How to Formulate Acrylic Resin for Low-Temperature Curing

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acrylic Resin Low-Temperature Curing Background and Objectives

Acrylic resins have been a cornerstone in the coatings and adhesives industry since their commercial introduction in the 1930s. Initially developed as alternatives to natural resins, these synthetic polymers quickly gained prominence due to their versatility, durability, and excellent adhesion properties. The evolution of acrylic resin technology has been marked by continuous improvements in formulation techniques, expanding their application across diverse industries including automotive, construction, electronics, and medical devices.

Traditional acrylic resin curing processes typically require elevated temperatures ranging from 120°C to 180°C to achieve optimal cross-linking and performance properties. This high-temperature requirement presents significant limitations in terms of energy consumption, substrate compatibility, and processing efficiency. The increasing demand for sustainable manufacturing processes and the need to apply coatings on heat-sensitive substrates have driven the industry toward developing low-temperature curing acrylic resin systems.

The technological trajectory of acrylic resins has seen several paradigm shifts, from solvent-based to water-based systems, and from thermal curing to radiation curing technologies. Recent advancements in polymer chemistry, particularly in the development of novel initiator systems and functional monomers, have opened new possibilities for low-temperature curing without compromising performance characteristics.

The primary objective of this technical research is to investigate and evaluate innovative approaches to formulate acrylic resins capable of effective curing at temperatures below 80°C. This temperature threshold represents a significant reduction from conventional curing requirements while maintaining the performance standards expected in commercial applications. Specifically, the research aims to identify key components and formulation strategies that enable efficient cross-linking at reduced temperatures.

Secondary objectives include assessing the environmental and economic benefits of low-temperature curing acrylic systems, including reduced energy consumption, decreased carbon footprint, and expanded application possibilities for heat-sensitive substrates. Additionally, the research seeks to establish a comprehensive understanding of the relationship between molecular architecture and curing behavior to guide future formulation development.

The technological significance of this research extends beyond immediate application benefits. Low-temperature curing acrylic resins represent a critical advancement in sustainable manufacturing practices and align with global initiatives to reduce industrial energy consumption. Furthermore, these systems potentially enable new applications in emerging fields such as flexible electronics, medical implants, and advanced composite materials where thermal sensitivity is a primary concern.

This research is positioned at the intersection of polymer chemistry, materials science, and process engineering, requiring a multidisciplinary approach to address the complex challenges associated with low-temperature curing mechanisms while maintaining or enhancing the performance characteristics that have made acrylic resins indispensable in modern industrial applications.

Traditional acrylic resin curing processes typically require elevated temperatures ranging from 120°C to 180°C to achieve optimal cross-linking and performance properties. This high-temperature requirement presents significant limitations in terms of energy consumption, substrate compatibility, and processing efficiency. The increasing demand for sustainable manufacturing processes and the need to apply coatings on heat-sensitive substrates have driven the industry toward developing low-temperature curing acrylic resin systems.

The technological trajectory of acrylic resins has seen several paradigm shifts, from solvent-based to water-based systems, and from thermal curing to radiation curing technologies. Recent advancements in polymer chemistry, particularly in the development of novel initiator systems and functional monomers, have opened new possibilities for low-temperature curing without compromising performance characteristics.

The primary objective of this technical research is to investigate and evaluate innovative approaches to formulate acrylic resins capable of effective curing at temperatures below 80°C. This temperature threshold represents a significant reduction from conventional curing requirements while maintaining the performance standards expected in commercial applications. Specifically, the research aims to identify key components and formulation strategies that enable efficient cross-linking at reduced temperatures.

Secondary objectives include assessing the environmental and economic benefits of low-temperature curing acrylic systems, including reduced energy consumption, decreased carbon footprint, and expanded application possibilities for heat-sensitive substrates. Additionally, the research seeks to establish a comprehensive understanding of the relationship between molecular architecture and curing behavior to guide future formulation development.

The technological significance of this research extends beyond immediate application benefits. Low-temperature curing acrylic resins represent a critical advancement in sustainable manufacturing practices and align with global initiatives to reduce industrial energy consumption. Furthermore, these systems potentially enable new applications in emerging fields such as flexible electronics, medical implants, and advanced composite materials where thermal sensitivity is a primary concern.

