Acrylic Resin vs Polyamide: Heat Deflection Analysis

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Resistance Background and Objectives

Thermal resistance, particularly heat deflection temperature (HDT), represents a critical parameter in polymer material selection for engineering applications. The historical development of thermal resistance testing dates back to the 1930s when standardized methods were first established to quantify a material's ability to maintain structural integrity under load at elevated temperatures. This evolution of testing methodologies has paralleled the growing demand for materials capable of withstanding increasingly challenging thermal environments across industries.

Acrylic resins and polyamides represent two distinct polymer families with significantly different thermal performance characteristics. Acrylic resins, developed commercially in the 1930s, have traditionally been valued for their optical clarity and weather resistance, while exhibiting moderate thermal resistance properties. Polyamides, first introduced as Nylon in the late 1930s, were engineered specifically to provide superior mechanical strength and thermal stability for industrial applications.

The technological trajectory of both materials has been marked by continuous improvements in thermal resistance through various modification techniques. For acrylics, this has included the development of impact-modified variants and heat-resistant grades through copolymerization and reinforcement strategies. Polyamides have evolved through the introduction of various types (PA6, PA66, PA12, etc.) and enhancement techniques including glass fiber reinforcement and crystallinity optimization to achieve higher heat deflection temperatures.

Current industry demands are driving the need for comprehensive comparative analysis between these material families, particularly in applications where thermal performance represents a critical design parameter. The automotive, electronics, and aerospace sectors increasingly require materials that can maintain dimensional stability and mechanical integrity under elevated temperature conditions, while also meeting other performance criteria such as weight reduction and cost efficiency.

The primary objective of this analysis is to establish a systematic comparison framework for evaluating the heat deflection characteristics of acrylic resins versus polyamides across various grades and modifications. This includes quantifying the relationship between material composition and thermal resistance, identifying the underlying molecular and structural factors that contribute to heat deflection behavior, and developing predictive models for thermal performance under various loading conditions.

Additionally, this investigation aims to map the practical application boundaries for both material families based on their thermal resistance profiles, providing engineering teams with decision-making tools for material selection in thermally demanding environments. The analysis will further explore emerging modification technologies that promise to extend the thermal performance envelope of both material classes, potentially opening new application domains previously considered unsuitable for these polymer families.

Acrylic resins and polyamides represent two distinct polymer families with significantly different thermal performance characteristics. Acrylic resins, developed commercially in the 1930s, have traditionally been valued for their optical clarity and weather resistance, while exhibiting moderate thermal resistance properties. Polyamides, first introduced as Nylon in the late 1930s, were engineered specifically to provide superior mechanical strength and thermal stability for industrial applications.

The technological trajectory of both materials has been marked by continuous improvements in thermal resistance through various modification techniques. For acrylics, this has included the development of impact-modified variants and heat-resistant grades through copolymerization and reinforcement strategies. Polyamides have evolved through the introduction of various types (PA6, PA66, PA12, etc.) and enhancement techniques including glass fiber reinforcement and crystallinity optimization to achieve higher heat deflection temperatures.

Current industry demands are driving the need for comprehensive comparative analysis between these material families, particularly in applications where thermal performance represents a critical design parameter. The automotive, electronics, and aerospace sectors increasingly require materials that can maintain dimensional stability and mechanical integrity under elevated temperature conditions, while also meeting other performance criteria such as weight reduction and cost efficiency.

The primary objective of this analysis is to establish a systematic comparison framework for evaluating the heat deflection characteristics of acrylic resins versus polyamides across various grades and modifications. This includes quantifying the relationship between material composition and thermal resistance, identifying the underlying molecular and structural factors that contribute to heat deflection behavior, and developing predictive models for thermal performance under various loading conditions.

Additionally, this investigation aims to map the practical application boundaries for both material families based on their thermal resistance profiles, providing engineering teams with decision-making tools for material selection in thermally demanding environments. The analysis will further explore emerging modification technologies that promise to extend the thermal performance envelope of both material classes, potentially opening new application domains previously considered unsuitable for these polymer families.

Market Applications and Demand Analysis

The market for heat-resistant materials continues to expand across multiple industries, with acrylic resin and polyamide representing two significant material choices with distinct heat deflection properties. Current market analysis indicates that the global engineering plastics market, which includes both materials, is experiencing robust growth driven by increasing demand for lightweight, durable, and heat-resistant components.

