How to Reduce Acrylic Resin Cracking in Thick Film Layers

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Cracking Background and Objectives

Acrylic resins have been widely utilized in various industrial applications since their commercial introduction in the 1930s. These versatile polymers, primarily based on poly(methyl methacrylate) (PMMA) and its derivatives, have gained significant traction in coatings, adhesives, and structural applications due to their exceptional optical clarity, weatherability, and mechanical properties. However, the persistent challenge of cracking in thick film layers has limited their full potential in high-performance applications.

The phenomenon of acrylic resin cracking in thick films has been documented since the 1950s, with early research focusing primarily on empirical solutions rather than fundamental understanding of the underlying mechanisms. The evolution of this technical challenge parallels the increasing demand for thicker acrylic applications in automotive components, architectural elements, and advanced optical systems.

Recent technological advancements have expanded the application scope of thick acrylic films, particularly in emerging fields such as flexible electronics, advanced display technologies, and biomedical devices. This expansion has heightened the urgency to address the cracking issue, as these applications demand both dimensional stability and mechanical integrity under various environmental conditions.

The primary mechanisms contributing to acrylic resin cracking in thick films include internal stress accumulation during polymerization and curing, differential thermal expansion/contraction, solvent evaporation dynamics, and environmental aging effects. These factors interact in complex ways, creating a multifaceted technical challenge that requires a comprehensive approach to resolution.

Industry data indicates that cracking-related failures account for approximately 15-20% of quality issues in thick acrylic film applications, representing significant economic impact across multiple sectors. The financial implications extend beyond direct material losses to include production delays, warranty claims, and reputation damage for manufacturers.

The technical objectives of this investigation are threefold: first, to develop a comprehensive understanding of the fundamental mechanisms driving crack formation and propagation in thick acrylic resin films; second, to evaluate existing mitigation strategies and their effectiveness across different application scenarios; and third, to identify novel approaches that can significantly reduce or eliminate cracking while maintaining the desirable properties of acrylic resins.

This research aims to establish quantifiable parameters for crack resistance in thick acrylic films, develop predictive models for crack formation under various conditions, and formulate practical guidelines for manufacturers to implement effective anti-cracking strategies. The ultimate goal is to enable the reliable production of thick acrylic film layers with enhanced durability and performance characteristics, thereby expanding their application potential in advanced technological fields.

The phenomenon of acrylic resin cracking in thick films has been documented since the 1950s, with early research focusing primarily on empirical solutions rather than fundamental understanding of the underlying mechanisms. The evolution of this technical challenge parallels the increasing demand for thicker acrylic applications in automotive components, architectural elements, and advanced optical systems.

Recent technological advancements have expanded the application scope of thick acrylic films, particularly in emerging fields such as flexible electronics, advanced display technologies, and biomedical devices. This expansion has heightened the urgency to address the cracking issue, as these applications demand both dimensional stability and mechanical integrity under various environmental conditions.

The primary mechanisms contributing to acrylic resin cracking in thick films include internal stress accumulation during polymerization and curing, differential thermal expansion/contraction, solvent evaporation dynamics, and environmental aging effects. These factors interact in complex ways, creating a multifaceted technical challenge that requires a comprehensive approach to resolution.

Industry data indicates that cracking-related failures account for approximately 15-20% of quality issues in thick acrylic film applications, representing significant economic impact across multiple sectors. The financial implications extend beyond direct material losses to include production delays, warranty claims, and reputation damage for manufacturers.

The technical objectives of this investigation are threefold: first, to develop a comprehensive understanding of the fundamental mechanisms driving crack formation and propagation in thick acrylic resin films; second, to evaluate existing mitigation strategies and their effectiveness across different application scenarios; and third, to identify novel approaches that can significantly reduce or eliminate cracking while maintaining the desirable properties of acrylic resins.

This research aims to establish quantifiable parameters for crack resistance in thick acrylic films, develop predictive models for crack formation under various conditions, and formulate practical guidelines for manufacturers to implement effective anti-cracking strategies. The ultimate goal is to enable the reliable production of thick acrylic film layers with enhanced durability and performance characteristics, thereby expanding their application potential in advanced technological fields.

