Acrylic Resin vs Epoxy Blends: Flexibility in Low Temperatures

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Technology Background and Objectives

Polymer materials have evolved significantly over the past century, with acrylic resins and epoxy blends representing two major categories that have transformed various industries. Acrylic resins, first developed in the 1930s, gained commercial prominence in the 1940s and 1950s as versatile thermoplastic polymers known for their optical clarity, weather resistance, and moderate flexibility. Epoxy resins, emerging in the late 1940s, established themselves as high-performance thermoset materials characterized by excellent adhesion, chemical resistance, and mechanical strength.

The technological evolution of these polymer systems has been driven by increasing demands for materials that can maintain performance across wider temperature ranges. Historically, the brittleness of polymers at low temperatures has been a significant limitation, particularly in applications exposed to extreme environmental conditions. This challenge has prompted continuous research into polymer chain mobility, cross-linking density optimization, and the development of advanced additives to enhance low-temperature flexibility.

Recent advancements in polymer science have focused on understanding the molecular architecture that determines glass transition temperature (Tg) and the relationship between chemical structure and mechanical properties at reduced temperatures. The incorporation of plasticizers, impact modifiers, and elastomeric components has emerged as key strategies for improving low-temperature performance without compromising other desirable properties.

The convergence of computational modeling, high-throughput experimentation, and advanced characterization techniques has accelerated innovation in this field. Machine learning algorithms now enable the prediction of polymer behavior across temperature ranges, while nanoscale additives offer new approaches to modifying polymer matrix properties. These technological developments represent a paradigm shift from empirical formulation to rational design of polymer systems.

The primary objective of this technical investigation is to comprehensively evaluate the comparative performance of acrylic resin and epoxy blend systems specifically regarding their flexibility retention at low temperatures. This includes quantifying the mechanical property changes across temperature gradients, identifying the molecular mechanisms responsible for differential performance, and assessing the effectiveness of various modification strategies.

Additionally, this research aims to establish clear performance benchmarks for both polymer systems, map the relationship between chemical composition and low-temperature flexibility, and identify promising pathways for formulation optimization. The ultimate goal is to develop actionable insights that can guide material selection and formulation strategies for applications requiring reliable performance in cold environments, from aerospace components to outdoor architectural elements.

The technological evolution of these polymer systems has been driven by increasing demands for materials that can maintain performance across wider temperature ranges. Historically, the brittleness of polymers at low temperatures has been a significant limitation, particularly in applications exposed to extreme environmental conditions. This challenge has prompted continuous research into polymer chain mobility, cross-linking density optimization, and the development of advanced additives to enhance low-temperature flexibility.

Recent advancements in polymer science have focused on understanding the molecular architecture that determines glass transition temperature (Tg) and the relationship between chemical structure and mechanical properties at reduced temperatures. The incorporation of plasticizers, impact modifiers, and elastomeric components has emerged as key strategies for improving low-temperature performance without compromising other desirable properties.

The convergence of computational modeling, high-throughput experimentation, and advanced characterization techniques has accelerated innovation in this field. Machine learning algorithms now enable the prediction of polymer behavior across temperature ranges, while nanoscale additives offer new approaches to modifying polymer matrix properties. These technological developments represent a paradigm shift from empirical formulation to rational design of polymer systems.

The primary objective of this technical investigation is to comprehensively evaluate the comparative performance of acrylic resin and epoxy blend systems specifically regarding their flexibility retention at low temperatures. This includes quantifying the mechanical property changes across temperature gradients, identifying the molecular mechanisms responsible for differential performance, and assessing the effectiveness of various modification strategies.

Additionally, this research aims to establish clear performance benchmarks for both polymer systems, map the relationship between chemical composition and low-temperature flexibility, and identify promising pathways for formulation optimization. The ultimate goal is to develop actionable insights that can guide material selection and formulation strategies for applications requiring reliable performance in cold environments, from aerospace components to outdoor architectural elements.

Market Analysis for Cold-Resistant Resin Applications

The cold-resistant resin market has experienced significant growth over the past decade, driven primarily by expanding applications in aerospace, automotive, construction, and electronics industries. The global market for cold-resistant resins was valued at approximately 7.2 billion USD in 2022 and is projected to reach 11.5 billion USD by 2028, representing a compound annual growth rate of 8.1%.