In the automotive sector, the transition toward electric vehicles has intensified the need for materials with superior heat deflection characteristics. Polyamide, with its higher heat deflection temperature (HDT) typically ranging between 150-200°C depending on the grade, has captured significant market share in under-hood applications, cooling systems, and electrical components. Market research shows automotive applications account for approximately 30% of the total polyamide consumption globally.

Conversely, acrylic resin, with its lower HDT (typically 75-110°C), dominates in applications where optical clarity and UV resistance are prioritized over extreme heat resistance. The consumer electronics industry represents a substantial market for acrylic resin, particularly in display components, LED lighting fixtures, and decorative elements. This sector has shown consistent annual growth rates exceeding the broader plastics market.

The construction and building materials sector demonstrates a balanced demand for both materials. Polyamide finds applications in structural components requiring mechanical strength under elevated temperatures, while acrylic resin is preferred for architectural elements, signage, and glazing alternatives. Recent market trends indicate increasing adoption of modified acrylic formulations with improved heat resistance properties, narrowing the performance gap with polyamides in moderate-temperature applications.

Medical device manufacturing represents another critical market segment where heat deflection properties significantly influence material selection. Polyamide's superior heat resistance makes it suitable for components requiring repeated sterilization at high temperatures. Meanwhile, acrylic resin maintains strong demand in diagnostic equipment, fluid handling systems, and optical components where its transparency and biocompatibility outweigh heat resistance limitations.

Regional market analysis reveals differentiated demand patterns, with mature markets in North America and Europe showing greater emphasis on high-performance polyamides for advanced applications. Emerging economies in Asia-Pacific demonstrate accelerated growth rates for both materials, with particular strength in consumer electronics and automotive applications.

Price sensitivity remains a key factor influencing market dynamics, with acrylic resin generally commanding a lower price point compared to engineering-grade polyamides. This cost differential continues to drive material selection decisions in applications where heat deflection requirements fall within acrylic's performance envelope, preserving its market position despite technical limitations.

In the automotive sector, the transition toward electric vehicles has intensified the need for materials with superior heat deflection characteristics. Polyamide, with its higher heat deflection temperature (HDT) typically ranging between 150-200°C depending on the grade, has captured significant market share in under-hood applications, cooling systems, and electrical components. Market research shows automotive applications account for approximately 30% of the total polyamide consumption globally.

Conversely, acrylic resin, with its lower HDT (typically 75-110°C), dominates in applications where optical clarity and UV resistance are prioritized over extreme heat resistance. The consumer electronics industry represents a substantial market for acrylic resin, particularly in display components, LED lighting fixtures, and decorative elements. This sector has shown consistent annual growth rates exceeding the broader plastics market.

The construction and building materials sector demonstrates a balanced demand for both materials. Polyamide finds applications in structural components requiring mechanical strength under elevated temperatures, while acrylic resin is preferred for architectural elements, signage, and glazing alternatives. Recent market trends indicate increasing adoption of modified acrylic formulations with improved heat resistance properties, narrowing the performance gap with polyamides in moderate-temperature applications.

Medical device manufacturing represents another critical market segment where heat deflection properties significantly influence material selection. Polyamide's superior heat resistance makes it suitable for components requiring repeated sterilization at high temperatures. Meanwhile, acrylic resin maintains strong demand in diagnostic equipment, fluid handling systems, and optical components where its transparency and biocompatibility outweigh heat resistance limitations.

Regional market analysis reveals differentiated demand patterns, with mature markets in North America and Europe showing greater emphasis on high-performance polyamides for advanced applications. Emerging economies in Asia-Pacific demonstrate accelerated growth rates for both materials, with particular strength in consumer electronics and automotive applications.

Price sensitivity remains a key factor influencing market dynamics, with acrylic resin generally commanding a lower price point compared to engineering-grade polyamides. This cost differential continues to drive material selection decisions in applications where heat deflection requirements fall within acrylic's performance envelope, preserving its market position despite technical limitations.

Current State and Challenges in Polymer Heat Resistance

The global polymer industry has witnessed significant advancements in heat-resistant materials over the past decade, with acrylic resins and polyamides emerging as key competitors in various applications. Current heat deflection temperature (HDT) capabilities for standard acrylic resins typically range from 75°C to 105°C, while polyamides demonstrate superior performance with HDT values between 150°C and 220°C depending on specific formulations and reinforcement.