This research is positioned at the intersection of polymer chemistry, materials science, and process engineering, requiring a multidisciplinary approach to address the complex challenges associated with low-temperature curing mechanisms while maintaining or enhancing the performance characteristics that have made acrylic resins indispensable in modern industrial applications.

Market Analysis for Low-Temperature Curing Acrylic Systems

The global market for low-temperature curing acrylic systems has been experiencing significant growth, driven primarily by increasing demand across automotive refinishing, industrial coatings, and construction applications. This market segment is particularly attractive due to its energy efficiency advantages, reduced carbon footprint, and compatibility with heat-sensitive substrates.

Current market valuations place the low-temperature curing acrylic resin sector at approximately $3.2 billion globally, with projections indicating a compound annual growth rate of 5.7% through 2028. The Asia-Pacific region, particularly China and India, represents the fastest-growing market due to rapid industrialization and increasing adoption of environmentally friendly coating technologies.

Key market drivers include stringent environmental regulations limiting VOC emissions, rising energy costs prompting manufacturers to seek more efficient curing processes, and growing consumer preference for sustainable products. The automotive refinish segment currently holds the largest market share at 38%, followed by industrial maintenance coatings at 27% and architectural coatings at 21%.

Customer demand analysis reveals a clear preference shift toward water-based low-temperature curing acrylic systems over solvent-based alternatives, with water-based formulations now accounting for 56% of market share. This trend is expected to continue as regulatory pressures increase globally.

Market segmentation by application shows diverse growth patterns, with electronics applications showing the highest growth potential (8.3% CAGR), followed by medical devices (7.1%) and automotive components (6.4%). These high-growth segments are characterized by demanding performance requirements including chemical resistance, weatherability, and precise adhesion properties.

Competitive analysis indicates a moderately fragmented market with the top five manufacturers controlling approximately 42% of global market share. Regional players with specialized formulations for local market needs maintain strong positions in their respective territories. Price sensitivity varies significantly by application, with commodity architectural coatings showing high price elasticity while specialized industrial applications demonstrate greater willingness to pay premium prices for performance benefits.

Distribution channels are evolving, with direct-to-manufacturer sales remaining dominant for large-volume industrial applications, while digital platforms and specialized distributors are gaining importance for smaller volume, high-margin specialty applications. This shift is reshaping market access strategies for both established players and new entrants.

Future market projections indicate continued growth potential, particularly in emerging economies where infrastructure development and manufacturing expansion create sustained demand. However, market maturity in North America and Western Europe suggests that innovation in formulation technology will be critical for maintaining growth rates in these regions.

Current market valuations place the low-temperature curing acrylic resin sector at approximately $3.2 billion globally, with projections indicating a compound annual growth rate of 5.7% through 2028. The Asia-Pacific region, particularly China and India, represents the fastest-growing market due to rapid industrialization and increasing adoption of environmentally friendly coating technologies.

Key market drivers include stringent environmental regulations limiting VOC emissions, rising energy costs prompting manufacturers to seek more efficient curing processes, and growing consumer preference for sustainable products. The automotive refinish segment currently holds the largest market share at 38%, followed by industrial maintenance coatings at 27% and architectural coatings at 21%.

Customer demand analysis reveals a clear preference shift toward water-based low-temperature curing acrylic systems over solvent-based alternatives, with water-based formulations now accounting for 56% of market share. This trend is expected to continue as regulatory pressures increase globally.

Market segmentation by application shows diverse growth patterns, with electronics applications showing the highest growth potential (8.3% CAGR), followed by medical devices (7.1%) and automotive components (6.4%). These high-growth segments are characterized by demanding performance requirements including chemical resistance, weatherability, and precise adhesion properties.

Competitive analysis indicates a moderately fragmented market with the top five manufacturers controlling approximately 42% of global market share. Regional players with specialized formulations for local market needs maintain strong positions in their respective territories. Price sensitivity varies significantly by application, with commodity architectural coatings showing high price elasticity while specialized industrial applications demonstrate greater willingness to pay premium prices for performance benefits.

Distribution channels are evolving, with direct-to-manufacturer sales remaining dominant for large-volume industrial applications, while digital platforms and specialized distributors are gaining importance for smaller volume, high-margin specialty applications. This shift is reshaping market access strategies for both established players and new entrants.