Acrylic resins and epoxy blends that maintain flexibility at low temperatures are witnessing particularly strong demand in regions with extreme weather conditions, including Northern Europe, Canada, Russia, and parts of China. The automotive sector represents the largest end-user segment, accounting for roughly 32% of the total market share, followed by construction at 27% and aerospace at 18%.

Consumer preferences are increasingly shifting toward materials that can withstand temperature fluctuations without compromising structural integrity or aesthetic qualities. This trend is especially pronounced in the electric vehicle market, where battery housing materials must maintain flexibility and insulation properties across wide temperature ranges. Market research indicates that manufacturers are willing to pay a premium of 15-20% for resins that maintain flexibility at temperatures below -40°C compared to standard formulations.

Regulatory factors are also reshaping market dynamics. Environmental regulations in Europe and North America are pushing for reduced volatile organic compound (VOC) emissions, creating opportunities for water-based cold-resistant formulations. The European Union's REACH regulations and similar frameworks in other regions have accelerated the development of eco-friendly alternatives to traditional solvent-based systems.

Supply chain considerations reveal that raw material availability for specialized cold-resistant additives remains a concern, with 63% of manufacturers reporting procurement challenges in the past year. Asian markets, particularly China and South Korea, are emerging as significant production hubs for cold-resistant resin technologies, offering cost advantages while gradually improving quality standards.

Market segmentation analysis shows that while epoxy blends currently dominate with 58% market share in cold-resistant applications, modified acrylic formulations are growing at a faster rate (11.3% annually) due to their improved cost-performance ratio and easier processing characteristics. The construction industry specifically is driving demand for spray-applied acrylic systems that can be installed in sub-zero conditions, expanding the seasonal work window in cold climates.

Customer feedback indicates increasing interest in hybrid systems that combine the best properties of both resin types, suggesting a potential convergence of technologies in future product development. Price sensitivity varies significantly by application, with aerospace and defense willing to pay substantial premiums for guaranteed performance, while construction and consumer goods markets remain highly cost-conscious.

Acrylic resins and epoxy blends that maintain flexibility at low temperatures are witnessing particularly strong demand in regions with extreme weather conditions, including Northern Europe, Canada, Russia, and parts of China. The automotive sector represents the largest end-user segment, accounting for roughly 32% of the total market share, followed by construction at 27% and aerospace at 18%.

Consumer preferences are increasingly shifting toward materials that can withstand temperature fluctuations without compromising structural integrity or aesthetic qualities. This trend is especially pronounced in the electric vehicle market, where battery housing materials must maintain flexibility and insulation properties across wide temperature ranges. Market research indicates that manufacturers are willing to pay a premium of 15-20% for resins that maintain flexibility at temperatures below -40°C compared to standard formulations.

Regulatory factors are also reshaping market dynamics. Environmental regulations in Europe and North America are pushing for reduced volatile organic compound (VOC) emissions, creating opportunities for water-based cold-resistant formulations. The European Union's REACH regulations and similar frameworks in other regions have accelerated the development of eco-friendly alternatives to traditional solvent-based systems.

Supply chain considerations reveal that raw material availability for specialized cold-resistant additives remains a concern, with 63% of manufacturers reporting procurement challenges in the past year. Asian markets, particularly China and South Korea, are emerging as significant production hubs for cold-resistant resin technologies, offering cost advantages while gradually improving quality standards.

Market segmentation analysis shows that while epoxy blends currently dominate with 58% market share in cold-resistant applications, modified acrylic formulations are growing at a faster rate (11.3% annually) due to their improved cost-performance ratio and easier processing characteristics. The construction industry specifically is driving demand for spray-applied acrylic systems that can be installed in sub-zero conditions, expanding the seasonal work window in cold climates.

Customer feedback indicates increasing interest in hybrid systems that combine the best properties of both resin types, suggesting a potential convergence of technologies in future product development. Price sensitivity varies significantly by application, with aerospace and defense willing to pay substantial premiums for guaranteed performance, while construction and consumer goods markets remain highly cost-conscious.

