How to Optimize Acrylic Resin Curing in Composite Manufacturing

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Curing Technology Background and Objectives

Acrylic resin curing technology has evolved significantly over the past several decades, transforming from simple thermosetting processes to sophisticated, controlled polymerization systems. Initially developed in the 1940s, acrylic resins gained prominence in composite manufacturing due to their excellent mechanical properties, weather resistance, and optical clarity. The evolution of curing technologies has been driven by increasing demands for faster production cycles, reduced energy consumption, and enhanced final product performance.

Traditional thermal curing methods dominated the industry until the 1980s, when radiation-curing technologies, particularly UV and electron beam systems, began to emerge as viable alternatives. These advancements marked a pivotal shift in manufacturing capabilities, enabling rapid curing at ambient temperatures and significantly reducing volatile organic compound (VOC) emissions. The 2000s witnessed further refinement with the introduction of dual-cure systems combining different initiation mechanisms to optimize both surface and depth curing.

Recent technological developments have focused on precision control of the polymerization process, with particular emphasis on managing exothermic reactions, minimizing shrinkage, and ensuring uniform curing throughout complex composite structures. Digital monitoring systems and predictive modeling have become increasingly important tools for optimizing cure parameters in real-time, addressing the persistent challenge of achieving consistent quality across varying environmental conditions.

The current research landscape is characterized by efforts to develop more environmentally sustainable curing processes, including water-based systems, bio-derived initiators, and energy-efficient curing equipment. These innovations align with growing regulatory pressures and market demands for greener manufacturing practices while maintaining or improving performance characteristics.

The primary objectives of acrylic resin curing optimization in composite manufacturing center around several key performance indicators: reducing cycle time to increase production efficiency; minimizing energy consumption; ensuring complete and uniform cure throughout the composite structure; controlling exothermic reactions to prevent thermal damage; and achieving consistent mechanical properties in the final product. Additionally, there is growing emphasis on developing curing protocols that accommodate increasingly complex composite geometries and hybrid material systems.

Looking forward, the field is moving toward intelligent curing systems that integrate real-time monitoring, machine learning algorithms, and adaptive control mechanisms to optimize curing parameters dynamically. These smart systems aim to address the inherent variability in raw materials and environmental conditions that have historically challenged quality control in composite manufacturing. The ultimate goal is to establish predictable, repeatable curing processes that maximize material performance while minimizing resource consumption and environmental impact.

Traditional thermal curing methods dominated the industry until the 1980s, when radiation-curing technologies, particularly UV and electron beam systems, began to emerge as viable alternatives. These advancements marked a pivotal shift in manufacturing capabilities, enabling rapid curing at ambient temperatures and significantly reducing volatile organic compound (VOC) emissions. The 2000s witnessed further refinement with the introduction of dual-cure systems combining different initiation mechanisms to optimize both surface and depth curing.

Recent technological developments have focused on precision control of the polymerization process, with particular emphasis on managing exothermic reactions, minimizing shrinkage, and ensuring uniform curing throughout complex composite structures. Digital monitoring systems and predictive modeling have become increasingly important tools for optimizing cure parameters in real-time, addressing the persistent challenge of achieving consistent quality across varying environmental conditions.

The current research landscape is characterized by efforts to develop more environmentally sustainable curing processes, including water-based systems, bio-derived initiators, and energy-efficient curing equipment. These innovations align with growing regulatory pressures and market demands for greener manufacturing practices while maintaining or improving performance characteristics.

The primary objectives of acrylic resin curing optimization in composite manufacturing center around several key performance indicators: reducing cycle time to increase production efficiency; minimizing energy consumption; ensuring complete and uniform cure throughout the composite structure; controlling exothermic reactions to prevent thermal damage; and achieving consistent mechanical properties in the final product. Additionally, there is growing emphasis on developing curing protocols that accommodate increasingly complex composite geometries and hybrid material systems.

Looking forward, the field is moving toward intelligent curing systems that integrate real-time monitoring, machine learning algorithms, and adaptive control mechanisms to optimize curing parameters dynamically. These smart systems aim to address the inherent variability in raw materials and environmental conditions that have historically challenged quality control in composite manufacturing. The ultimate goal is to establish predictable, repeatable curing processes that maximize material performance while minimizing resource consumption and environmental impact.

