How to Optimize Acrylic Resin Curing in 3D Printing Applications

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Curing Technology Background and Objectives

Acrylic resin curing technology in 3D printing has evolved significantly over the past two decades, transforming from experimental applications to mainstream manufacturing processes. The technology originated in the 1980s with the development of stereolithography (SLA), but has seen accelerated advancement since the early 2000s with the introduction of digital light processing (DLP) and more recently with continuous liquid interface production (CLIP) technologies. These developments have progressively improved resolution, speed, and material properties of printed objects.

The fundamental principle behind acrylic resin curing involves photopolymerization, where liquid monomers and oligomers are converted into solid polymers through exposure to specific wavelengths of light. This process has been continuously refined to address challenges such as oxygen inhibition, shrinkage, and thermal stress during curing, which have historically limited the dimensional accuracy and mechanical properties of printed parts.

Current technological trends indicate a shift toward more environmentally friendly formulations with reduced volatile organic compounds (VOCs) and improved biocompatibility for medical applications. Additionally, there is growing interest in dual-cure systems that combine photopolymerization with thermal or moisture-curing mechanisms to enhance mechanical properties and post-processing options.

The primary objectives for optimizing acrylic resin curing in 3D printing applications include: reducing curing times without compromising structural integrity; enhancing resolution capabilities to enable more intricate geometries; improving the uniformity of curing across varying part thicknesses; and developing more robust post-processing methods to achieve desired surface finishes and mechanical properties.

Another critical goal is to expand the functional range of cured acrylic resins, particularly in terms of heat resistance, chemical stability, and mechanical durability. This expansion would enable broader industrial applications beyond current limitations, especially in automotive, aerospace, and consumer electronics sectors where high-performance materials are essential.

Energy efficiency represents another important objective, as current curing processes can be energy-intensive. Innovations in LED technology and more efficient photoinitiators are being explored to reduce the energy footprint of the curing process while maintaining or improving curing speed and quality.

The integration of real-time monitoring and feedback systems during the curing process is emerging as a key development area. These systems aim to optimize curing parameters dynamically based on part geometry, resin characteristics, and environmental conditions, potentially revolutionizing quality control and repeatability in acrylic resin 3D printing applications.

The fundamental principle behind acrylic resin curing involves photopolymerization, where liquid monomers and oligomers are converted into solid polymers through exposure to specific wavelengths of light. This process has been continuously refined to address challenges such as oxygen inhibition, shrinkage, and thermal stress during curing, which have historically limited the dimensional accuracy and mechanical properties of printed parts.

Current technological trends indicate a shift toward more environmentally friendly formulations with reduced volatile organic compounds (VOCs) and improved biocompatibility for medical applications. Additionally, there is growing interest in dual-cure systems that combine photopolymerization with thermal or moisture-curing mechanisms to enhance mechanical properties and post-processing options.

The primary objectives for optimizing acrylic resin curing in 3D printing applications include: reducing curing times without compromising structural integrity; enhancing resolution capabilities to enable more intricate geometries; improving the uniformity of curing across varying part thicknesses; and developing more robust post-processing methods to achieve desired surface finishes and mechanical properties.

Another critical goal is to expand the functional range of cured acrylic resins, particularly in terms of heat resistance, chemical stability, and mechanical durability. This expansion would enable broader industrial applications beyond current limitations, especially in automotive, aerospace, and consumer electronics sectors where high-performance materials are essential.

Energy efficiency represents another important objective, as current curing processes can be energy-intensive. Innovations in LED technology and more efficient photoinitiators are being explored to reduce the energy footprint of the curing process while maintaining or improving curing speed and quality.

The integration of real-time monitoring and feedback systems during the curing process is emerging as a key development area. These systems aim to optimize curing parameters dynamically based on part geometry, resin characteristics, and environmental conditions, potentially revolutionizing quality control and repeatability in acrylic resin 3D printing applications.