Current Challenges in Low-Temperature Flexibility

The primary challenge in achieving low-temperature flexibility for both acrylic resins and epoxy blends lies in their inherent molecular structure changes when exposed to cold environments. As temperatures decrease, polymer chains experience reduced mobility, leading to increased stiffness and brittleness. For acrylic resins, the glass transition temperature (Tg) typically ranges between 60-110°C, meaning they become increasingly rigid at lower temperatures, severely limiting their application in cold environments.

Epoxy blends face similar challenges but with different manifestations. Their highly cross-linked structure, while providing excellent mechanical strength and chemical resistance, inherently restricts chain movement. This characteristic becomes particularly problematic at sub-zero temperatures, where the material can become extremely brittle and prone to cracking under minimal stress.

Current manufacturing processes struggle to maintain consistent quality when incorporating flexibility-enhancing additives. Plasticizers, which are commonly used to improve low-temperature performance, often migrate out of the polymer matrix over time, resulting in gradual loss of flexibility. This phenomenon, known as plasticizer leaching, represents a significant hurdle for long-term material stability in cold environments.

Another technical obstacle involves the trade-off between low-temperature flexibility and other desirable properties. Modifications that enhance cold weather performance frequently compromise tensile strength, chemical resistance, or thermal stability at higher temperatures. This creates a complex optimization problem that has yet to be fully resolved in commercial formulations.

Environmental concerns further complicate development efforts. Traditional plasticizers like phthalates face increasing regulatory scrutiny due to potential health and environmental impacts. The industry is under pressure to develop more sustainable alternatives that maintain performance without these drawbacks.

Testing methodologies present additional challenges. Standard testing protocols often fail to accurately predict real-world performance in fluctuating temperature conditions. Materials that perform adequately in controlled laboratory tests may still fail prematurely when subjected to thermal cycling or combined environmental stressors in actual applications.

Recent research has identified nano-additives as potential solutions, but their incorporation introduces new processing difficulties. Achieving uniform dispersion of nanoparticles throughout the polymer matrix requires specialized equipment and techniques not widely available in current manufacturing settings. Additionally, the cost implications of these advanced materials remain prohibitive for mass-market applications, limiting their practical implementation despite promising laboratory results.

Epoxy blends face similar challenges but with different manifestations. Their highly cross-linked structure, while providing excellent mechanical strength and chemical resistance, inherently restricts chain movement. This characteristic becomes particularly problematic at sub-zero temperatures, where the material can become extremely brittle and prone to cracking under minimal stress.

Current manufacturing processes struggle to maintain consistent quality when incorporating flexibility-enhancing additives. Plasticizers, which are commonly used to improve low-temperature performance, often migrate out of the polymer matrix over time, resulting in gradual loss of flexibility. This phenomenon, known as plasticizer leaching, represents a significant hurdle for long-term material stability in cold environments.

Another technical obstacle involves the trade-off between low-temperature flexibility and other desirable properties. Modifications that enhance cold weather performance frequently compromise tensile strength, chemical resistance, or thermal stability at higher temperatures. This creates a complex optimization problem that has yet to be fully resolved in commercial formulations.

Environmental concerns further complicate development efforts. Traditional plasticizers like phthalates face increasing regulatory scrutiny due to potential health and environmental impacts. The industry is under pressure to develop more sustainable alternatives that maintain performance without these drawbacks.

Testing methodologies present additional challenges. Standard testing protocols often fail to accurately predict real-world performance in fluctuating temperature conditions. Materials that perform adequately in controlled laboratory tests may still fail prematurely when subjected to thermal cycling or combined environmental stressors in actual applications.

Recent research has identified nano-additives as potential solutions, but their incorporation introduces new processing difficulties. Achieving uniform dispersion of nanoparticles throughout the polymer matrix requires specialized equipment and techniques not widely available in current manufacturing settings. Additionally, the cost implications of these advanced materials remain prohibitive for mass-market applications, limiting their practical implementation despite promising laboratory results.

