Optimizing Acrylic Resin Pigment Dispersion for Uniform Coatings

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Pigment Dispersion Background and Objectives

Acrylic resin pigment dispersion technology has evolved significantly over the past several decades, transitioning from basic mechanical mixing methods to sophisticated dispersion techniques that leverage advanced understanding of colloidal chemistry and surface interactions. The journey began in the 1950s with the commercial introduction of acrylic resins, which revolutionized the coating industry due to their exceptional durability, weather resistance, and optical clarity compared to traditional alternatives.

The 1970s and 1980s marked a period of substantial innovation in dispersion technology, with the development of high-speed dispersers and media mills that significantly improved pigment wetting and stabilization. By the 1990s, the focus shifted toward understanding the fundamental molecular interactions between pigment particles and resin matrices, leading to the development of specialized dispersing additives and surface-modified pigments.

Recent technological advancements have been driven by increasing demands for higher performance coatings with enhanced properties such as color consistency, gloss retention, and environmental sustainability. The industry has witnessed a growing emphasis on nano-sized pigment particles, which offer superior color strength and transparency but present unique dispersion challenges due to their high surface area and tendency to agglomerate.

Current technological trends indicate a movement toward more efficient dispersion processes that minimize energy consumption while maximizing pigment utilization. This includes the development of pre-dispersed pigment concentrates, in-line mixing systems, and computer-controlled dispersion equipment that can adapt to varying formulation requirements in real-time.

The primary objective of optimizing acrylic resin pigment dispersion is to achieve uniform, stable, and reproducible coatings with enhanced aesthetic and functional properties. This involves developing systematic approaches to overcome challenges related to pigment wetting, stabilization, and incorporation into the resin matrix without compromising application properties or long-term stability.

Specific technical goals include reducing dispersion time and energy requirements, minimizing pigment agglomeration during storage and application, improving color consistency across production batches, and enhancing the overall efficiency of the manufacturing process. Additionally, there is a growing focus on developing dispersion technologies that are compatible with waterborne and high-solids formulations to meet increasingly stringent environmental regulations.

The optimization of pigment dispersion in acrylic resins represents a critical factor in determining the final performance characteristics of coatings, including color development, hiding power, gloss, and durability. As such, advancements in this field have far-reaching implications for various industries, from architectural coatings to automotive finishes and industrial applications.

The 1970s and 1980s marked a period of substantial innovation in dispersion technology, with the development of high-speed dispersers and media mills that significantly improved pigment wetting and stabilization. By the 1990s, the focus shifted toward understanding the fundamental molecular interactions between pigment particles and resin matrices, leading to the development of specialized dispersing additives and surface-modified pigments.

Recent technological advancements have been driven by increasing demands for higher performance coatings with enhanced properties such as color consistency, gloss retention, and environmental sustainability. The industry has witnessed a growing emphasis on nano-sized pigment particles, which offer superior color strength and transparency but present unique dispersion challenges due to their high surface area and tendency to agglomerate.

Current technological trends indicate a movement toward more efficient dispersion processes that minimize energy consumption while maximizing pigment utilization. This includes the development of pre-dispersed pigment concentrates, in-line mixing systems, and computer-controlled dispersion equipment that can adapt to varying formulation requirements in real-time.

The primary objective of optimizing acrylic resin pigment dispersion is to achieve uniform, stable, and reproducible coatings with enhanced aesthetic and functional properties. This involves developing systematic approaches to overcome challenges related to pigment wetting, stabilization, and incorporation into the resin matrix without compromising application properties or long-term stability.

Specific technical goals include reducing dispersion time and energy requirements, minimizing pigment agglomeration during storage and application, improving color consistency across production batches, and enhancing the overall efficiency of the manufacturing process. Additionally, there is a growing focus on developing dispersion technologies that are compatible with waterborne and high-solids formulations to meet increasingly stringent environmental regulations.

The optimization of pigment dispersion in acrylic resins represents a critical factor in determining the final performance characteristics of coatings, including color development, hiding power, gloss, and durability. As such, advancements in this field have far-reaching implications for various industries, from architectural coatings to automotive finishes and industrial applications.

