How to Minimize Acrylic Resin Microcracking in Thin Films

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Microcracking Background and Objectives

Acrylic resins have been widely utilized in thin film applications since their commercial introduction in the 1930s. Initially developed as alternatives to natural polymers, these versatile materials quickly gained prominence across multiple industries due to their exceptional optical clarity, weatherability, and processing characteristics. The evolution of acrylic resin technology has been marked by continuous improvements in formulation chemistry, with significant advancements occurring during the 1960s and 1980s when manufacturers developed specialized grades for coating applications.

The microcracking phenomenon in acrylic thin films represents a persistent challenge that has become increasingly critical as applications demand ever-thinner coatings with superior performance characteristics. Historically, this issue became particularly prominent in the 1990s as electronic devices and optical applications began requiring films below 100 microns in thickness, where traditional formulations exhibited increased susceptibility to environmental and mechanical stresses.

Recent technological trends indicate a growing emphasis on nano-engineered acrylic systems, with particular focus on controlling polymer chain architecture and cross-linking density to enhance crack resistance. The incorporation of elastomeric components and the development of hybrid organic-inorganic systems represent emerging approaches that have shown promising results in laboratory settings since 2015, though commercial implementation remains limited.

The primary objective of this technical investigation is to comprehensively evaluate current methodologies for minimizing microcracking in acrylic resin thin films, with particular emphasis on films under 50 microns in thickness. Specifically, we aim to identify the fundamental mechanisms driving crack initiation and propagation, assess the effectiveness of existing mitigation strategies, and explore novel approaches that could potentially overcome current limitations.

Secondary objectives include quantifying the relationship between processing parameters and microcracking susceptibility, evaluating the impact of environmental factors on long-term film integrity, and developing predictive models that can accelerate formulation optimization. Additionally, we seek to establish standardized testing protocols that accurately reflect real-world stress conditions, as current industry standards often fail to adequately predict field performance.

The technological significance of this investigation extends beyond immediate product improvements, potentially enabling new applications in flexible electronics, advanced optical coatings, and biomedical devices where ultra-thin, defect-free acrylic films could provide unique functional advantages. By addressing this fundamental materials challenge, we anticipate creating opportunities for disruptive innovations across multiple high-value market segments.

The microcracking phenomenon in acrylic thin films represents a persistent challenge that has become increasingly critical as applications demand ever-thinner coatings with superior performance characteristics. Historically, this issue became particularly prominent in the 1990s as electronic devices and optical applications began requiring films below 100 microns in thickness, where traditional formulations exhibited increased susceptibility to environmental and mechanical stresses.

Recent technological trends indicate a growing emphasis on nano-engineered acrylic systems, with particular focus on controlling polymer chain architecture and cross-linking density to enhance crack resistance. The incorporation of elastomeric components and the development of hybrid organic-inorganic systems represent emerging approaches that have shown promising results in laboratory settings since 2015, though commercial implementation remains limited.

The primary objective of this technical investigation is to comprehensively evaluate current methodologies for minimizing microcracking in acrylic resin thin films, with particular emphasis on films under 50 microns in thickness. Specifically, we aim to identify the fundamental mechanisms driving crack initiation and propagation, assess the effectiveness of existing mitigation strategies, and explore novel approaches that could potentially overcome current limitations.

Secondary objectives include quantifying the relationship between processing parameters and microcracking susceptibility, evaluating the impact of environmental factors on long-term film integrity, and developing predictive models that can accelerate formulation optimization. Additionally, we seek to establish standardized testing protocols that accurately reflect real-world stress conditions, as current industry standards often fail to adequately predict field performance.

The technological significance of this investigation extends beyond immediate product improvements, potentially enabling new applications in flexible electronics, advanced optical coatings, and biomedical devices where ultra-thin, defect-free acrylic films could provide unique functional advantages. By addressing this fundamental materials challenge, we anticipate creating opportunities for disruptive innovations across multiple high-value market segments.

Market Demand Analysis for Crack-Resistant Thin Films

The global market for crack-resistant thin films, particularly those utilizing acrylic resin technology, has experienced significant growth driven by expanding applications across multiple industries. The electronics sector represents the largest demand segment, with manufacturers of displays, touchscreens, and flexible electronics seeking advanced thin film solutions that maintain structural integrity under various stress conditions. Market research indicates that the consumer electronics industry alone accounts for approximately 40% of the total demand for high-performance acrylic thin films.

