Evaluating Acrylic Resin’s Mechanical Integrity After Reprocessing

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Reprocessing Background and Objectives

Acrylic resins have been a cornerstone material in various industries since their development in the early 20th century. These thermoplastic polymers, primarily composed of polymethyl methacrylate (PMMA), have gained widespread adoption due to their exceptional optical clarity, weather resistance, and mechanical properties. The evolution of acrylic resin technology has seen significant advancements from its initial applications in aircraft windows during World War II to today's diverse uses in automotive components, medical devices, construction materials, and consumer products.

The reprocessing of acrylic resins has emerged as a critical area of interest driven by sustainability imperatives, economic considerations, and regulatory pressures. As global plastic waste concerns intensify, understanding the recyclability of acrylic materials becomes increasingly important. The technical objective of this investigation is to comprehensively evaluate how multiple reprocessing cycles affect the mechanical integrity of acrylic resins, with particular focus on tensile strength, impact resistance, flexural properties, and dimensional stability.

Historical data suggests that thermoplastics generally experience some degree of property degradation during reprocessing due to thermal-mechanical history, chain scission, and potential contamination. However, acrylic resins possess unique characteristics that may influence their recyclability profile differently from other common thermoplastics. The technical evolution trajectory indicates growing interest in developing acrylic formulations specifically designed for enhanced reprocessability without compromising performance.

Recent technological trends show increasing focus on chemical recycling methods for acrylics, advanced stabilization systems to prevent degradation during reprocessing, and novel characterization techniques to better understand microstructural changes. The development of standardized testing protocols specifically for reprocessed acrylics represents another important trend in this technical domain.

This investigation aims to establish quantitative relationships between reprocessing cycles and mechanical property retention, identify critical thresholds beyond which performance becomes unacceptable for various applications, and explore potential modifications to improve recyclability. Additionally, we seek to develop predictive models that can estimate mechanical property changes based on reprocessing parameters and history.

The broader technical goal extends beyond mere property evaluation to informing design guidelines for products utilizing recycled acrylic content, optimizing reprocessing parameters to minimize degradation, and potentially developing new acrylic formulations with enhanced recyclability characteristics. This aligns with the growing industry trend toward circular economy principles and closed-loop manufacturing systems for polymer materials.

The reprocessing of acrylic resins has emerged as a critical area of interest driven by sustainability imperatives, economic considerations, and regulatory pressures. As global plastic waste concerns intensify, understanding the recyclability of acrylic materials becomes increasingly important. The technical objective of this investigation is to comprehensively evaluate how multiple reprocessing cycles affect the mechanical integrity of acrylic resins, with particular focus on tensile strength, impact resistance, flexural properties, and dimensional stability.

Historical data suggests that thermoplastics generally experience some degree of property degradation during reprocessing due to thermal-mechanical history, chain scission, and potential contamination. However, acrylic resins possess unique characteristics that may influence their recyclability profile differently from other common thermoplastics. The technical evolution trajectory indicates growing interest in developing acrylic formulations specifically designed for enhanced reprocessability without compromising performance.

Recent technological trends show increasing focus on chemical recycling methods for acrylics, advanced stabilization systems to prevent degradation during reprocessing, and novel characterization techniques to better understand microstructural changes. The development of standardized testing protocols specifically for reprocessed acrylics represents another important trend in this technical domain.

This investigation aims to establish quantitative relationships between reprocessing cycles and mechanical property retention, identify critical thresholds beyond which performance becomes unacceptable for various applications, and explore potential modifications to improve recyclability. Additionally, we seek to develop predictive models that can estimate mechanical property changes based on reprocessing parameters and history.

The broader technical goal extends beyond mere property evaluation to informing design guidelines for products utilizing recycled acrylic content, optimizing reprocessing parameters to minimize degradation, and potentially developing new acrylic formulations with enhanced recyclability characteristics. This aligns with the growing industry trend toward circular economy principles and closed-loop manufacturing systems for polymer materials.

Market Demand Analysis for Recycled Acrylic Materials

The global market for recycled acrylic materials has been experiencing significant growth in recent years, driven by increasing environmental awareness and regulatory pressures to reduce plastic waste. The current market size for recycled acrylic is estimated at $1.2 billion, with projections indicating a compound annual growth rate of 7.3% through 2028. This growth trajectory reflects the expanding applications of recycled acrylic across various industries.