Market Analysis of Uniform Coating Applications

The uniform coating applications market has witnessed substantial growth over the past decade, primarily driven by increasing demand across automotive, construction, electronics, and furniture industries. The global market for high-performance coatings reached approximately $85 billion in 2022, with uniform acrylic resin coatings representing a significant segment valued at $23 billion. Industry analysts project a compound annual growth rate of 5.7% through 2028, outpacing the broader chemicals sector.

Consumer preferences have shifted dramatically toward products with flawless finishes and consistent appearance, particularly in premium market segments. This trend is especially pronounced in automotive applications, where uniform coatings directly impact consumer perception of quality and subsequently influence purchasing decisions. Market research indicates that 78% of consumers cite finish quality as a "very important" factor when evaluating automotive and furniture products.

Regulatory frameworks worldwide continue to tighten restrictions on volatile organic compounds (VOCs) and hazardous air pollutants, creating strong market pull for water-based acrylic formulations with optimized pigment dispersion. The European Union's implementation of the Industrial Emissions Directive and similar regulations in North America have accelerated industry transition toward environmentally sustainable coating technologies.

Geographically, Asia-Pacific represents the fastest-growing market for uniform coatings, with China and India leading regional demand growth at 8.3% annually. This expansion is fueled by rapid industrialization, infrastructure development, and increasing disposable income driving consumer goods consumption. North America and Europe maintain significant market shares, with particular emphasis on high-performance and specialty applications.

The industrial coatings segment dominates application markets, accounting for 42% of total uniform coating consumption, followed by architectural applications at 28%. Emerging applications in electronics, medical devices, and renewable energy infrastructure present substantial growth opportunities, with projected market expansion exceeding 10% annually in these sectors.

Customer pain points consistently identified in market surveys include coating durability, application efficiency, and color consistency across production batches. Manufacturers report that achieving uniform pigment dispersion remains a critical technical challenge, with production inefficiencies and quality control issues directly impacting profitability. Industry data suggests that coating defects and rework requirements represent approximately 15% of production costs across manufacturing sectors.

Market differentiation increasingly depends on technical performance metrics including dispersion stability, color consistency, and application properties. Premium pricing of 30-45% is achievable for coating products demonstrating superior uniformity and consistency, particularly in high-visibility applications.

Consumer preferences have shifted dramatically toward products with flawless finishes and consistent appearance, particularly in premium market segments. This trend is especially pronounced in automotive applications, where uniform coatings directly impact consumer perception of quality and subsequently influence purchasing decisions. Market research indicates that 78% of consumers cite finish quality as a "very important" factor when evaluating automotive and furniture products.

Regulatory frameworks worldwide continue to tighten restrictions on volatile organic compounds (VOCs) and hazardous air pollutants, creating strong market pull for water-based acrylic formulations with optimized pigment dispersion. The European Union's implementation of the Industrial Emissions Directive and similar regulations in North America have accelerated industry transition toward environmentally sustainable coating technologies.

Geographically, Asia-Pacific represents the fastest-growing market for uniform coatings, with China and India leading regional demand growth at 8.3% annually. This expansion is fueled by rapid industrialization, infrastructure development, and increasing disposable income driving consumer goods consumption. North America and Europe maintain significant market shares, with particular emphasis on high-performance and specialty applications.

The industrial coatings segment dominates application markets, accounting for 42% of total uniform coating consumption, followed by architectural applications at 28%. Emerging applications in electronics, medical devices, and renewable energy infrastructure present substantial growth opportunities, with projected market expansion exceeding 10% annually in these sectors.

Customer pain points consistently identified in market surveys include coating durability, application efficiency, and color consistency across production batches. Manufacturers report that achieving uniform pigment dispersion remains a critical technical challenge, with production inefficiencies and quality control issues directly impacting profitability. Industry data suggests that coating defects and rework requirements represent approximately 15% of production costs across manufacturing sectors.

Market differentiation increasingly depends on technical performance metrics including dispersion stability, color consistency, and application properties. Premium pricing of 30-45% is achievable for coating products demonstrating superior uniformity and consistency, particularly in high-visibility applications.

Technical Challenges in Pigment Dispersion Technology

Pigment dispersion in acrylic resin systems presents several significant technical challenges that impact coating uniformity, stability, and performance. The primary challenge lies in achieving optimal particle size distribution of pigments within the resin matrix. When pigment particles agglomerate, they create visible defects, color inconsistencies, and reduced hiding power in the final coating. This agglomeration occurs due to strong inter-particle forces, particularly Van der Waals attractions, which must be overcome through proper dispersion techniques.