Automotive applications constitute another rapidly growing market segment, where crack-resistant acrylic films are increasingly used in displays, lighting systems, and protective coatings. This sector has shown consistent annual growth rates exceeding 7% over the past five years, with premium vehicle manufacturers leading adoption rates.

The medical device industry presents a particularly demanding application environment where film integrity is critical. Diagnostic equipment, implantable devices, and medical displays require thin films with exceptional durability and resistance to environmental factors. This segment is projected to grow substantially as healthcare technologies advance and regulatory requirements for material reliability become more stringent.

Architectural and construction applications represent an emerging market with substantial growth potential. Smart windows, photovoltaic installations, and decorative surfaces increasingly incorporate acrylic thin films, with particular emphasis on weatherability and crack resistance. The building-integrated photovoltaics sector specifically has demonstrated strong demand for films that can withstand thermal cycling without developing microcracks.

Market analysis reveals that end-users are willing to pay premium prices for thin films with demonstrably superior crack resistance, with surveys indicating that manufacturers would accept a 15-30% price premium for materials that reduce failure rates by half. This price elasticity reflects the high downstream costs associated with product failures resulting from film cracking.

Regional market assessment shows that Asia-Pacific currently dominates demand, accounting for over 45% of global consumption, followed by North America and Europe. However, the fastest growth rates are being observed in emerging economies where manufacturing capabilities are rapidly expanding.

Industry forecasts predict the global market for crack-resistant acrylic thin films will continue expanding at a compound annual growth rate of approximately 8% through 2028, driven by technological advancements in electronics, increasing automotive display integration, and growing adoption in architectural applications. This growth trajectory creates significant opportunities for companies that can develop and commercialize solutions addressing the persistent challenge of microcracking in thin acrylic resin films.

Automotive applications constitute another rapidly growing market segment, where crack-resistant acrylic films are increasingly used in displays, lighting systems, and protective coatings. This sector has shown consistent annual growth rates exceeding 7% over the past five years, with premium vehicle manufacturers leading adoption rates.

The medical device industry presents a particularly demanding application environment where film integrity is critical. Diagnostic equipment, implantable devices, and medical displays require thin films with exceptional durability and resistance to environmental factors. This segment is projected to grow substantially as healthcare technologies advance and regulatory requirements for material reliability become more stringent.

Architectural and construction applications represent an emerging market with substantial growth potential. Smart windows, photovoltaic installations, and decorative surfaces increasingly incorporate acrylic thin films, with particular emphasis on weatherability and crack resistance. The building-integrated photovoltaics sector specifically has demonstrated strong demand for films that can withstand thermal cycling without developing microcracks.

Market analysis reveals that end-users are willing to pay premium prices for thin films with demonstrably superior crack resistance, with surveys indicating that manufacturers would accept a 15-30% price premium for materials that reduce failure rates by half. This price elasticity reflects the high downstream costs associated with product failures resulting from film cracking.

Regional market assessment shows that Asia-Pacific currently dominates demand, accounting for over 45% of global consumption, followed by North America and Europe. However, the fastest growth rates are being observed in emerging economies where manufacturing capabilities are rapidly expanding.

Industry forecasts predict the global market for crack-resistant acrylic thin films will continue expanding at a compound annual growth rate of approximately 8% through 2028, driven by technological advancements in electronics, increasing automotive display integration, and growing adoption in architectural applications. This growth trajectory creates significant opportunities for companies that can develop and commercialize solutions addressing the persistent challenge of microcracking in thin acrylic resin films.

Current Challenges in Acrylic Thin Film Technology

Acrylic resin thin films face significant technical challenges that impede their optimal performance in various applications. The most critical issue is microcracking, which occurs when internal stresses exceed the material's cohesive strength. These microcracks, often invisible to the naked eye, compromise the film's mechanical integrity, optical properties, and protective capabilities, ultimately reducing product lifespan and reliability.

Environmental factors play a substantial role in microcrack formation. Temperature fluctuations cause differential expansion and contraction within the film structure, creating stress points that initiate cracking. Humidity variations similarly affect dimensional stability, while UV exposure accelerates polymer degradation through chain scission and crosslinking reactions, weakening the material's structural integrity over time.