Market Analysis for Composite Manufacturing Applications

The global composite manufacturing market has been experiencing significant growth, with a market value reaching $90.6 billion in 2022 and projected to grow at a CAGR of 7.8% through 2030. Within this expanding sector, acrylic resin-based composites represent a substantial segment due to their versatility, cost-effectiveness, and performance characteristics. The optimization of acrylic resin curing processes directly impacts product quality, production efficiency, and market competitiveness.

The automotive industry remains one of the largest consumers of composite materials, accounting for approximately 24% of the total market share. The demand for lightweight, high-strength materials to improve fuel efficiency and reduce emissions continues to drive adoption of advanced composite solutions, including those utilizing optimized acrylic resin systems. The aerospace sector follows closely, representing about 18% of market demand, where precise curing processes are critical for meeting stringent safety and performance requirements.

Construction and infrastructure applications constitute another significant market segment at 20%, with growing interest in corrosion-resistant and durable composite materials for bridges, buildings, and other structures. The marine industry, though smaller at 8% of the market, presents unique opportunities for acrylic resin composites due to their excellent water resistance properties when properly cured.

Regional analysis indicates that North America and Europe currently lead in advanced composite manufacturing technologies, including sophisticated acrylic resin curing methods. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by expanding manufacturing capabilities in China, Japan, and South Korea, along with increasing domestic demand for high-performance composite products.

Market trends reveal increasing customer requirements for faster production cycles without compromising quality, creating direct demand for optimized curing technologies. Additionally, environmental regulations are pushing manufacturers toward lower-emission curing processes and more sustainable production methods, with VOC emissions becoming a critical consideration in acrylic resin curing optimization.

Economic analysis suggests that investments in advanced curing technologies typically yield ROI within 18-24 months through reduced cycle times, decreased energy consumption, and improved product consistency. Companies that have implemented optimized curing processes report production efficiency improvements of 15-30% and defect rate reductions of up to 40%, creating significant competitive advantages in price-sensitive market segments.

The market for curing equipment and process control systems is also expanding, with specialized UV curing systems, thermal management solutions, and real-time monitoring technologies experiencing particularly strong growth as manufacturers seek comprehensive optimization solutions for their acrylic resin composite production processes.

The automotive industry remains one of the largest consumers of composite materials, accounting for approximately 24% of the total market share. The demand for lightweight, high-strength materials to improve fuel efficiency and reduce emissions continues to drive adoption of advanced composite solutions, including those utilizing optimized acrylic resin systems. The aerospace sector follows closely, representing about 18% of market demand, where precise curing processes are critical for meeting stringent safety and performance requirements.

Construction and infrastructure applications constitute another significant market segment at 20%, with growing interest in corrosion-resistant and durable composite materials for bridges, buildings, and other structures. The marine industry, though smaller at 8% of the market, presents unique opportunities for acrylic resin composites due to their excellent water resistance properties when properly cured.

Regional analysis indicates that North America and Europe currently lead in advanced composite manufacturing technologies, including sophisticated acrylic resin curing methods. However, the Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, driven by expanding manufacturing capabilities in China, Japan, and South Korea, along with increasing domestic demand for high-performance composite products.

Market trends reveal increasing customer requirements for faster production cycles without compromising quality, creating direct demand for optimized curing technologies. Additionally, environmental regulations are pushing manufacturers toward lower-emission curing processes and more sustainable production methods, with VOC emissions becoming a critical consideration in acrylic resin curing optimization.

Economic analysis suggests that investments in advanced curing technologies typically yield ROI within 18-24 months through reduced cycle times, decreased energy consumption, and improved product consistency. Companies that have implemented optimized curing processes report production efficiency improvements of 15-30% and defect rate reductions of up to 40%, creating significant competitive advantages in price-sensitive market segments.

The market for curing equipment and process control systems is also expanding, with specialized UV curing systems, thermal management solutions, and real-time monitoring technologies experiencing particularly strong growth as manufacturers seek comprehensive optimization solutions for their acrylic resin composite production processes.