Market Demand Analysis for Crack-Resistant Thick Films

The global market for crack-resistant acrylic resin thick films has been experiencing significant growth, driven by increasing applications in electronics, automotive displays, optical devices, and architectural elements. The demand for these specialized materials is primarily fueled by industries requiring high optical clarity combined with mechanical durability in challenging environments.

In the electronics sector, manufacturers of touchscreens, display panels, and protective covers are actively seeking solutions to prevent cracking in thick acrylic layers, as device dimensions increase while thickness requirements decrease. Market research indicates that the consumer electronics segment alone accounts for approximately 40% of the total demand for crack-resistant acrylic films, with annual growth rates exceeding the industry average.

The automotive industry represents another substantial market segment, particularly with the rising integration of large-format displays and touch interfaces in vehicle interiors. Premium and mid-range vehicle manufacturers are increasingly specifying crack-resistant acrylic materials for instrument clusters and infotainment systems, creating a steady demand growth of 12-15% annually in this vertical.

Architectural applications constitute an emerging market with considerable potential, especially in regions experiencing extreme temperature variations. Building facades, interior partitions, and decorative elements utilizing thick acrylic films require enhanced crack resistance to maintain aesthetic appeal and structural integrity over extended periods. This segment is projected to grow at 8-10% annually over the next five years.

Geographically, Asia-Pacific dominates the market consumption, with China, Japan, and South Korea collectively accounting for over 50% of global demand. North America and Europe follow with approximately 25% and 20% market share respectively, primarily driven by high-end applications in aerospace, medical devices, and premium consumer products.

Market analysis reveals a price premium of 15-30% for crack-resistant formulations compared to standard acrylic resins, indicating customers' willingness to pay for enhanced performance. This premium has been gradually decreasing as manufacturing technologies mature and competition intensifies among material suppliers.

Industry surveys highlight that end-users prioritize three key performance attributes: thermal cycling resistance, impact strength, and long-term optical clarity retention. Materials that successfully address these requirements while maintaining processability compatible with existing manufacturing equipment command the highest market value and adoption rates.

The market forecast suggests a compound annual growth rate of 7.8% for crack-resistant thick acrylic films through 2028, with particularly strong growth in applications requiring films exceeding 3mm thickness, where cracking issues are most prevalent and challenging to resolve.

In the electronics sector, manufacturers of touchscreens, display panels, and protective covers are actively seeking solutions to prevent cracking in thick acrylic layers, as device dimensions increase while thickness requirements decrease. Market research indicates that the consumer electronics segment alone accounts for approximately 40% of the total demand for crack-resistant acrylic films, with annual growth rates exceeding the industry average.

The automotive industry represents another substantial market segment, particularly with the rising integration of large-format displays and touch interfaces in vehicle interiors. Premium and mid-range vehicle manufacturers are increasingly specifying crack-resistant acrylic materials for instrument clusters and infotainment systems, creating a steady demand growth of 12-15% annually in this vertical.

Architectural applications constitute an emerging market with considerable potential, especially in regions experiencing extreme temperature variations. Building facades, interior partitions, and decorative elements utilizing thick acrylic films require enhanced crack resistance to maintain aesthetic appeal and structural integrity over extended periods. This segment is projected to grow at 8-10% annually over the next five years.

Geographically, Asia-Pacific dominates the market consumption, with China, Japan, and South Korea collectively accounting for over 50% of global demand. North America and Europe follow with approximately 25% and 20% market share respectively, primarily driven by high-end applications in aerospace, medical devices, and premium consumer products.

Market analysis reveals a price premium of 15-30% for crack-resistant formulations compared to standard acrylic resins, indicating customers' willingness to pay for enhanced performance. This premium has been gradually decreasing as manufacturing technologies mature and competition intensifies among material suppliers.

Industry surveys highlight that end-users prioritize three key performance attributes: thermal cycling resistance, impact strength, and long-term optical clarity retention. Materials that successfully address these requirements while maintaining processability compatible with existing manufacturing equipment command the highest market value and adoption rates.

The market forecast suggests a compound annual growth rate of 7.8% for crack-resistant thick acrylic films through 2028, with particularly strong growth in applications requiring films exceeding 3mm thickness, where cracking issues are most prevalent and challenging to resolve.