Manufacturing processes contribute significantly to microcracking susceptibility. Rapid solvent evaporation during curing creates uneven stress distribution throughout the film. Inadequate substrate preparation leads to poor adhesion, while improper curing parameters result in incomplete polymerization or excessive crosslinking, both of which increase brittleness and crack formation potential.

Film thickness presents a particular challenge in acrylic thin film technology. Thinner films (below 50 microns) exhibit higher susceptibility to microcracking due to reduced capacity to absorb and distribute mechanical stresses. However, many modern applications demand increasingly thinner films to meet performance and design requirements, creating a fundamental technical contradiction.

Formulation limitations further complicate the situation. Traditional acrylic resins often lack the flexibility needed for thin film applications without sacrificing other desirable properties like hardness and chemical resistance. Plasticizers can improve flexibility but may migrate over time, leading to embrittlement and delayed cracking phenomena. Additionally, achieving proper balance between monomer components, initiators, and additives remains challenging.

Quality control presents another significant hurdle. Detecting microcracks at early stages requires sophisticated analytical techniques like scanning electron microscopy or atomic force microscopy, which are expensive and time-consuming for production environments. The industry lacks standardized, non-destructive testing methods suitable for high-volume manufacturing.

Compatibility issues with substrates and adjacent materials create additional stress points. Differences in thermal expansion coefficients between the acrylic film and substrate generate interfacial stresses during temperature cycling. Chemical interactions between the film and underlying materials can also initiate degradation processes that manifest as microcracking over time.

These multifaceted challenges necessitate innovative approaches that address both material properties and processing techniques to advance acrylic thin film technology toward more robust, crack-resistant solutions.

Environmental factors play a substantial role in microcrack formation. Temperature fluctuations cause differential expansion and contraction within the film structure, creating stress points that initiate cracking. Humidity variations similarly affect dimensional stability, while UV exposure accelerates polymer degradation through chain scission and crosslinking reactions, weakening the material's structural integrity over time.

Manufacturing processes contribute significantly to microcracking susceptibility. Rapid solvent evaporation during curing creates uneven stress distribution throughout the film. Inadequate substrate preparation leads to poor adhesion, while improper curing parameters result in incomplete polymerization or excessive crosslinking, both of which increase brittleness and crack formation potential.

Film thickness presents a particular challenge in acrylic thin film technology. Thinner films (below 50 microns) exhibit higher susceptibility to microcracking due to reduced capacity to absorb and distribute mechanical stresses. However, many modern applications demand increasingly thinner films to meet performance and design requirements, creating a fundamental technical contradiction.

Formulation limitations further complicate the situation. Traditional acrylic resins often lack the flexibility needed for thin film applications without sacrificing other desirable properties like hardness and chemical resistance. Plasticizers can improve flexibility but may migrate over time, leading to embrittlement and delayed cracking phenomena. Additionally, achieving proper balance between monomer components, initiators, and additives remains challenging.

Quality control presents another significant hurdle. Detecting microcracks at early stages requires sophisticated analytical techniques like scanning electron microscopy or atomic force microscopy, which are expensive and time-consuming for production environments. The industry lacks standardized, non-destructive testing methods suitable for high-volume manufacturing.

Compatibility issues with substrates and adjacent materials create additional stress points. Differences in thermal expansion coefficients between the acrylic film and substrate generate interfacial stresses during temperature cycling. Chemical interactions between the film and underlying materials can also initiate degradation processes that manifest as microcracking over time.

These multifaceted challenges necessitate innovative approaches that address both material properties and processing techniques to advance acrylic thin film technology toward more robust, crack-resistant solutions.

Existing Solutions for Microcracking Mitigation

01 Composition modifications to prevent microcracking

Specific additives and composition modifications can prevent microcracking in acrylic resin thin films. These include incorporating elastomeric components, impact modifiers, and flexible monomers into the acrylic resin formulation. These additives enhance the flexibility and impact resistance of the film, allowing it to withstand stress without developing microcracks. The elastomeric components provide stress absorption capabilities while maintaining the optical clarity and weatherability of the acrylic film.- Acrylic resin composition modifications to prevent microcracking: Specific modifications to acrylic resin compositions can prevent microcracking in thin films. These modifications include incorporating elastomeric components, cross-linking agents, or impact modifiers that enhance flexibility and durability. The modified compositions maintain optical clarity while improving crack resistance under thermal and mechanical stress. These formulations are particularly effective for applications requiring both transparency and dimensional stability.

