Additive Manufacturing Of Liquid Metal Cooling Manifolds

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal AM Technology Evolution and Objectives

Additive manufacturing (AM) of liquid metal cooling manifolds represents a significant technological advancement in thermal management systems. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the potential of liquid metals as heat transfer mediums due to their exceptional thermal conductivity properties. Initially, conventional manufacturing methods limited the geometric complexity and efficiency of cooling manifolds, creating a technological gap that AM processes aimed to address.

The progression of liquid metal AM technology has been marked by several key developmental phases. The first phase (2000-2010) focused primarily on material science research, establishing the fundamental properties and behaviors of various liquid metal alloys suitable for cooling applications. During this period, gallium-based alloys emerged as promising candidates due to their low melting points and non-toxicity compared to traditional mercury-based alternatives.

The second phase (2010-2015) witnessed the convergence of AM technologies with liquid metal applications. Early experiments utilized modified extrusion-based printing techniques, which faced significant challenges related to oxidation, wetting behavior, and structural integrity. These initial attempts provided valuable insights but yielded limited practical applications due to reliability concerns.

A breakthrough period emerged between 2015-2020, characterized by the development of specialized AM processes specifically designed for liquid metal cooling manifolds. Direct metal laser sintering (DMLS) and electron beam melting (EBM) technologies were adapted to accommodate the unique properties of liquid metal alloys, enabling the creation of complex internal cooling channels that were previously impossible to manufacture.

The current technological landscape (2020-present) has seen rapid advancement in multi-material AM approaches, allowing for the integration of liquid metal cooling manifolds within larger functional components. This integration capability has dramatically expanded potential applications across industries including aerospace, high-performance computing, and electric vehicle thermal management systems.

The primary objectives driving this technological evolution include: achieving higher cooling efficiency through optimized geometries; reducing manufacturing complexity and lead times; enabling weight reduction through design optimization; improving reliability and operational lifespan; and developing scalable production methods for commercial viability. Recent research has increasingly focused on sustainability aspects, exploring recyclable liquid metal formulations and energy-efficient manufacturing processes.

Looking forward, the technology roadmap aims to overcome remaining challenges in material compatibility, long-term stability, and cost-effectiveness while expanding the range of compatible liquid metal alloys and operating temperature ranges to meet emerging industrial requirements.

The progression of liquid metal AM technology has been marked by several key developmental phases. The first phase (2000-2010) focused primarily on material science research, establishing the fundamental properties and behaviors of various liquid metal alloys suitable for cooling applications. During this period, gallium-based alloys emerged as promising candidates due to their low melting points and non-toxicity compared to traditional mercury-based alternatives.

The second phase (2010-2015) witnessed the convergence of AM technologies with liquid metal applications. Early experiments utilized modified extrusion-based printing techniques, which faced significant challenges related to oxidation, wetting behavior, and structural integrity. These initial attempts provided valuable insights but yielded limited practical applications due to reliability concerns.

A breakthrough period emerged between 2015-2020, characterized by the development of specialized AM processes specifically designed for liquid metal cooling manifolds. Direct metal laser sintering (DMLS) and electron beam melting (EBM) technologies were adapted to accommodate the unique properties of liquid metal alloys, enabling the creation of complex internal cooling channels that were previously impossible to manufacture.

The current technological landscape (2020-present) has seen rapid advancement in multi-material AM approaches, allowing for the integration of liquid metal cooling manifolds within larger functional components. This integration capability has dramatically expanded potential applications across industries including aerospace, high-performance computing, and electric vehicle thermal management systems.

The primary objectives driving this technological evolution include: achieving higher cooling efficiency through optimized geometries; reducing manufacturing complexity and lead times; enabling weight reduction through design optimization; improving reliability and operational lifespan; and developing scalable production methods for commercial viability. Recent research has increasingly focused on sustainability aspects, exploring recyclable liquid metal formulations and energy-efficient manufacturing processes.

Looking forward, the technology roadmap aims to overcome remaining challenges in material compatibility, long-term stability, and cost-effectiveness while expanding the range of compatible liquid metal alloys and operating temperature ranges to meet emerging industrial requirements.