Technical Challenges in Thick Acrylic Film Applications

Acrylic resins, when applied in thick film layers, face significant technical challenges that limit their performance and durability. The primary issue is cracking, which occurs due to internal stresses that develop during the curing process. These stresses are particularly problematic in films exceeding 100 microns in thickness, where the differential shrinkage between surface and deeper layers creates substantial tension.

The polymerization kinetics of acrylic resins contribute significantly to cracking phenomena. As the outer layer cures rapidly upon exposure to air or UV radiation, it contracts while deeper layers remain uncured. This differential curing rate establishes a shrinkage gradient that manifests as surface cracks once the internal stress exceeds the material's cohesive strength.

Temperature fluctuations during application and curing exacerbate these challenges. Rapid temperature changes can induce thermal expansion and contraction cycles that further stress the material structure. Industry data indicates that temperature variations of just 10°C during curing can increase crack formation by up to 30% in films exceeding 200 microns.

Solvent evaporation rates present another critical challenge. In solvent-based acrylic systems, rapid solvent loss creates voids within the polymer matrix that act as stress concentration points. Research has shown that controlling evaporation rates through solvent selection and environmental parameters can reduce crack formation by 40-60%, but this often extends curing times beyond practical manufacturing constraints.

The molecular weight distribution of the acrylic polymer significantly impacts film integrity. Higher molecular weight fractions provide enhanced mechanical strength but reduce flow properties and increase internal stress during curing. Conversely, lower molecular weight components improve flow but compromise the final mechanical properties of the cured film.

Substrate interaction further complicates thick film applications. Differential adhesion strength across the substrate surface creates localized stress points that initiate crack propagation. This is particularly problematic with porous or thermally active substrates that interact dynamically with the acrylic layer during curing.

Additives intended to enhance performance often introduce their own complications. Plasticizers that improve flexibility can migrate over time, leading to delayed cracking phenomena. Similarly, fillers used to reduce shrinkage may create heterogeneous stress distribution if poorly dispersed, actually increasing crack formation in certain regions of the film.

Recent studies have identified oxygen inhibition as a significant factor in surface quality issues. Oxygen molecules interfere with free-radical polymerization at the air interface, creating a partially cured surface layer with different mechanical properties than the bulk material, contributing to stress development and subsequent cracking.

The polymerization kinetics of acrylic resins contribute significantly to cracking phenomena. As the outer layer cures rapidly upon exposure to air or UV radiation, it contracts while deeper layers remain uncured. This differential curing rate establishes a shrinkage gradient that manifests as surface cracks once the internal stress exceeds the material's cohesive strength.

Temperature fluctuations during application and curing exacerbate these challenges. Rapid temperature changes can induce thermal expansion and contraction cycles that further stress the material structure. Industry data indicates that temperature variations of just 10°C during curing can increase crack formation by up to 30% in films exceeding 200 microns.

Solvent evaporation rates present another critical challenge. In solvent-based acrylic systems, rapid solvent loss creates voids within the polymer matrix that act as stress concentration points. Research has shown that controlling evaporation rates through solvent selection and environmental parameters can reduce crack formation by 40-60%, but this often extends curing times beyond practical manufacturing constraints.

The molecular weight distribution of the acrylic polymer significantly impacts film integrity. Higher molecular weight fractions provide enhanced mechanical strength but reduce flow properties and increase internal stress during curing. Conversely, lower molecular weight components improve flow but compromise the final mechanical properties of the cured film.

Substrate interaction further complicates thick film applications. Differential adhesion strength across the substrate surface creates localized stress points that initiate crack propagation. This is particularly problematic with porous or thermally active substrates that interact dynamically with the acrylic layer during curing.

Additives intended to enhance performance often introduce their own complications. Plasticizers that improve flexibility can migrate over time, leading to delayed cracking phenomena. Similarly, fillers used to reduce shrinkage may create heterogeneous stress distribution if poorly dispersed, actually increasing crack formation in certain regions of the film.

Recent studies have identified oxygen inhibition as a significant factor in surface quality issues. Oxygen molecules interfere with free-radical polymerization at the air interface, creating a partially cured surface layer with different mechanical properties than the bulk material, contributing to stress development and subsequent cracking.