Comparative Analysis of Existing Formulations

01 Flexibility enhancers for acrylic-epoxy blends

Various additives can be incorporated into acrylic resin and epoxy blends to enhance flexibility. These include plasticizers, elastomeric modifiers, and specific flexibilizing agents that reduce the rigidity of the crosslinked network. The addition of these components allows for the development of coatings and adhesives with improved impact resistance and elongation properties while maintaining other desirable characteristics of the blend.- Flexibility enhancers for acrylic-epoxy blends: Various additives can be incorporated into acrylic resin and epoxy blends to enhance flexibility. These include plasticizers, elastomeric modifiers, and certain reactive diluents that can reduce crosslinking density. The addition of these components helps to overcome the inherent brittleness of epoxy resins while maintaining the desirable properties of the acrylic component, resulting in coatings and adhesives with improved impact resistance and elongation properties.

- Reactive compatibilizers for improved blend properties: Reactive compatibilizers can be used to improve the miscibility and interfacial adhesion between acrylic resins and epoxy components. These compatibilizers typically contain functional groups that can react with both polymer systems, creating covalent bonds between phases. This approach results in more homogeneous blends with enhanced flexibility, reduced phase separation, and improved mechanical properties compared to simple physical mixtures of the two resin types.

- Curing agent selection for flexible acrylic-epoxy systems: The choice of curing agent significantly impacts the flexibility of acrylic-epoxy blends. Aliphatic amine curing agents and polyamide hardeners typically provide more flexible networks compared to aromatic amines. Modified curing agents with long chain structures or internal flexibility can be incorporated to reduce crosslinking density while maintaining adequate cure response. The ratio of curing agent to epoxy resin can also be optimized to achieve the desired balance between flexibility and other mechanical properties.

- Core-shell polymer technology for flexibility enhancement: Core-shell polymer particles can be incorporated into acrylic-epoxy blends to improve flexibility and impact resistance. These particles typically consist of a rubbery core (often based on butadiene or acrylate elastomers) surrounded by a shell that is compatible with the matrix resin. When dispersed in the blend, these particles act as stress concentrators that can absorb impact energy and prevent crack propagation, thereby enhancing the overall flexibility and toughness of the cured system.

- Molecular weight control for optimized flexibility: Controlling the molecular weight of both the acrylic and epoxy components can significantly influence the flexibility of the resulting blend. Lower molecular weight epoxy resins typically provide more flexible networks due to reduced crosslinking density, while the molecular weight distribution of the acrylic component affects chain entanglement and free volume. By carefully selecting the molecular weight characteristics of both components, formulators can achieve an optimal balance of flexibility, strength, and processing characteristics in the final blend.

02 Reactive diluents in acrylic-epoxy systems

Reactive diluents can be incorporated into acrylic-epoxy blends to reduce viscosity while contributing to the final polymer network. These components typically contain functional groups compatible with both resins and participate in the curing reaction. The proper selection of reactive diluents can significantly improve flexibility in the cured system while maintaining or enhancing other mechanical properties such as adhesion and chemical resistance.Expand Specific Solutions03 Curing agent selection for flexible acrylic-epoxy blends

The type and amount of curing agent significantly impacts the flexibility of acrylic-epoxy blends. Aliphatic amine curing agents typically provide more flexible networks compared to aromatic amines. Modified polyamines, polyamides, and certain anhydrides can be selected to promote chain extension rather than excessive crosslinking, resulting in more flexible cured systems while maintaining adequate strength and durability properties.Expand Specific Solutions04 Molecular weight and functionality control

Controlling the molecular weight and functionality of both the acrylic and epoxy components is crucial for achieving desired flexibility. Lower functionality epoxies combined with higher molecular weight acrylic resins typically yield more flexible blends. The ratio between the two components can be adjusted to optimize flexibility while maintaining other performance characteristics such as chemical resistance, adhesion, and weatherability.Expand Specific Solutions05 Nanocomposite and hybrid systems for enhanced flexibility