Future market projections indicate continued growth potential, particularly in emerging economies where infrastructure development and manufacturing expansion create sustained demand. However, market maturity in North America and Western Europe suggests that innovation in formulation technology will be critical for maintaining growth rates in these regions.

Technical Challenges in Low-Temperature Curing Formulations

The development of low-temperature curing acrylic resin formulations faces several significant technical challenges that must be overcome to achieve optimal performance. Traditional acrylic resins typically require elevated temperatures (above 120°C) for complete curing, which limits their application in heat-sensitive substrates and increases energy consumption during manufacturing processes.

One primary challenge is achieving adequate crosslinking density at lower temperatures. The reaction kinetics of conventional acrylic polymerization systems slow dramatically at reduced temperatures, resulting in incomplete network formation and compromised mechanical properties. This necessitates the development of more reactive functional groups or alternative crosslinking mechanisms that can operate efficiently below 80°C.

Catalyst efficiency represents another major hurdle. Current catalytic systems often exhibit diminished activity at lower temperatures, leading to extended cure times that are impractical for industrial applications. Research into novel metal-organic catalysts and photoinitiator systems shows promise, but issues with stability, toxicity, and compatibility with various acrylic formulations remain problematic.

Balancing cure speed with pot life presents a significant formulation dilemma. Systems reactive enough to cure rapidly at low temperatures typically exhibit reduced shelf stability and working time. This creates manufacturing challenges and increases waste due to premature gelation. Advanced inhibitor systems and dual-cure mechanisms are being explored to address this contradiction.

Shrinkage control during polymerization becomes more challenging at lower temperatures. The slower reaction kinetics can lead to uneven stress distribution within the curing material, resulting in warpage, cracking, or poor adhesion to substrates. Incorporating specialized oligomers and phase-change materials has shown some success in mitigating these effects.

Moisture sensitivity often increases in low-temperature curing systems. Many of the more reactive components introduced to facilitate low-temperature curing are hygroscopic or water-reactive, creating formulation stability issues and potential application problems in humid environments. Hydrophobic additives and moisture scavengers must be carefully balanced to maintain performance without compromising cure efficiency.

Adhesion to diverse substrates at lower cure temperatures represents another significant challenge. The reduced thermal energy available during curing often results in weaker interfacial bonding, particularly to low-energy surfaces like polyolefins. This necessitates the development of specialized adhesion promoters and surface treatment protocols specifically designed for low-temperature applications.

Achieving regulatory compliance while maintaining performance adds complexity to formulation efforts. Many highly reactive components that enable low-temperature curing may present health or environmental concerns, limiting their commercial viability. Finding alternatives that balance reactivity with safety profiles acceptable for various market segments requires extensive testing and validation.

One primary challenge is achieving adequate crosslinking density at lower temperatures. The reaction kinetics of conventional acrylic polymerization systems slow dramatically at reduced temperatures, resulting in incomplete network formation and compromised mechanical properties. This necessitates the development of more reactive functional groups or alternative crosslinking mechanisms that can operate efficiently below 80°C.

Catalyst efficiency represents another major hurdle. Current catalytic systems often exhibit diminished activity at lower temperatures, leading to extended cure times that are impractical for industrial applications. Research into novel metal-organic catalysts and photoinitiator systems shows promise, but issues with stability, toxicity, and compatibility with various acrylic formulations remain problematic.

Balancing cure speed with pot life presents a significant formulation dilemma. Systems reactive enough to cure rapidly at low temperatures typically exhibit reduced shelf stability and working time. This creates manufacturing challenges and increases waste due to premature gelation. Advanced inhibitor systems and dual-cure mechanisms are being explored to address this contradiction.

Shrinkage control during polymerization becomes more challenging at lower temperatures. The slower reaction kinetics can lead to uneven stress distribution within the curing material, resulting in warpage, cracking, or poor adhesion to substrates. Incorporating specialized oligomers and phase-change materials has shown some success in mitigating these effects.

Moisture sensitivity often increases in low-temperature curing systems. Many of the more reactive components introduced to facilitate low-temperature curing are hygroscopic or water-reactive, creating formulation stability issues and potential application problems in humid environments. Hydrophobic additives and moisture scavengers must be carefully balanced to maintain performance without compromising cure efficiency.

