Acrylic Resin vs Silicone Acrylate: Coating Elasticity Comparison

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coating Elasticity Technology Background and Objectives

Coating elasticity has emerged as a critical property in various industrial applications, evolving significantly over the past decades. The development trajectory of coating elasticity technology began in the 1950s with basic polymer science and has since advanced through continuous innovation in material chemistry and application techniques. The fundamental understanding of elasticity in coatings has transitioned from empirical observations to precise molecular engineering, enabling tailored solutions for specific performance requirements.

The evolution of coating elasticity technology has been driven by increasing demands across multiple sectors including automotive, construction, electronics, and medical devices. Each industry presents unique challenges that have spurred technological advancements. For instance, the automotive industry requires coatings that maintain elasticity despite exposure to extreme temperatures and chemical agents, while medical applications demand biocompatible elastic coatings that can withstand sterilization processes.

Acrylic resins and silicone acrylates represent two major milestones in this technological progression. Acrylic resins, introduced commercially in the 1930s, gained prominence in coating applications by the 1960s due to their versatility and cost-effectiveness. Silicone acrylates emerged later as hybrid materials, combining the durability of acrylics with the exceptional elasticity and thermal stability of silicones, marking a significant advancement in coating technology during the 1980s and 1990s.

Recent technological trends indicate a shift toward nano-engineered coating systems that offer unprecedented control over elasticity properties at the molecular level. The integration of computational modeling and high-throughput experimentation has accelerated innovation in this field, allowing for rapid development and optimization of new formulations with precisely tuned elastic responses.

The primary technical objectives in comparing acrylic resin and silicone acrylate coating elasticity include quantifying performance differences across various environmental conditions, establishing standardized testing methodologies for elasticity measurement, and developing predictive models for long-term performance. Additionally, there is significant interest in understanding the molecular mechanisms that contribute to elasticity retention over time, particularly under challenging conditions such as UV exposure, temperature cycling, and chemical contact.

Future technological goals include developing coatings with self-healing elastic properties, reducing environmental impact through bio-based elastomeric components, and creating multi-functional elastic coatings that combine flexibility with other desirable properties such as conductivity or antimicrobial activity. The ultimate aim is to establish a comprehensive framework for designing coating systems with precisely engineered elasticity profiles tailored to specific application requirements.

The evolution of coating elasticity technology has been driven by increasing demands across multiple sectors including automotive, construction, electronics, and medical devices. Each industry presents unique challenges that have spurred technological advancements. For instance, the automotive industry requires coatings that maintain elasticity despite exposure to extreme temperatures and chemical agents, while medical applications demand biocompatible elastic coatings that can withstand sterilization processes.

Acrylic resins and silicone acrylates represent two major milestones in this technological progression. Acrylic resins, introduced commercially in the 1930s, gained prominence in coating applications by the 1960s due to their versatility and cost-effectiveness. Silicone acrylates emerged later as hybrid materials, combining the durability of acrylics with the exceptional elasticity and thermal stability of silicones, marking a significant advancement in coating technology during the 1980s and 1990s.

Recent technological trends indicate a shift toward nano-engineered coating systems that offer unprecedented control over elasticity properties at the molecular level. The integration of computational modeling and high-throughput experimentation has accelerated innovation in this field, allowing for rapid development and optimization of new formulations with precisely tuned elastic responses.

The primary technical objectives in comparing acrylic resin and silicone acrylate coating elasticity include quantifying performance differences across various environmental conditions, establishing standardized testing methodologies for elasticity measurement, and developing predictive models for long-term performance. Additionally, there is significant interest in understanding the molecular mechanisms that contribute to elasticity retention over time, particularly under challenging conditions such as UV exposure, temperature cycling, and chemical contact.

Future technological goals include developing coatings with self-healing elastic properties, reducing environmental impact through bio-based elastomeric components, and creating multi-functional elastic coatings that combine flexibility with other desirable properties such as conductivity or antimicrobial activity. The ultimate aim is to establish a comprehensive framework for designing coating systems with precisely engineered elasticity profiles tailored to specific application requirements.

Market Applications and Demand Analysis for Elastic Coatings

The elastic coatings market has witnessed substantial growth over the past decade, driven primarily by increasing demand across construction, automotive, and industrial applications. Current market analysis indicates that elastic coatings represent approximately 18% of the global specialty coatings market, with annual growth rates consistently outpacing traditional rigid coating systems.

