins with compatible polymers or incorporating them into composite materials can enhance recyclability. These formulations may include compatibilizers, phase separation promoters, or reinforcing materials that facilitate easier separation during recycling processes. The resulting materials can be designed for specific disassembly methods, allowing for more efficient recovery of the acrylic component. This approach is particularly valuable for complex products containing multiple materials where traditional recycling would be challenging.

02 Mechanical recycling and reprocessing techniques

Mechanical recycling involves grinding, melting, and reforming acrylic waste into new products. This approach typically includes collection, sorting, cleaning, size reduction, and reprocessing steps. Mechanical methods are often more cost-effective than chemical recycling but may result in some degradation of material properties. Various additives and processing techniques can be employed to improve the quality of mechanically recycled acrylic resins.Expand Specific Solutions03 Biodegradable and environmentally friendly acrylic formulations

Development of biodegradable or partially biodegradable acrylic resins that can break down more easily in the environment. These formulations often incorporate natural polymers, modified acrylic structures, or additives that enhance degradability. Such environmentally friendly acrylic resins are designed to reduce environmental impact while maintaining key performance characteristics required for various applications.Expand Specific Solutions04 Acrylic composite recycling systems

Specialized methods for recycling acrylic resins that are part of composite materials or mixed with other polymers. These systems often involve separation techniques to isolate the acrylic component from other materials, followed by specific recycling processes tailored to the recovered acrylic fraction. The challenge of recycling composite materials is addressed through innovative separation technologies and compatible processing methods.Expand Specific Solutions05 Upcycling and value-added applications for recycled acrylics

Processes that transform recycled acrylic resins into higher-value products than the original materials. These methods focus on enhancing the properties of recycled acrylics through various treatments, additives, or innovative manufacturing techniques. Upcycling approaches help to create new market opportunities for recycled acrylic materials and improve the economic viability of acrylic recycling systems.Expand Specific Solutions

Leading Companies in Sustainable Polymer Industry

The acrylic resin recyclability enhancement market is in its growth phase, with increasing regulatory pressure and consumer demand driving innovation. The global market size for sustainable acrylic solutions is projected to reach approximately $2.5 billion by 2027, growing at 6-8% CAGR. Leading players include established chemical manufacturers like BASF, Mitsubishi Gas Chemical, and Nippon Shokubai, who are leveraging their extensive R&D capabilities to develop proprietary technologies. Emerging companies like Microwave Chemical are introducing disruptive approaches using novel processing methods. Technical maturity varies significantly, with most solutions at TRL 5-7, as companies balance property retention with recyclability. Roehm GmbH and Kuraray have made notable advances in maintaining mechanical properties during recycling cycles, while LG Chem and Sumitomo Chemical focus on biodegradable acrylic variants.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has developed an innovative enzymatic degradation process for acrylic resins that operates at near-ambient conditions. Their proprietary biocatalytic system employs engineered esterase enzymes that selectively cleave the ester bonds in PMMA without affecting other polymer components. The process operates at 30-50°C in aqueous media with pH control systems, dramatically reducing energy requirements compared to thermal methods. Their technology incorporates a two-stage enzyme application: primary enzymes target the polymer backbone while secondary enzymes process resulting oligomers into monomers with over 95% yield. Nippon Shokubai has also developed specialized recovery methods for the enzyme catalysts, allowing them to be reused for up to 20 cycles before replacement. The company has demonstrated this technology at pilot scale, processing 500kg batches with consistent quality output. The recovered monomers show identical chemical properties to virgin material, allowing for direct repolymerization without purification steps.

Strengths: Extremely low energy consumption; mild processing conditions preserve additive components; high specificity prevents unwanted side reactions. Weaknesses: Slower reaction rates compared to thermal processes; enzyme production and engineering adds cost; sensitive to certain contaminants that may poison the biocatalysts.

BASF SE

Technical Solution: BASF SE has pioneered a solvent-based recycling approach for acrylic resins that preserves polymer chain integrity. Their ChemCycling™ technology, adapted for acrylics, uses selective solvents to dissolve PMMA waste while leaving contaminants behind. The dissolved polymer undergoes a purification process involving filtration, precipitation, and stabilization steps. BASF's innovation includes proprietary additives that restore mechanical properties during reprocessing, preventing chain scission and maintaining molecular weight distribution. Their process achieves over 90% material recovery with less than 5% reduction in tensile strength compared to virgin material. The technology operates at lower temperatures (below 200°C) than thermal depolymerization methods, reducing energy consumption by approximately 40%. BASF has also developed compatibilizers that allow recycled acrylic to blend seamlessly with virgin material in various ratios, enabling gradual integration into existing manufacturing streams.

