How to Modify Acrylic Resin for Conductive Coatings

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Acrylic Resin Technology Background and Objectives

Conductive acrylic resins represent a significant technological advancement in the field of polymer science, emerging from the convergence of traditional polymer chemistry and electronic materials engineering. The evolution of this technology can be traced back to the 1970s when researchers first began exploring methods to impart electrical conductivity to traditionally insulating polymeric materials. Over subsequent decades, acrylic resins have gained prominence due to their exceptional optical clarity, weather resistance, and mechanical properties, making them ideal candidates for modification into conductive materials.

The technological trajectory has been characterized by progressive improvements in conductivity levels, from early developments achieving modest conductivity suitable only for antistatic applications to contemporary formulations capable of supporting advanced electronic functions. Recent advancements have been driven by the growing demand for flexible electronics, electromagnetic interference (EMI) shielding, and transparent conductive films for touch screens and displays.

Current research focuses on several key modification approaches: incorporation of conductive fillers such as carbon nanotubes, graphene, and metal nanoparticles; chemical modification of the acrylic backbone to introduce conjugated segments; and development of hybrid organic-inorganic systems that combine the processability of acrylics with the conductivity of inorganic materials.

The primary technical objectives in this field include achieving higher conductivity levels while maintaining the inherent advantages of acrylic resins, such as transparency, flexibility, and environmental stability. Specifically, researchers aim to develop formulations that can achieve sheet resistivity below 100 ohms/square while maintaining optical transparency above 85%. Additionally, there is significant interest in creating systems that can be processed using conventional coating techniques without requiring specialized equipment or extreme processing conditions.

Another critical objective is enhancing the durability of conductive acrylic coatings, particularly their resistance to environmental factors such as humidity, UV radiation, and temperature fluctuations, which can significantly impact conductivity over time. The development of self-healing capabilities to maintain conductivity despite mechanical damage represents an emerging frontier in this technology.

The field is also witnessing increased attention toward environmentally sustainable approaches, with efforts to reduce or eliminate toxic components traditionally used in conductive formulations, such as certain metal compounds. This aligns with broader industry trends toward green chemistry and sustainable materials development.

As we look toward future developments, the integration of multifunctionality—combining conductivity with properties such as antimicrobial activity, self-cleaning capabilities, or stimuli-responsiveness—represents a promising direction that could significantly expand the application scope of conductive acrylic coatings across diverse industries.

The technological trajectory has been characterized by progressive improvements in conductivity levels, from early developments achieving modest conductivity suitable only for antistatic applications to contemporary formulations capable of supporting advanced electronic functions. Recent advancements have been driven by the growing demand for flexible electronics, electromagnetic interference (EMI) shielding, and transparent conductive films for touch screens and displays.

Current research focuses on several key modification approaches: incorporation of conductive fillers such as carbon nanotubes, graphene, and metal nanoparticles; chemical modification of the acrylic backbone to introduce conjugated segments; and development of hybrid organic-inorganic systems that combine the processability of acrylics with the conductivity of inorganic materials.

The primary technical objectives in this field include achieving higher conductivity levels while maintaining the inherent advantages of acrylic resins, such as transparency, flexibility, and environmental stability. Specifically, researchers aim to develop formulations that can achieve sheet resistivity below 100 ohms/square while maintaining optical transparency above 85%. Additionally, there is significant interest in creating systems that can be processed using conventional coating techniques without requiring specialized equipment or extreme processing conditions.

Another critical objective is enhancing the durability of conductive acrylic coatings, particularly their resistance to environmental factors such as humidity, UV radiation, and temperature fluctuations, which can significantly impact conductivity over time. The development of self-healing capabilities to maintain conductivity despite mechanical damage represents an emerging frontier in this technology.

The field is also witnessing increased attention toward environmentally sustainable approaches, with efforts to reduce or eliminate toxic components traditionally used in conductive formulations, such as certain metal compounds. This aligns with broader industry trends toward green chemistry and sustainable materials development.

As we look toward future developments, the integration of multifunctionality—combining conductivity with properties such as antimicrobial activity, self-cleaning capabilities, or stimuli-responsiveness—represents a promising direction that could significantly expand the application scope of conductive acrylic coatings across diverse industries.