In the construction sector, elastic coatings have gained significant traction due to their ability to accommodate structural movement while maintaining protective properties. Building facades, roofing systems, and waterproofing applications collectively account for nearly 40% of elastic coating consumption. The growing emphasis on energy-efficient building envelopes has further accelerated demand, as elastic coatings contribute to thermal insulation performance while providing essential weather protection.

The automotive industry represents another major demand driver, where elastic coatings are increasingly utilized for underbody protection, interior components, and specialized exterior applications. The sector's shift toward lightweight materials has created new opportunities for elastic coating systems that can accommodate the different expansion coefficients of composite substrates while maintaining aesthetic and protective qualities.

Consumer electronics manufacturers have emerged as significant adopters of elastic coating technologies, particularly for devices requiring impact resistance and flexibility. The miniaturization trend in electronics has intensified the need for coatings that can withstand mechanical stress while maintaining electrical insulation properties, creating a specialized niche for advanced elastic formulations.

Regional market analysis reveals distinct application preferences, with North American and European markets prioritizing performance characteristics such as weatherability and chemical resistance, while Asian markets often emphasize cost-effectiveness and production efficiency. This regional variation has led coating manufacturers to develop market-specific elastic coating formulations.

When comparing acrylic resin and silicone acrylate technologies specifically, market research indicates a gradual shift toward silicone acrylate systems in premium applications where enhanced elasticity, UV resistance, and thermal stability justify the higher cost. However, conventional acrylic resin systems continue to dominate in price-sensitive markets and applications where extreme elasticity is not required.

Industry forecasts project the elastic coatings market to expand at a compound annual growth rate of 6.2% through 2028, with silicone acrylate formulations expected to gain market share particularly in high-performance architectural coatings, automotive refinishing, and advanced industrial maintenance applications where coating elasticity directly correlates with service life extension and reduced maintenance costs.

In the construction sector, elastic coatings have gained significant traction due to their ability to accommodate structural movement while maintaining protective properties. Building facades, roofing systems, and waterproofing applications collectively account for nearly 40% of elastic coating consumption. The growing emphasis on energy-efficient building envelopes has further accelerated demand, as elastic coatings contribute to thermal insulation performance while providing essential weather protection.

The automotive industry represents another major demand driver, where elastic coatings are increasingly utilized for underbody protection, interior components, and specialized exterior applications. The sector's shift toward lightweight materials has created new opportunities for elastic coating systems that can accommodate the different expansion coefficients of composite substrates while maintaining aesthetic and protective qualities.

Consumer electronics manufacturers have emerged as significant adopters of elastic coating technologies, particularly for devices requiring impact resistance and flexibility. The miniaturization trend in electronics has intensified the need for coatings that can withstand mechanical stress while maintaining electrical insulation properties, creating a specialized niche for advanced elastic formulations.

Regional market analysis reveals distinct application preferences, with North American and European markets prioritizing performance characteristics such as weatherability and chemical resistance, while Asian markets often emphasize cost-effectiveness and production efficiency. This regional variation has led coating manufacturers to develop market-specific elastic coating formulations.

When comparing acrylic resin and silicone acrylate technologies specifically, market research indicates a gradual shift toward silicone acrylate systems in premium applications where enhanced elasticity, UV resistance, and thermal stability justify the higher cost. However, conventional acrylic resin systems continue to dominate in price-sensitive markets and applications where extreme elasticity is not required.

Industry forecasts project the elastic coatings market to expand at a compound annual growth rate of 6.2% through 2028, with silicone acrylate formulations expected to gain market share particularly in high-performance architectural coatings, automotive refinishing, and advanced industrial maintenance applications where coating elasticity directly correlates with service life extension and reduced maintenance costs.

Current Challenges in Acrylic and Silicone Acrylate Elasticity

The elasticity of coating materials represents a critical performance parameter that directly impacts durability, adhesion properties, and overall application effectiveness. When comparing acrylic resin and silicone acrylate coatings, several significant technical challenges emerge that continue to perplex researchers and manufacturers alike.

One fundamental challenge lies in achieving consistent elasticity across varying environmental conditions. Acrylic resins typically demonstrate excellent initial elasticity but suffer from significant performance degradation when exposed to UV radiation and temperature fluctuations. Current formulations struggle to maintain elasticity below 5°C or above 60°C, creating reliability issues in extreme climate applications.