Current Anti-Cracking Solutions for Thick Films

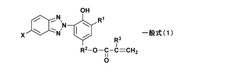

01 Acrylic resin compositions with improved crack resistance

Specific acrylic resin compositions can be formulated to improve crack resistance under various environmental conditions. These compositions typically include modified acrylic polymers with enhanced molecular structures that provide better flexibility and durability. The incorporation of certain comonomers and cross-linking agents can significantly reduce the tendency of acrylic resins to crack when exposed to stress, temperature variations, or weathering conditions.- Acrylic resin compositions with improved crack resistance: Specific acrylic resin compositions can be formulated to improve crack resistance under various environmental conditions. These compositions typically include modified acrylic polymers with specific molecular weights and functional groups that enhance flexibility while maintaining other desirable properties. The addition of certain comonomers or cross-linking agents can significantly improve the resin's ability to withstand stress without cracking.

- Impact modifiers for preventing acrylic resin cracking: Impact modifiers can be incorporated into acrylic resin formulations to prevent cracking under mechanical stress or impact. These modifiers typically consist of elastomeric particles or core-shell polymers that absorb energy and distribute stress throughout the material. The proper selection and concentration of impact modifiers can significantly enhance the crack resistance of acrylic resins without compromising optical clarity or other performance characteristics.

- Thermal stabilization methods for acrylic resins: Thermal stabilization techniques can prevent cracking in acrylic resins exposed to temperature fluctuations or heat. These methods include incorporating heat stabilizers, antioxidants, or UV absorbers into the resin formulation. Additionally, specific processing conditions and thermal treatment protocols can enhance the resin's resistance to thermal stress-induced cracking by relieving internal stresses and optimizing the polymer structure.

- Chemical modification of acrylic polymers to reduce cracking: Chemical modification of acrylic polymers through copolymerization with specific monomers or post-polymerization treatments can significantly reduce cracking tendencies. These modifications often involve introducing flexible segments into the polymer backbone, controlling the degree of crosslinking, or adding functional groups that enhance intermolecular interactions. Such chemical modifications can improve the overall toughness and crack resistance of acrylic resins while maintaining their desirable optical and mechanical properties.

- Processing techniques to minimize acrylic resin cracking: Specific processing techniques can be employed to minimize cracking in acrylic resin products. These include optimized molding conditions, controlled cooling rates, annealing processes, and stress-relief treatments. Proper material handling, processing temperature control, and mold design also play crucial roles in preventing crack formation. Additionally, surface treatments or coatings can be applied to finished acrylic products to enhance their resistance to environmental stress cracking.

02 Impact modifiers for acrylic resins

Impact modifiers can be incorporated into acrylic resin formulations to enhance their resistance to cracking under mechanical stress. These modifiers typically consist of elastomeric particles or core-shell polymers that absorb impact energy and prevent crack propagation. The proper dispersion and compatibility of these modifiers within the acrylic matrix is crucial for achieving optimal crack resistance while maintaining other desirable properties of the resin.Expand Specific Solutions03 Thermal stabilization techniques for preventing acrylic resin cracking

Thermal stabilization techniques can prevent cracking in acrylic resins exposed to temperature fluctuations. These methods involve incorporating heat stabilizers, antioxidants, and UV absorbers that protect the polymer chains from degradation at elevated temperatures. Additionally, controlling the polymerization process to achieve optimal molecular weight distribution and reducing residual stress during processing can significantly improve the thermal crack resistance of acrylic resins.Expand Specific Solutions04 Surface treatments and coatings to prevent cracking

Various surface treatments and coating technologies can be applied to acrylic resins to enhance their resistance to cracking. These include specialized primer systems, protective overlays, and surface modification techniques that create a barrier against environmental factors that promote cracking. Some approaches involve the application of silane coupling agents or fluoropolymer coatings that improve the interfacial adhesion and reduce surface tension, thereby minimizing crack initiation at the surface level.Expand Specific Solutions05 Additives and fillers for crack prevention in acrylic resins