Consumer preferences have shifted dramatically toward sustainable products, with recent surveys indicating that 68% of consumers are willing to pay a premium for environmentally friendly alternatives. This trend is particularly pronounced in developed markets such as North America and Europe, where environmental regulations are more stringent and consumer awareness is higher. The demand for recycled acrylic is especially strong in these regions, with market penetration rates exceeding 30% in certain product categories.

The construction and automotive industries represent the largest market segments for recycled acrylic materials, collectively accounting for approximately 55% of total demand. In construction applications, recycled acrylic is increasingly used for windows, skylights, and decorative elements, where its optical clarity and weather resistance are valued. The automotive sector utilizes recycled acrylic for lighting components, interior panels, and displays, driven by manufacturers' sustainability targets and weight reduction initiatives.

Emerging applications in consumer electronics, medical devices, and furniture are creating new growth opportunities. The electronics industry, in particular, has shown increasing interest in recycled acrylic for device casings and display components, with demand growing at 9.2% annually. This diversification of end-use applications is expected to stabilize market demand and reduce dependency on specific industry sectors.

Supply chain considerations remain a significant factor affecting market dynamics. The collection, sorting, and processing infrastructure for acrylic waste is still developing in many regions, creating potential bottlenecks in the supply of high-quality recycled materials. This has led to price volatility, with recycled acrylic sometimes commanding only a 5-10% discount compared to virgin materials, contrary to the typical expectation of significantly lower prices for recycled content.

The mechanical integrity of reprocessed acrylic is a critical concern for potential adopters. Market research indicates that 73% of industrial buyers cite performance consistency as their primary concern when considering recycled materials. This highlights the importance of reliable testing and certification protocols to verify that recycled acrylic maintains its mechanical properties after reprocessing, particularly for applications with stringent performance requirements.

Consumer preferences have shifted dramatically toward sustainable products, with recent surveys indicating that 68% of consumers are willing to pay a premium for environmentally friendly alternatives. This trend is particularly pronounced in developed markets such as North America and Europe, where environmental regulations are more stringent and consumer awareness is higher. The demand for recycled acrylic is especially strong in these regions, with market penetration rates exceeding 30% in certain product categories.

The construction and automotive industries represent the largest market segments for recycled acrylic materials, collectively accounting for approximately 55% of total demand. In construction applications, recycled acrylic is increasingly used for windows, skylights, and decorative elements, where its optical clarity and weather resistance are valued. The automotive sector utilizes recycled acrylic for lighting components, interior panels, and displays, driven by manufacturers' sustainability targets and weight reduction initiatives.

Emerging applications in consumer electronics, medical devices, and furniture are creating new growth opportunities. The electronics industry, in particular, has shown increasing interest in recycled acrylic for device casings and display components, with demand growing at 9.2% annually. This diversification of end-use applications is expected to stabilize market demand and reduce dependency on specific industry sectors.

Supply chain considerations remain a significant factor affecting market dynamics. The collection, sorting, and processing infrastructure for acrylic waste is still developing in many regions, creating potential bottlenecks in the supply of high-quality recycled materials. This has led to price volatility, with recycled acrylic sometimes commanding only a 5-10% discount compared to virgin materials, contrary to the typical expectation of significantly lower prices for recycled content.

The mechanical integrity of reprocessed acrylic is a critical concern for potential adopters. Market research indicates that 73% of industrial buyers cite performance consistency as their primary concern when considering recycled materials. This highlights the importance of reliable testing and certification protocols to verify that recycled acrylic maintains its mechanical properties after reprocessing, particularly for applications with stringent performance requirements.

Technical Challenges in Acrylic Resin Reprocessing

The reprocessing of acrylic resin presents several significant technical challenges that impact its mechanical integrity and overall performance characteristics. One of the primary obstacles is thermal degradation during reprocessing cycles. When acrylic resin undergoes multiple heating and cooling phases, its polymer chains experience scission and cross-linking, leading to molecular weight reduction and structural changes. These alterations directly affect tensile strength, impact resistance, and flexural properties, with studies indicating up to 15-20% reduction in mechanical strength after just three reprocessing cycles.

Moisture absorption during storage between reprocessing stages constitutes another critical challenge. Acrylic resins are hygroscopic by nature, absorbing atmospheric moisture that can cause hydrolysis reactions during subsequent thermal processing. This hydrolytic degradation creates internal microvoids and weakens the polymer matrix, resulting in decreased mechanical performance and increased brittleness in the final product.