Market Analysis for Conductive Coating Applications

The global market for conductive coatings has been experiencing robust growth, driven primarily by increasing demand in electronics, automotive, aerospace, and healthcare sectors. The conductive coatings market was valued at approximately $24.8 billion in 2022 and is projected to reach $31.5 billion by 2028, growing at a CAGR of 6.2% during the forecast period. Within this broader market, acrylic-based conductive coatings represent a significant segment due to their versatility, cost-effectiveness, and environmental advantages.

Electronics manufacturing constitutes the largest application segment, accounting for nearly 40% of the market share. The miniaturization trend in consumer electronics and the growing adoption of flexible electronics have intensified the demand for high-performance conductive coatings that can be applied to various substrates while maintaining conductivity and durability. Acrylic-based solutions are particularly valued in this sector for their adhesion properties and processability.

The automotive industry represents another substantial market for conductive coatings, particularly with the accelerating transition toward electric vehicles (EVs). Conductive coatings are essential for electromagnetic interference (EMI) shielding, static discharge prevention, and various sensor applications. The global EV market expansion, with annual growth rates exceeding 25%, directly correlates with increased demand for specialized conductive coating solutions.

Healthcare applications for conductive coatings are emerging as a high-growth segment, particularly in medical devices, biosensors, and antimicrobial surfaces. Modified acrylic resins that combine conductivity with biocompatibility are experiencing heightened interest, with this segment projected to grow at over 8% annually through 2028.

Geographically, Asia-Pacific dominates the conductive coatings market, accounting for approximately 45% of global consumption, with China, Japan, and South Korea being the primary contributors. North America and Europe follow with market shares of approximately 25% and 20% respectively, with particular strength in high-performance and specialty applications.

Customer requirements are increasingly focused on multifunctional coatings that combine conductivity with other properties such as transparency, flexibility, weather resistance, and sustainability. This trend has accelerated research into modified acrylic resins that can deliver enhanced performance while meeting environmental regulations, particularly regarding VOC emissions and recyclability.

Price sensitivity varies significantly across application segments, with consumer electronics manufacturers typically more cost-conscious than aerospace or medical device producers. The average price point for specialty conductive acrylic coatings ranges from $15-45 per kilogram, depending on performance specifications and production volume.

Electronics manufacturing constitutes the largest application segment, accounting for nearly 40% of the market share. The miniaturization trend in consumer electronics and the growing adoption of flexible electronics have intensified the demand for high-performance conductive coatings that can be applied to various substrates while maintaining conductivity and durability. Acrylic-based solutions are particularly valued in this sector for their adhesion properties and processability.

The automotive industry represents another substantial market for conductive coatings, particularly with the accelerating transition toward electric vehicles (EVs). Conductive coatings are essential for electromagnetic interference (EMI) shielding, static discharge prevention, and various sensor applications. The global EV market expansion, with annual growth rates exceeding 25%, directly correlates with increased demand for specialized conductive coating solutions.

Healthcare applications for conductive coatings are emerging as a high-growth segment, particularly in medical devices, biosensors, and antimicrobial surfaces. Modified acrylic resins that combine conductivity with biocompatibility are experiencing heightened interest, with this segment projected to grow at over 8% annually through 2028.

Geographically, Asia-Pacific dominates the conductive coatings market, accounting for approximately 45% of global consumption, with China, Japan, and South Korea being the primary contributors. North America and Europe follow with market shares of approximately 25% and 20% respectively, with particular strength in high-performance and specialty applications.

Customer requirements are increasingly focused on multifunctional coatings that combine conductivity with other properties such as transparency, flexibility, weather resistance, and sustainability. This trend has accelerated research into modified acrylic resins that can deliver enhanced performance while meeting environmental regulations, particularly regarding VOC emissions and recyclability.

Price sensitivity varies significantly across application segments, with consumer electronics manufacturers typically more cost-conscious than aerospace or medical device producers. The average price point for specialty conductive acrylic coatings ranges from $15-45 per kilogram, depending on performance specifications and production volume.

Current Challenges in Acrylic Resin Modification

Despite significant advancements in conductive coating technology, modifying acrylic resins for electrical conductivity presents several persistent challenges. The primary obstacle remains achieving high conductivity while maintaining the inherent advantages of acrylic resins, such as transparency, weatherability, and mechanical flexibility. Current conductive fillers like carbon black, graphene, and metal nanoparticles often compromise these properties when incorporated at concentrations sufficient for meaningful conductivity.