Current Curing Techniques and Technical Challenges

Acrylic resin curing in composite manufacturing currently employs several established techniques, each with specific advantages and limitations. Thermal curing remains the most widespread method, utilizing conventional ovens or autoclaves to initiate polymerization through heat application. This approach offers reliability and consistent results but suffers from high energy consumption and lengthy processing times, often requiring 1-4 hours depending on part thickness and resin formulation. The thermal gradients created during heating can also introduce residual stresses and potential warping in finished components.

UV curing represents a faster alternative, where photoinitiators in the resin respond to ultraviolet radiation, enabling curing times of minutes rather than hours. However, this technique faces significant challenges with thick or opaque composites due to limited light penetration depth, typically restricted to 3-5mm in most formulations. This limitation necessitates multiple exposure cycles or hybrid curing approaches for thicker components.

Electron beam curing has emerged as a promising technique for specialized applications, offering rapid processing without photoinitiators. The high-energy electrons can penetrate deeper than UV light, but the equipment costs remain prohibitively expensive for many manufacturers, with initial investments often exceeding $500,000 for industrial-scale systems.

Microwave curing technology has gained attention for its volumetric heating capabilities, potentially eliminating thermal gradients. However, technical challenges persist in achieving uniform electromagnetic field distribution, particularly for complex geometries. Current research indicates that standing waves and hotspots can lead to inconsistent cure profiles and localized overheating.

The industry also faces significant challenges regarding cure monitoring and control. Real-time monitoring systems using dielectric analysis or fiber optic sensors show promise but remain difficult to implement in production environments. The lack of reliable in-situ monitoring creates quality control issues, often resulting in over-curing to ensure complete polymerization, which increases cycle times and energy consumption.

Environmental and regulatory pressures present additional challenges, with increasing restrictions on volatile organic compound (VOC) emissions from traditional acrylic resin systems. Low-VOC formulations typically exhibit different curing kinetics and often require modified processing parameters, creating implementation barriers for manufacturers with established processes.

Scale-up challenges persist when transitioning from laboratory to production environments. Curing behavior can differ significantly between small test specimens and full-scale components due to thermal mass effects and exothermic reaction dynamics. This discrepancy frequently necessitates extensive process revalidation and parameter optimization during industrialization phases.

UV curing represents a faster alternative, where photoinitiators in the resin respond to ultraviolet radiation, enabling curing times of minutes rather than hours. However, this technique faces significant challenges with thick or opaque composites due to limited light penetration depth, typically restricted to 3-5mm in most formulations. This limitation necessitates multiple exposure cycles or hybrid curing approaches for thicker components.

Electron beam curing has emerged as a promising technique for specialized applications, offering rapid processing without photoinitiators. The high-energy electrons can penetrate deeper than UV light, but the equipment costs remain prohibitively expensive for many manufacturers, with initial investments often exceeding $500,000 for industrial-scale systems.

Microwave curing technology has gained attention for its volumetric heating capabilities, potentially eliminating thermal gradients. However, technical challenges persist in achieving uniform electromagnetic field distribution, particularly for complex geometries. Current research indicates that standing waves and hotspots can lead to inconsistent cure profiles and localized overheating.

The industry also faces significant challenges regarding cure monitoring and control. Real-time monitoring systems using dielectric analysis or fiber optic sensors show promise but remain difficult to implement in production environments. The lack of reliable in-situ monitoring creates quality control issues, often resulting in over-curing to ensure complete polymerization, which increases cycle times and energy consumption.

Environmental and regulatory pressures present additional challenges, with increasing restrictions on volatile organic compound (VOC) emissions from traditional acrylic resin systems. Low-VOC formulations typically exhibit different curing kinetics and often require modified processing parameters, creating implementation barriers for manufacturers with established processes.

Scale-up challenges persist when transitioning from laboratory to production environments. Curing behavior can differ significantly between small test specimens and full-scale components due to thermal mass effects and exothermic reaction dynamics. This discrepancy frequently necessitates extensive process revalidation and parameter optimization during industrialization phases.