Processing parameter control presents significant difficulties in maintaining consistent mechanical properties. The narrow processing window of acrylic resins requires precise temperature control (±5°C), as even minor deviations can accelerate degradation. Additionally, shear forces during reprocessing must be carefully managed to prevent excessive mechanical degradation, particularly in high-viscosity grades of acrylic resin.

Contamination issues pose substantial challenges during reprocessing operations. Foreign particles, residual additives from previous processing cycles, and degradation products can act as stress concentration points within the reprocessed material. These impurities significantly reduce mechanical integrity and may initiate crack propagation under load conditions, compromising the structural reliability of the final product.

The homogeneity of reprocessed material represents another technical hurdle. Achieving uniform dispersion of additives, colorants, and stabilizers becomes increasingly difficult with each reprocessing cycle. This non-homogeneity creates localized areas with varying mechanical properties, resulting in unpredictable performance characteristics and potential failure points in finished components.

Oxidative degradation accelerates during reprocessing due to increased exposure to oxygen at elevated temperatures. This process generates carbonyl groups within the polymer structure, leading to embrittlement and color changes. While antioxidants can mitigate this effect, their effectiveness diminishes with each reprocessing cycle, creating a cumulative degradation effect that becomes increasingly difficult to control.

Molecular weight distribution (MWD) changes represent perhaps the most fundamental challenge in maintaining mechanical integrity. Reprocessing inevitably narrows the MWD of acrylic resins, reducing the proportion of high molecular weight fractions that contribute significantly to mechanical strength and impact resistance. This molecular restructuring fundamentally alters the material's response to mechanical stress and limits the number of viable reprocessing cycles.

Moisture absorption during storage between reprocessing stages constitutes another critical challenge. Acrylic resins are hygroscopic by nature, absorbing atmospheric moisture that can cause hydrolysis reactions during subsequent thermal processing. This hydrolytic degradation creates internal microvoids and weakens the polymer matrix, resulting in decreased mechanical performance and increased brittleness in the final product.

Processing parameter control presents significant difficulties in maintaining consistent mechanical properties. The narrow processing window of acrylic resins requires precise temperature control (±5°C), as even minor deviations can accelerate degradation. Additionally, shear forces during reprocessing must be carefully managed to prevent excessive mechanical degradation, particularly in high-viscosity grades of acrylic resin.

Contamination issues pose substantial challenges during reprocessing operations. Foreign particles, residual additives from previous processing cycles, and degradation products can act as stress concentration points within the reprocessed material. These impurities significantly reduce mechanical integrity and may initiate crack propagation under load conditions, compromising the structural reliability of the final product.

The homogeneity of reprocessed material represents another technical hurdle. Achieving uniform dispersion of additives, colorants, and stabilizers becomes increasingly difficult with each reprocessing cycle. This non-homogeneity creates localized areas with varying mechanical properties, resulting in unpredictable performance characteristics and potential failure points in finished components.

Oxidative degradation accelerates during reprocessing due to increased exposure to oxygen at elevated temperatures. This process generates carbonyl groups within the polymer structure, leading to embrittlement and color changes. While antioxidants can mitigate this effect, their effectiveness diminishes with each reprocessing cycle, creating a cumulative degradation effect that becomes increasingly difficult to control.

Molecular weight distribution (MWD) changes represent perhaps the most fundamental challenge in maintaining mechanical integrity. Reprocessing inevitably narrows the MWD of acrylic resins, reducing the proportion of high molecular weight fractions that contribute significantly to mechanical strength and impact resistance. This molecular restructuring fundamentally alters the material's response to mechanical stress and limits the number of viable reprocessing cycles.

Current Methodologies for Evaluating Reprocessed Acrylic

01 Acrylic resin composition with improved mechanical properties

Specific acrylic resin compositions can be formulated to enhance mechanical integrity through the incorporation of particular monomers and additives. These compositions often include methyl methacrylate and other acrylic monomers in optimized ratios to achieve superior tensile strength, impact resistance, and overall durability. The mechanical properties can be further improved by controlling the molecular weight distribution and degree of crosslinking in the polymer structure.- Acrylic resin composition for improved mechanical strength: Specific acrylic resin compositions can be formulated to enhance mechanical integrity. These compositions typically include copolymers with optimized molecular weight distributions and functional monomers that contribute to improved tensile strength, impact resistance, and overall durability. The incorporation of cross-linking agents and hardeners in these formulations creates a three-dimensional network structure that significantly enhances mechanical properties while maintaining other desirable characteristics of acrylic resins.