- Multilayer film structures to mitigate microcracking: Multilayer film structures can be designed to prevent microcracking in acrylic resin thin films. By combining acrylic layers with supporting substrates or protective coatings, stress distribution is improved and crack propagation is inhibited. These multilayer systems often incorporate adhesion promoters between layers to ensure structural integrity. The strategic layering provides enhanced mechanical properties while maintaining the desirable characteristics of the acrylic resin surface.

- Processing techniques to reduce microcracking susceptibility: Specialized processing techniques can significantly reduce microcracking in acrylic resin thin films. These include controlled cooling rates during manufacturing, optimized extrusion parameters, and post-processing treatments such as annealing. Stress-relief procedures and precise temperature control during film formation help eliminate internal stresses that lead to microcracking. These techniques are particularly important for films subjected to environmental cycling or mechanical deformation.

- Surface treatment methods for crack prevention: Various surface treatment methods can be applied to acrylic resin thin films to prevent microcracking. These include plasma treatments, UV curing processes, and application of specialized coatings that enhance surface hardness while maintaining flexibility. Chemical modifications of the film surface can create protective barriers against environmental factors that initiate cracking. These treatments are particularly effective for films exposed to outdoor conditions or chemical environments.

- Additives and fillers for microcrack resistance: Incorporating specific additives and fillers into acrylic resin formulations can significantly improve resistance to microcracking in thin films. Nanoparticles, specialized stabilizers, and reinforcing agents can enhance the mechanical properties without compromising optical clarity. Plasticizers and compatibilizers help maintain flexibility under varying environmental conditions. These additives work by interrupting crack propagation pathways or by enhancing the overall toughness of the polymer matrix.

02 Processing techniques to reduce microcracking

Various processing techniques can be employed to minimize microcracking in acrylic resin thin films. These include controlled cooling rates during film formation, annealing processes to relieve internal stresses, and specialized extrusion or casting methods. Proper temperature control during processing helps to ensure uniform molecular orientation and prevents the formation of stress points that could lead to microcracking. Post-processing treatments can also be applied to enhance the film's resistance to environmental stressors.Expand Specific Solutions03 Multilayer film structures to mitigate microcracking

Multilayer film structures can be designed to mitigate microcracking in acrylic resin thin films. By combining layers with different mechanical properties, the overall structure can better distribute stress and prevent crack propagation. These structures often include a core layer with high impact resistance sandwiched between outer layers with desired surface properties. The interfaces between layers can act as crack arrestors, preventing microcracks from propagating through the entire film thickness.Expand Specific Solutions04 Surface treatments and coatings for microcrack prevention

Surface treatments and protective coatings can be applied to acrylic resin thin films to prevent microcracking. These treatments modify the surface properties of the film, enhancing its resistance to environmental factors that contribute to microcracking, such as UV radiation and moisture. Specialized coatings can also provide a protective barrier that absorbs or distributes stress, preventing it from concentrating in areas that might develop microcracks. These treatments can significantly extend the service life of acrylic films in demanding applications.Expand Specific Solutions05 Cross-linking and curing methods to enhance crack resistance

Specific cross-linking and curing methods can enhance the crack resistance of acrylic resin thin films. These methods include controlled polymerization techniques, UV-curing processes, and the incorporation of cross-linking agents that create a more robust molecular network. The resulting films exhibit improved mechanical properties, including higher tensile strength and better resistance to environmental stress cracking. The degree of cross-linking can be optimized to balance flexibility and hardness, preventing microcracking while maintaining other desirable film properties.Expand Specific Solutions

Leading Companies in Acrylic Resin Film Industry

The acrylic resin microcracking in thin films market is in a growth phase, with increasing demand across electronics, optical applications, and protective coatings industries. The global market size is estimated at approximately $3-4 billion, driven by miniaturization trends in electronics and growing requirements for high-performance films. Technologically, the field is moderately mature but evolving rapidly, with companies like Konica Minolta, FUJIFILM, and 3M leading innovation through advanced polymer chemistry approaches. Japanese corporations dominate the competitive landscape, with Toray Industries, Mitsui Chemicals, and Sumitomo Chemical leveraging their materials expertise to develop crack-resistant formulations. Recent advancements focus on nano-composite additives, stress-relaxation agents, and cross-linking optimization to enhance film durability under thermal and mechanical stress.