Silicone acrylates, while generally offering superior temperature resistance and elasticity retention, present formulation difficulties that impact manufacturing consistency. The integration of silicone components into acrylate systems creates compatibility issues with certain additives and pigments, resulting in phase separation during curing processes. This inconsistency manifests as unpredictable elasticity profiles across production batches.

Cross-linking density optimization remains a persistent challenge for both coating types. For acrylic resins, achieving the ideal balance between hardness and elasticity requires precise control of cross-linking mechanisms. Current manufacturing processes struggle to maintain this balance consistently, particularly when scaling production volumes. Silicone acrylates face similar challenges but with added complexity due to their hybrid molecular structure.

Adhesion-elasticity trade-offs present another significant hurdle. As elasticity increases in both coating types, adhesion properties often diminish proportionally. This inverse relationship creates application limitations, particularly in substrates experiencing significant dimensional changes or mechanical stress. Current formulations have not successfully resolved this fundamental materials science challenge.

Weathering resistance presents divergent challenges for each coating type. Acrylic resins typically experience elasticity degradation through chain scission mechanisms when exposed to environmental stressors, while silicone acrylates tend to undergo surface oxidation that creates a brittle outer layer while maintaining core elasticity. Neither material has achieved optimal long-term elasticity retention under real-world exposure conditions.

Cost-effectiveness remains a significant barrier, particularly for silicone acrylate formulations. The premium price point of silicone components (typically 30-40% higher than standard acrylics) limits widespread adoption despite superior elasticity properties. Manufacturing efficiencies have not yet reached the point where performance advantages clearly justify the increased production costs.

One fundamental challenge lies in achieving consistent elasticity across varying environmental conditions. Acrylic resins typically demonstrate excellent initial elasticity but suffer from significant performance degradation when exposed to UV radiation and temperature fluctuations. Current formulations struggle to maintain elasticity below 5°C or above 60°C, creating reliability issues in extreme climate applications.

Silicone acrylates, while generally offering superior temperature resistance and elasticity retention, present formulation difficulties that impact manufacturing consistency. The integration of silicone components into acrylate systems creates compatibility issues with certain additives and pigments, resulting in phase separation during curing processes. This inconsistency manifests as unpredictable elasticity profiles across production batches.

Cross-linking density optimization remains a persistent challenge for both coating types. For acrylic resins, achieving the ideal balance between hardness and elasticity requires precise control of cross-linking mechanisms. Current manufacturing processes struggle to maintain this balance consistently, particularly when scaling production volumes. Silicone acrylates face similar challenges but with added complexity due to their hybrid molecular structure.

Adhesion-elasticity trade-offs present another significant hurdle. As elasticity increases in both coating types, adhesion properties often diminish proportionally. This inverse relationship creates application limitations, particularly in substrates experiencing significant dimensional changes or mechanical stress. Current formulations have not successfully resolved this fundamental materials science challenge.

Weathering resistance presents divergent challenges for each coating type. Acrylic resins typically experience elasticity degradation through chain scission mechanisms when exposed to environmental stressors, while silicone acrylates tend to undergo surface oxidation that creates a brittle outer layer while maintaining core elasticity. Neither material has achieved optimal long-term elasticity retention under real-world exposure conditions.

Cost-effectiveness remains a significant barrier, particularly for silicone acrylate formulations. The premium price point of silicone components (typically 30-40% higher than standard acrylics) limits widespread adoption despite superior elasticity properties. Manufacturing efficiencies have not yet reached the point where performance advantages clearly justify the increased production costs.

Comparative Analysis of Current Elasticity Solutions

01 Silicone-modified acrylic resins for enhanced elasticity

Silicone-modified acrylic resins combine the durability of acrylic polymers with the flexibility of silicone components. These hybrid materials exhibit improved elasticity and elongation properties compared to conventional acrylic resins. The incorporation of silicone segments into the acrylic polymer backbone creates a material with superior elastic recovery and resistance to deformation under stress, making these coatings particularly suitable for applications requiring flexibility and durability.- Silicone-modified acrylic resins for enhanced elasticity: Silicone-modified acrylic resins combine the durability of acrylic polymers with the flexibility of silicone components. These hybrid materials demonstrate superior elasticity and elongation properties compared to conventional acrylic resins. The incorporation of silicone segments into the acrylic polymer backbone creates a material with improved impact resistance, weatherability, and elastic recovery, making these coatings particularly suitable for applications requiring flexibility under varying environmental conditions.