Market Analysis for Optimized 3D Printing Resins

The global market for 3D printing resins, particularly acrylic-based formulations, has experienced significant growth in recent years, driven by expanding applications across industries such as healthcare, automotive, aerospace, and consumer goods. The market for photopolymer resins used in 3D printing was valued at approximately $1.5 billion in 2022 and is projected to grow at a compound annual growth rate of 17% through 2028.

Demand for optimized acrylic resins is particularly strong in the dental and medical sectors, where precision, biocompatibility, and mechanical properties are critical. The dental 3D printing market alone is expected to reach $7.9 billion by 2027, with a substantial portion attributed to acrylic-based materials for dental models, surgical guides, and prosthetics.

Consumer preferences are increasingly shifting toward materials that offer faster curing times without compromising structural integrity or surface finish quality. Market research indicates that manufacturers who can reduce curing times by 30-40% while maintaining or improving mechanical properties gain significant competitive advantage, with potential price premiums of 15-25% over standard formulations.

Environmental considerations are becoming increasingly important market drivers. Regulations limiting volatile organic compound (VOC) emissions and growing consumer awareness have created demand for low-odor, low-toxicity formulations. Companies offering environmentally friendly alternatives have reported sales growth rates 2.5 times higher than those of conventional products in certain regions, particularly Europe and North America.

Regional analysis shows Asia-Pacific as the fastest-growing market for optimized 3D printing resins, with China and Japan leading adoption. North America remains the largest market by value, particularly for high-performance applications requiring specialized curing processes. European markets show strong preference for environmentally sustainable formulations with optimized energy consumption during the curing process.

Price sensitivity varies significantly by application segment. Industrial prototyping remains highly price-sensitive, while medical and aerospace applications demonstrate willingness to pay premium prices for materials with superior curing characteristics and certified performance properties. The average price premium for optimized curing resins ranges from 20-45% depending on the specific performance advantages and application requirements.

Market forecasts indicate that innovations in curing technology will continue to drive material development, with particular growth expected in dual-cure systems that combine UV and thermal curing mechanisms to optimize both processing speed and material properties. This segment is projected to grow at 22% annually through 2028, outpacing the broader market.

Demand for optimized acrylic resins is particularly strong in the dental and medical sectors, where precision, biocompatibility, and mechanical properties are critical. The dental 3D printing market alone is expected to reach $7.9 billion by 2027, with a substantial portion attributed to acrylic-based materials for dental models, surgical guides, and prosthetics.

Consumer preferences are increasingly shifting toward materials that offer faster curing times without compromising structural integrity or surface finish quality. Market research indicates that manufacturers who can reduce curing times by 30-40% while maintaining or improving mechanical properties gain significant competitive advantage, with potential price premiums of 15-25% over standard formulations.

Environmental considerations are becoming increasingly important market drivers. Regulations limiting volatile organic compound (VOC) emissions and growing consumer awareness have created demand for low-odor, low-toxicity formulations. Companies offering environmentally friendly alternatives have reported sales growth rates 2.5 times higher than those of conventional products in certain regions, particularly Europe and North America.

Regional analysis shows Asia-Pacific as the fastest-growing market for optimized 3D printing resins, with China and Japan leading adoption. North America remains the largest market by value, particularly for high-performance applications requiring specialized curing processes. European markets show strong preference for environmentally sustainable formulations with optimized energy consumption during the curing process.

Price sensitivity varies significantly by application segment. Industrial prototyping remains highly price-sensitive, while medical and aerospace applications demonstrate willingness to pay premium prices for materials with superior curing characteristics and certified performance properties. The average price premium for optimized curing resins ranges from 20-45% depending on the specific performance advantages and application requirements.

Market forecasts indicate that innovations in curing technology will continue to drive material development, with particular growth expected in dual-cure systems that combine UV and thermal curing mechanisms to optimize both processing speed and material properties. This segment is projected to grow at 22% annually through 2028, outpacing the broader market.

Current Challenges in Acrylic Resin Curing Processes

Despite significant advancements in 3D printing technologies, acrylic resin curing processes continue to face several critical challenges that limit the full potential of this manufacturing method. One of the primary obstacles is achieving uniform curing throughout the printed object. The photopolymerization process often results in uneven curing, with surface layers receiving more light exposure than internal structures. This creates mechanical property variations within the same printed part, leading to inconsistent performance and potential structural weaknesses.