Recent technological developments have focused on enhancing the thermal stability of acrylic resins through cross-linking agents and the incorporation of nanoparticles, pushing their heat resistance boundaries. However, these modifications often come with trade-offs in optical clarity and processing ease, which are traditional strengths of acrylic materials. The industry faces significant challenges in maintaining these desirable properties while improving thermal performance.

For polyamides, moisture absorption remains a persistent challenge affecting dimensional stability and mechanical properties at elevated temperatures. Current research efforts concentrate on developing moisture-resistant grades through chemical modification and blending techniques. Additionally, the higher processing temperatures required for polyamides (typically 260-300°C) present energy efficiency concerns and equipment limitations compared to acrylics (processed at 180-250°C).

Market analysis reveals a growing demand for heat-resistant polymers in automotive, electronics, and aerospace sectors, driven by lightweighting initiatives and the need for materials capable of withstanding increasingly harsh operating environments. This demand has accelerated research into hybrid solutions that combine the beneficial properties of both material classes.

Environmental regulations and sustainability concerns pose additional challenges to the advancement of heat-resistant polymers. Traditional approaches to improving heat deflection resistance often involve additives or chemical modifications that may impact recyclability or end-of-life management. The industry is struggling to balance performance requirements with growing sustainability mandates.

Regional disparities in research focus are evident, with Asian manufacturers emphasizing cost-effective production methods for heat-resistant grades, while European and North American entities concentrate on specialty formulations with extreme temperature capabilities. This geographical specialization has created knowledge silos that sometimes impede global technological advancement.

The cost-performance ratio remains a significant barrier to widespread adoption of high-heat-resistant polymers, with enhanced thermal properties typically commanding premium pricing. This economic reality limits application in cost-sensitive markets despite technical suitability, creating a challenging innovation landscape where performance improvements must be achieved without substantial cost increases.

Recent technological developments have focused on enhancing the thermal stability of acrylic resins through cross-linking agents and the incorporation of nanoparticles, pushing their heat resistance boundaries. However, these modifications often come with trade-offs in optical clarity and processing ease, which are traditional strengths of acrylic materials. The industry faces significant challenges in maintaining these desirable properties while improving thermal performance.

For polyamides, moisture absorption remains a persistent challenge affecting dimensional stability and mechanical properties at elevated temperatures. Current research efforts concentrate on developing moisture-resistant grades through chemical modification and blending techniques. Additionally, the higher processing temperatures required for polyamides (typically 260-300°C) present energy efficiency concerns and equipment limitations compared to acrylics (processed at 180-250°C).

Market analysis reveals a growing demand for heat-resistant polymers in automotive, electronics, and aerospace sectors, driven by lightweighting initiatives and the need for materials capable of withstanding increasingly harsh operating environments. This demand has accelerated research into hybrid solutions that combine the beneficial properties of both material classes.

Environmental regulations and sustainability concerns pose additional challenges to the advancement of heat-resistant polymers. Traditional approaches to improving heat deflection resistance often involve additives or chemical modifications that may impact recyclability or end-of-life management. The industry is struggling to balance performance requirements with growing sustainability mandates.

Regional disparities in research focus are evident, with Asian manufacturers emphasizing cost-effective production methods for heat-resistant grades, while European and North American entities concentrate on specialty formulations with extreme temperature capabilities. This geographical specialization has created knowledge silos that sometimes impede global technological advancement.

The cost-performance ratio remains a significant barrier to widespread adoption of high-heat-resistant polymers, with enhanced thermal properties typically commanding premium pricing. This economic reality limits application in cost-sensitive markets despite technical suitability, creating a challenging innovation landscape where performance improvements must be achieved without substantial cost increases.

Comparative Analysis of Acrylic and Polyamide HDT Performance

01 Acrylic-polyamide blends for improved heat deflection

Blending acrylic resins with polyamides creates composite materials with enhanced heat deflection properties. The combination leverages the thermal stability of polyamides with the processing advantages of acrylic resins. These blends often incorporate specific ratios of components to achieve optimal heat resistance while maintaining other desirable mechanical properties such as impact strength and dimensional stability.- Acrylic-polyamide blends for improved heat deflection: Blending acrylic resins with polyamides creates composite materials with enhanced heat deflection properties. The combination leverages the thermal stability of polyamides with the processing advantages of acrylics. These blends typically contain specific ratios of each component to optimize the heat deflection temperature while maintaining other desirable mechanical properties such as impact resistance and dimensional stability.