Adhesion to diverse substrates at lower cure temperatures represents another significant challenge. The reduced thermal energy available during curing often results in weaker interfacial bonding, particularly to low-energy surfaces like polyolefins. This necessitates the development of specialized adhesion promoters and surface treatment protocols specifically designed for low-temperature applications.

Achieving regulatory compliance while maintaining performance adds complexity to formulation efforts. Many highly reactive components that enable low-temperature curing may present health or environmental concerns, limiting their commercial viability. Finding alternatives that balance reactivity with safety profiles acceptable for various market segments requires extensive testing and validation.

Current Formulation Approaches for Low-Temperature Curing

01 Low temperature curing acrylic resins

Some acrylic resin formulations are designed to cure at relatively low temperatures, typically between room temperature and 100°C. These formulations often incorporate specific catalysts or hardeners that enable polymerization at lower temperatures. Low temperature curing acrylic resins are particularly useful for applications where heat-sensitive substrates are involved or where energy efficiency is a concern. These formulations may include special additives to ensure complete curing and optimal mechanical properties despite the lower curing temperatures.- Low temperature curing acrylic resins: Some acrylic resin formulations are designed to cure at relatively low temperatures, typically between room temperature and 80°C. These formulations often include specific catalysts or hardeners that enable polymerization at lower temperatures. Low temperature curing acrylic resins are particularly useful for applications where heat-sensitive substrates are involved or where energy efficiency is a priority.

- Medium temperature curing acrylic resins: Medium temperature curing acrylic resins typically cure in the range of 80-150°C. This temperature range offers a balance between cure speed and energy consumption. These formulations often provide good mechanical properties and chemical resistance while not requiring extremely high temperatures for processing. They are commonly used in industrial coatings, adhesives, and composite applications.

- High temperature curing acrylic resins: High temperature curing acrylic resins require temperatures above 150°C to achieve complete polymerization and optimal properties. These formulations are designed for applications demanding superior thermal stability, chemical resistance, and mechanical strength. The high curing temperature enables complete cross-linking of the polymer chains, resulting in enhanced durability and performance in extreme environments.

- UV-assisted thermal curing of acrylic resins: Some acrylic resin systems employ a combination of UV radiation and thermal curing to achieve optimal properties. The UV exposure initiates the polymerization process, which is then completed by thermal curing at moderate temperatures. This dual-cure approach can reduce overall curing temperatures while maintaining or improving the final properties of the cured resin. It offers advantages in terms of energy efficiency and processing speed.

- Additives affecting curing temperature of acrylic resins: Various additives can be incorporated into acrylic resin formulations to modify their curing temperature profiles. These include catalysts, accelerators, inhibitors, and reactive diluents. By carefully selecting and balancing these additives, the curing temperature can be tailored to specific application requirements. Some additives can lower the curing temperature by enhancing reaction kinetics, while others can improve the properties of resins cured at lower temperatures.

02 High temperature curing acrylic resins

High temperature curing acrylic resins typically require temperatures above 120°C to achieve complete polymerization and optimal properties. These formulations are designed for applications where high thermal stability and superior mechanical properties are required. The higher curing temperatures often result in increased cross-linking density, which enhances the resin's resistance to chemicals, heat, and mechanical stress. These formulations may include thermal stabilizers to prevent degradation during the curing process.Expand Specific Solutions03 Multi-stage curing processes for acrylic resins

Some acrylic resin systems employ multi-stage curing processes involving different temperature profiles. These processes typically begin with a lower temperature pre-cure phase followed by a higher temperature post-cure phase. This approach allows for better control of the polymerization reaction, reduced internal stresses, and improved final properties. Multi-stage curing can also help minimize the formation of defects such as bubbles or cracks in the cured resin. The specific temperature profiles are carefully designed based on the resin chemistry and intended application.Expand Specific Solutions04 UV-assisted thermal curing of acrylic resins

UV-assisted thermal curing combines ultraviolet radiation with heat to cure acrylic resins. This dual-cure approach can significantly reduce the required curing temperature while maintaining or improving the final properties of the cured resin. The UV radiation initiates the polymerization process, which is then completed by thermal curing at lower temperatures than would be required for thermal curing alone. This method is particularly useful for thick or complex parts where UV penetration might be limited.Expand Specific Solutions05 Effect of additives on acrylic resin curing temperature