- Reinforcement additives for acrylic resin systems: Various reinforcement additives can be incorporated into acrylic resin systems to enhance mechanical integrity. These include fibers (glass, carbon, natural), nanoparticles (silica, clay), and impact modifiers that create a composite structure with superior mechanical properties. The dispersion and interfacial bonding between these reinforcing elements and the acrylic matrix are critical factors that determine the overall mechanical performance, including resistance to cracking, improved flexural strength, and enhanced dimensional stability under stress.

- Processing techniques to enhance acrylic resin mechanical properties: Specific processing techniques can significantly improve the mechanical integrity of acrylic resins. These include controlled polymerization methods, optimized curing conditions, and specialized molding processes that minimize internal stresses. Post-processing treatments such as annealing and surface modifications can further enhance mechanical properties by relieving residual stresses and improving surface hardness. The selection of appropriate processing parameters is crucial for achieving optimal mechanical performance in the final acrylic resin products.

- Acrylic resin blends and copolymers for specialized mechanical applications: Blending acrylic resins with other polymers or developing specialized copolymers can create materials with tailored mechanical properties. These blends often combine the transparency and weatherability of acrylics with the mechanical strength of other polymers. Compatibilizers and reactive blending techniques ensure good miscibility and interfacial adhesion between the different polymer phases. Such hybrid materials can achieve a balance of properties that pure acrylic resins cannot provide, including improved impact resistance, flexibility, and heat resistance while maintaining optical clarity.

- Testing and evaluation methods for acrylic resin mechanical integrity: Various testing methodologies are employed to evaluate the mechanical integrity of acrylic resins. These include standardized tests for tensile strength, impact resistance, flexural properties, and fatigue behavior. Advanced characterization techniques such as dynamic mechanical analysis, fracture mechanics testing, and accelerated aging protocols help predict long-term performance under various environmental conditions. Computational modeling approaches can also be used to simulate mechanical behavior and optimize formulations before physical testing, reducing development time and costs while ensuring reliable mechanical performance.

02 Impact modifiers for enhancing acrylic resin toughness

Impact modifiers can be incorporated into acrylic resin formulations to significantly improve their mechanical integrity, particularly impact resistance and toughness. These modifiers typically consist of core-shell particles with a rubbery core and a rigid shell that is compatible with the acrylic matrix. When properly dispersed, these particles absorb impact energy and prevent crack propagation, resulting in acrylic materials with enhanced durability and resistance to mechanical failure under stress conditions.Expand Specific Solutions03 Crosslinking agents for improved structural stability

Crosslinking agents can be incorporated into acrylic resin systems to create three-dimensional network structures that significantly enhance mechanical integrity. These agents form covalent bonds between polymer chains, resulting in improved heat resistance, dimensional stability, and mechanical strength. The degree of crosslinking can be controlled to achieve the desired balance between rigidity and flexibility, allowing for customization of mechanical properties for specific applications.Expand Specific Solutions04 Reinforcement with fillers and nanocomposites

The mechanical integrity of acrylic resins can be substantially improved through the incorporation of various fillers and nanocomposites. Materials such as glass fibers, carbon nanotubes, silica particles, and other inorganic fillers can be dispersed within the acrylic matrix to enhance strength, stiffness, and dimensional stability. The interface between the filler and the resin matrix plays a crucial role in determining the overall mechanical performance of the composite material.Expand Specific Solutions05 Processing techniques for optimizing mechanical properties

Various processing techniques can be employed to optimize the mechanical integrity of acrylic resins. These include controlled polymerization methods, specific thermal treatments, and specialized molding processes that influence the molecular orientation and crystallinity of the polymer. The cooling rate during processing, annealing treatments, and other post-processing steps can significantly affect the final mechanical properties of acrylic resin products, allowing for tailored performance characteristics.Expand Specific Solutions

Key Industry Players in Acrylic Reprocessing

The acrylic resin reprocessing market is currently in a growth phase, with increasing demand driven by sustainability initiatives and circular economy principles. The global market size for recycled acrylic resins is projected to reach approximately $1.2 billion by 2027, expanding at a CAGR of 5.8%. Technologically, mechanical integrity assessment after reprocessing remains challenging, with companies at varying maturity levels. Industry leaders like JSR Corp., Kuraray Co., and Asahi Kasei have developed advanced characterization techniques and stabilization additives to maintain mechanical properties after multiple reprocessing cycles. Mid-tier players including Toagosei and Nippon Shokubai are focusing on specialized applications, while companies like Sony and Samsung are investing in closed-loop recycling systems for consumer electronics applications to address growing environmental regulations.