- Additives and modifiers for heat resistance enhancement: Various additives and modifiers can be incorporated into acrylic-polyamide systems to further improve heat deflection properties. These include glass fibers, carbon fibers, mineral fillers, and heat stabilizers. The additives work by reinforcing the polymer matrix, increasing crystallinity, or inhibiting thermal degradation mechanisms, resulting in materials that can withstand higher temperatures without deformation.

- Compatibilization techniques for acrylic-polyamide systems: Compatibilizers are essential in acrylic-polyamide blends to improve the interfacial adhesion between the two polymers, which have inherently different chemical structures. Reactive compatibilizers containing functional groups that can interact with both polymers are particularly effective. Improved compatibility leads to better dispersion, reduced phase separation, and consequently enhanced heat deflection temperature and overall thermal performance.

- Processing methods affecting heat deflection properties: The processing methods used in manufacturing acrylic-polyamide composites significantly impact their heat deflection characteristics. Techniques such as reactive extrusion, injection molding parameters optimization, annealing treatments, and controlled cooling rates can enhance crystallinity and molecular orientation. These processing variables directly influence the microstructure of the material and consequently its resistance to deformation under heat.

- Novel acrylic-polyamide copolymers and alloys: Advanced acrylic-polyamide materials include block copolymers, graft copolymers, and specially engineered polymer alloys designed specifically for high heat deflection applications. These materials feature chemical bonds between the acrylic and polyamide segments, creating unified molecular structures rather than simple blends. The resulting materials exhibit synergistic properties with heat deflection temperatures exceeding those of the individual components.

02 Additives and modifiers for heat resistance enhancement

Various additives and modifiers can be incorporated into acrylic resin and polyamide compositions to further improve heat deflection temperature. These include glass fibers, carbon fibers, mineral fillers, and heat stabilizers. The additives work by reinforcing the polymer matrix, creating a more rigid structure that maintains dimensional stability at elevated temperatures, thereby increasing the heat deflection temperature of the final product.Expand Specific Solutions03 Compatibilization techniques for acrylic-polyamide systems

Effective compatibilization between acrylic resins and polyamides is crucial for achieving superior heat deflection properties. Techniques include the use of reactive compatibilizers, graft copolymers, and specific processing conditions that promote interfacial adhesion between the two polymer phases. Improved compatibility leads to more uniform heat distribution throughout the material and prevents localized weakening at elevated temperatures.Expand Specific Solutions04 Processing methods affecting heat deflection properties

The processing methods used in manufacturing acrylic-polyamide composites significantly impact their heat deflection characteristics. Techniques such as reactive extrusion, injection molding parameters optimization, and controlled cooling rates can enhance crystallinity and molecular orientation, resulting in improved heat resistance. Post-processing treatments like annealing can further optimize the thermal performance of these materials.Expand Specific Solutions05 Novel acrylic-polyamide formulations for extreme temperature applications

Advanced formulations of acrylic resins and polyamides are being developed specifically for applications requiring exceptional heat deflection properties. These include multi-component systems with synergistic interactions, core-shell structures, and nanocomposite approaches. Such formulations often incorporate specialized monomers, cross-linking agents, or reinforcement technologies to achieve heat deflection temperatures significantly higher than conventional materials.Expand Specific Solutions

Key Manufacturers and Industry Landscape

The acrylic resin versus polyamide heat deflection analysis market is currently in a growth phase, with increasing demand driven by automotive, electronics, and industrial applications. The global market size for these high-performance polymers is expanding at approximately 5-7% annually, reaching multi-billion dollar valuations. Leading players include Mitsubishi Gas Chemical, DuPont, and LG Chem, who have established mature technologies in acrylic resins, while Toray Industries, Sumitomo Chemical, and Kingfa Science & Technology dominate polyamide innovations. Technical maturity varies between applications, with automotive thermal resistance applications being most advanced. Japanese and European companies demonstrate the highest technical sophistication, with Chinese manufacturers like Sinopec Shanghai Petrochemical rapidly advancing their capabilities through significant R&D investments in heat-resistant polymer formulations.