Various additives can significantly influence the curing temperature requirements of acrylic resins. Catalysts and accelerators can lower the curing temperature by facilitating the polymerization reaction at lower thermal energy levels. Conversely, inhibitors can be used to increase the temperature stability of the formulation, preventing premature curing during storage or processing. Fillers and reinforcing agents may also affect the curing behavior by altering the thermal conductivity and heat distribution within the resin system. The proper selection of additives allows for customization of the curing profile to meet specific application requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The acrylic resin low-temperature curing technology market is in a growth phase, with increasing demand driven by energy efficiency requirements across industries. The global market size is estimated at $3.5-4 billion, expanding at 5-7% CAGR. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include LG Chem and Nippon Shokubai with advanced monomer technologies, Kaneka and RESONAC developing specialized catalysts, Mitsui Chemicals and Toray focusing on automotive applications, while Mitsubishi Gas Chemical and Jiangsu Sanmu Group concentrate on industrial coatings. Japanese and Korean companies dominate R&D, with emerging competition from Chinese manufacturers like Shandong Youquan offering cost-competitive alternatives.

LG Chem Ltd.

Technical Solution: LG Chem has developed innovative acrylic resin formulations for low-temperature curing applications, particularly in automotive coatings and adhesives. Their technology employs a dual-catalyst system combining photoinitiators and thermal catalysts that work synergistically to achieve complete polymerization at temperatures as low as 80-100°C. The company's proprietary formulation incorporates modified acrylic monomers with reduced activation energy barriers and specialized reactive diluents that maintain low viscosity while enhancing crosslinking efficiency. LG Chem has also pioneered the use of core-shell structured nanoparticles as toughening agents that don't compromise the low-temperature cure profile. Their formulations typically achieve 95%+ cure rates at temperatures 30-40°C lower than conventional systems, while maintaining excellent adhesion properties and chemical resistance.

Strengths: Superior energy efficiency with significant reduction in curing temperatures; excellent adhesion properties even at low cure temperatures; maintains high chemical and weather resistance. Weaknesses: Higher raw material costs compared to conventional systems; requires precise formulation control; some formulations may have shorter pot life due to reactive component combinations.

Kaneka Corp.

Technical Solution: Kaneka Corporation has developed advanced acrylic resin systems for low-temperature curing applications through their proprietary "Hybrid Acrylic Technology." This approach combines conventional acrylic backbones with silicone-modified side chains and specialized functional groups that enable crosslinking at temperatures as low as 90°C. Their formulation incorporates novel photo-thermal dual-cure initiators that activate sequentially, allowing for initial network formation via UV exposure followed by complete cure at reduced thermal energy input. Kaneka's technology also features nano-dispersed reactive oligomers that reduce the glass transition temperature of the uncured resin while maintaining excellent mechanical properties in the final cured product. The company has successfully implemented these systems in electronics applications, particularly for temperature-sensitive substrates, achieving full cure in 15-30 minutes at temperatures 40-50°C lower than traditional acrylic systems while maintaining excellent adhesion and durability.

Strengths: Excellent compatibility with temperature-sensitive electronic components; superior flexibility and impact resistance; good balance of adhesion and cohesive strength. Weaknesses: Relatively high cost compared to conventional systems; some formulations require specialized application equipment; limited shelf life for certain highly reactive component combinations.

Key Patents and Innovations in Catalyst Systems

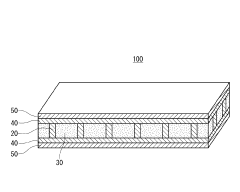

Acrylic resin composition and panel material for building

PatentPendingJP2023061791A

Innovation

- An acrylic resin composition with a polymerizable compound and curing agent that allows for low-temperature curing and maintains a high elastic modulus retention rate even at elevated temperatures, using a radical polymerization mechanism to achieve a Tg-less cured product.

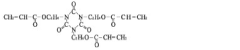

Low‑temperature curable resin composition, coating film forming method using same, resin mortar and fiber reinforced resin

PatentWO2009147953A1

Innovation

- A low-temperature curable resin composition comprising a radically polymerizable resin, unsaturated monomer, cobalt metal salt, hydroxyl group-containing aromatic tertiary amine, and organic peroxide, which allows for rapid curing, low odor, and improved workability and durability at temperatures of 0°C or less.