Dispersion stability represents another critical challenge. Conductive particles tend to agglomerate due to strong van der Waals forces and electrostatic interactions, creating non-uniform distribution within the acrylic matrix. This agglomeration not only reduces conductivity efficiency but also creates weak points in the coating structure, compromising mechanical integrity and surface quality.

Interface compatibility between acrylic polymers and conductive fillers presents significant hurdles. The hydrophilic nature of many conductive materials contrasts with the relatively hydrophobic character of acrylic resins, resulting in poor adhesion and phase separation. Current surface modification techniques for fillers often involve complex chemical processes that add considerable cost and environmental concerns to manufacturing.

Processing difficulties also plague current modification approaches. The addition of conductive materials typically increases viscosity dramatically, complicating application methods like spray coating or roll-to-roll processing. This higher viscosity often necessitates the use of additional solvents, raising environmental and health concerns while potentially compromising coating performance.

Long-term stability remains problematic for conductive acrylic coatings. Environmental factors such as UV exposure, moisture, and temperature fluctuations can degrade the conductive network over time. Oxidation of metallic fillers and physical stress from thermal cycling frequently lead to conductivity loss and coating failure in field applications.

Cost-effectiveness continues to be a significant barrier to widespread adoption. High-performance conductive fillers like silver nanoparticles, carbon nanotubes, and graphene remain expensive, while processing modifications add further costs. The industry struggles to balance performance requirements with economic viability, particularly for large-scale applications.

Regulatory compliance adds another layer of complexity. Many conductive additives face increasing scrutiny regarding environmental impact and human health effects. Nanomaterials in particular are subject to evolving regulations worldwide, creating uncertainty in product development pipelines and potential market restrictions.

Dispersion stability represents another critical challenge. Conductive particles tend to agglomerate due to strong van der Waals forces and electrostatic interactions, creating non-uniform distribution within the acrylic matrix. This agglomeration not only reduces conductivity efficiency but also creates weak points in the coating structure, compromising mechanical integrity and surface quality.

Interface compatibility between acrylic polymers and conductive fillers presents significant hurdles. The hydrophilic nature of many conductive materials contrasts with the relatively hydrophobic character of acrylic resins, resulting in poor adhesion and phase separation. Current surface modification techniques for fillers often involve complex chemical processes that add considerable cost and environmental concerns to manufacturing.

Processing difficulties also plague current modification approaches. The addition of conductive materials typically increases viscosity dramatically, complicating application methods like spray coating or roll-to-roll processing. This higher viscosity often necessitates the use of additional solvents, raising environmental and health concerns while potentially compromising coating performance.

Long-term stability remains problematic for conductive acrylic coatings. Environmental factors such as UV exposure, moisture, and temperature fluctuations can degrade the conductive network over time. Oxidation of metallic fillers and physical stress from thermal cycling frequently lead to conductivity loss and coating failure in field applications.

Cost-effectiveness continues to be a significant barrier to widespread adoption. High-performance conductive fillers like silver nanoparticles, carbon nanotubes, and graphene remain expensive, while processing modifications add further costs. The industry struggles to balance performance requirements with economic viability, particularly for large-scale applications.

Regulatory compliance adds another layer of complexity. Many conductive additives face increasing scrutiny regarding environmental impact and human health effects. Nanomaterials in particular are subject to evolving regulations worldwide, creating uncertainty in product development pipelines and potential market restrictions.

Existing Acrylic Resin Modification Methods

01 Conductive fillers in acrylic resin

Incorporating conductive fillers such as carbon black, graphite, metal particles, or carbon nanotubes into acrylic resin matrices can significantly enhance electrical conductivity. The type, size, distribution, and concentration of these fillers determine the level of conductivity achieved. These composite materials maintain the processability and mechanical properties of acrylic resins while gaining electrical conductivity suitable for various applications including EMI shielding and antistatic surfaces.- Conductive fillers in acrylic resin: Incorporating conductive fillers such as carbon black, graphite, metal particles, or carbon nanotubes into acrylic resin matrices can significantly enhance electrical conductivity. The type, size, distribution, and concentration of these fillers determine the level of conductivity achieved. These composite materials maintain the processability and mechanical properties of acrylic resins while gaining electrical conductivity suitable for various applications including EMI shielding and antistatic surfaces.