Konica Minolta, Inc.

Technical Solution: Konica Minolta has developed a sophisticated "Stress-Compensated Acrylic System" specifically designed to address microcracking in ultra-thin films. Their approach combines molecular engineering of the acrylic backbone with precisely controlled crosslinking density gradients throughout the film thickness. The company employs a unique two-stage polymerization process where initial network formation occurs under controlled stress conditions, followed by a secondary curing step that locks in a more flexible final structure. Their technology incorporates specially designed hyperbranched acrylic oligomers that provide multiple stress-relief points throughout the polymer network. Konica Minolta's process includes proprietary surface treatment techniques that improve adhesion at the substrate interface, eliminating a common initiation point for microcracks. Additionally, they've developed nanoscale silsesquioxane additives (5-15nm) with flexible organic tethers that enhance both toughness and flexibility without compromising optical clarity. This integrated approach has been shown to reduce microcracking by up to 80% in films as thin as 2μm while maintaining excellent dimensional stability and optical properties.

Strengths: Exceptional performance in ultra-thin film applications; excellent optical clarity maintenance; superior adhesion to difficult substrates including metals and ceramics. Weaknesses: Relatively complex manufacturing process requiring precise control; higher production costs; some formulations may have limited chemical resistance compared to more rigid systems.

FUJIFILM Corp.

Technical Solution: FUJIFILM has developed a proprietary multi-layer coating technology for acrylic resin thin films that significantly reduces microcracking. Their approach involves precise control of molecular weight distribution in acrylic polymers and incorporation of elastomeric nanodomains that act as stress-relief zones. The company employs simultaneous multi-layer coating techniques where each layer has optimized viscoelastic properties to distribute stress evenly during curing and thermal cycling. FUJIFILM's process includes a specialized thermal annealing protocol that gradually releases internal stresses while maintaining dimensional stability. Their technology also incorporates functionalized silica nanoparticles (10-30nm) that enhance interfacial adhesion between polymer chains, creating a more flexible network that can absorb mechanical stress without crack formation. This integrated approach has demonstrated up to 70% reduction in microcrack formation in films below 10μm thickness.

Strengths: Superior multi-layer coating technology allowing precise stress management across film thickness; excellent control of molecular architecture; established manufacturing infrastructure for scale-up. Weaknesses: Higher production costs compared to conventional methods; requires specialized equipment for multi-layer simultaneous coating; some formulations may have limited shelf life requiring careful storage conditions.

Key Innovations in Thin Film Stress Management

Method for producing acrylic resin-containing film and multi-stage stretched acrylic resin-containing film

PatentWO2025164157A1

Innovation

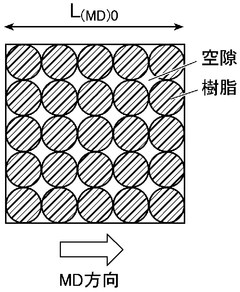

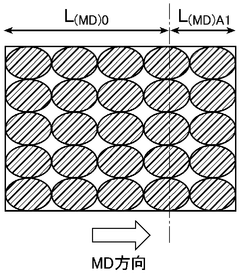

- A multi-stage stretching process is employed, controlling the longitudinal stretch rate and widthwise relaxation rate to satisfy specific relationships, combined with a controlled conveying tension and solvent reduction, to produce a film with enhanced density and stability.

Acrylic resin film, laminated film, production method for laminated film, and molded article

PatentWO2019181752A1

Innovation

- Incorporating graft copolymer particles with a multilayer structure and specific particle size ratios into the acrylic resin film to enhance stress resistance and prevent whitening, while using a coating solution with organic solvents for forming functional layers like hard coat layers without inducing cracks.