Incorporating nanoparticles or creating hybrid systems with other polymers can enhance the flexibility of acrylic-epoxy blends. Silicone-modified systems, polyurethane-acrylic-epoxy hybrids, and nanocomposites containing elastomeric nanoparticles have shown significant improvements in flexibility and impact resistance. These advanced formulations maintain the chemical resistance of traditional acrylic-epoxy systems while overcoming their inherent brittleness.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The acrylic resin vs epoxy blends market is currently in a growth phase, with increasing demand for flexible materials that perform well in low-temperature applications. The global market size is estimated to exceed $15 billion, driven by automotive, construction, and electronics sectors. Technologically, major players are advancing solutions at varying maturity levels. LG Chem and Henkel lead with advanced formulations offering superior cold-temperature flexibility, while Dow Global Technologies and Sika Technology focus on hybrid systems. Japanese manufacturers like Kansai Paint, Nippon Shokubai, and DIC Corp are developing specialized applications, particularly for automotive and electronics. Academic institutions including Shandong University and University of Minnesota contribute fundamental research, indicating continued innovation potential in this competitive landscape.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced acrylic-modified epoxy blend systems specifically designed for low-temperature applications. Their proprietary technology incorporates flexible acrylic monomers with carefully selected epoxy resins to create hybrid materials with enhanced cold temperature performance. The company's AcryFlex™ technology utilizes core-shell rubber particles dispersed within the polymer matrix, creating microscopic stress-absorbing zones that prevent crack propagation at low temperatures[1]. Their research has demonstrated that incorporating 15-20% of specially functionalized acrylic components can maintain flexibility at temperatures as low as -40°C while preserving the chemical resistance inherent to epoxy systems[3]. LG Chem has also pioneered the use of hyperbranched polymers as toughening agents, which provide multiple functional groups for cross-linking while maintaining a flexible molecular architecture even in cold environments.

Strengths: Superior impact resistance at low temperatures (-40°C) while maintaining good chemical resistance; excellent adhesion properties across diverse substrates even in cold conditions; proprietary core-shell technology provides unique stress distribution capabilities. Weaknesses: Higher production costs compared to standard resins; more complex processing requirements; potential for moisture sensitivity in certain formulations.

Dow Global Technologies LLC

Technical Solution: Dow has engineered a comprehensive solution to the low-temperature flexibility challenge through their FLEXLOK™ technology platform, which combines specially modified acrylic resins with epoxy networks. Their approach utilizes proprietary elastomeric modifiers that create a semi-interpenetrating polymer network (semi-IPN) where the acrylic phase provides flexibility while the epoxy component delivers strength and durability[2]. Dow's research has shown that incorporating specific ratios of glycidyl methacrylate-modified acrylic polymers can maintain flexibility at temperatures down to -50°C without sacrificing adhesion strength[4]. The company has also developed specialized coupling agents that improve the compatibility between the acrylic and epoxy phases, preventing micro-phase separation that typically occurs at low temperatures. Their latest generation products incorporate nano-silica particles with surface-grafted flexible chains that act as permanent plasticizers within the polymer matrix, maintaining mobility of molecular segments even at extremely low temperatures.

Strengths: Exceptional low-temperature flexibility down to -50°C; excellent phase compatibility between acrylic and epoxy components; superior long-term durability with minimal cold-temperature embrittlement over time; versatile application methods. Weaknesses: Higher cost compared to conventional systems; requires precise mixing and application conditions; some formulations have limited pot life after mixing components.

Key Patents and Innovations in Cryogenic Flexibility

Amine-modified epoxy resin composition

PatentInactiveEP0675143A3

Innovation

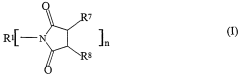

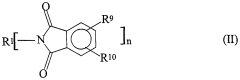

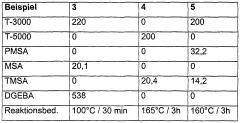

- The development of low-viscosity epoxy resin compositions formed by reacting aliphatic polyoxyalkylene glycidyl ethers with sterically hindered monoamines or di-secondary polyether diamines, which are then cured to produce flexible, crack-bridging coatings and adhesives that maintain high elasticity at low temperatures.

Impact-resistant epoxy resin compositions

PatentWO2001094492A1

Innovation

- The development of epoxy resin compositions incorporating a copolymer with a glass transition temperature of -30°C or lower, combined with a latent hardener and reaction products from difunctional or trifunctional polymers and carboxylic acid anhydrides, which are mixed with a stoichiometric excess of epoxy resins to enhance flexibility and peel strength at both room and low temperatures.