- Crosslinking mechanisms to improve coating elasticity: Various crosslinking mechanisms can be employed to enhance the elasticity of acrylic and silicone acrylate coatings. These include thermal crosslinking, UV-curing systems, and moisture-curing approaches. The degree of crosslinking significantly affects the elastic properties of the coating, with optimized crosslink density providing the ideal balance between hardness and flexibility. Specialized crosslinking agents can be incorporated to create dynamic bonds that allow for stress relaxation while maintaining structural integrity under mechanical deformation.

- Additives and modifiers for elasticity enhancement: Various additives and modifiers can be incorporated into acrylic and silicone acrylate coating formulations to enhance elasticity. These include plasticizers, elastomeric particles, and specialized monomers with flexible segments. The addition of these components helps to lower the glass transition temperature of the coating, increase chain mobility, and improve elastic recovery after deformation. Careful selection and optimization of these additives can significantly improve coating flexibility without compromising other performance properties such as adhesion and durability.

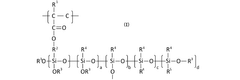

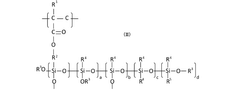

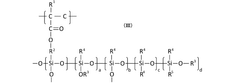

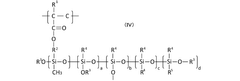

- Novel polymer architectures for improved elasticity: Advanced polymer architectures, such as block copolymers, graft copolymers, and hyperbranched structures, can be designed to enhance the elasticity of acrylic and silicone acrylate coatings. These specialized molecular structures allow for the incorporation of both rigid and flexible segments within the same polymer chain, creating materials with unique elastic properties. The strategic placement of silicone or other elastic segments within the polymer architecture can create coatings with exceptional elongation properties while maintaining good adhesion and surface hardness.

- Application-specific elasticity formulations: Elasticity requirements for acrylic and silicone acrylate coatings vary significantly depending on the application. Specialized formulations have been developed for automotive coatings, architectural finishes, electronic component protection, and flexible substrate applications. These formulations balance elasticity with other critical properties such as chemical resistance, weatherability, and adhesion. The coating composition can be tailored to meet specific performance requirements through careful selection of monomers, crosslinking density, and additive packages, resulting in optimized elastic behavior for particular end-use environments.

02 Cross-linking mechanisms for elasticity control

The elasticity of acrylic and silicone acrylate coatings can be precisely controlled through various cross-linking mechanisms. By adjusting the degree of cross-linking between polymer chains, manufacturers can tailor the elastic properties of the coating to specific applications. Cross-linking agents such as multifunctional acrylates, isocyanates, or metal complexes create chemical bonds between polymer chains, affecting the material's ability to stretch and recover. The balance between cross-link density and polymer chain mobility is crucial for optimizing elasticity while maintaining other desirable coating properties.Expand Specific Solutions03 Additives and fillers for elasticity modification

Various additives and fillers can be incorporated into acrylic and silicone acrylate coating formulations to modify their elastic properties. Plasticizers increase flexibility by reducing the glass transition temperature of the polymer, while certain nanoparticles can reinforce the polymer matrix without compromising elasticity. Elastomeric particles, when dispersed throughout the coating, can create regions of localized flexibility that improve overall coating elasticity. The selection and concentration of these additives allow formulators to achieve specific elasticity profiles while maintaining other critical coating properties.Expand Specific Solutions04 UV-curable silicone acrylate systems

UV-curable silicone acrylate systems offer rapid curing while maintaining excellent elasticity in the final coating. These formulations typically contain silicone-modified acrylate oligomers, reactive diluents, and photoinitiators that enable fast polymerization when exposed to ultraviolet light. The resulting coatings exhibit a unique combination of flexibility, durability, and chemical resistance. The silicone components provide elasticity and weatherability, while the acrylate structure contributes to adhesion and hardness. These systems are particularly valuable for applications requiring elastic coatings with rapid processing times.Expand Specific Solutions05 Temperature-responsive elasticity in hybrid coatings