Surface chemistry compatibility between pigments and acrylic resins represents another major hurdle. Many pigments, especially inorganic varieties, possess hydrophilic surfaces that resist wetting by the relatively hydrophobic acrylic medium. This incompatibility leads to poor incorporation, floating defects, and separation during storage. Manufacturers must carefully select appropriate dispersing additives that can modify surface interactions and create stable interfaces between the pigment and resin phases.

Viscosity management during the dispersion process creates additional complexity. The incorporation of pigments typically increases system viscosity, which can impede efficient mixing and lead to incomplete dispersion. Conversely, if viscosity becomes too low during high-shear processing, the system may not generate sufficient forces to break down agglomerates effectively. This delicate balance requires precise formulation and process control.

Stability over time represents a persistent challenge in pigmented acrylic systems. Even well-dispersed pigments can gradually flocculate during storage or application, leading to color drift, sedimentation, and inconsistent appearance. This phenomenon is particularly problematic in systems subjected to temperature fluctuations, pH changes, or mechanical stress during application.

Manufacturing scale-up introduces further complications, as dispersion processes that work effectively in laboratory settings often perform differently at production scale. Variables such as equipment geometry, shear profiles, and heat transfer characteristics can significantly impact dispersion quality. The energy efficiency of dispersion processes also presents challenges, as high-energy milling operations increase production costs and may introduce contamination from equipment wear.

Environmental and regulatory constraints have intensified technical challenges in recent years. The industry-wide shift away from solvent-based systems toward waterborne and high-solids formulations has necessitated new approaches to pigment dispersion. These eco-friendly systems often provide less efficient pigment wetting and stabilization, requiring more sophisticated dispersant technologies and processing methods to achieve comparable performance to traditional solvent-based systems.

Surface chemistry compatibility between pigments and acrylic resins represents another major hurdle. Many pigments, especially inorganic varieties, possess hydrophilic surfaces that resist wetting by the relatively hydrophobic acrylic medium. This incompatibility leads to poor incorporation, floating defects, and separation during storage. Manufacturers must carefully select appropriate dispersing additives that can modify surface interactions and create stable interfaces between the pigment and resin phases.

Viscosity management during the dispersion process creates additional complexity. The incorporation of pigments typically increases system viscosity, which can impede efficient mixing and lead to incomplete dispersion. Conversely, if viscosity becomes too low during high-shear processing, the system may not generate sufficient forces to break down agglomerates effectively. This delicate balance requires precise formulation and process control.

Stability over time represents a persistent challenge in pigmented acrylic systems. Even well-dispersed pigments can gradually flocculate during storage or application, leading to color drift, sedimentation, and inconsistent appearance. This phenomenon is particularly problematic in systems subjected to temperature fluctuations, pH changes, or mechanical stress during application.

Manufacturing scale-up introduces further complications, as dispersion processes that work effectively in laboratory settings often perform differently at production scale. Variables such as equipment geometry, shear profiles, and heat transfer characteristics can significantly impact dispersion quality. The energy efficiency of dispersion processes also presents challenges, as high-energy milling operations increase production costs and may introduce contamination from equipment wear.

Environmental and regulatory constraints have intensified technical challenges in recent years. The industry-wide shift away from solvent-based systems toward waterborne and high-solids formulations has necessitated new approaches to pigment dispersion. These eco-friendly systems often provide less efficient pigment wetting and stabilization, requiring more sophisticated dispersant technologies and processing methods to achieve comparable performance to traditional solvent-based systems.

Current Dispersion Methodologies and Formulations

01 Acrylic resin composition for improved pigment dispersion

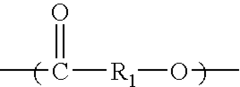

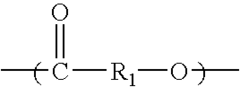

Specific acrylic resin compositions can be formulated to enhance pigment dispersion uniformity. These compositions typically include copolymers with functional groups that interact favorably with pigment surfaces. The molecular weight, acid value, and glass transition temperature of the acrylic resin are critical parameters that affect pigment wetting and stabilization. Optimized acrylic resins can prevent pigment agglomeration and ensure uniform distribution throughout the coating system.- Acrylic resin composition for improved pigment dispersion: Specific acrylic resin compositions can be formulated to enhance pigment dispersion uniformity. These compositions typically include carefully selected monomers, molecular weight distributions, and functional groups that improve compatibility with pigments. The resin structure can be designed with pigment-affinity segments that interact favorably with pigment surfaces, preventing agglomeration and promoting stable, uniform dispersions in coating applications.