Environmental Impact and VOC Regulations

The environmental impact of acrylic resin formulations for low-temperature curing has become increasingly significant as global sustainability concerns grow. Traditional acrylic resin systems often contain high levels of volatile organic compounds (VOCs) that evaporate during application and curing processes, contributing to air pollution and potential health hazards. These emissions can lead to ground-level ozone formation, respiratory irritation, and other environmental consequences that regulatory bodies worldwide have sought to address through increasingly stringent regulations.

VOC regulations have evolved substantially over the past two decades, with major markets implementing progressively stricter limits. The European Union's Directive 2004/42/EC established comprehensive VOC content limits for decorative paints and varnishes, which have been periodically revised downward. Similarly, the United States Environmental Protection Agency (EPA) has implemented regulations under the Clean Air Act that limit VOC emissions from architectural coatings and industrial applications. In Asia, countries like China and Japan have also introduced their own regulatory frameworks, with China's VOC regulations becoming particularly stringent in recent years.

These regulatory pressures have created significant challenges for acrylic resin formulators, especially in the context of low-temperature curing systems. The traditional approach of using higher solvent content to facilitate low-temperature film formation conflicts directly with VOC reduction goals. This has accelerated research into alternative technologies such as waterborne systems, high-solids formulations, and radiation-curable resins that can maintain performance while reducing environmental impact.

The industry has responded with several innovative approaches to meet these challenges. Waterborne acrylic dispersions have been reformulated with advanced coalescent technologies that facilitate film formation at lower temperatures without relying on traditional high-VOC solvents. High-solids acrylic resins with optimized molecular weight distributions and functional group densities have enabled formulators to reduce solvent content while maintaining application properties and low-temperature cure capabilities.

Emerging technologies in the field include bio-based acrylic monomers derived from renewable resources, which can reduce the carbon footprint of acrylic resin systems while maintaining their performance characteristics. Additionally, hybrid systems combining acrylic chemistry with other polymer types have shown promise in achieving low-temperature cure with minimal environmental impact. These innovations represent significant progress toward sustainable coating solutions that can meet both performance requirements and environmental regulations.

The economic implications of these regulatory trends are substantial, with manufacturers facing increased costs for reformulation, testing, and compliance documentation. However, companies that successfully navigate these challenges often gain competitive advantages through access to restricted markets and alignment with consumer preferences for environmentally responsible products.

VOC regulations have evolved substantially over the past two decades, with major markets implementing progressively stricter limits. The European Union's Directive 2004/42/EC established comprehensive VOC content limits for decorative paints and varnishes, which have been periodically revised downward. Similarly, the United States Environmental Protection Agency (EPA) has implemented regulations under the Clean Air Act that limit VOC emissions from architectural coatings and industrial applications. In Asia, countries like China and Japan have also introduced their own regulatory frameworks, with China's VOC regulations becoming particularly stringent in recent years.

These regulatory pressures have created significant challenges for acrylic resin formulators, especially in the context of low-temperature curing systems. The traditional approach of using higher solvent content to facilitate low-temperature film formation conflicts directly with VOC reduction goals. This has accelerated research into alternative technologies such as waterborne systems, high-solids formulations, and radiation-curable resins that can maintain performance while reducing environmental impact.

The industry has responded with several innovative approaches to meet these challenges. Waterborne acrylic dispersions have been reformulated with advanced coalescent technologies that facilitate film formation at lower temperatures without relying on traditional high-VOC solvents. High-solids acrylic resins with optimized molecular weight distributions and functional group densities have enabled formulators to reduce solvent content while maintaining application properties and low-temperature cure capabilities.

Emerging technologies in the field include bio-based acrylic monomers derived from renewable resources, which can reduce the carbon footprint of acrylic resin systems while maintaining their performance characteristics. Additionally, hybrid systems combining acrylic chemistry with other polymer types have shown promise in achieving low-temperature cure with minimal environmental impact. These innovations represent significant progress toward sustainable coating solutions that can meet both performance requirements and environmental regulations.

The economic implications of these regulatory trends are substantial, with manufacturers facing increased costs for reformulation, testing, and compliance documentation. However, companies that successfully navigate these challenges often gain competitive advantages through access to restricted markets and alignment with consumer preferences for environmentally responsible products.