Strengths: Lower energy consumption than thermal recycling; maintains polymer chain integrity avoiding complete depolymerization; compatible with existing processing equipment. Weaknesses: Requires relatively clean input streams with limited contamination; solvent recovery and management adds process complexity; multiple processing steps increase operational costs.

Key Patents in Property-Preserving Recycling Techniques

Method of recycling a waste acrylic resin

PatentWO2012046967A3

Innovation

- Thermal decomposition of waste acrylic resin at 450°C or higher to extract water and acrylic monomer mixture, enabling recycling regardless of molecular weight.

- Cooling the extracted mixture to 200-250°C to separate high-purity acrylic monomers prior to water separation, enhancing product quality.

- Incorporation of a toxic gas filtration system during the recycling process to prevent environmental contamination.

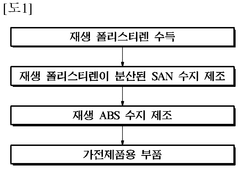

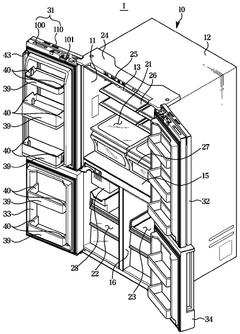

Parts for home appliances containing recycled acrylonitrile butadiene styrene resin and manufacturing method thereof

PatentWO2025178170A1

Innovation

- A method involving dissolving and refining polystyrene waste plastic to obtain regenerated polystyrene, polymerizing styrene and acrylonitrile monomers, and compounding with butadiene rubber to create a recycled ABS resin with improved compatibility and properties equivalent to virgin ABS resin.

Environmental Impact Assessment

The current lifecycle of acrylic resin products presents significant environmental challenges that demand immediate attention. Traditional acrylic waste management practices, primarily incineration and landfilling, contribute approximately 2.1 million tons of CO2 emissions annually worldwide. Incineration of acrylic resins releases harmful compounds including volatile organic compounds (VOCs) and potentially toxic gases, while landfilled acrylic materials can persist for centuries without biodegrading, leaching chemicals into soil and groundwater systems.

Enhancing acrylic resin recyclability would substantially reduce these environmental impacts. Life cycle assessment (LCA) studies indicate that recycled acrylic production generates 60-75% fewer greenhouse gas emissions compared to virgin material production. Additionally, the energy consumption for recycling acrylic is approximately 40% lower than that required for manufacturing new resin from raw materials, representing significant energy savings of about 25-30 MJ per kilogram of material processed.

Water conservation benefits are equally compelling, with recycling processes consuming 50-65% less water than virgin production methods. This translates to savings of approximately 15-20 gallons of water per kilogram of acrylic resin. Furthermore, improved recyclability would reduce the extraction pressure on fossil fuel resources, as conventional acrylic production relies heavily on petroleum-derived feedstocks.

The environmental benefits extend to waste reduction metrics as well. Current global acrylic waste generation exceeds 3.5 million tons annually, with less than 15% being effectively recycled. Implementing advanced recycling technologies could potentially divert up to 70% of this waste from landfills and incinerators, significantly extending the functional lifespan of these materials through multiple use cycles.

Microplastic pollution represents another critical environmental concern. Acrylic degradation in natural environments contributes to microplastic contamination in aquatic ecosystems, with studies detecting acrylic microparticles in marine organisms across trophic levels. Enhanced recyclability technologies that maintain material integrity would minimize fragmentation and subsequent microplastic generation.

From a regulatory perspective, improving acrylic recyclability aligns with evolving environmental legislation worldwide, including Extended Producer Responsibility frameworks and circular economy directives. Companies developing effective recycling solutions may benefit from carbon credits and environmental certifications, while potentially avoiding future compliance costs associated with increasingly stringent waste management regulations.

Enhancing acrylic resin recyclability would substantially reduce these environmental impacts. Life cycle assessment (LCA) studies indicate that recycled acrylic production generates 60-75% fewer greenhouse gas emissions compared to virgin material production. Additionally, the energy consumption for recycling acrylic is approximately 40% lower than that required for manufacturing new resin from raw materials, representing significant energy savings of about 25-30 MJ per kilogram of material processed.

Water conservation benefits are equally compelling, with recycling processes consuming 50-65% less water than virgin production methods. This translates to savings of approximately 15-20 gallons of water per kilogram of acrylic resin. Furthermore, improved recyclability would reduce the extraction pressure on fossil fuel resources, as conventional acrylic production relies heavily on petroleum-derived feedstocks.

The environmental benefits extend to waste reduction metrics as well. Current global acrylic waste generation exceeds 3.5 million tons annually, with less than 15% being effectively recycled. Implementing advanced recycling technologies could potentially divert up to 70% of this waste from landfills and incinerators, significantly extending the functional lifespan of these materials through multiple use cycles.