- Dispersant additives and surfactants for pigment uniformity: Various dispersant additives and surfactants can be incorporated into acrylic resin formulations to improve pigment dispersion uniformity. These additives work by modifying the interface between the pigment particles and the resin matrix, reducing surface tension and preventing flocculation. Specialized dispersants with both hydrophilic and hydrophobic segments can effectively encapsulate pigment particles, maintaining separation and ensuring uniform distribution throughout the acrylic medium.

- Processing techniques for uniform pigment dispersion: Specific processing techniques can significantly improve pigment dispersion uniformity in acrylic resin systems. These include optimized mixing parameters, high-shear dispersion methods, and controlled temperature processing. Advanced techniques such as pre-dispersion of pigments, sequential addition protocols, and multi-stage mixing processes can break down agglomerates and ensure consistent particle distribution throughout the acrylic matrix.

- Solvent selection and optimization for dispersion stability: The selection and optimization of solvent systems plays a crucial role in achieving uniform pigment dispersion in acrylic resins. Appropriate solvent combinations can improve pigment wetting, prevent settling, and maintain long-term dispersion stability. Solvent blends can be tailored to match the solubility parameters of both the pigment and resin, creating a compatible environment that promotes uniform distribution and prevents phase separation during application and drying.

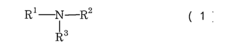

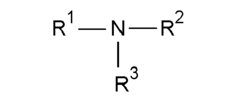

- Modified acrylic resins with pigment-affinity functional groups: Acrylic resins can be modified with specific functional groups that enhance pigment affinity and improve dispersion uniformity. These modifications include the incorporation of amine, carboxylic acid, or hydroxyl groups that can interact with pigment surfaces through hydrogen bonding or ionic interactions. Such functionalized resins act as polymeric dispersants, creating steric barriers between pigment particles and preventing reagglomeration, resulting in more stable and uniform pigment dispersions.

02 Dispersant additives for acrylic resin systems

Specialized dispersant additives can be incorporated into acrylic resin formulations to improve pigment dispersion uniformity. These dispersants typically contain both hydrophilic and hydrophobic segments that help stabilize pigment particles in the resin matrix. Common dispersant types include polymeric dispersants, surfactants, and wetting agents that reduce interfacial tension between pigment and resin. The proper selection and concentration of dispersants significantly enhance the overall dispersion quality and stability.Expand Specific Solutions03 Processing techniques for uniform pigment dispersion

Various processing techniques can be employed to achieve uniform pigment dispersion in acrylic resin systems. High-shear mixing, ball milling, and sand milling are effective methods for breaking down pigment agglomerates. The processing parameters such as mixing speed, temperature, and duration significantly impact dispersion quality. Advanced techniques like ultrasonic dispersion and high-pressure homogenization can further enhance uniformity by applying intense mechanical forces to separate pigment particles and distribute them evenly throughout the acrylic resin matrix.Expand Specific Solutions04 Surface treatment of pigments for acrylic resin compatibility

Surface modification of pigments can significantly improve their compatibility with acrylic resin systems. Treatments include silane coupling agents, phosphate esters, or polymer encapsulation that alter the surface chemistry of pigments to enhance their interaction with the resin matrix. These treatments reduce the tendency of pigments to agglomerate and improve their wetting characteristics. Surface-treated pigments disperse more readily in acrylic resins, resulting in more uniform color development and improved coating performance.Expand Specific Solutions05 Solvent selection for acrylic resin pigment systems