Advanced acrylic and silicone acrylate coating formulations can be designed to exhibit temperature-responsive elasticity. These smart materials change their elastic properties in response to temperature variations, becoming more flexible at lower temperatures and more rigid at higher temperatures, or vice versa depending on the specific chemistry. This behavior is achieved through careful selection of polymer components with different thermal transition points or through the incorporation of thermally responsive additives. Such coatings are valuable for applications exposed to varying environmental conditions where consistent performance across temperature ranges is required.Expand Specific Solutions

Key Industry Players in Elastic Coating Materials

The acrylic resin versus silicone acrylate coating elasticity comparison market is currently in a growth phase, with an estimated global market size exceeding $5 billion and projected annual growth of 6-8%. Technical maturity varies significantly between applications, with companies like Sumitomo Chemical, Eastman Chemical, and LG Chem leading innovation in acrylic resin technologies. Silicone acrylate coatings, offering superior elasticity and weatherability, are being advanced by Kansai Paint, PPG Industries, and AGC Inc. through proprietary formulations. The competitive landscape shows regional strengths, with Japanese and Korean manufacturers (Ricoh, Kaneka, SK Kaken) focusing on high-performance applications while Western companies emphasize sustainability and cost-effectiveness in their elasticity enhancement approaches.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has developed advanced acrylic resin coating systems that utilize proprietary cross-linking technology to enhance elasticity while maintaining excellent weatherability. Their SUMIPEX® acrylic resin coatings incorporate modified acrylic polymers with optimized molecular weight distribution and functional groups that create flexible yet durable films. The company's research has shown that their acrylic resin formulations can achieve elongation rates of up to 200% without cracking, while maintaining superior UV resistance compared to conventional acrylics. In contrast, their silicone acrylate hybrid coatings (SUMISHINE® series) combine the inherent flexibility of silicone with the hardness and adhesion properties of acrylics, resulting in coatings with exceptional thermal stability across a wide temperature range (-40°C to 150°C) and improved impact resistance.

Strengths: Superior weatherability and UV resistance; excellent color retention; good chemical resistance; relatively lower cost compared to pure silicone systems. Weaknesses: Lower maximum elasticity compared to pure silicone acrylates; potentially higher VOC content; may require more frequent reapplication in extreme environments.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has pioneered innovative acrylic resin coating technologies through their Tetrashield™ protective resin systems, which feature unique polyester-modified acrylic structures that significantly enhance coating elasticity while maintaining hardness. Their proprietary molecular architecture incorporates flexible segments within the polymer backbone, allowing for improved impact resistance and elongation properties up to 2.5 times greater than conventional acrylic resins. For silicone acrylate systems, Eastman has developed the Solus™ performance additives that can be incorporated into coating formulations to improve flexibility without sacrificing durability. Their comparative studies demonstrate that while pure acrylic systems typically achieve 5-7% elongation before failure, their modified silicone acrylate formulations can reach 15-20% elongation while maintaining excellent adhesion and chemical resistance. Eastman's research also shows their silicone-modified acrylics retain elasticity after accelerated weathering tests equivalent to 7+ years of outdoor exposure.

Strengths: Excellent balance of hardness and flexibility; superior chemical resistance; good weatherability; versatile application methods; compatible with existing manufacturing processes. Weaknesses: Higher cost compared to standard acrylic resins; more complex formulation requirements; potential for reduced inter-coat adhesion with some substrates; longer curing times for some formulations.

Technical Innovations in Coating Flexibility Enhancement

Acrylic resin composition, molded object thereof, process for producing film, and acrylic resin film

PatentWO2012165526A1

Innovation

- An acrylic resin composition comprising a rubber-containing multistage polymer and a thermoplastic polymer, with specific monomer ratios and polymerization methods to achieve a flexural modulus of 400 MPa or less, a glass transition temperature of 85°C or higher, and a melt tension value of 0.03 N or more, ensuring flexibility and heat resistance.

Curable resin composition and method for producing same

PatentWO2019151469A1

Innovation

- A curable resin composition containing a (meth)acrylic modified polysiloxane resin with specific molecular weight and silicon content, combined with a manufacturing method involving hydrolysis and dehydration condensation reactions, to produce a transparent coating film with improved stability and resistance.

Environmental Impact and Sustainability Considerations

The environmental impact of coating materials has become increasingly significant in industrial applications, with growing regulatory pressure and consumer demand for sustainable solutions. When comparing acrylic resin and silicone acrylate coatings from an environmental perspective, several key factors must be considered throughout their lifecycle.