Existing Optimization Solutions for Acrylic Resin Curing

01 Temperature control in acrylic resin curing

Optimizing the temperature during the curing process of acrylic resins significantly affects the final properties of the material. Controlled heating rates and specific temperature profiles can enhance cross-linking efficiency, reduce curing time, and improve mechanical properties. Advanced temperature control systems that provide precise heating and cooling cycles help achieve consistent curing results and prevent defects such as warping or incomplete polymerization.- Temperature control in acrylic resin curing: Optimizing the temperature during the curing process of acrylic resins significantly impacts the final product quality. Controlled heating rates and specific temperature profiles can enhance cross-linking efficiency while preventing defects like bubbles or stress cracks. Advanced temperature control systems allow for precise thermal management throughout the curing cycle, resulting in improved mechanical properties and dimensional stability of the cured resin.

- Catalyst and initiator systems for acrylic resin curing: The selection and concentration of catalysts and initiators play a crucial role in optimizing acrylic resin curing. Various peroxide-based initiators, metal-based catalysts, and photoinitiators can be employed depending on the specific application requirements. The proper catalyst system can reduce curing time, lower energy consumption, and improve the degree of conversion, resulting in enhanced physical and chemical properties of the final product.

- UV and radiation curing techniques: UV and radiation curing methods offer significant advantages for acrylic resin systems, including rapid curing times, reduced energy consumption, and environmentally friendly processing. These techniques utilize specific photoinitiators that generate free radicals when exposed to UV light or other radiation sources. Optimization of radiation intensity, exposure time, and photoinitiator concentration can lead to improved curing efficiency and superior mechanical properties in the final product.

- Additives and modifiers for improved curing performance: Various additives and modifiers can be incorporated into acrylic resin formulations to enhance curing performance. These include cross-linking agents, stabilizers, accelerators, and reactive diluents. The strategic use of these additives can optimize viscosity during application, improve cure speed, enhance adhesion properties, and increase the overall durability of the cured resin. Careful selection of compatible additives is essential to achieve the desired balance of processing characteristics and final properties.

- Process parameter optimization and monitoring systems: Advanced process control and monitoring systems enable real-time optimization of acrylic resin curing. Parameters such as humidity, pressure, airflow, and curing time can be precisely controlled and adjusted based on feedback from sensors. Implementation of statistical process control methods and machine learning algorithms allows for continuous improvement of curing protocols. These sophisticated monitoring systems help maintain consistent quality while minimizing energy consumption and production costs.

02 Catalyst and initiator systems for acrylic resin curing

The selection and optimization of catalyst and initiator systems play a crucial role in acrylic resin curing. Different types of peroxide initiators, metal-based catalysts, and photoinitiators can be used to control the polymerization rate and degree of cross-linking. The concentration and combination of these components can be adjusted to achieve desired curing speeds, lower curing temperatures, or specific material properties. Advanced catalyst systems enable more efficient energy utilization during the curing process.Expand Specific Solutions03 UV and radiation curing techniques

Ultraviolet (UV) and other radiation-based curing methods offer advantages for acrylic resin systems including rapid curing times, lower energy consumption, and reduced environmental impact. These techniques utilize photoinitiators that generate free radicals when exposed to specific wavelengths of light, initiating the polymerization process. Optimization involves adjusting radiation intensity, exposure time, and photoinitiator concentration to achieve complete curing while maintaining desired material properties. Advanced UV-LED systems provide more precise control over the curing process.Expand Specific Solutions04 Formulation additives for improved curing performance

Various additives can be incorporated into acrylic resin formulations to enhance curing performance and final properties. These include cross-linking agents, stabilizers, accelerators, and modifiers that influence reaction kinetics and network formation. Optimization of these additives can reduce curing shrinkage, improve adhesion, enhance thermal stability, and increase mechanical strength. The synergistic effects between different additives must be carefully balanced to achieve optimal curing results without compromising other material properties.Expand Specific Solutions05 Process monitoring and control systems

Advanced monitoring and control systems enable real-time optimization of acrylic resin curing processes. Technologies such as infrared spectroscopy, dielectric analysis, and rheological measurements can track the progression of curing reactions and provide feedback for process adjustments. Automated systems that integrate multiple parameters including temperature, pressure, and cure degree allow for adaptive control strategies that optimize energy efficiency and product quality. These systems help establish reproducible curing protocols and facilitate quality assurance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Composite Curing