The choice of solvent system plays a crucial role in achieving uniform pigment dispersion in acrylic resins. Solvents affect the solubility of the resin, the wetting of pigment surfaces, and the overall rheology of the system. A properly selected solvent or solvent blend can improve pigment wetting and stabilization. Factors such as solvent polarity, evaporation rate, and compatibility with both pigment and resin components must be considered to optimize dispersion uniformity and prevent issues like flocculation or settling during storage.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The acrylic resin pigment dispersion market for uniform coatings is in a mature growth phase, with an estimated global market size exceeding $5 billion and steady annual growth of 4-5%. The competitive landscape features established chemical conglomerates like DIC Corp., Mitsui Chemicals, and Toyo Aluminium KK dominating with comprehensive product portfolios, while specialized players such as Nippon Shokubai and Sanyo Chemical Industries focus on high-performance dispersions. Technical innovation centers on nano-dispersion technology, with companies like Toyocolor and Clariant leading advancements in particle size control and stability enhancement. Academic-industry partnerships, particularly involving Kyoto University and Xiamen University, are accelerating development of environmentally friendly formulations with improved performance characteristics.

Kansai Paint Co., Ltd.

Technical Solution: Kansai Paint has developed an innovative "Nano-Dispersion Technology" for acrylic resin systems that achieves uniform pigment distribution through a multi-stage process. Their approach begins with surface modification of pigment particles using proprietary functional silanes that create strong chemical bonds with the acrylic matrix. The technology incorporates specially engineered hyperdispersants with optimized molecular weights and anchoring group densities tailored to specific pigment chemistries. Kansai's process utilizes controlled energy input dispersion equipment with precise temperature management to prevent localized overheating that can degrade dispersant performance. Their system includes synergistic wetting agent packages that reduce interfacial tension between pigment and resin phases while enhancing flow characteristics. Kansai has also developed automated quality control systems that monitor particle size distribution in real-time during manufacturing to ensure batch-to-batch consistency in optical properties and application performance.

Strengths: Superior color development and hiding power; excellent stability in high-temperature applications; reduced settling during long-term storage. Weaknesses: Complex formulation process requiring specialized equipment; higher raw material costs; some formulations show sensitivity to pH fluctuations during application.

DIC Corp.

Technical Solution: DIC Corporation has engineered a comprehensive acrylic resin pigment dispersion system called "PigmentEx" that utilizes amphiphilic block copolymers with precisely controlled hydrophilic-lipophilic balance (HLB) values. Their technology employs specially designed hyperdispersants with multiple anchoring groups that form strong associations with pigment surfaces while the solvated polymer chains extend into the acrylic medium, creating robust steric barriers. DIC's approach incorporates pre-dispersion treatment of pigments with surface-active agents that modify particle interfaces for enhanced compatibility with acrylic matrices. Their process utilizes sequential high-energy dispersion stages with controlled temperature profiles to prevent reagglomeration during manufacturing. The company has also developed synergistic dispersant packages that combine polymeric and non-polymeric components to address different pigment chemistries within the same formulation.

Strengths: Exceptional color development and transparency; superior long-term stability even at elevated temperatures; versatility across various pigment chemistries. Weaknesses: Complex formulation process requiring precise control parameters; higher raw material costs; some formulations have compatibility limitations with certain additives.

Key Patents and Innovations in Pigment Dispersion

Acrylic resin composition dispersed in water

PatentInactiveEP1582570B1

Innovation

- A water-based acrylic resin composition combining a polymer with a long-chain aliphatic hydrocarbon group, an oxazoline compound with multiple oxazoline rings, and a specific nitrogen-containing compound, which are thermally crosslinked to enhance coating properties and stability, allowing for a one-package composition with reduced organic solvent content and improved dispersion stability.

Production method of pigment-dispersing resin

PatentActiveUS20080268269A1

Innovation

- A pigment-dispersing resin is produced by copolymerizing a specific mixture of polymerizable unsaturated monomers in a reaction solvent with at least 30% organic solvent, containing divalent groups, phosphoric acid, and/or sulfonic acid groups, which improves pigment dispersion and film properties.

Environmental Compliance and VOC Regulations

The regulatory landscape for coating formulations has undergone significant transformation in recent decades, with environmental compliance and VOC (Volatile Organic Compounds) regulations becoming increasingly stringent worldwide. For acrylic resin pigment dispersion systems, these regulations present both challenges and opportunities for innovation. The U.S. Environmental Protection Agency's Clean Air Act and the European Union's VOC Solvents Emissions Directive have established strict limits on VOC content in architectural coatings, industrial finishes, and specialty applications.