Temperature control during the curing process presents another significant challenge. Acrylic resins are highly sensitive to temperature fluctuations, which can dramatically affect viscosity, flow characteristics, and ultimately curing behavior. Exothermic reactions during polymerization can create localized hotspots, causing internal stresses, warping, and dimensional inaccuracies in the final product.

Oxygen inhibition remains a persistent issue in acrylic resin curing. When exposed to atmospheric oxygen, free radicals generated during the photopolymerization process are scavenged, significantly reducing curing efficiency at surfaces exposed to air. This inhibition layer creates tacky surfaces requiring post-processing and compromises the mechanical integrity of printed parts at air-resin interfaces.

Light penetration depth limitations constrain the curing process, particularly for thicker or more complex geometries. As light travels through the resin, its intensity diminishes exponentially due to absorption and scattering effects. This phenomenon, known as the Beer-Lambert effect, results in decreasing curing efficiency with depth, limiting the maximum thickness achievable in a single curing cycle.

The formulation complexity of acrylic resins presents additional challenges. Modern printing applications demand increasingly specialized material properties, requiring complex resin formulations with multiple photoinitiators, monomers, oligomers, and additives. Balancing these components to achieve optimal curing while maintaining desired mechanical, optical, and thermal properties remains extremely difficult.

Post-curing requirements add complexity to the manufacturing workflow. Most acrylic resin prints require secondary UV exposure to complete polymerization and achieve optimal mechanical properties. This additional step introduces variability, extends production time, and complicates quality control procedures.

Environmental and health concerns also pose significant challenges. Many acrylic resins and their components are classified as irritants or potential sensitizers, requiring careful handling protocols. Volatile organic compounds released during printing and curing raise indoor air quality concerns, while uncured resin waste presents environmental disposal challenges that must be addressed for sustainable manufacturing practices.

Temperature control during the curing process presents another significant challenge. Acrylic resins are highly sensitive to temperature fluctuations, which can dramatically affect viscosity, flow characteristics, and ultimately curing behavior. Exothermic reactions during polymerization can create localized hotspots, causing internal stresses, warping, and dimensional inaccuracies in the final product.

Oxygen inhibition remains a persistent issue in acrylic resin curing. When exposed to atmospheric oxygen, free radicals generated during the photopolymerization process are scavenged, significantly reducing curing efficiency at surfaces exposed to air. This inhibition layer creates tacky surfaces requiring post-processing and compromises the mechanical integrity of printed parts at air-resin interfaces.

Light penetration depth limitations constrain the curing process, particularly for thicker or more complex geometries. As light travels through the resin, its intensity diminishes exponentially due to absorption and scattering effects. This phenomenon, known as the Beer-Lambert effect, results in decreasing curing efficiency with depth, limiting the maximum thickness achievable in a single curing cycle.

The formulation complexity of acrylic resins presents additional challenges. Modern printing applications demand increasingly specialized material properties, requiring complex resin formulations with multiple photoinitiators, monomers, oligomers, and additives. Balancing these components to achieve optimal curing while maintaining desired mechanical, optical, and thermal properties remains extremely difficult.

Post-curing requirements add complexity to the manufacturing workflow. Most acrylic resin prints require secondary UV exposure to complete polymerization and achieve optimal mechanical properties. This additional step introduces variability, extends production time, and complicates quality control procedures.

Environmental and health concerns also pose significant challenges. Many acrylic resins and their components are classified as irritants or potential sensitizers, requiring careful handling protocols. Volatile organic compounds released during printing and curing raise indoor air quality concerns, while uncured resin waste presents environmental disposal challenges that must be addressed for sustainable manufacturing practices.