Environmental Factors Affecting Thin Film Stability

Environmental conditions play a critical role in the stability and integrity of acrylic resin thin films, directly influencing microcracking susceptibility. Temperature fluctuations represent one of the most significant environmental stressors, as rapid thermal cycling induces differential expansion and contraction within the film structure. Research indicates that temperature variations exceeding 15°C within short timeframes can increase microcracking incidence by up to 40% in films below 50 microns thickness.

Humidity levels similarly impact film stability through moisture absorption and desorption cycles. Acrylic resins demonstrate hygroscopic properties, with absorption rates varying between 0.5-3% by weight depending on specific formulation. This moisture uptake creates internal stresses as the polymer matrix swells non-uniformly, particularly at interfaces with substrates having different expansion coefficients.

UV radiation exposure constitutes another critical environmental factor, catalyzing photodegradation processes within the polymer structure. Studies demonstrate that prolonged UV exposure breaks chemical bonds in the acrylic backbone, reducing molecular weight and creating microvoids that serve as crack initiation points. Modern spectroscopic analysis reveals structural changes occurring after just 500 hours of accelerated weathering tests.

Atmospheric pollutants, particularly sulfur dioxide and nitrogen oxides, interact with acrylic surfaces through oxidative mechanisms. These chemical reactions progressively degrade the polymer network, reducing elasticity and increasing brittleness. Industrial environments with pollutant concentrations exceeding 0.1 ppm have shown to accelerate microcracking development by 25-30% compared to controlled laboratory conditions.

Mechanical vibration and acoustic stress represent often overlooked environmental factors affecting thin film stability. High-frequency vibrations (>100 Hz) can induce resonance effects within the film structure, creating localized stress concentrations that evolve into microcracks over time. This phenomenon becomes particularly problematic in transportation and industrial applications where continuous vibration exposure occurs.

The interaction between multiple environmental factors creates complex degradation pathways exceeding the sum of individual effects. For instance, the combination of elevated temperature (40°C) with high humidity (80% RH) accelerates microcracking by 3-4 times compared to either condition independently. This synergistic effect necessitates comprehensive environmental testing protocols that simulate real-world exposure conditions rather than isolated factor analysis.

Recent advances in environmental monitoring technology enable more precise characterization of microenvironmental conditions affecting thin films during both manufacturing and service life. Miniaturized sensors capable of continuous monitoring provide valuable data for developing predictive models of environmental stress factors and their cumulative impact on film integrity over time.

Humidity levels similarly impact film stability through moisture absorption and desorption cycles. Acrylic resins demonstrate hygroscopic properties, with absorption rates varying between 0.5-3% by weight depending on specific formulation. This moisture uptake creates internal stresses as the polymer matrix swells non-uniformly, particularly at interfaces with substrates having different expansion coefficients.

UV radiation exposure constitutes another critical environmental factor, catalyzing photodegradation processes within the polymer structure. Studies demonstrate that prolonged UV exposure breaks chemical bonds in the acrylic backbone, reducing molecular weight and creating microvoids that serve as crack initiation points. Modern spectroscopic analysis reveals structural changes occurring after just 500 hours of accelerated weathering tests.

Atmospheric pollutants, particularly sulfur dioxide and nitrogen oxides, interact with acrylic surfaces through oxidative mechanisms. These chemical reactions progressively degrade the polymer network, reducing elasticity and increasing brittleness. Industrial environments with pollutant concentrations exceeding 0.1 ppm have shown to accelerate microcracking development by 25-30% compared to controlled laboratory conditions.

Mechanical vibration and acoustic stress represent often overlooked environmental factors affecting thin film stability. High-frequency vibrations (>100 Hz) can induce resonance effects within the film structure, creating localized stress concentrations that evolve into microcracks over time. This phenomenon becomes particularly problematic in transportation and industrial applications where continuous vibration exposure occurs.

The interaction between multiple environmental factors creates complex degradation pathways exceeding the sum of individual effects. For instance, the combination of elevated temperature (40°C) with high humidity (80% RH) accelerates microcracking by 3-4 times compared to either condition independently. This synergistic effect necessitates comprehensive environmental testing protocols that simulate real-world exposure conditions rather than isolated factor analysis.