Current VOC regulations typically restrict emissions to 250-350 g/L for most architectural coatings, with some jurisdictions like California's South Coast Air Quality Management District (SCAQMD) imposing even lower limits of 50-100 g/L. These constraints directly impact formulation strategies for acrylic resin systems, as traditional solvent-based dispersions often exceed these thresholds significantly.

The shift toward waterborne acrylic systems represents a primary adaptation strategy, though these formulations face technical challenges in pigment dispersion efficiency and coating performance. Waterborne systems typically require specialized dispersing agents and surface-modified pigments to achieve stability comparable to solvent-based counterparts. Recent innovations in hyperdispersant technologies have enabled VOC reductions while maintaining dispersion quality, with manufacturers developing novel amphiphilic block copolymers specifically designed for aqueous environments.

Beyond VOC content, regulations increasingly address hazardous air pollutants (HAPs) and substances of very high concern (SVHCs). The EU's REACH regulation and similar frameworks globally have restricted or eliminated certain dispersing agents and additives previously common in coating formulations. Manufacturers must now navigate complex compliance requirements across different markets, often necessitating region-specific formulation adjustments.

Emerging regulatory trends indicate further restrictions on formaldehyde-releasing biocides, alkylphenol ethoxylates (APEs), and certain preservatives used in waterborne systems. Forward-thinking manufacturers are proactively reformulating with bio-based alternatives and developing entirely new chemistries that anticipate future regulatory constraints.

The economic implications of compliance are substantial, with reformulation costs potentially reaching millions for large product portfolios. However, companies embracing sustainable chemistry principles often discover performance advantages alongside regulatory compliance. High-efficiency dispersants that enable lower VOC content frequently deliver superior color development, stability, and application properties, creating market differentiation opportunities.

Certification programs like Green Seal, LEED, and various eco-labels provide additional market incentives for low-VOC formulations, though navigating these voluntary standards adds another layer of complexity to product development strategies. Successful optimization of acrylic resin pigment dispersion increasingly requires a holistic approach that balances regulatory compliance, performance requirements, and sustainability objectives.

Current VOC regulations typically restrict emissions to 250-350 g/L for most architectural coatings, with some jurisdictions like California's South Coast Air Quality Management District (SCAQMD) imposing even lower limits of 50-100 g/L. These constraints directly impact formulation strategies for acrylic resin systems, as traditional solvent-based dispersions often exceed these thresholds significantly.

The shift toward waterborne acrylic systems represents a primary adaptation strategy, though these formulations face technical challenges in pigment dispersion efficiency and coating performance. Waterborne systems typically require specialized dispersing agents and surface-modified pigments to achieve stability comparable to solvent-based counterparts. Recent innovations in hyperdispersant technologies have enabled VOC reductions while maintaining dispersion quality, with manufacturers developing novel amphiphilic block copolymers specifically designed for aqueous environments.

Beyond VOC content, regulations increasingly address hazardous air pollutants (HAPs) and substances of very high concern (SVHCs). The EU's REACH regulation and similar frameworks globally have restricted or eliminated certain dispersing agents and additives previously common in coating formulations. Manufacturers must now navigate complex compliance requirements across different markets, often necessitating region-specific formulation adjustments.

Emerging regulatory trends indicate further restrictions on formaldehyde-releasing biocides, alkylphenol ethoxylates (APEs), and certain preservatives used in waterborne systems. Forward-thinking manufacturers are proactively reformulating with bio-based alternatives and developing entirely new chemistries that anticipate future regulatory constraints.

The economic implications of compliance are substantial, with reformulation costs potentially reaching millions for large product portfolios. However, companies embracing sustainable chemistry principles often discover performance advantages alongside regulatory compliance. High-efficiency dispersants that enable lower VOC content frequently deliver superior color development, stability, and application properties, creating market differentiation opportunities.

Certification programs like Green Seal, LEED, and various eco-labels provide additional market incentives for low-VOC formulations, though navigating these voluntary standards adds another layer of complexity to product development strategies. Successful optimization of acrylic resin pigment dispersion increasingly requires a holistic approach that balances regulatory compliance, performance requirements, and sustainability objectives.