Current Curing Methodologies and Parameters

01 Temperature control in acrylic resin curing

Optimizing the temperature during the curing process of acrylic resins significantly impacts the final product quality. Controlled heating rates and specific temperature profiles can enhance cross-linking efficiency while preventing defects like bubbles or stress cracks. Advanced temperature control systems allow for precise thermal management throughout the curing cycle, resulting in improved mechanical properties and dimensional stability of the cured resin.- Temperature control in acrylic resin curing: Optimizing the temperature during the curing process of acrylic resins significantly impacts the final product quality. Controlled heating rates and specific temperature profiles can enhance crosslinking density and mechanical properties. Advanced temperature control systems allow for precise thermal management throughout the curing cycle, reducing defects and ensuring consistent polymerization. This approach can be particularly effective for thick sections where heat distribution is critical.

- Catalyst and initiator systems for acrylic resin curing: The selection and concentration of catalysts and initiators play a crucial role in optimizing acrylic resin curing. Different initiator systems can be employed to control reaction kinetics, pot life, and cure speed. Peroxide-based initiators, metal catalysts, and photoinitiators offer various advantages depending on the application requirements. Synergistic combinations of multiple catalysts can provide balanced curing profiles with improved efficiency and reduced energy consumption.

- UV and radiation curing techniques: UV and radiation curing methods offer rapid polymerization of acrylic resins with reduced energy consumption. These techniques enable precise control over the curing process, resulting in improved surface properties and reduced shrinkage. Photoinitiators can be optimized to match specific wavelengths of light, enhancing curing efficiency. Advanced UV-LED systems provide more uniform curing with less heat generation compared to traditional mercury lamps, making them suitable for heat-sensitive substrates.

- Additives and modifiers for improved curing performance: Various additives and modifiers can enhance the curing performance of acrylic resins. These include crosslinking agents, reactive diluents, and stabilizers that improve flow properties and final mechanical characteristics. Nanoparticles and reinforcing fillers can be incorporated to enhance thermal conductivity and mechanical strength. Specialty additives can reduce shrinkage during curing, minimize stress development, and improve adhesion to various substrates.

- Environmental and energy-efficient curing methods: Environmentally friendly and energy-efficient curing methods for acrylic resins include water-based systems, low-VOC formulations, and ambient temperature curing technologies. These approaches reduce environmental impact while maintaining performance properties. Microwave and infrared curing techniques offer energy savings through targeted heating. Two-component systems that cure at room temperature eliminate the need for external heat sources, reducing energy consumption and carbon footprint in manufacturing processes.

02 Catalyst and initiator systems for acrylic resin curing

The selection and concentration of catalysts and initiators play a crucial role in optimizing acrylic resin curing. Various peroxide-based initiators, metal-based catalysts, and photoinitiators can be employed depending on the specific application requirements. The proper catalyst system can reduce curing time, lower energy consumption, and improve the cross-linking density of the final product, resulting in enhanced mechanical and chemical resistance properties.Expand Specific Solutions03 UV and radiation curing techniques

UV and radiation curing methods offer rapid and energy-efficient alternatives for acrylic resin curing. These techniques utilize specific wavelengths of light or radiation to initiate polymerization reactions, allowing for faster production cycles and reduced energy consumption. Advanced UV-LED systems and controlled radiation exposure can optimize cross-linking density while minimizing heat-related defects, making them particularly suitable for heat-sensitive substrates and applications requiring precise curing control.Expand Specific Solutions04 Additives and modifiers for improved curing performance

Various additives and modifiers can be incorporated into acrylic resin formulations to enhance curing performance. These include cross-linking agents, stabilizers, accelerators, and reactive diluents that can optimize viscosity, improve flow characteristics, and enhance the final properties of the cured material. Careful selection of these components can address specific challenges such as shrinkage control, adhesion improvement, and enhanced weatherability of the cured acrylic resin systems.Expand Specific Solutions05 Process optimization and monitoring techniques