Specific additives and fillers can be incorporated into acrylic resin formulations to prevent cracking. These include plasticizers that enhance flexibility, nanofillers that reinforce the polymer matrix, and specialty additives that improve stress distribution. The proper selection and dispersion of these components can significantly enhance the crack resistance of acrylic resins while maintaining or improving other physical properties such as transparency, processability, and chemical resistance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The acrylic resin cracking reduction market is in a growth phase, with increasing demand for thick film applications across electronics, automotive, and construction industries. The market size is expanding as manufacturers seek solutions to enhance product durability and performance. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include Kaneka Corp. and Nippon Shokubai with advanced acrylic resin formulations, Kuraray and Mitsubishi Gas Chemical offering specialized crack-resistant additives, while DIC Corp. and Sumitomo Chemical focus on high-performance coating technologies. Konica Minolta and FUJIFILM contribute optical-grade solutions, with 3M and Nitto Denko developing proprietary film technologies that address thermal expansion challenges in thick acrylic applications.

Kaneka Corp.

Technical Solution: Kaneka Corporation has developed an innovative approach to reducing acrylic resin cracking in thick film layers through their "Kane-Flex" acrylic technology. Their solution incorporates specially engineered acrylic copolymers with optimized molecular weight distribution and controlled tacticity to enhance flexibility while maintaining optical clarity. Kaneka's technology utilizes a proprietary blend of reactive plasticizers that become chemically incorporated into the polymer network during curing, preventing migration and ensuring long-term performance. Their formulation includes specially modified core-shell impact modifiers with nanoscale dimensions (30-50nm) that effectively absorb and dissipate stress throughout the material. Kaneka has also developed a gradient polymerization technique that creates a subtle composition variation through the thickness of the film, with more flexible components concentrated in areas most prone to stress concentration. Additionally, their process incorporates precise thermal management during curing to minimize residual stresses[8][9].

Strengths: Exceptional resistance to environmental stress cracking; maintains high transparency (>92% light transmission) despite modifier addition; excellent adhesion to various substrates including metals and composites. Weaknesses: Requires precise process control during manufacturing; slightly higher moisture absorption compared to conventional acrylics; premium pricing position in the market.

Arkema France SA

Technical Solution: Arkema has developed a comprehensive approach to reduce acrylic resin cracking in thick film layers through their Altuglas® technology. Their solution incorporates impact modifiers with core-shell structures that absorb and dissipate stress throughout the polymer matrix. These elastomeric cores are encapsulated within shells that are compatible with the acrylic matrix, ensuring proper dispersion. Arkema's technology also includes specialized plasticizers that increase chain mobility without compromising mechanical properties. Their formulations incorporate cross-linking agents at optimized concentrations to create a network structure that maintains flexibility while enhancing cohesive strength. Additionally, they've developed proprietary thermal curing profiles that minimize internal stresses during polymerization and cooling phases[1][3].

Strengths: Superior impact resistance even at low temperatures; excellent optical clarity maintained despite modifier addition; enhanced weatherability for outdoor applications. Weaknesses: Higher production costs compared to standard acrylics; slightly reduced hardness in some formulations; requires precise processing control to achieve optimal properties.

Key Patents and Research on Crack Prevention

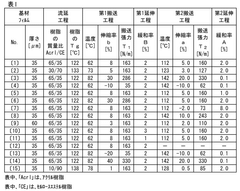

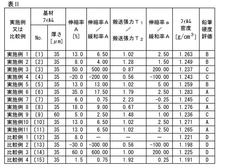

Method for producing acrylic resin-containing film and multi-stage stretched acrylic resin-containing film

PatentWO2025164157A1

Innovation

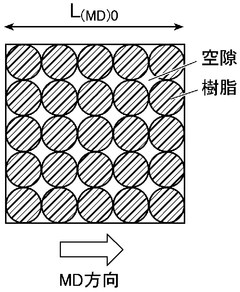

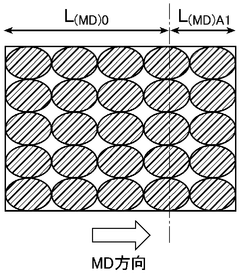

- A multi-stage stretching process is employed, controlling the longitudinal stretch rate and widthwise relaxation rate to satisfy specific relationships, combined with a controlled conveying tension and solvent reduction, to produce a film with enhanced density and stability.