- Ionic conductivity in acrylic polymer electrolytes: Acrylic resins can be modified to function as polymer electrolytes with enhanced ionic conductivity for battery and energy storage applications. This is achieved by incorporating ionic salts, plasticizers, or functional groups that facilitate ion transport. Cross-linking structures and network formation within the acrylic matrix can create pathways for ion movement while maintaining dimensional stability. These materials combine mechanical strength with electrochemical performance.

- Surface modification techniques for conductivity: Surface treatments and modifications of acrylic resins can enhance their electrical conductivity without altering bulk properties. Techniques include plasma treatment, chemical functionalization, and deposition of conductive layers. These modifications create conductive pathways on the resin surface while preserving optical clarity and mechanical properties. Such treatments enable the use of acrylic resins in applications requiring static dissipation or moderate conductivity.

- Copolymerization for enhanced conductivity: Copolymerization of acrylic monomers with conductive or functional comonomers can intrinsically enhance the electrical properties of the resulting resin. By incorporating monomers containing conjugated structures, ionic groups, or polarizable moieties, the electrical conductivity can be tailored at the molecular level. This approach allows for homogeneous conductivity throughout the material without relying solely on additives or fillers, making it suitable for applications requiring uniform electrical properties.

- Thermal conductivity enhancement in acrylic composites: Beyond electrical conductivity, acrylic resins can be formulated to enhance thermal conductivity for heat management applications. This is achieved by incorporating thermally conductive fillers such as ceramic particles, boron nitride, or metal oxides. The orientation and interconnection of these fillers create pathways for heat transfer while maintaining the processing advantages of acrylic resins. These thermally conductive composites find applications in LED housings, electronic encapsulants, and thermal interface materials.

02 Ionic conductivity in acrylic polymer electrolytes

Acrylic resins can be formulated as polymer electrolytes with ionic conductivity by incorporating salts, ionic liquids, or polar functional groups. These materials facilitate ion transport through the polymer matrix, making them suitable for applications in batteries, fuel cells, and other electrochemical devices. The ionic conductivity can be enhanced by controlling the crosslinking density, adding plasticizers, or introducing specific functional groups that promote ion mobility.Expand Specific Solutions03 Surface modification techniques for conductivity

Surface treatments and modifications of acrylic resins can enhance their electrical conductivity without significantly altering bulk properties. Techniques include plasma treatment, chemical functionalization, metallization, and conductive coating applications. These methods create conductive pathways on the resin surface while maintaining the core mechanical properties of the acrylic material, enabling applications in printed electronics, sensors, and touch-responsive interfaces.Expand Specific Solutions04 Copolymerization for enhanced conductivity

Copolymerization of acrylic monomers with conductive or conductivity-enhancing comonomers creates resins with intrinsic electrical properties. By incorporating monomers containing conjugated systems, ionic groups, or polarizable moieties, the resulting copolymers exhibit enhanced charge transport capabilities. This approach allows for molecular-level control of conductivity properties while maintaining the processability and versatility characteristic of acrylic resins.Expand Specific Solutions05 Temperature and environmental effects on conductivity

The electrical conductivity of acrylic resins is significantly influenced by temperature, humidity, and environmental conditions. Formulations can be designed to maintain consistent conductivity across varying conditions or to respond to specific environmental triggers. Understanding these relationships enables the development of acrylic resin systems with stable electrical performance for reliable operation in diverse applications and environments.Expand Specific Solutions

Leading Companies in Conductive Coating Industry

The conductive coatings market based on modified acrylic resin technology is currently in a growth phase, with increasing applications across automotive, electronics, and construction industries. The global market size is expanding rapidly due to rising demand for lightweight, corrosion-resistant materials with electrical conductivity properties. Technologically, this field shows moderate maturity with ongoing innovation. Leading players include BASF SE and LG Chem developing advanced polymer formulations, while Nippon Paint and Sherwin-Williams focus on application-specific solutions. Japanese companies like Kansai Paint and Sumitomo Chemical demonstrate strong R&D capabilities in specialized conductive additives. Chinese manufacturers such as Guangzhou Human Chemicals and Yatu Advanced Materials are emerging as cost-competitive suppliers, particularly in automotive refinish segments. The technology continues evolving toward environmentally friendly water-based formulations with enhanced conductivity performance.