The acrylic resin curing optimization market in composite manufacturing is currently in a growth phase, with an estimated global market size of $3.5-4 billion and projected annual growth of 6-8%. The competitive landscape features established chemical conglomerates like DIC Corp., Arkema France, and Mitsui Chemicals dominating with comprehensive product portfolios, alongside specialized players such as Hexcel Composites and Texas Research International offering niche solutions. Technical maturity varies significantly across applications, with aerospace companies like Boeing and ArianeGroup driving innovation in high-performance composites, while automotive applications (supported by DENSO and LG Chem) are rapidly evolving. Japanese firms (Mitsubishi Rayon, Kaneka) lead in UV-curing technologies, while Chinese manufacturers (CPIC, Shanghai PRET) are gaining market share through cost-effective solutions and increasing R&D investments.

Arkema France SA

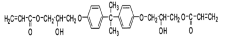

Technical Solution: Arkema has pioneered thermoplastic acrylic resin systems for composites that utilize their patented Elium® technology, which enables room-temperature radical polymerization of liquid acrylic resins. Their innovation centers on peroxide-based initiator systems with controlled decomposition kinetics, allowing precise adjustment of gel times from 1 to 60 minutes depending on manufacturing requirements. The company has developed specialized accelerators that work synergistically with their initiators to achieve complete cure at temperatures as low as 20°C, eliminating the need for energy-intensive post-curing steps. Arkema's formulations incorporate proprietary internal mold release agents and low-shrinkage additives that minimize residual stresses in the final composite parts. Their latest generation systems feature self-healing capabilities through reversible dynamic bonds within the polymer network.

Strengths: Room-temperature curing capability eliminates need for autoclaves or heated molds, recyclability of thermoplastic matrix allows for sustainable manufacturing, and compatibility with existing thermoset composite equipment. Weaknesses: Lower temperature resistance compared to some thermoset systems, and potentially higher raw material costs.

The Boeing Co.

Technical Solution: Boeing has developed proprietary microwave-assisted curing technology for acrylic resins in aerospace composite manufacturing. Their system utilizes specifically designed susceptors embedded within the resin matrix that selectively absorb microwave energy, generating localized heating precisely where needed for polymerization. This approach achieves uniform curing throughout complex geometries with varying thicknesses. Boeing's technology incorporates real-time dielectric monitoring sensors that track the degree of cure throughout the process, enabling adaptive power modulation to optimize cure cycles. Their advanced process control algorithms predict and compensate for exothermic reactions, preventing thermal runaway in thick sections. The company has also engineered specialized vacuum bagging materials compatible with microwave energy fields that maintain consistent pressure during cure while allowing volatile removal.

Strengths: Significantly reduced cure times (up to 80% faster than conventional methods), more uniform heating throughout complex parts, and lower energy consumption compared to autoclave curing. Weaknesses: High initial capital investment for microwave equipment, and potential electromagnetic compatibility issues requiring specialized manufacturing facilities.

Key Innovations in Curing Process Control and Monitoring

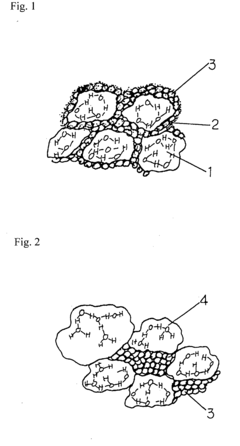

Composite acrylic resin composition

PatentInactiveUS20040209978A1

Innovation

- A composite using a pulverized aggregate with a permanent electric charge, such as garnet, combined with a low-alkaline cement and an acrylic resin emulsion prepared in alkali-ion water with a specific pH and nuclear magnetic resonance signal, enhancing adhesion and strength while reducing permeability and improving curing speed.

Composite material

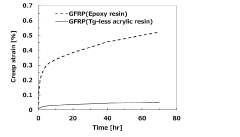

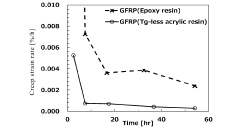

PatentInactiveJP2023061798A

Innovation

- A composite material using a cured acrylic resin composition with a maximum loss tangent tan δ of 0.12 or less, combined with reinforcing fibers, allows for low-temperature curing and reduces creep phenomena, making it suitable for both small and large-sized parts.