Acrylic resin film, laminated film, production method for laminated film, and molded article

PatentWO2019181752A1

Innovation

- Incorporating graft copolymer particles with a multilayer structure and specific particle size ratios into the acrylic resin film to enhance stress resistance and prevent whitening, while using a coating solution with organic solvents for forming functional layers like hard coat layers without inducing cracks.

Environmental Factors Affecting Resin Performance

Environmental conditions play a crucial role in the performance and longevity of acrylic resin systems, particularly in thick film applications. Temperature fluctuations represent one of the most significant environmental stressors affecting resin stability. When thick acrylic films experience rapid temperature changes, differential thermal expansion occurs between the surface and interior layers, generating internal stress that often manifests as cracking. Research indicates that temperature cycling between -20°C and 50°C can increase crack formation by up to 300% compared to constant temperature environments.

Humidity levels similarly impact resin performance through moisture absorption mechanisms. Acrylic resins typically absorb 1-3% moisture by weight, which can plasticize the polymer matrix and alter mechanical properties. In thick film applications, this absorption occurs unevenly, creating moisture gradients that induce internal stress. Studies have demonstrated that relative humidity fluctuations between 30% and 80% significantly accelerate crack propagation in films exceeding 500μm thickness.

UV radiation exposure constitutes another critical environmental factor affecting thick acrylic films. Prolonged UV exposure initiates photodegradation processes that break polymer chains and create free radicals, leading to embrittlement and reduced elongation properties. This degradation is particularly problematic in thick films where surface layers may become significantly more brittle than interior portions, creating mechanical property gradients that promote crack formation.

Atmospheric pollutants, particularly sulfur dioxide and nitrogen oxides, can catalyze degradation reactions in acrylic resins. These compounds penetrate the resin surface and form acidic microenvironments that accelerate polymer breakdown. Research has shown that thick films exposed to industrial atmospheres exhibit 40-60% higher cracking rates than those in clean environments, with the effect being more pronounced as film thickness increases beyond 1mm.

Mechanical vibration and acoustic stress represent often overlooked environmental factors that can induce or accelerate cracking in thick acrylic films. Continuous low-amplitude vibrations, common in industrial settings, create cyclic stress patterns that gradually weaken the polymer structure. This effect becomes particularly significant when the vibration frequency approaches the natural resonance frequency of the resin layer, potentially reducing the time-to-failure by 25-40% in thick film applications.

The combined effect of multiple environmental stressors typically produces synergistic degradation that exceeds the sum of individual factors. For instance, the combination of high humidity and temperature cycling has been shown to accelerate crack formation by up to 500% compared to either factor alone. This synergistic effect becomes increasingly pronounced as film thickness increases, making environmental control particularly critical for thick acrylic film applications.

Humidity levels similarly impact resin performance through moisture absorption mechanisms. Acrylic resins typically absorb 1-3% moisture by weight, which can plasticize the polymer matrix and alter mechanical properties. In thick film applications, this absorption occurs unevenly, creating moisture gradients that induce internal stress. Studies have demonstrated that relative humidity fluctuations between 30% and 80% significantly accelerate crack propagation in films exceeding 500μm thickness.

UV radiation exposure constitutes another critical environmental factor affecting thick acrylic films. Prolonged UV exposure initiates photodegradation processes that break polymer chains and create free radicals, leading to embrittlement and reduced elongation properties. This degradation is particularly problematic in thick films where surface layers may become significantly more brittle than interior portions, creating mechanical property gradients that promote crack formation.

Atmospheric pollutants, particularly sulfur dioxide and nitrogen oxides, can catalyze degradation reactions in acrylic resins. These compounds penetrate the resin surface and form acidic microenvironments that accelerate polymer breakdown. Research has shown that thick films exposed to industrial atmospheres exhibit 40-60% higher cracking rates than those in clean environments, with the effect being more pronounced as film thickness increases beyond 1mm.

Mechanical vibration and acoustic stress represent often overlooked environmental factors that can induce or accelerate cracking in thick acrylic films. Continuous low-amplitude vibrations, common in industrial settings, create cyclic stress patterns that gradually weaken the polymer structure. This effect becomes particularly significant when the vibration frequency approaches the natural resonance frequency of the resin layer, potentially reducing the time-to-failure by 25-40% in thick film applications.