Advanced process monitoring and control techniques are essential for optimizing acrylic resin curing. Real-time monitoring systems using spectroscopic methods, rheological measurements, and thermal analysis can provide valuable data on the curing progress. Implementing statistical process control and machine learning algorithms enables adaptive curing protocols that respond to variations in raw materials and environmental conditions, ensuring consistent quality and performance of the final cured acrylic resin products.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The acrylic resin curing optimization in 3D printing market is currently in a growth phase, with increasing adoption across industrial and consumer applications. The global market size is expanding rapidly, driven by advancements in additive manufacturing technologies. Technical maturity varies significantly among key players, with companies like PhiChem Corp., Arkema France SA, and Huntsman Advanced Materials leading with advanced formulations. Chinese companies including Shenzhen Yongchanghe Technology, Guangdong Bossin Novel Materials, and Farsoon Technologies are rapidly closing the technology gap. Academic institutions such as Jiangnan University, Shenzhen University, and UESTC are contributing significant research to improve curing processes. The competitive landscape shows a blend of established chemical corporations and specialized 3D printing material developers competing to address challenges in curing speed, precision, and material properties.

Shenzhen University

Technical Solution: Shenzhen University's research team has developed an innovative approach to acrylic resin curing for 3D printing applications through their "Adaptive Network Formation" technology. Their method employs a carefully designed mixture of mono-, di-, and tri-functional acrylate monomers that form interpenetrating polymer networks with controlled cross-linking density. The university's research has pioneered the use of thiol-ene click chemistry in conjunction with traditional free-radical polymerization, resulting in significantly reduced oxygen inhibition and improved surface cure. Their system incorporates photoinitiators with different absorption spectra and quantum yields, enabling sequential activation during the curing process. This staged polymerization approach minimizes internal stress and shrinkage. Shenzhen University has also developed a novel post-processing technique using supercritical CO2 to extract unreacted monomers while simultaneously enhancing the mechanical properties of the printed parts through controlled swelling and relaxation of the polymer network.

Strengths: Excellent balance between toughness and rigidity in cured parts; significantly reduced oxygen inhibition at surfaces; minimal volumetric shrinkage during curing. Weaknesses: Complex formulations requiring precise mixing ratios; longer processing times compared to conventional systems; currently limited to laboratory-scale production.

Arkema France SA

Technical Solution: Arkema has developed the N3xtDimension® photocurable resins specifically optimized for 3D printing applications. Their technology focuses on dual-cure mechanisms combining UV-initiated radical polymerization with thermal post-curing to achieve optimal mechanical properties. The company employs proprietary photoinitiator systems that enable rapid curing at specific wavelengths (365-405nm) while maintaining excellent depth penetration. Their formulations incorporate oligomers with carefully controlled molecular weight distributions to balance viscosity and reactivity. Arkema has also pioneered temperature-controlled curing chambers that maintain precise thermal conditions during the polymerization process, resulting in more uniform cross-linking density and reduced internal stress. Their latest innovation includes oxygen-inhibition resistant formulations that cure effectively even in ambient conditions without requiring inert atmospheres.

Strengths: Superior mechanical properties with high impact resistance and elongation at break; excellent dimensional stability with minimal shrinkage during curing; versatile formulations adaptable to various printing technologies. Weaknesses: Higher cost compared to standard resins; some formulations require specialized curing equipment; longer post-processing times for optimal properties.

Key Patents and Innovations in Resin Curing

Curable compositions including a polyester (METH)acrylate oligomer

PatentPendingEP4574858A1

Innovation

- A curable composition comprising a free radical polymerizable resin with a polyester (meth)acrylate oligomer, a cationically polymerizable resin, a free radical photoinitiator, and a photoacid generator, which provides a hybrid curing mechanism to enhance mechanical properties while minimizing adverse effects on cure time and strength.

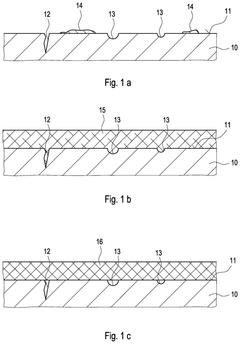

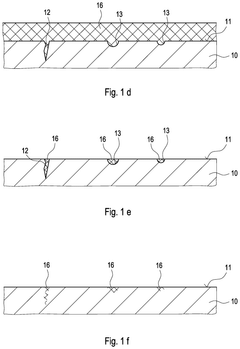

Method for the post-treatment of printed 3D objects

PatentPendingUS20240375363A1

Innovation

- A method involving exposure of the 3-D object to an aftertreatment fluid that penetrates into fissures and pores due to capillarity, followed by removal of the fluid and subsequent light irradiation for post-curing, ensuring improved surface quality and increased strength.