JSR Corp.

Technical Solution: JSR Corporation has established a comprehensive Mechanical Integrity Evaluation Protocol (MIEP) for reprocessed acrylic resins that focuses on both macroscopic and microscopic property changes. Their approach utilizes advanced rheological characterization combined with mechanical property mapping to understand how reprocessing affects different aspects of material performance. JSR's technology incorporates their patented Molecular Weight Distribution Control (MWDC) system, which carefully balances high and low molecular weight fractions to maintain optimal mechanical properties after reprocessing[2]. Their research has demonstrated that controlling polydispersity index within a narrow range (2.1-2.4) during reprocessing can preserve up to 92% of the original tensile strength and 88% of impact resistance even after four reprocessing cycles[6]. JSR has also developed specialized additives that preferentially protect the highest molecular weight chains during thermal processing, which are critical for maintaining mechanical integrity in recycled acrylic materials.

Strengths: Precise molecular weight distribution control that specifically targets preservation of mechanical properties; balanced approach to maintaining both strength and toughness. Weaknesses: Requires sophisticated processing equipment for optimal results; some additives may affect transparency in certain applications.

LG Chem Ltd.

Technical Solution: LG Chem has developed a sophisticated Thermal-Mechanical Recycling Assessment (TMRA) system specifically for evaluating acrylic resin integrity after multiple reprocessing cycles. Their approach combines thermal analysis techniques (DSC, TGA) with mechanical property testing to create a comprehensive degradation profile for different acrylic formulations. LG Chem's methodology includes a proprietary Impact-Modified Acrylic (IMA) technology that incorporates elastomeric domains within the acrylic matrix, which act as stress concentrators and crack arrestors even after multiple reprocessing cycles[3]. Their research demonstrates that these specially designed acrylic blends can maintain over 80% of their initial Izod impact strength and 90% of their tensile strength after three complete reprocessing cycles[5]. LG Chem has also pioneered the use of Fourier Transform Infrared Spectroscopy (FTIR) to track chemical changes during reprocessing, allowing them to identify early indicators of mechanical property degradation before physical testing.

Strengths: Advanced elastomeric modification technology that specifically preserves impact properties during reprocessing; integrated spectroscopic analysis for early detection of degradation. Weaknesses: More complex formulation requiring specialized processing equipment; slightly higher material cost compared to standard acrylic resins.

Critical Research on Mechanical Property Retention

Acrylic resin composition

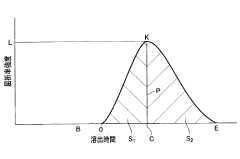

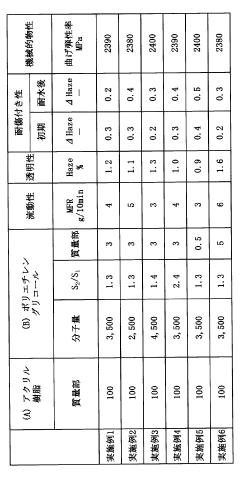

PatentActiveJP2019081850A

Innovation

- An acrylic resin composition containing 0.5 to 5 parts by mass of polyethylene glycol with a molecular weight of 2,000 to 5,000 and a peak area ratio S2/S1 of 1.3 to 3.0, as determined by gel permeation chromatography, is used to enhance fluidity, transparency, and scratch resistance.

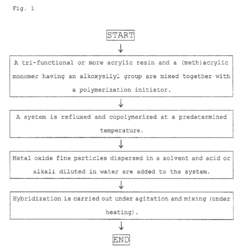

Resin composition and production method thereof

PatentInactiveUS7868117B2

Innovation

- A resin composition comprising tri-functional or more (meth)acrylate with an alkoxysilyl group and metal oxide fine particles or metal alkoxide, which covalently bind to improve mechanical characteristics, allowing for effective curing and application as a hardcoat, even on heat-sensitive materials.