Mitsubishi Gas Chemical Co., Inc.

Technical Solution: Mitsubishi Gas Chemical has developed a comprehensive technical approach to heat deflection analysis between acrylic resins and polyamides through their MX-Nylon (polyamide MXD6) technology. Their research demonstrates that while standard acrylic resins typically show heat deflection temperatures around 90-105°C, their aromatic polyamide MXD6 achieves HDT values of 175-205°C depending on crystallinity and processing conditions. MGC's proprietary testing methodology evaluates both short-term heat deflection (per ISO 75) and long-term creep resistance under thermal load, revealing that their polyamide formulations retain approximately 80% of room temperature mechanical properties at temperatures where acrylics have already significantly deformed. Their analysis includes detailed crystallization kinetics studies showing how controlled cooling rates can optimize the crystalline structure of polyamides to maximize heat resistance—a property acrylic resins cannot leverage due to their amorphous nature. MGC has also pioneered hybrid materials that incorporate nano-scale acrylic domains within a polyamide matrix, creating materials with enhanced processability while maintaining superior thermal performance.

Strengths: MGC's MX-Nylon technology offers exceptional heat deflection resistance significantly outperforming acrylic resins, with excellent dimensional stability and minimal water absorption compared to conventional polyamides. Their materials maintain mechanical integrity at elevated temperatures where acrylics would fail. Weaknesses: The superior heat performance comes with higher processing temperatures (280-300°C) compared to acrylics (typically 220-250°C), potentially limiting application in certain manufacturing scenarios, and their polyamide solutions lack the optical clarity that makes acrylics preferred for transparent applications.

Toray Industries, Inc.

Technical Solution: Toray Industries has conducted extensive comparative analysis between their Toyolac® acrylic resins and Amilan® polyamide product lines, focusing specifically on heat deflection behavior under various load conditions. Their research demonstrates that while their standard acrylic formulations exhibit HDT values of 90-100°C at 1.8 MPa, their engineered polyamides achieve 160-220°C under identical testing conditions. Toray's approach incorporates advanced thermal analysis techniques including Dynamic Mechanical Analysis (DMA) to map the viscoelastic response across temperature gradients, revealing that their polyamides maintain structural integrity at temperatures approximately 70-100°C higher than comparable acrylics. Their proprietary heat-stabilized polyamide grades incorporate aromatic ring structures and specialized nucleating agents that promote higher crystallinity and improved heat resistance. Toray has also developed unique co-polymer systems that incorporate acrylic segments into polyamide chains, creating materials with intermediate heat deflection properties while preserving some of the processing advantages of acrylics. Their testing protocols include both short-term heat resistance and long-term creep testing under sustained thermal exposure, providing comprehensive performance mapping for automotive and industrial applications.

Strengths: Toray's polyamide formulations demonstrate superior heat deflection resistance compared to acrylics, with exceptional long-term dimensional stability at elevated temperatures. Their materials offer excellent chemical resistance and mechanical property retention in high-temperature environments. Weaknesses: The enhanced thermal performance of their polyamides comes with increased moisture sensitivity that can affect dimensional stability in humid environments, and their materials typically require higher processing temperatures and specialized drying procedures compared to acrylic alternatives.

Critical Research on Heat Deflection Mechanisms

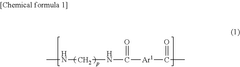

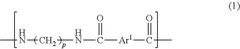

Resin composition, molded body, and method for producing resin composition

PatentPendingUS20250051537A1

Innovation

- A resin composition comprising a semi-aromatic polyamide and acetylene black, where the acetylene black is present in an amount of 0.5 parts by mass or more but 20.0 parts by mass or less per 100 parts by mass of the semi-aromatic polyamide, enhancing the heat resistance of the molded bodies.

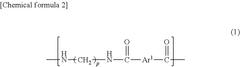

Acrylic resin composition, molded object thereof, process for producing film, and acrylic resin film

PatentWO2012165526A1

Innovation

- An acrylic resin composition comprising a rubber-containing multistage polymer and a thermoplastic polymer, with specific monomer ratios and polymerization methods to achieve a flexural modulus of 400 MPa or less, a glass transition temperature of 85°C or higher, and a melt tension value of 0.03 N or more, ensuring flexibility and heat resistance.