Environmental Impact and Sustainability Considerations

The environmental impact of acrylic resin curing processes in composite manufacturing has become increasingly significant as sustainability considerations gain prominence across industries. Traditional curing methods often involve substantial energy consumption, particularly when utilizing thermal curing techniques that require maintaining high temperatures for extended periods. This energy-intensive process contributes significantly to the carbon footprint of composite manufacturing operations, raising concerns about greenhouse gas emissions and climate change impacts.

Volatile organic compound (VOC) emissions represent another critical environmental challenge associated with acrylic resin curing. During the curing process, these compounds are released into the atmosphere, contributing to air pollution and potentially affecting both worker health and surrounding communities. Recent regulatory frameworks in major manufacturing regions have imposed increasingly stringent limitations on permissible VOC emissions, compelling manufacturers to seek alternative curing technologies and formulations.

Waste generation throughout the acrylic resin curing lifecycle presents additional sustainability challenges. Incomplete curing, quality control rejections, and excess material usage all contribute to manufacturing waste streams that may contain partially polymerized resins and various additives. These materials often require specialized disposal procedures and may present environmental hazards if improperly managed. The development of more efficient curing processes that minimize waste generation represents a significant opportunity for environmental improvement.

Water consumption and potential contamination issues also merit consideration in acrylic resin curing operations. Certain manufacturing processes utilize water for cooling or as part of post-curing treatments, creating potential pathways for contamination if process waters are not properly managed. Advanced water recycling systems and closed-loop processing approaches offer promising solutions to mitigate these impacts.

The transition toward more sustainable curing technologies has gained momentum in recent years, with UV-curing systems emerging as a particularly promising alternative. These systems typically consume significantly less energy than thermal curing methods and can reduce VOC emissions substantially. Additionally, bio-based acrylic resins derived from renewable resources are being developed as alternatives to petroleum-based formulations, potentially reducing the overall carbon footprint of composite materials.

Life cycle assessment (LCA) methodologies have become increasingly important tools for evaluating the comprehensive environmental impacts of different acrylic resin curing approaches. These assessments consider impacts across the entire product lifecycle, from raw material extraction through manufacturing, use, and eventual disposal or recycling. LCA data increasingly informs both regulatory compliance strategies and market positioning, as customers and end-users demonstrate growing preference for environmentally responsible manufacturing processes.

Volatile organic compound (VOC) emissions represent another critical environmental challenge associated with acrylic resin curing. During the curing process, these compounds are released into the atmosphere, contributing to air pollution and potentially affecting both worker health and surrounding communities. Recent regulatory frameworks in major manufacturing regions have imposed increasingly stringent limitations on permissible VOC emissions, compelling manufacturers to seek alternative curing technologies and formulations.

Waste generation throughout the acrylic resin curing lifecycle presents additional sustainability challenges. Incomplete curing, quality control rejections, and excess material usage all contribute to manufacturing waste streams that may contain partially polymerized resins and various additives. These materials often require specialized disposal procedures and may present environmental hazards if improperly managed. The development of more efficient curing processes that minimize waste generation represents a significant opportunity for environmental improvement.

Water consumption and potential contamination issues also merit consideration in acrylic resin curing operations. Certain manufacturing processes utilize water for cooling or as part of post-curing treatments, creating potential pathways for contamination if process waters are not properly managed. Advanced water recycling systems and closed-loop processing approaches offer promising solutions to mitigate these impacts.

The transition toward more sustainable curing technologies has gained momentum in recent years, with UV-curing systems emerging as a particularly promising alternative. These systems typically consume significantly less energy than thermal curing methods and can reduce VOC emissions substantially. Additionally, bio-based acrylic resins derived from renewable resources are being developed as alternatives to petroleum-based formulations, potentially reducing the overall carbon footprint of composite materials.

Life cycle assessment (LCA) methodologies have become increasingly important tools for evaluating the comprehensive environmental impacts of different acrylic resin curing approaches. These assessments consider impacts across the entire product lifecycle, from raw material extraction through manufacturing, use, and eventual disposal or recycling. LCA data increasingly informs both regulatory compliance strategies and market positioning, as customers and end-users demonstrate growing preference for environmentally responsible manufacturing processes.