Cost-Benefit Analysis of Low-Temperature Curing Systems

The implementation of low-temperature curing systems for acrylic resins presents a complex economic equation that must be carefully evaluated. Initial investment costs for transitioning to low-temperature curing technologies typically include equipment modifications, reformulation expenses, and potential production line adjustments. These capital expenditures can range from moderate to significant depending on existing infrastructure and the specific technology adopted.

Energy consumption represents one of the most compelling economic advantages of low-temperature curing systems. Traditional acrylic resin curing often requires temperatures of 140-180°C, whereas low-temperature alternatives can operate effectively at 80-120°C. This temperature reduction translates to energy savings of approximately 25-40% in most manufacturing environments, with corresponding reductions in utility costs that typically achieve return on investment within 12-24 months.

Production efficiency gains constitute another significant economic benefit. Low-temperature curing systems generally demonstrate faster cycle times, with curing periods reduced by 15-30% compared to conventional methods. This acceleration enables higher throughput on existing equipment, effectively increasing production capacity without proportional increases in capital expenditure or facility footprint.

Quality-related cost factors must also be considered in the economic analysis. Low-temperature curing often results in reduced thermal stress on substrates and components, decreasing rejection rates by an average of 5-15% in precision applications. This improvement in first-pass yield represents substantial savings in material costs and rework expenses, particularly in high-value product manufacturing.

Environmental compliance costs increasingly favor low-temperature curing technologies. Reduced energy consumption directly correlates with lower carbon emissions, potentially qualifying manufacturers for carbon credits or avoiding carbon taxes in regulated markets. Additionally, many low-temperature formulations release fewer volatile organic compounds (VOCs), reducing abatement equipment requirements and associated operational costs.

Maintenance economics also typically favor low-temperature systems. Operating at lower thermal loads generally extends equipment lifespan and reduces maintenance frequency, with documented maintenance cost reductions of 10-20% in comparable manufacturing environments. This factor becomes particularly significant in continuous production operations where equipment downtime carries substantial opportunity costs.

When evaluating total cost of ownership over a standard 5-year horizon, most manufacturing operations implementing low-temperature acrylic resin curing systems achieve positive return on investment, with payback periods averaging 18-30 months depending on production volume, energy costs, and specific application requirements. The economic case strengthens further when factoring in potential regulatory incentives and the marketing value of reduced environmental impact.

Energy consumption represents one of the most compelling economic advantages of low-temperature curing systems. Traditional acrylic resin curing often requires temperatures of 140-180°C, whereas low-temperature alternatives can operate effectively at 80-120°C. This temperature reduction translates to energy savings of approximately 25-40% in most manufacturing environments, with corresponding reductions in utility costs that typically achieve return on investment within 12-24 months.

Production efficiency gains constitute another significant economic benefit. Low-temperature curing systems generally demonstrate faster cycle times, with curing periods reduced by 15-30% compared to conventional methods. This acceleration enables higher throughput on existing equipment, effectively increasing production capacity without proportional increases in capital expenditure or facility footprint.

Quality-related cost factors must also be considered in the economic analysis. Low-temperature curing often results in reduced thermal stress on substrates and components, decreasing rejection rates by an average of 5-15% in precision applications. This improvement in first-pass yield represents substantial savings in material costs and rework expenses, particularly in high-value product manufacturing.

Environmental compliance costs increasingly favor low-temperature curing technologies. Reduced energy consumption directly correlates with lower carbon emissions, potentially qualifying manufacturers for carbon credits or avoiding carbon taxes in regulated markets. Additionally, many low-temperature formulations release fewer volatile organic compounds (VOCs), reducing abatement equipment requirements and associated operational costs.

Maintenance economics also typically favor low-temperature systems. Operating at lower thermal loads generally extends equipment lifespan and reduces maintenance frequency, with documented maintenance cost reductions of 10-20% in comparable manufacturing environments. This factor becomes particularly significant in continuous production operations where equipment downtime carries substantial opportunity costs.

When evaluating total cost of ownership over a standard 5-year horizon, most manufacturing operations implementing low-temperature acrylic resin curing systems achieve positive return on investment, with payback periods averaging 18-30 months depending on production volume, energy costs, and specific application requirements. The economic case strengthens further when factoring in potential regulatory incentives and the marketing value of reduced environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!