Kansai Paint Co., Ltd.

Technical Solution: Kansai Paint has developed sophisticated methods for modifying acrylic resins to create conductive coatings through their proprietary "ALES" technology platform. Their approach involves chemical modification of acrylic polymer chains with functional groups that can interact with and stabilize conductive additives. Kansai utilizes a controlled grafting technique to incorporate conductive polymer segments like polythiophene derivatives directly onto acrylic backbones, creating inherently conductive hybrid polymers. Their innovation includes the development of specially designed surfactants that enable stable dispersions of conductive nanoparticles within waterborne acrylic systems, addressing environmental concerns while maintaining performance. Kansai Paint has pioneered a multi-layer coating system where modified acrylic primers create an interfacial layer that enhances adhesion of subsequent conductive layers. Their research has demonstrated that incorporating specific ionic compounds into acrylic matrices can create ion-conductive pathways that supplement electronic conductivity, particularly useful in humidity-sensing applications. Kansai has also developed self-stratifying acrylic formulations where conductive components migrate to specific layers during curing, optimizing both surface conductivity and bulk properties.

Strengths: Excellent adhesion to diverse substrates; superior weatherability and UV resistance; compatibility with existing application equipment; good balance of conductivity and traditional coating properties. Weaknesses: Relatively high cost compared to conventional coatings; potential for reduced scratch resistance in highly conductive formulations; requires careful formulation to maintain stability.

LG Chem Ltd.

Technical Solution: LG Chem has developed sophisticated methods for modifying acrylic resins to create conductive coatings through their proprietary "TechPolymer" technology. Their approach involves grafting conductive polymers like polyaniline (PANI) and polypyrrole (PPy) onto acrylic backbones through controlled radical polymerization techniques. This creates covalent bonds between the conductive elements and the acrylic matrix, ensuring long-term stability. LG Chem utilizes a unique core-shell particle technology where conductive nanoparticles are encapsulated within modified acrylic microspheres, allowing for high conductivity while maintaining excellent film formation properties. Their innovation includes the development of self-healing conductive networks within the acrylic matrix that can restore conductivity after mechanical damage. LG Chem has also pioneered the use of ionic liquids as plasticizers in acrylic systems, which simultaneously enhance conductivity and improve flexibility. Their research has demonstrated that incorporating specially designed silane coupling agents can significantly improve adhesion to difficult substrates while maintaining conductive pathways.

Strengths: Exceptional durability and adhesion properties; ability to achieve high conductivity with minimal impact on optical clarity; excellent chemical resistance; compatible with various application methods. Weaknesses: Complex manufacturing process increases production costs; requires specialized equipment for some formulations; potential for reduced shelf stability in certain environmental conditions.

Key Patents in Conductive Acrylic Coating Technology

Modified epoxy acrylate resin conductive adhesive and preparation method and application thereof

PatentInactiveUS20220340794A1

Innovation

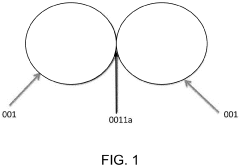

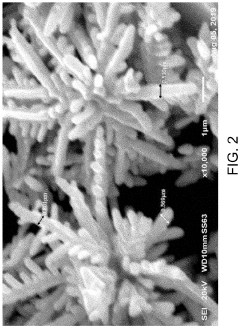

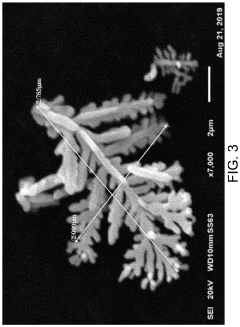

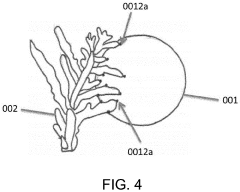

- A modified epoxy acrylate resin conductive adhesive is developed, incorporating conductive particles with a three-dimensional dendritic microstructure, along with a silane coupling agent and initiator, to enhance adhesion and conductivity, allowing for faster curing and improved toughness.

Patent

Innovation

- Introduction of conductive nanoparticles (such as carbon nanotubes, graphene, or metal nanoparticles) into acrylic resin matrix to create conductive pathways while maintaining the optical and mechanical properties of the base resin.