Quality Assurance and Testing Protocols for Cured Composites

Quality assurance and testing protocols are essential components in the optimization of acrylic resin curing processes for composite manufacturing. These protocols ensure that the final cured composites meet industry standards and performance requirements while maintaining consistency across production batches.

The foundation of effective quality assurance begins with standardized testing methodologies that evaluate key performance indicators of cured acrylic composites. These include mechanical property tests such as flexural strength, tensile strength, and impact resistance measurements according to ASTM D790, D638, and D256 standards respectively. Thermal analysis techniques, particularly Differential Scanning Calorimetry (DSC) and Dynamic Mechanical Analysis (DMA), provide critical data on the degree of cure and glass transition temperature, which directly correlate to the optimization of curing parameters.

Non-destructive testing (NDT) methods have emerged as valuable tools for quality control in acrylic composite manufacturing. Ultrasonic inspection can detect internal voids or delaminations, while infrared thermography identifies areas of inconsistent cure through thermal pattern analysis. These techniques allow manufacturers to verify cure uniformity without sacrificing production parts.

Real-time monitoring systems represent the cutting edge of quality assurance for acrylic resin curing. Dielectric analysis (DEA) sensors embedded within the composite during manufacturing can track the progression of cure by measuring changes in ionic mobility. Similarly, fiber optic sensors provide temperature and strain data from within the composite structure during the curing process, enabling immediate adjustments to optimize cure parameters.

Statistical process control (SPC) methodologies should be implemented to establish control limits for critical cure parameters such as temperature profiles, pressure application, and cure time. By continuously monitoring these variables against established baselines, manufacturers can identify process drift before it results in defective parts, significantly reducing waste and improving production efficiency.

Accelerated aging tests are crucial for predicting long-term performance of cured acrylic composites. Environmental chambers simulating UV exposure, temperature cycling, and humidity conditions can compress years of service conditions into weeks of testing, providing valuable data on the durability of the curing process optimization strategies.

Documentation and traceability systems form the final component of comprehensive quality assurance protocols. Digital systems that record cure parameters, test results, and material batch information create an auditable trail that supports both continuous improvement initiatives and regulatory compliance requirements in industries such as aerospace, automotive, and medical device manufacturing.

The foundation of effective quality assurance begins with standardized testing methodologies that evaluate key performance indicators of cured acrylic composites. These include mechanical property tests such as flexural strength, tensile strength, and impact resistance measurements according to ASTM D790, D638, and D256 standards respectively. Thermal analysis techniques, particularly Differential Scanning Calorimetry (DSC) and Dynamic Mechanical Analysis (DMA), provide critical data on the degree of cure and glass transition temperature, which directly correlate to the optimization of curing parameters.

Non-destructive testing (NDT) methods have emerged as valuable tools for quality control in acrylic composite manufacturing. Ultrasonic inspection can detect internal voids or delaminations, while infrared thermography identifies areas of inconsistent cure through thermal pattern analysis. These techniques allow manufacturers to verify cure uniformity without sacrificing production parts.

Real-time monitoring systems represent the cutting edge of quality assurance for acrylic resin curing. Dielectric analysis (DEA) sensors embedded within the composite during manufacturing can track the progression of cure by measuring changes in ionic mobility. Similarly, fiber optic sensors provide temperature and strain data from within the composite structure during the curing process, enabling immediate adjustments to optimize cure parameters.

Statistical process control (SPC) methodologies should be implemented to establish control limits for critical cure parameters such as temperature profiles, pressure application, and cure time. By continuously monitoring these variables against established baselines, manufacturers can identify process drift before it results in defective parts, significantly reducing waste and improving production efficiency.

Accelerated aging tests are crucial for predicting long-term performance of cured acrylic composites. Environmental chambers simulating UV exposure, temperature cycling, and humidity conditions can compress years of service conditions into weeks of testing, providing valuable data on the durability of the curing process optimization strategies.

Documentation and traceability systems form the final component of comprehensive quality assurance protocols. Digital systems that record cure parameters, test results, and material batch information create an auditable trail that supports both continuous improvement initiatives and regulatory compliance requirements in industries such as aerospace, automotive, and medical device manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!