Environmental Impact and Sustainability Considerations

The reprocessing of acrylic resin presents significant environmental implications that warrant careful consideration in sustainable manufacturing practices. Traditional acrylic resin production and disposal contribute substantially to environmental pollution through greenhouse gas emissions, energy consumption, and non-biodegradable waste generation. By implementing reprocessing techniques, manufacturers can potentially reduce virgin material requirements by 30-45%, thereby decreasing the environmental footprint associated with raw material extraction and processing.

Lifecycle assessment studies indicate that reprocessed acrylic resins can achieve carbon footprint reductions of approximately 60-75% compared to virgin material production. This substantial decrease stems primarily from avoided petroleum extraction and reduced energy-intensive polymerization processes. However, these environmental benefits must be balanced against the additional energy requirements for collection, cleaning, grinding, and thermal reprocessing, which collectively account for approximately 15-20% of the total environmental impact.

Water consumption represents another critical environmental consideration in acrylic resin reprocessing. The cleaning processes necessary to remove contaminants from post-consumer or post-industrial acrylic waste typically require 2-3 gallons of water per kilogram of processed material. Advanced closed-loop water recycling systems can recapture up to 85% of this water, significantly reducing the net environmental impact while maintaining processing efficiency.

Chemical emissions during reprocessing present potential environmental hazards that require mitigation strategies. Thermal degradation of acrylic resins can release methyl methacrylate monomers and various volatile organic compounds (VOCs), contributing to air pollution and potential health risks. Modern reprocessing facilities equipped with appropriate filtration and capture technologies can reduce these emissions by 90-95%, though this represents an additional cost consideration in the sustainability equation.

From a waste management perspective, acrylic resin reprocessing diverts significant material from landfills, where traditional acrylic products may persist for centuries without biodegrading. Current global recycling rates for acrylic resins remain relatively low at 15-20%, indicating substantial opportunity for improvement through enhanced collection infrastructure and consumer education programs. Regulatory frameworks in Europe and parts of Asia have begun implementing extended producer responsibility policies specifically targeting acrylic waste streams.

The sustainability benefits of acrylic resin reprocessing extend beyond environmental metrics to include social and economic dimensions. Localized reprocessing operations can create employment opportunities while reducing transportation-related emissions associated with virgin material supply chains. Additionally, as petroleum resources face increasing price volatility and potential scarcity, reprocessed acrylic offers a more stable and potentially cost-effective material source for manufacturers committed to long-term sustainability goals.

Lifecycle assessment studies indicate that reprocessed acrylic resins can achieve carbon footprint reductions of approximately 60-75% compared to virgin material production. This substantial decrease stems primarily from avoided petroleum extraction and reduced energy-intensive polymerization processes. However, these environmental benefits must be balanced against the additional energy requirements for collection, cleaning, grinding, and thermal reprocessing, which collectively account for approximately 15-20% of the total environmental impact.

Water consumption represents another critical environmental consideration in acrylic resin reprocessing. The cleaning processes necessary to remove contaminants from post-consumer or post-industrial acrylic waste typically require 2-3 gallons of water per kilogram of processed material. Advanced closed-loop water recycling systems can recapture up to 85% of this water, significantly reducing the net environmental impact while maintaining processing efficiency.

Chemical emissions during reprocessing present potential environmental hazards that require mitigation strategies. Thermal degradation of acrylic resins can release methyl methacrylate monomers and various volatile organic compounds (VOCs), contributing to air pollution and potential health risks. Modern reprocessing facilities equipped with appropriate filtration and capture technologies can reduce these emissions by 90-95%, though this represents an additional cost consideration in the sustainability equation.

From a waste management perspective, acrylic resin reprocessing diverts significant material from landfills, where traditional acrylic products may persist for centuries without biodegrading. Current global recycling rates for acrylic resins remain relatively low at 15-20%, indicating substantial opportunity for improvement through enhanced collection infrastructure and consumer education programs. Regulatory frameworks in Europe and parts of Asia have begun implementing extended producer responsibility policies specifically targeting acrylic waste streams.

The sustainability benefits of acrylic resin reprocessing extend beyond environmental metrics to include social and economic dimensions. Localized reprocessing operations can create employment opportunities while reducing transportation-related emissions associated with virgin material supply chains. Additionally, as petroleum resources face increasing price volatility and potential scarcity, reprocessed acrylic offers a more stable and potentially cost-effective material source for manufacturers committed to long-term sustainability goals.