Quality Control Metrics for Coating Uniformity

Establishing robust quality control metrics is essential for ensuring coating uniformity when working with acrylic resin pigment dispersions. The primary metrics that should be monitored include spectrophotometric color consistency, gloss level uniformity, film thickness variation, and surface defect quantification. These parameters collectively provide a comprehensive assessment of coating quality and uniformity.

Spectrophotometric measurements offer precise color evaluation through CIE L*a*b* values, with Delta-E values below 1.0 typically indicating acceptable color matching. Industry standards recommend maintaining Delta-E variations below 0.5 across a single coated surface to ensure visual uniformity. Regular calibration of spectrophotometers is crucial for maintaining measurement accuracy, with verification against standard color tiles recommended before each testing session.

Gloss level consistency serves as another critical metric, measured at standardized angles (20°, 60°, and 85°) depending on the coating's intended finish. For high-gloss acrylic coatings, measurements at 20° provide the most sensitive indication of surface uniformity, while semi-gloss and matte finishes are better evaluated at 60° and 85° respectively. Statistical process control charts should track gloss variations, with standard deviations maintained below 5% of the mean value.

Film thickness uniformity directly impacts both aesthetic and functional properties of acrylic coatings. Non-destructive measurement techniques such as ultrasonic and magnetic gauges enable comprehensive mapping of thickness variations across coated surfaces. The coefficient of variation (CV) for thickness measurements should remain below 10% for industrial applications and below 5% for premium architectural and automotive finishes.

Surface defect quantification requires both automated and visual inspection protocols. Digital imaging systems with machine learning algorithms can detect and classify defects including pinholes, craters, and orange peel effects. The industry standard acceptance criterion typically allows no more than 5 defects per square meter for premium finishes and 10-15 defects per square meter for standard industrial applications.

Rheological properties of the coating during application significantly impact final uniformity. In-process viscosity monitoring using rotational viscometers should maintain readings within ±10% of target specifications. Temperature control during application is equally important, with variations kept within ±2°C to ensure consistent flow and leveling properties of the acrylic resin system.

Implementing statistical process control (SPC) methodologies enables continuous monitoring of these metrics, with control charts establishing upper and lower control limits for each parameter. Regular calibration of all measurement equipment and cross-validation between different testing methods ensures data reliability and facilitates early detection of process drift before it impacts product quality.

Spectrophotometric measurements offer precise color evaluation through CIE L*a*b* values, with Delta-E values below 1.0 typically indicating acceptable color matching. Industry standards recommend maintaining Delta-E variations below 0.5 across a single coated surface to ensure visual uniformity. Regular calibration of spectrophotometers is crucial for maintaining measurement accuracy, with verification against standard color tiles recommended before each testing session.

Gloss level consistency serves as another critical metric, measured at standardized angles (20°, 60°, and 85°) depending on the coating's intended finish. For high-gloss acrylic coatings, measurements at 20° provide the most sensitive indication of surface uniformity, while semi-gloss and matte finishes are better evaluated at 60° and 85° respectively. Statistical process control charts should track gloss variations, with standard deviations maintained below 5% of the mean value.

Film thickness uniformity directly impacts both aesthetic and functional properties of acrylic coatings. Non-destructive measurement techniques such as ultrasonic and magnetic gauges enable comprehensive mapping of thickness variations across coated surfaces. The coefficient of variation (CV) for thickness measurements should remain below 10% for industrial applications and below 5% for premium architectural and automotive finishes.

Surface defect quantification requires both automated and visual inspection protocols. Digital imaging systems with machine learning algorithms can detect and classify defects including pinholes, craters, and orange peel effects. The industry standard acceptance criterion typically allows no more than 5 defects per square meter for premium finishes and 10-15 defects per square meter for standard industrial applications.

Rheological properties of the coating during application significantly impact final uniformity. In-process viscosity monitoring using rotational viscometers should maintain readings within ±10% of target specifications. Temperature control during application is equally important, with variations kept within ±2°C to ensure consistent flow and leveling properties of the acrylic resin system.

Implementing statistical process control (SPC) methodologies enables continuous monitoring of these metrics, with control charts establishing upper and lower control limits for each parameter. Regular calibration of all measurement equipment and cross-validation between different testing methods ensures data reliability and facilitates early detection of process drift before it impacts product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!