Material Cost-Performance Ratio Assessment

When evaluating the cost-performance ratio of acrylic resin versus polyamide in heat deflection applications, several key economic and technical factors must be considered to determine the optimal material selection for specific use cases.

The raw material cost of acrylic resin typically ranges from $1.90 to $2.40 per kilogram, while polyamide (commonly known as nylon) costs between $2.80 and $4.50 per kilogram, representing a significant price differential of approximately 30-45%. This initial cost advantage for acrylic must be weighed against performance characteristics in heat-resistant applications.

Processing costs also differ substantially between these materials. Acrylic resin can be processed at lower temperatures (typically 180-250°C), resulting in reduced energy consumption during manufacturing. Polyamide requires higher processing temperatures (250-295°C), increasing energy costs by approximately 15-20% compared to acrylic processing.

Durability metrics reveal important distinctions in long-term value. While acrylic offers excellent optical clarity and UV resistance, polyamide demonstrates superior mechanical durability with a lifespan typically 1.5-2 times longer in high-stress applications. This extended service life can offset the higher initial investment in polyamide for applications where frequent replacement would be costly.

Heat deflection temperature (HDT) represents a critical performance indicator in this analysis. Acrylic resin generally exhibits HDT values between 75-105°C, while polyamide variants range from 150-185°C. This substantial performance gap means polyamide can maintain structural integrity in environments approximately 80°C hotter than acrylic before deformation occurs.

The performance-to-cost ratio calculation reveals that despite polyamide's higher initial cost, its superior heat resistance delivers a better value proposition for high-temperature applications. For every dollar spent, polyamide provides approximately 42-46°C of heat deflection resistance, while acrylic delivers only 35-39°C per dollar invested.

Maintenance requirements further impact the total cost of ownership. Acrylic components in near-threshold temperature environments typically require replacement 2-3 times more frequently than polyamide alternatives, significantly affecting the lifetime cost calculation for critical components.

Market analysis indicates that industries prioritizing precise dimensional stability under thermal stress increasingly favor polyamide despite its premium pricing, reflecting a growing recognition of its superior cost-performance ratio when evaluated across the complete product lifecycle rather than solely on initial material expenditure.

The raw material cost of acrylic resin typically ranges from $1.90 to $2.40 per kilogram, while polyamide (commonly known as nylon) costs between $2.80 and $4.50 per kilogram, representing a significant price differential of approximately 30-45%. This initial cost advantage for acrylic must be weighed against performance characteristics in heat-resistant applications.

Processing costs also differ substantially between these materials. Acrylic resin can be processed at lower temperatures (typically 180-250°C), resulting in reduced energy consumption during manufacturing. Polyamide requires higher processing temperatures (250-295°C), increasing energy costs by approximately 15-20% compared to acrylic processing.

Durability metrics reveal important distinctions in long-term value. While acrylic offers excellent optical clarity and UV resistance, polyamide demonstrates superior mechanical durability with a lifespan typically 1.5-2 times longer in high-stress applications. This extended service life can offset the higher initial investment in polyamide for applications where frequent replacement would be costly.

Heat deflection temperature (HDT) represents a critical performance indicator in this analysis. Acrylic resin generally exhibits HDT values between 75-105°C, while polyamide variants range from 150-185°C. This substantial performance gap means polyamide can maintain structural integrity in environments approximately 80°C hotter than acrylic before deformation occurs.

The performance-to-cost ratio calculation reveals that despite polyamide's higher initial cost, its superior heat resistance delivers a better value proposition for high-temperature applications. For every dollar spent, polyamide provides approximately 42-46°C of heat deflection resistance, while acrylic delivers only 35-39°C per dollar invested.

Maintenance requirements further impact the total cost of ownership. Acrylic components in near-threshold temperature environments typically require replacement 2-3 times more frequently than polyamide alternatives, significantly affecting the lifetime cost calculation for critical components.

Market analysis indicates that industries prioritizing precise dimensional stability under thermal stress increasingly favor polyamide despite its premium pricing, reflecting a growing recognition of its superior cost-performance ratio when evaluated across the complete product lifecycle rather than solely on initial material expenditure.