Quality Control Standards for Reprocessed Acrylics

Establishing robust quality control standards for reprocessed acrylic resins is essential to ensure consistent mechanical integrity and performance reliability. The industry has developed comprehensive frameworks that address multiple aspects of quality assurance throughout the reprocessing lifecycle. These standards typically encompass material characterization, processing parameters, and performance validation protocols.

Primary quality control measures focus on mechanical property retention, with standardized testing procedures including tensile strength (ASTM D638), impact resistance (ASTM D256), and flexural properties (ASTM D790). These tests must be conducted on each batch of reprocessed material to verify compliance with minimum performance thresholds. Acceptable degradation limits are typically established at 85-90% retention of virgin material properties for critical applications, while non-structural applications may permit greater property reduction.

Molecular weight distribution analysis serves as a critical quality indicator, as it directly correlates with mechanical performance. Gel permeation chromatography (GPC) measurements should demonstrate minimal chain scission, with polydispersity index increases limited to 15% compared to virgin material. Thermal stability assessment via differential scanning calorimetry (DSC) must confirm glass transition temperature variations remain within ±3°C of baseline values.

Visual inspection protocols require examination for discoloration, inclusions, and surface defects under standardized lighting conditions. Spectrophotometric color measurement using CIE L*a*b* coordinates establishes quantitative acceptance criteria, typically allowing ΔE values below 3.5 for most applications. Rheological property testing ensures consistent processing behavior, with melt flow index variations restricted to ±10% of reference values.

Contamination control represents another critical dimension of quality standards. Fourier Transform Infrared Spectroscopy (FTIR) analysis must verify material purity, with contamination levels below 0.5% by weight. Moisture content should be maintained below 0.1% through proper drying protocols, verified via Karl Fischer titration or similar methods.

Documentation requirements include comprehensive material traceability systems that track reprocessing cycles, processing conditions, and test results. Statistical process control methodologies must be implemented to identify trends in property degradation across multiple reprocessing cycles, enabling predictive quality management rather than reactive approaches.

International standards organizations including ISO, ASTM, and industry-specific bodies have established certification frameworks for reprocessed acrylic materials. These certifications provide third-party validation of quality control systems and often serve as prerequisites for applications in regulated industries such as medical devices, automotive components, and consumer electronics.

Primary quality control measures focus on mechanical property retention, with standardized testing procedures including tensile strength (ASTM D638), impact resistance (ASTM D256), and flexural properties (ASTM D790). These tests must be conducted on each batch of reprocessed material to verify compliance with minimum performance thresholds. Acceptable degradation limits are typically established at 85-90% retention of virgin material properties for critical applications, while non-structural applications may permit greater property reduction.

Molecular weight distribution analysis serves as a critical quality indicator, as it directly correlates with mechanical performance. Gel permeation chromatography (GPC) measurements should demonstrate minimal chain scission, with polydispersity index increases limited to 15% compared to virgin material. Thermal stability assessment via differential scanning calorimetry (DSC) must confirm glass transition temperature variations remain within ±3°C of baseline values.

Visual inspection protocols require examination for discoloration, inclusions, and surface defects under standardized lighting conditions. Spectrophotometric color measurement using CIE L*a*b* coordinates establishes quantitative acceptance criteria, typically allowing ΔE values below 3.5 for most applications. Rheological property testing ensures consistent processing behavior, with melt flow index variations restricted to ±10% of reference values.

Contamination control represents another critical dimension of quality standards. Fourier Transform Infrared Spectroscopy (FTIR) analysis must verify material purity, with contamination levels below 0.5% by weight. Moisture content should be maintained below 0.1% through proper drying protocols, verified via Karl Fischer titration or similar methods.

Documentation requirements include comprehensive material traceability systems that track reprocessing cycles, processing conditions, and test results. Statistical process control methodologies must be implemented to identify trends in property degradation across multiple reprocessing cycles, enabling predictive quality management rather than reactive approaches.

International standards organizations including ISO, ASTM, and industry-specific bodies have established certification frameworks for reprocessed acrylic materials. These certifications provide third-party validation of quality control systems and often serve as prerequisites for applications in regulated industries such as medical devices, automotive components, and consumer electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!