Environmental Impact and Sustainability Considerations

The optimization of acrylic resin curing in 3D printing applications carries significant environmental implications that warrant careful consideration. Traditional photopolymer resins often contain potentially harmful chemicals, including photoinitiators, monomers, and oligomers that can pose environmental hazards if improperly handled or disposed of. The uncured resin waste, in particular, represents a substantial environmental concern as it can contaminate water systems and harm aquatic ecosystems if released untreated.

Energy consumption during the curing process presents another environmental challenge. UV curing systems, especially high-powered industrial units, consume considerable electricity, contributing to carbon emissions when powered by non-renewable energy sources. The development of more energy-efficient curing technologies, such as LED-based systems that operate at specific wavelengths, offers promising reductions in energy usage while maintaining effective polymerization.

Material efficiency in the curing process directly impacts sustainability metrics. Optimized curing parameters can significantly reduce material waste by minimizing the amount of uncured resin requiring disposal. Advanced process control systems that precisely deliver the necessary energy for complete polymerization without excess can improve both environmental performance and economic efficiency, creating a dual benefit for manufacturers.

Recent innovations in bio-based acrylic resins represent a significant advancement toward sustainability. These formulations incorporate renewable raw materials derived from plant sources rather than petroleum-based compounds, reducing the carbon footprint associated with resin production. Some manufacturers have successfully developed partially bio-based resins with comparable mechanical properties to conventional alternatives, though challenges remain in achieving fully bio-based solutions with equivalent performance characteristics.

Post-processing waste management constitutes a critical aspect of environmental stewardship in 3D printing operations. Implementing closed-loop systems for solvent recovery and reuse can dramatically reduce hazardous waste generation. Additionally, emerging technologies for biodegradable support structures and water-soluble cleaning solutions offer pathways to minimize environmental impact during the finishing stages of production.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of additive manufacturing materials. The European Union's REACH regulations and similar initiatives globally are driving manufacturers toward greener formulations with reduced volatile organic compounds (VOCs) and hazardous air pollutants. Forward-thinking companies are proactively reformulating their resins to meet or exceed these regulatory requirements, positioning sustainability as a competitive advantage rather than merely a compliance obligation.

Energy consumption during the curing process presents another environmental challenge. UV curing systems, especially high-powered industrial units, consume considerable electricity, contributing to carbon emissions when powered by non-renewable energy sources. The development of more energy-efficient curing technologies, such as LED-based systems that operate at specific wavelengths, offers promising reductions in energy usage while maintaining effective polymerization.

Material efficiency in the curing process directly impacts sustainability metrics. Optimized curing parameters can significantly reduce material waste by minimizing the amount of uncured resin requiring disposal. Advanced process control systems that precisely deliver the necessary energy for complete polymerization without excess can improve both environmental performance and economic efficiency, creating a dual benefit for manufacturers.

Recent innovations in bio-based acrylic resins represent a significant advancement toward sustainability. These formulations incorporate renewable raw materials derived from plant sources rather than petroleum-based compounds, reducing the carbon footprint associated with resin production. Some manufacturers have successfully developed partially bio-based resins with comparable mechanical properties to conventional alternatives, though challenges remain in achieving fully bio-based solutions with equivalent performance characteristics.

Post-processing waste management constitutes a critical aspect of environmental stewardship in 3D printing operations. Implementing closed-loop systems for solvent recovery and reuse can dramatically reduce hazardous waste generation. Additionally, emerging technologies for biodegradable support structures and water-soluble cleaning solutions offer pathways to minimize environmental impact during the finishing stages of production.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of additive manufacturing materials. The European Union's REACH regulations and similar initiatives globally are driving manufacturers toward greener formulations with reduced volatile organic compounds (VOCs) and hazardous air pollutants. Forward-thinking companies are proactively reformulating their resins to meet or exceed these regulatory requirements, positioning sustainability as a competitive advantage rather than merely a compliance obligation.