- Surface modification of acrylic resin with conductive polymers (like PEDOT:PSS or polyaniline) through grafting or interpenetrating network formation to impart conductivity while preserving transparency.

- Integration of self-healing mechanisms within conductive acrylic coatings to repair microcracks and maintain conductivity over extended periods of use and environmental exposure.

Environmental Impact and Sustainability Considerations

The development of conductive coatings based on modified acrylic resins raises significant environmental and sustainability considerations that must be addressed throughout their lifecycle. Traditional conductive coatings often contain heavy metals, volatile organic compounds (VOCs), and other environmentally harmful substances that pose risks to ecosystems and human health. Modified acrylic resin systems offer opportunities to reduce these impacts through more sustainable formulation approaches.

Water-based acrylic resin systems represent a significant advancement in reducing environmental footprint compared to solvent-based alternatives. These formulations substantially decrease VOC emissions during application and curing processes, contributing to improved air quality and reduced respiratory health risks for workers and end-users. Additionally, the elimination or reduction of toxic heavy metals like lead, cadmium, and hexavalent chromium in modern conductive coating formulations addresses critical environmental contamination concerns.

The carbon footprint of conductive acrylic coatings must be evaluated across their entire lifecycle, from raw material extraction to end-of-life disposal. Incorporating bio-based acrylic monomers derived from renewable resources presents a promising approach to reducing reliance on petroleum-based feedstocks. Several research initiatives have demonstrated successful integration of bio-based components while maintaining essential conductive properties, though scale-up challenges remain.

Recyclability and waste management considerations are increasingly important for conductive coating systems. Acrylic resins modified with easily separable conductive fillers facilitate more effective recycling processes. Innovative approaches include designing coatings with reversible crosslinking mechanisms that allow for material recovery and reuse at end-of-life. However, composite materials containing nanomaterials present unique waste management challenges that require specialized handling protocols.

Energy consumption during production and application represents another critical sustainability factor. Low-temperature curing acrylic systems significantly reduce energy requirements compared to high-temperature alternatives. Recent advancements in UV-curable conductive acrylic formulations have demonstrated energy savings of up to 70% versus conventional thermal curing processes, while simultaneously reducing processing time.

Regulatory compliance is evolving rapidly in this sector, with frameworks like REACH in Europe and similar initiatives globally imposing stricter requirements on chemical composition. Forward-thinking manufacturers are proactively developing acrylic resin systems that not only meet current standards but anticipate future regulatory restrictions, particularly regarding nanomaterials and persistent organic compounds that may present long-term environmental risks.

Water-based acrylic resin systems represent a significant advancement in reducing environmental footprint compared to solvent-based alternatives. These formulations substantially decrease VOC emissions during application and curing processes, contributing to improved air quality and reduced respiratory health risks for workers and end-users. Additionally, the elimination or reduction of toxic heavy metals like lead, cadmium, and hexavalent chromium in modern conductive coating formulations addresses critical environmental contamination concerns.

The carbon footprint of conductive acrylic coatings must be evaluated across their entire lifecycle, from raw material extraction to end-of-life disposal. Incorporating bio-based acrylic monomers derived from renewable resources presents a promising approach to reducing reliance on petroleum-based feedstocks. Several research initiatives have demonstrated successful integration of bio-based components while maintaining essential conductive properties, though scale-up challenges remain.

Recyclability and waste management considerations are increasingly important for conductive coating systems. Acrylic resins modified with easily separable conductive fillers facilitate more effective recycling processes. Innovative approaches include designing coatings with reversible crosslinking mechanisms that allow for material recovery and reuse at end-of-life. However, composite materials containing nanomaterials present unique waste management challenges that require specialized handling protocols.

Energy consumption during production and application represents another critical sustainability factor. Low-temperature curing acrylic systems significantly reduce energy requirements compared to high-temperature alternatives. Recent advancements in UV-curable conductive acrylic formulations have demonstrated energy savings of up to 70% versus conventional thermal curing processes, while simultaneously reducing processing time.

Regulatory compliance is evolving rapidly in this sector, with frameworks like REACH in Europe and similar initiatives globally imposing stricter requirements on chemical composition. Forward-thinking manufacturers are proactively developing acrylic resin systems that not only meet current standards but anticipate future regulatory restrictions, particularly regarding nanomaterials and persistent organic compounds that may present long-term environmental risks.