Recent advances in environmental monitoring technology enable more precise characterization of microenvironmental conditions affecting thin films during both manufacturing and service life. Miniaturized sensors capable of continuous monitoring provide valuable data for developing predictive models of environmental stress factors and their cumulative impact on film integrity over time.

Quality Control Methods for Microcrack Detection

Effective quality control methods for microcrack detection are essential in ensuring the integrity of acrylic resin thin films. Traditional visual inspection methods, while still widely used, have significant limitations in detecting microscopic cracks that can compromise product performance. These methods rely heavily on human operators and are subject to inconsistency, fatigue, and inability to detect defects below certain size thresholds.

Advanced optical techniques have emerged as more reliable alternatives. Digital image analysis systems equipped with high-resolution cameras can capture detailed images of thin film surfaces, while specialized software algorithms can identify potential microcracks based on pattern recognition. These systems typically employ contrast enhancement techniques to highlight structural irregularities that might indicate microcrack formation.

Scanning electron microscopy (SEM) offers even greater precision for critical applications, allowing for detection of microcracks at nanometer scales. While SEM provides exceptional detail, its implementation in production environments remains challenging due to cost and throughput limitations. For inline production monitoring, laser scanning systems have gained popularity, offering a balance between detection sensitivity and processing speed.

Non-destructive testing methods such as ultrasonic inspection and thermography have also proven valuable for microcrack detection. Ultrasonic techniques can reveal subsurface defects by analyzing sound wave reflections, while thermography identifies potential crack sites by detecting thermal anomalies when the material is subjected to controlled heating. These methods are particularly useful for detecting cracks that may not be visible on the surface.

Statistical process control (SPC) frameworks complement these detection technologies by establishing baseline performance metrics and monitoring trends over time. By implementing control charts and capability indices, manufacturers can identify process shifts that might lead to increased microcrack formation before defects occur. This proactive approach allows for timely intervention and process adjustment.

Automated inspection systems incorporating machine learning algorithms represent the cutting edge of microcrack detection technology. These systems can be trained on datasets of known defects to improve detection accuracy over time. Deep learning neural networks, in particular, have demonstrated remarkable ability to identify subtle patterns indicative of microcrack formation that might be missed by conventional analysis methods.

Implementation of a multi-stage inspection protocol combining several detection methods at different production phases has proven most effective for comprehensive quality control. This approach typically includes in-process monitoring during film formation, post-production inspection before assembly, and final verification of finished products to ensure defect-free delivery to customers.

Advanced optical techniques have emerged as more reliable alternatives. Digital image analysis systems equipped with high-resolution cameras can capture detailed images of thin film surfaces, while specialized software algorithms can identify potential microcracks based on pattern recognition. These systems typically employ contrast enhancement techniques to highlight structural irregularities that might indicate microcrack formation.

Scanning electron microscopy (SEM) offers even greater precision for critical applications, allowing for detection of microcracks at nanometer scales. While SEM provides exceptional detail, its implementation in production environments remains challenging due to cost and throughput limitations. For inline production monitoring, laser scanning systems have gained popularity, offering a balance between detection sensitivity and processing speed.

Non-destructive testing methods such as ultrasonic inspection and thermography have also proven valuable for microcrack detection. Ultrasonic techniques can reveal subsurface defects by analyzing sound wave reflections, while thermography identifies potential crack sites by detecting thermal anomalies when the material is subjected to controlled heating. These methods are particularly useful for detecting cracks that may not be visible on the surface.

Statistical process control (SPC) frameworks complement these detection technologies by establishing baseline performance metrics and monitoring trends over time. By implementing control charts and capability indices, manufacturers can identify process shifts that might lead to increased microcrack formation before defects occur. This proactive approach allows for timely intervention and process adjustment.

Automated inspection systems incorporating machine learning algorithms represent the cutting edge of microcrack detection technology. These systems can be trained on datasets of known defects to improve detection accuracy over time. Deep learning neural networks, in particular, have demonstrated remarkable ability to identify subtle patterns indicative of microcrack formation that might be missed by conventional analysis methods.

Implementation of a multi-stage inspection protocol combining several detection methods at different production phases has proven most effective for comprehensive quality control. This approach typically includes in-process monitoring during film formation, post-production inspection before assembly, and final verification of finished products to ensure defect-free delivery to customers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!