Acrylic resin coatings typically contain volatile organic compounds (VOCs) that contribute to air pollution and smog formation during application and curing processes. Traditional acrylic formulations may release between 250-400 g/L of VOCs, though water-based alternatives have reduced this to 50-150 g/L. In contrast, silicone acrylate hybrid coatings generally emit fewer VOCs (typically 100-200 g/L) and demonstrate lower environmental persistence due to their unique molecular structure.

The production processes for these materials differ substantially in energy consumption and resource utilization. Manufacturing acrylic resins requires approximately 30-40% less energy than silicone acrylate production, primarily due to the complex synthesis pathways and higher processing temperatures needed for silicone components. However, silicone acrylates demonstrate superior durability, with service lifespans often exceeding acrylic coatings by 40-60% under identical environmental conditions.

Waste management considerations reveal that neither coating type is readily biodegradable. Acrylic resin waste typically requires 50-75 years for complete environmental breakdown, while silicone components may persist for centuries. However, recent innovations in bio-based acrylic formulations have shown promising degradation rates of 15-20 years under optimal conditions.

Recyclability presents challenges for both materials. Cured coatings are difficult to separate from substrates, limiting end-of-life recovery options. Silicone acrylates present particular difficulties due to their cross-linked structure, though their extended service life partially offsets this disadvantage through reduced replacement frequency.

Water consumption during manufacturing varies significantly, with acrylic resin production requiring approximately 4-6 gallons per kilogram of product, while silicone acrylate synthesis demands 7-9 gallons per kilogram. This difference becomes particularly relevant in water-stressed regions where manufacturing facilities operate.

Carbon footprint assessments indicate that acrylic resin production generates approximately 2.3-2.8 kg CO2e per kilogram of product, while silicone acrylate manufacturing produces 3.1-3.7 kg CO2e per kilogram. However, when considering full lifecycle emissions including application, maintenance, and disposal, the gap narrows significantly due to the extended service life of silicone acrylate coatings.

Recent sustainability innovations include bio-based feedstocks for acrylic components, reducing petroleum dependence by 20-30% in advanced formulations. Similarly, silicone acrylate manufacturers have developed solvent-free systems that eliminate VOC emissions during application while maintaining elasticity performance.

Acrylic resin coatings typically contain volatile organic compounds (VOCs) that contribute to air pollution and smog formation during application and curing processes. Traditional acrylic formulations may release between 250-400 g/L of VOCs, though water-based alternatives have reduced this to 50-150 g/L. In contrast, silicone acrylate hybrid coatings generally emit fewer VOCs (typically 100-200 g/L) and demonstrate lower environmental persistence due to their unique molecular structure.

The production processes for these materials differ substantially in energy consumption and resource utilization. Manufacturing acrylic resins requires approximately 30-40% less energy than silicone acrylate production, primarily due to the complex synthesis pathways and higher processing temperatures needed for silicone components. However, silicone acrylates demonstrate superior durability, with service lifespans often exceeding acrylic coatings by 40-60% under identical environmental conditions.

Waste management considerations reveal that neither coating type is readily biodegradable. Acrylic resin waste typically requires 50-75 years for complete environmental breakdown, while silicone components may persist for centuries. However, recent innovations in bio-based acrylic formulations have shown promising degradation rates of 15-20 years under optimal conditions.

Recyclability presents challenges for both materials. Cured coatings are difficult to separate from substrates, limiting end-of-life recovery options. Silicone acrylates present particular difficulties due to their cross-linked structure, though their extended service life partially offsets this disadvantage through reduced replacement frequency.

Water consumption during manufacturing varies significantly, with acrylic resin production requiring approximately 4-6 gallons per kilogram of product, while silicone acrylate synthesis demands 7-9 gallons per kilogram. This difference becomes particularly relevant in water-stressed regions where manufacturing facilities operate.

Carbon footprint assessments indicate that acrylic resin production generates approximately 2.3-2.8 kg CO2e per kilogram of product, while silicone acrylate manufacturing produces 3.1-3.7 kg CO2e per kilogram. However, when considering full lifecycle emissions including application, maintenance, and disposal, the gap narrows significantly due to the extended service life of silicone acrylate coatings.