Performance Testing and Quality Control Standards

Performance testing and quality control standards for conductive acrylic resin coatings require comprehensive evaluation protocols to ensure consistent electrical, mechanical, and environmental performance. The primary electrical performance metrics include surface resistivity (measured in ohms per square), volume resistivity (ohm-cm), and conductivity stability over time. These properties are typically assessed using four-point probe measurements according to ASTM D257 standards, with target resistivity values ranging from 10^2 to 10^6 ohms depending on the specific application requirements.

Mechanical performance testing encompasses adhesion strength (ASTM D3359), abrasion resistance (ASTM D4060), flexibility (ASTM D522), and impact resistance (ASTM D2794). For conductive coatings, the critical challenge lies in maintaining electrical properties while achieving adequate mechanical durability. Quality control protocols must verify that conductivity remains stable after mechanical stress tests, as microfractures can significantly impair electrical performance without being visually apparent.

Environmental durability testing constitutes another crucial aspect of quality control, involving accelerated weathering (ASTM G154), humidity resistance (ASTM D2247), salt spray exposure (ASTM B117), and thermal cycling tests. These assessments evaluate how environmental factors affect both the physical integrity and conductive properties of the coating. Particular attention must be paid to the potential for oxidation of conductive fillers, which can dramatically reduce conductivity over time.

Consistency in manufacturing requires statistical process control methods with defined acceptance criteria. Key parameters monitored include viscosity (ASTM D562), solid content percentage, particle size distribution of conductive fillers, and dispersion quality. Advanced quality control laboratories employ optical microscopy and scanning electron microscopy to evaluate filler dispersion patterns and identify potential agglomeration issues that could create conductivity "hot spots" or dead zones.

Emerging quality control standards increasingly incorporate real-time monitoring systems that can detect variations in coating performance during application. These systems utilize impedance spectroscopy and infrared analysis to provide immediate feedback on coating quality. Additionally, non-destructive testing methods such as eddy current testing are becoming standard for evaluating conductivity uniformity across large coated surfaces.

Industry-specific standards vary significantly, with more stringent requirements for aerospace and medical applications compared to consumer electronics or automotive sectors. For instance, medical device coatings must meet biocompatibility standards (ISO 10993) in addition to conductivity requirements, while aerospace applications demand compliance with flammability and outgassing specifications (NASA-STD-6001).

Mechanical performance testing encompasses adhesion strength (ASTM D3359), abrasion resistance (ASTM D4060), flexibility (ASTM D522), and impact resistance (ASTM D2794). For conductive coatings, the critical challenge lies in maintaining electrical properties while achieving adequate mechanical durability. Quality control protocols must verify that conductivity remains stable after mechanical stress tests, as microfractures can significantly impair electrical performance without being visually apparent.

Environmental durability testing constitutes another crucial aspect of quality control, involving accelerated weathering (ASTM G154), humidity resistance (ASTM D2247), salt spray exposure (ASTM B117), and thermal cycling tests. These assessments evaluate how environmental factors affect both the physical integrity and conductive properties of the coating. Particular attention must be paid to the potential for oxidation of conductive fillers, which can dramatically reduce conductivity over time.

Consistency in manufacturing requires statistical process control methods with defined acceptance criteria. Key parameters monitored include viscosity (ASTM D562), solid content percentage, particle size distribution of conductive fillers, and dispersion quality. Advanced quality control laboratories employ optical microscopy and scanning electron microscopy to evaluate filler dispersion patterns and identify potential agglomeration issues that could create conductivity "hot spots" or dead zones.

Emerging quality control standards increasingly incorporate real-time monitoring systems that can detect variations in coating performance during application. These systems utilize impedance spectroscopy and infrared analysis to provide immediate feedback on coating quality. Additionally, non-destructive testing methods such as eddy current testing are becoming standard for evaluating conductivity uniformity across large coated surfaces.

Industry-specific standards vary significantly, with more stringent requirements for aerospace and medical applications compared to consumer electronics or automotive sectors. For instance, medical device coatings must meet biocompatibility standards (ISO 10993) in addition to conductivity requirements, while aerospace applications demand compliance with flammability and outgassing specifications (NASA-STD-6001).

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!