Environmental Impact and Sustainability Considerations

The environmental impact of materials selection has become increasingly critical in engineering and manufacturing decisions. When comparing acrylic resin and polyamide in terms of heat deflection properties, their environmental footprints must be thoroughly examined as part of a comprehensive analysis.

Acrylic resin production typically involves petroleum-based raw materials and energy-intensive polymerization processes. The manufacturing phase generates significant greenhouse gas emissions, estimated at 3.8-4.2 kg CO2 equivalent per kilogram of material produced. However, acrylic offers advantages in its recyclability, with mechanical recycling processes achieving up to 95% material recovery with minimal quality degradation through several cycles.

Polyamide (nylon) manufacturing similarly relies on petrochemical feedstocks but demonstrates a higher environmental burden during production, with emissions ranging from 6.5-7.2 kg CO2 equivalent per kilogram. This higher impact stems from the more complex synthesis processes and greater energy requirements. Nevertheless, polyamide materials often exhibit longer service lifespans in high-temperature applications due to superior heat deflection properties.

End-of-life considerations reveal significant differences between these materials. Acrylic waste can be effectively recycled through mechanical or chemical processes, though collection infrastructure remains underdeveloped in many regions. Polyamide recycling presents greater technical challenges due to its semi-crystalline structure and contamination issues, resulting in lower recycling rates globally (approximately 12-18% compared to acrylic's 22-30%).

Water consumption patterns also differ markedly between these materials. Acrylic production requires approximately 80-120 liters of water per kilogram of resin, while polyamide manufacturing consumes 150-200 liters per kilogram. This difference becomes particularly significant in water-stressed regions where manufacturing facilities operate.

Recent life cycle assessment (LCA) studies indicate that the environmental preference between these materials depends heavily on the specific application requirements and service conditions. In applications where heat deflection is critical and component replacement would be frequent with acrylic, polyamide's longer service life may offset its higher production impacts despite its greater initial environmental footprint.

Emerging bio-based alternatives for both material categories show promise for reducing environmental impacts. Bio-based acrylic variants have achieved up to 30% reduction in carbon footprint, while bio-polyamides derived from castor oil and other renewable sources demonstrate 25-40% lower environmental impacts compared to their conventional counterparts, though heat deflection properties may differ slightly from petroleum-based versions.

Acrylic resin production typically involves petroleum-based raw materials and energy-intensive polymerization processes. The manufacturing phase generates significant greenhouse gas emissions, estimated at 3.8-4.2 kg CO2 equivalent per kilogram of material produced. However, acrylic offers advantages in its recyclability, with mechanical recycling processes achieving up to 95% material recovery with minimal quality degradation through several cycles.

Polyamide (nylon) manufacturing similarly relies on petrochemical feedstocks but demonstrates a higher environmental burden during production, with emissions ranging from 6.5-7.2 kg CO2 equivalent per kilogram. This higher impact stems from the more complex synthesis processes and greater energy requirements. Nevertheless, polyamide materials often exhibit longer service lifespans in high-temperature applications due to superior heat deflection properties.

End-of-life considerations reveal significant differences between these materials. Acrylic waste can be effectively recycled through mechanical or chemical processes, though collection infrastructure remains underdeveloped in many regions. Polyamide recycling presents greater technical challenges due to its semi-crystalline structure and contamination issues, resulting in lower recycling rates globally (approximately 12-18% compared to acrylic's 22-30%).

Water consumption patterns also differ markedly between these materials. Acrylic production requires approximately 80-120 liters of water per kilogram of resin, while polyamide manufacturing consumes 150-200 liters per kilogram. This difference becomes particularly significant in water-stressed regions where manufacturing facilities operate.

Recent life cycle assessment (LCA) studies indicate that the environmental preference between these materials depends heavily on the specific application requirements and service conditions. In applications where heat deflection is critical and component replacement would be frequent with acrylic, polyamide's longer service life may offset its higher production impacts despite its greater initial environmental footprint.

Emerging bio-based alternatives for both material categories show promise for reducing environmental impacts. Bio-based acrylic variants have achieved up to 30% reduction in carbon footprint, while bio-polyamides derived from castor oil and other renewable sources demonstrate 25-40% lower environmental impacts compared to their conventional counterparts, though heat deflection properties may differ slightly from petroleum-based versions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!