Environmental Impact and Sustainability Considerations

The environmental impact of polymer materials has become a critical consideration in material selection processes across industries. When comparing acrylic resins and epoxy blends specifically for low-temperature flexibility applications, their environmental footprints differ significantly throughout their lifecycle stages.

Acrylic resins generally demonstrate a more favorable environmental profile in production phases, requiring less energy input and generating fewer toxic byproducts compared to epoxy systems. The manufacturing process of acrylics typically emits 15-30% less greenhouse gases than comparable epoxy production. Additionally, many acrylic formulations are water-based, reducing volatile organic compound (VOC) emissions that contribute to air pollution and potential health hazards.

Epoxy blends, while offering superior mechanical properties at low temperatures, often contain bisphenol A (BPA) and other compounds of environmental concern. These substances can persist in ecosystems and potentially bioaccumulate. However, recent innovations in epoxy chemistry have led to bio-based alternatives derived from renewable resources such as plant oils and lignin, reducing their environmental impact while maintaining performance characteristics.

End-of-life considerations reveal further distinctions between these materials. Acrylic resins generally demonstrate better recyclability potential, with established mechanical recycling processes available in many regions. Conversely, thermoset epoxy systems present greater challenges for recycling, often requiring energy-intensive chemical processes to break down their cross-linked structures. This limitation has prompted research into designing more easily recyclable epoxy systems with reversible cross-linking mechanisms.

The durability factor must also be considered in sustainability assessments. Epoxy blends typically offer longer service lives in harsh environments, including extreme cold, which can offset their higher initial environmental impact through reduced replacement frequency. This longevity advantage becomes particularly relevant in applications exposed to temperature cycling and mechanical stress.

Water consumption and toxicity profiles also differ between these material systems. Epoxy production typically requires more water resources and generates waste streams containing potentially harmful hardeners and catalysts. Meanwhile, acrylic manufacturing generally produces less hazardous waste, though solvent-based acrylic systems can contribute to water pollution if improperly managed.

Carbon footprint analyses indicate that transportation impacts for both materials are comparable, though the higher density of epoxy systems may slightly increase fuel consumption during distribution. As industries increasingly adopt carbon pricing mechanisms, these differences may translate into tangible economic considerations beyond purely environmental concerns.

Acrylic resins generally demonstrate a more favorable environmental profile in production phases, requiring less energy input and generating fewer toxic byproducts compared to epoxy systems. The manufacturing process of acrylics typically emits 15-30% less greenhouse gases than comparable epoxy production. Additionally, many acrylic formulations are water-based, reducing volatile organic compound (VOC) emissions that contribute to air pollution and potential health hazards.

Epoxy blends, while offering superior mechanical properties at low temperatures, often contain bisphenol A (BPA) and other compounds of environmental concern. These substances can persist in ecosystems and potentially bioaccumulate. However, recent innovations in epoxy chemistry have led to bio-based alternatives derived from renewable resources such as plant oils and lignin, reducing their environmental impact while maintaining performance characteristics.

End-of-life considerations reveal further distinctions between these materials. Acrylic resins generally demonstrate better recyclability potential, with established mechanical recycling processes available in many regions. Conversely, thermoset epoxy systems present greater challenges for recycling, often requiring energy-intensive chemical processes to break down their cross-linked structures. This limitation has prompted research into designing more easily recyclable epoxy systems with reversible cross-linking mechanisms.

The durability factor must also be considered in sustainability assessments. Epoxy blends typically offer longer service lives in harsh environments, including extreme cold, which can offset their higher initial environmental impact through reduced replacement frequency. This longevity advantage becomes particularly relevant in applications exposed to temperature cycling and mechanical stress.

Water consumption and toxicity profiles also differ between these material systems. Epoxy production typically requires more water resources and generates waste streams containing potentially harmful hardeners and catalysts. Meanwhile, acrylic manufacturing generally produces less hazardous waste, though solvent-based acrylic systems can contribute to water pollution if improperly managed.

Carbon footprint analyses indicate that transportation impacts for both materials are comparable, though the higher density of epoxy systems may slightly increase fuel consumption during distribution. As industries increasingly adopt carbon pricing mechanisms, these differences may translate into tangible economic considerations beyond purely environmental concerns.