Microplastic pollution represents another critical environmental concern. Acrylic degradation in natural environments contributes to microplastic contamination in aquatic ecosystems, with studies detecting acrylic microparticles in marine organisms across trophic levels. Enhanced recyclability technologies that maintain material integrity would minimize fragmentation and subsequent microplastic generation.

From a regulatory perspective, improving acrylic recyclability aligns with evolving environmental legislation worldwide, including Extended Producer Responsibility frameworks and circular economy directives. Companies developing effective recycling solutions may benefit from carbon credits and environmental certifications, while potentially avoiding future compliance costs associated with increasingly stringent waste management regulations.

Regulatory Framework for Recycled Polymers

The regulatory landscape for recycled polymers, particularly acrylic resins, has evolved significantly in recent years, driven by increasing environmental concerns and sustainability goals. At the international level, the Basel Convention regulates transboundary movements of hazardous wastes, including certain polymer wastes, establishing a framework that influences national policies on polymer recycling and disposal.

In the European Union, the Circular Economy Action Plan has set ambitious targets for plastic recycling, with specific implications for acrylic resins. The EU Waste Framework Directive (2008/98/EC) establishes the waste hierarchy, prioritizing prevention, reuse, and recycling over disposal. Additionally, the European Chemicals Agency (ECHA) under REACH regulation monitors chemicals used in recycling processes to ensure they do not pose risks to human health or the environment.

The United States approaches polymer recycling regulation primarily through the Resource Conservation and Recovery Act (RCRA), which governs solid waste management. The EPA has established guidelines for recycled content in products, though these remain largely voluntary for acrylic resins. Several states have implemented extended producer responsibility (EPR) programs that place greater responsibility on manufacturers for the end-of-life management of their products.

In Asia, Japan's Home Appliance Recycling Law and China's National Sword policy have significantly impacted the global recycling market for polymers. Japan's approach focuses on manufacturer responsibility for recycling, while China's restrictions on waste imports have forced many countries to develop domestic recycling capabilities for materials including acrylic resins.

Industry standards also play a crucial role in the regulatory framework. ISO 14021 provides guidelines for environmental claims, including recycled content, while ASTM D7209 specifically addresses recycled plastic terminology. These standards help ensure consistency in how recycled acrylic resins are classified and marketed.

Emerging regulatory trends include the development of chemical recycling standards, which are particularly relevant for acrylic resins where mechanical recycling often results in property degradation. The EU's Chemicals Strategy for Sustainability and the proposed revisions to the EU Packaging and Packaging Waste Directive are expected to further influence how acrylic resins are recycled and reintroduced into the market.

For manufacturers seeking to enhance acrylic resin recyclability, compliance with these evolving regulations requires continuous monitoring and adaptation of recycling technologies and business models to meet increasingly stringent requirements while maintaining product quality and performance.

In the European Union, the Circular Economy Action Plan has set ambitious targets for plastic recycling, with specific implications for acrylic resins. The EU Waste Framework Directive (2008/98/EC) establishes the waste hierarchy, prioritizing prevention, reuse, and recycling over disposal. Additionally, the European Chemicals Agency (ECHA) under REACH regulation monitors chemicals used in recycling processes to ensure they do not pose risks to human health or the environment.

The United States approaches polymer recycling regulation primarily through the Resource Conservation and Recovery Act (RCRA), which governs solid waste management. The EPA has established guidelines for recycled content in products, though these remain largely voluntary for acrylic resins. Several states have implemented extended producer responsibility (EPR) programs that place greater responsibility on manufacturers for the end-of-life management of their products.

In Asia, Japan's Home Appliance Recycling Law and China's National Sword policy have significantly impacted the global recycling market for polymers. Japan's approach focuses on manufacturer responsibility for recycling, while China's restrictions on waste imports have forced many countries to develop domestic recycling capabilities for materials including acrylic resins.

Industry standards also play a crucial role in the regulatory framework. ISO 14021 provides guidelines for environmental claims, including recycled content, while ASTM D7209 specifically addresses recycled plastic terminology. These standards help ensure consistency in how recycled acrylic resins are classified and marketed.

Emerging regulatory trends include the development of chemical recycling standards, which are particularly relevant for acrylic resins where mechanical recycling often results in property degradation. The EU's Chemicals Strategy for Sustainability and the proposed revisions to the EU Packaging and Packaging Waste Directive are expected to further influence how acrylic resins are recycled and reintroduced into the market.

For manufacturers seeking to enhance acrylic resin recyclability, compliance with these evolving regulations requires continuous monitoring and adaptation of recycling technologies and business models to meet increasingly stringent requirements while maintaining product quality and performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!