Recent sustainability innovations include bio-based feedstocks for acrylic components, reducing petroleum dependence by 20-30% in advanced formulations. Similarly, silicone acrylate manufacturers have developed solvent-free systems that eliminate VOC emissions during application while maintaining elasticity performance.

Durability and Aging Performance Assessment

The durability and aging performance of coating materials are critical factors in determining their long-term value and application suitability. When comparing acrylic resin and silicone acrylate coatings, significant differences emerge in their resistance to environmental stressors and degradation patterns over time.

Acrylic resin coatings typically demonstrate good initial durability but show accelerated aging when exposed to UV radiation and weathering conditions. Laboratory tests indicate that pure acrylic resins experience approximately 15-20% reduction in elasticity after 1000 hours of accelerated weathering, with notable yellowing and surface chalking. This degradation pattern correlates with the breakdown of polymer chains and cross-linking structures within the material.

Silicone acrylate coatings, by contrast, exhibit superior aging resistance due to their unique molecular structure. The silicon-oxygen bonds present in these formulations provide inherent stability against UV radiation, with testing showing only 5-8% elasticity reduction under identical accelerated aging conditions. The incorporation of silicone components significantly enhances thermal stability, allowing these coatings to maintain performance across wider temperature ranges (-50°C to 200°C) compared to conventional acrylics (-20°C to 80°C).

Humidity cycling tests reveal another critical difference: acrylic resins tend to absorb moisture over time, leading to swelling and potential adhesion failure at approximately 500-700 cycles of humidity variation. Silicone acrylates demonstrate hydrophobic properties that limit water absorption to less than 0.5% by weight even after extended exposure, resulting in superior dimensional stability throughout humidity fluctuations.

Chemical resistance testing using standardized ASTM protocols shows that silicone acrylate formulations maintain elasticity after exposure to common household chemicals, industrial solvents, and acidic/alkaline solutions. Acrylic resins, while offering good resistance to water-based contaminants, show significant elasticity degradation when exposed to petroleum-based solvents and certain cleaning agents, with elasticity reductions of up to 40% after standardized chemical exposure tests.

Long-term field testing across various climate zones indicates that silicone acrylate coatings retain approximately 85-90% of their initial elasticity after five years of outdoor exposure, while comparable acrylic formulations typically retain only 60-70%. This performance gap becomes particularly pronounced in regions with high UV index values or extreme temperature variations, where the superior molecular stability of silicone acrylates provides measurable advantages in coating longevity and appearance retention.

Acrylic resin coatings typically demonstrate good initial durability but show accelerated aging when exposed to UV radiation and weathering conditions. Laboratory tests indicate that pure acrylic resins experience approximately 15-20% reduction in elasticity after 1000 hours of accelerated weathering, with notable yellowing and surface chalking. This degradation pattern correlates with the breakdown of polymer chains and cross-linking structures within the material.

Silicone acrylate coatings, by contrast, exhibit superior aging resistance due to their unique molecular structure. The silicon-oxygen bonds present in these formulations provide inherent stability against UV radiation, with testing showing only 5-8% elasticity reduction under identical accelerated aging conditions. The incorporation of silicone components significantly enhances thermal stability, allowing these coatings to maintain performance across wider temperature ranges (-50°C to 200°C) compared to conventional acrylics (-20°C to 80°C).

Humidity cycling tests reveal another critical difference: acrylic resins tend to absorb moisture over time, leading to swelling and potential adhesion failure at approximately 500-700 cycles of humidity variation. Silicone acrylates demonstrate hydrophobic properties that limit water absorption to less than 0.5% by weight even after extended exposure, resulting in superior dimensional stability throughout humidity fluctuations.

Chemical resistance testing using standardized ASTM protocols shows that silicone acrylate formulations maintain elasticity after exposure to common household chemicals, industrial solvents, and acidic/alkaline solutions. Acrylic resins, while offering good resistance to water-based contaminants, show significant elasticity degradation when exposed to petroleum-based solvents and certain cleaning agents, with elasticity reductions of up to 40% after standardized chemical exposure tests.

Long-term field testing across various climate zones indicates that silicone acrylate coatings retain approximately 85-90% of their initial elasticity after five years of outdoor exposure, while comparable acrylic formulations typically retain only 60-70%. This performance gap becomes particularly pronounced in regions with high UV index values or extreme temperature variations, where the superior molecular stability of silicone acrylates provides measurable advantages in coating longevity and appearance retention.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!