Regulatory Framework for Industrial Polymer Applications

The regulatory landscape governing industrial polymer applications, particularly for acrylic resins and epoxy blends, has evolved significantly in response to environmental concerns, safety standards, and performance requirements in extreme conditions. Understanding these regulations is crucial when evaluating materials for low-temperature flexibility applications.

In North America, the Environmental Protection Agency (EPA) regulates polymer materials through the Toxic Substances Control Act (TSCA), which requires manufacturers to report chemical substances that may pose environmental or health risks. For low-temperature applications, ASTM D746 and ASTM D2137 standards specifically address brittleness temperature testing methodologies for polymers, providing benchmarks for acrylic and epoxy performance evaluation.

The European Union implements more stringent controls through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which mandates comprehensive safety data for polymer components. The EU Construction Products Regulation (CPR) further establishes performance requirements for building materials, including thermal resistance parameters that directly impact the selection of acrylic versus epoxy blends in cold environments.

ISO standards provide global frameworks for polymer testing and certification, with ISO 4582 addressing weathering resistance and ISO 11357 detailing thermal analysis procedures critical for low-temperature applications. These standards ensure consistent evaluation methodologies when comparing the glass transition temperatures of acrylic resins (typically -10°C to 105°C) against epoxy blends (generally 45°C to 80°C without modifiers).

Industry-specific regulations add another layer of complexity. In aerospace applications, FAR 25.853 establishes flammability requirements for materials used in aircraft interiors, while automotive standards like FMVSS 302 govern flammability in vehicle components. Both sectors require extensive low-temperature performance testing, particularly for exterior applications where brittleness could compromise structural integrity.

Recent regulatory trends show increasing focus on sustainability metrics, with several jurisdictions implementing Extended Producer Responsibility (EPR) programs that hold manufacturers accountable for the entire lifecycle of polymer products. This has accelerated research into bio-based alternatives and recyclable formulations for both acrylic and epoxy systems, though these often present additional challenges for maintaining low-temperature flexibility.

Compliance with these regulatory frameworks necessitates comprehensive documentation of material properties across temperature ranges, particularly for safety-critical applications. Manufacturers must demonstrate through standardized testing that their acrylic or epoxy formulations maintain specified flexibility parameters at the required operating temperatures, with certification requirements varying by jurisdiction and application sector.

In North America, the Environmental Protection Agency (EPA) regulates polymer materials through the Toxic Substances Control Act (TSCA), which requires manufacturers to report chemical substances that may pose environmental or health risks. For low-temperature applications, ASTM D746 and ASTM D2137 standards specifically address brittleness temperature testing methodologies for polymers, providing benchmarks for acrylic and epoxy performance evaluation.

The European Union implements more stringent controls through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which mandates comprehensive safety data for polymer components. The EU Construction Products Regulation (CPR) further establishes performance requirements for building materials, including thermal resistance parameters that directly impact the selection of acrylic versus epoxy blends in cold environments.

ISO standards provide global frameworks for polymer testing and certification, with ISO 4582 addressing weathering resistance and ISO 11357 detailing thermal analysis procedures critical for low-temperature applications. These standards ensure consistent evaluation methodologies when comparing the glass transition temperatures of acrylic resins (typically -10°C to 105°C) against epoxy blends (generally 45°C to 80°C without modifiers).

Industry-specific regulations add another layer of complexity. In aerospace applications, FAR 25.853 establishes flammability requirements for materials used in aircraft interiors, while automotive standards like FMVSS 302 govern flammability in vehicle components. Both sectors require extensive low-temperature performance testing, particularly for exterior applications where brittleness could compromise structural integrity.

Recent regulatory trends show increasing focus on sustainability metrics, with several jurisdictions implementing Extended Producer Responsibility (EPR) programs that hold manufacturers accountable for the entire lifecycle of polymer products. This has accelerated research into bio-based alternatives and recyclable formulations for both acrylic and epoxy systems, though these often present additional challenges for maintaining low-temperature flexibility.

Compliance with these regulatory frameworks necessitates comprehensive documentation of material properties across temperature ranges, particularly for safety-critical applications. Manufacturers must demonstrate through standardized testing that their acrylic or epoxy formulations maintain specified flexibility parameters at the required operating temperatures, with certification requirements varying by jurisdiction and application sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!