The combined effect of multiple environmental stressors typically produces synergistic degradation that exceeds the sum of individual factors. For instance, the combination of high humidity and temperature cycling has been shown to accelerate crack formation by up to 500% compared to either factor alone. This synergistic effect becomes increasingly pronounced as film thickness increases, making environmental control particularly critical for thick acrylic film applications.

Quality Control Methods for Thick Film Applications

Quality control is paramount in managing acrylic resin cracking issues in thick film applications. Implementing a comprehensive quality control framework begins with establishing clear specifications for material properties, including viscosity, solid content, and molecular weight distribution of acrylic resins. These specifications must be consistently verified through incoming material inspection protocols to ensure batch-to-batch consistency.

Process monitoring represents another critical aspect of quality control. Real-time monitoring of application parameters such as temperature, humidity, and curing conditions helps identify deviations that could lead to cracking. Advanced monitoring systems equipped with statistical process control (SPC) capabilities can detect trends before they result in defects, enabling proactive intervention.

Non-destructive testing methods have proven particularly valuable for thick film applications. Techniques such as ultrasonic inspection, digital image correlation, and infrared thermography can detect micro-cracks and stress concentrations before they develop into visible failures. These methods allow for 100% inspection without compromising product integrity.

Accelerated aging tests form an essential component of quality assurance protocols. By subjecting samples to extreme environmental conditions—including thermal cycling, UV exposure, and humidity fluctuations—manufacturers can predict long-term performance and identify potential cracking issues before products reach the market. Standardized test methods like ASTM D2565 and ISO 4892 provide reliable frameworks for these evaluations.

Documentation and traceability systems ensure that all quality control measures are properly recorded and retrievable. Each batch of acrylic resin should be traceable throughout the production process, with detailed records of processing parameters, test results, and any corrective actions taken. This information proves invaluable for root cause analysis when cracking issues do occur.

Continuous improvement methodologies such as Six Sigma and DMAIC (Define, Measure, Analyze, Improve, Control) should be integrated into quality control systems. Regular analysis of defect data, coupled with structured problem-solving approaches, drives ongoing refinement of processes and materials to progressively reduce cracking incidents over time.

Training programs for operators and quality personnel represent the human element of effective quality control. Ensuring that staff can recognize early warning signs of potential cracking issues and understand proper handling procedures for acrylic resins significantly reduces the risk of defects caused by procedural errors or mishandling.

Process monitoring represents another critical aspect of quality control. Real-time monitoring of application parameters such as temperature, humidity, and curing conditions helps identify deviations that could lead to cracking. Advanced monitoring systems equipped with statistical process control (SPC) capabilities can detect trends before they result in defects, enabling proactive intervention.

Non-destructive testing methods have proven particularly valuable for thick film applications. Techniques such as ultrasonic inspection, digital image correlation, and infrared thermography can detect micro-cracks and stress concentrations before they develop into visible failures. These methods allow for 100% inspection without compromising product integrity.

Accelerated aging tests form an essential component of quality assurance protocols. By subjecting samples to extreme environmental conditions—including thermal cycling, UV exposure, and humidity fluctuations—manufacturers can predict long-term performance and identify potential cracking issues before products reach the market. Standardized test methods like ASTM D2565 and ISO 4892 provide reliable frameworks for these evaluations.

Documentation and traceability systems ensure that all quality control measures are properly recorded and retrievable. Each batch of acrylic resin should be traceable throughout the production process, with detailed records of processing parameters, test results, and any corrective actions taken. This information proves invaluable for root cause analysis when cracking issues do occur.

Continuous improvement methodologies such as Six Sigma and DMAIC (Define, Measure, Analyze, Improve, Control) should be integrated into quality control systems. Regular analysis of defect data, coupled with structured problem-solving approaches, drives ongoing refinement of processes and materials to progressively reduce cracking incidents over time.

Training programs for operators and quality personnel represent the human element of effective quality control. Ensuring that staff can recognize early warning signs of potential cracking issues and understand proper handling procedures for acrylic resins significantly reduces the risk of defects caused by procedural errors or mishandling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!