Post-Processing Techniques for Enhanced Material Properties

Post-processing techniques have emerged as critical components in optimizing acrylic resin curing for 3D printing applications. These techniques significantly enhance the mechanical properties, durability, and overall performance of printed objects beyond what is achievable through the primary curing process alone.

UV post-curing represents the most widely adopted technique, involving the exposure of printed parts to controlled UV light environments after initial printing. This secondary curing process completes the polymerization of any unreacted monomers, resulting in improved tensile strength, reduced brittleness, and enhanced dimensional stability. Advanced UV post-curing chambers now offer precise control over intensity, wavelength, and exposure duration, allowing for customized material property development.

Thermal post-processing has demonstrated remarkable efficacy in stress relief and property enhancement. By subjecting printed components to carefully controlled heating cycles, internal stresses accumulated during printing can be effectively released. Research indicates that thermal treatments between 60-80°C for acrylic resins can increase flexural strength by up to 25% while simultaneously improving impact resistance properties.

Chemical post-processing techniques involve immersing printed parts in specialized solutions to modify surface characteristics and internal structures. Solvent smoothing using controlled exposure to compatible solvents like acetone or isopropyl alcohol can eliminate layer lines while maintaining dimensional accuracy. More advanced chemical treatments can introduce cross-linking agents that fundamentally alter the polymer network structure, resulting in superior chemical resistance and thermal stability.

Hybrid post-processing approaches combining multiple techniques have shown particularly promising results. Sequential application of thermal treatment followed by UV post-curing has been demonstrated to achieve synergistic improvements in material properties that exceed those obtained through either technique alone. Research from leading materials science institutions indicates that such hybrid approaches can increase the heat deflection temperature of acrylic resins by up to 40%.

Emerging technologies in post-processing include microwave-assisted curing, which enables more uniform heating throughout the part volume, and atmospheric plasma treatments that can selectively modify surface properties without affecting bulk characteristics. These advanced techniques offer unprecedented control over the final material properties of acrylic resin prints.

The selection of appropriate post-processing techniques must be guided by the specific application requirements, as each approach offers distinct advantages and potential trade-offs in terms of processing time, equipment costs, and resultant material properties.

UV post-curing represents the most widely adopted technique, involving the exposure of printed parts to controlled UV light environments after initial printing. This secondary curing process completes the polymerization of any unreacted monomers, resulting in improved tensile strength, reduced brittleness, and enhanced dimensional stability. Advanced UV post-curing chambers now offer precise control over intensity, wavelength, and exposure duration, allowing for customized material property development.

Thermal post-processing has demonstrated remarkable efficacy in stress relief and property enhancement. By subjecting printed components to carefully controlled heating cycles, internal stresses accumulated during printing can be effectively released. Research indicates that thermal treatments between 60-80°C for acrylic resins can increase flexural strength by up to 25% while simultaneously improving impact resistance properties.

Chemical post-processing techniques involve immersing printed parts in specialized solutions to modify surface characteristics and internal structures. Solvent smoothing using controlled exposure to compatible solvents like acetone or isopropyl alcohol can eliminate layer lines while maintaining dimensional accuracy. More advanced chemical treatments can introduce cross-linking agents that fundamentally alter the polymer network structure, resulting in superior chemical resistance and thermal stability.

Hybrid post-processing approaches combining multiple techniques have shown particularly promising results. Sequential application of thermal treatment followed by UV post-curing has been demonstrated to achieve synergistic improvements in material properties that exceed those obtained through either technique alone. Research from leading materials science institutions indicates that such hybrid approaches can increase the heat deflection temperature of acrylic resins by up to 40%.

Emerging technologies in post-processing include microwave-assisted curing, which enables more uniform heating throughout the part volume, and atmospheric plasma treatments that can selectively modify surface properties without affecting bulk characteristics. These advanced techniques offer unprecedented control over the final material properties of acrylic resin prints.

The selection of appropriate post-processing techniques must be guided by the specific application requirements, as each approach offers distinct advantages and potential trade-offs in terms of processing time, equipment costs, and resultant material properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!