Market Analysis for AM Cooling Manifold Solutions

The global market for additive manufacturing (AM) cooling manifold solutions is experiencing robust growth, driven by increasing demand for efficient thermal management systems across multiple industries. The market size for AM cooling solutions was valued at approximately $2.1 billion in 2022 and is projected to reach $4.7 billion by 2028, representing a compound annual growth rate (CAGR) of 14.3% during the forecast period.

The electronics and semiconductor industry constitutes the largest market segment, accounting for 37% of the total market share. This dominance is attributed to the escalating thermal challenges in high-performance computing, data centers, and advanced semiconductor packaging. The automotive sector follows closely at 28%, where the transition toward electric vehicles has intensified the need for sophisticated cooling solutions to manage battery thermal issues.

Aerospace and defense applications represent 18% of the market, with particular emphasis on lightweight, high-performance cooling systems for avionics and propulsion systems. The remaining 17% is distributed across medical devices, industrial machinery, and consumer electronics sectors.

Geographically, North America leads the market with 39% share, followed by Asia-Pacific (34%), Europe (21%), and rest of the world (6%). China and India are emerging as high-growth regions, with projected CAGRs of 17.2% and 16.8% respectively, outpacing the global average.

Key market drivers include miniaturization trends in electronics, increasing power densities in computing systems, and the shift toward more energy-efficient cooling solutions. The ability of AM to create complex internal cooling channels that traditional manufacturing methods cannot achieve has positioned it as a disruptive technology in thermal management.

Customer demand is increasingly focused on customized cooling solutions that can be rapidly prototyped and manufactured. A recent industry survey indicates that 73% of engineering firms value design flexibility as the primary advantage of AM cooling manifolds, followed by performance improvements (68%) and reduced lead times (59%).

Market challenges include high initial investment costs, material limitations for certain high-temperature applications, and quality consistency issues. However, technological advancements in metal AM processes, particularly in direct metal laser sintering (DMLS) and electron beam melting (EBM), are progressively addressing these barriers.

The competitive landscape features both established industrial manufacturing companies expanding into AM and specialized AM service providers. Strategic partnerships between material suppliers, equipment manufacturers, and end-users are becoming increasingly common, creating integrated value chains that accelerate market adoption.

The electronics and semiconductor industry constitutes the largest market segment, accounting for 37% of the total market share. This dominance is attributed to the escalating thermal challenges in high-performance computing, data centers, and advanced semiconductor packaging. The automotive sector follows closely at 28%, where the transition toward electric vehicles has intensified the need for sophisticated cooling solutions to manage battery thermal issues.

Aerospace and defense applications represent 18% of the market, with particular emphasis on lightweight, high-performance cooling systems for avionics and propulsion systems. The remaining 17% is distributed across medical devices, industrial machinery, and consumer electronics sectors.

Geographically, North America leads the market with 39% share, followed by Asia-Pacific (34%), Europe (21%), and rest of the world (6%). China and India are emerging as high-growth regions, with projected CAGRs of 17.2% and 16.8% respectively, outpacing the global average.

Key market drivers include miniaturization trends in electronics, increasing power densities in computing systems, and the shift toward more energy-efficient cooling solutions. The ability of AM to create complex internal cooling channels that traditional manufacturing methods cannot achieve has positioned it as a disruptive technology in thermal management.

Customer demand is increasingly focused on customized cooling solutions that can be rapidly prototyped and manufactured. A recent industry survey indicates that 73% of engineering firms value design flexibility as the primary advantage of AM cooling manifolds, followed by performance improvements (68%) and reduced lead times (59%).

Market challenges include high initial investment costs, material limitations for certain high-temperature applications, and quality consistency issues. However, technological advancements in metal AM processes, particularly in direct metal laser sintering (DMLS) and electron beam melting (EBM), are progressively addressing these barriers.

The competitive landscape features both established industrial manufacturing companies expanding into AM and specialized AM service providers. Strategic partnerships between material suppliers, equipment manufacturers, and end-users are becoming increasingly common, creating integrated value chains that accelerate market adoption.

Current Capabilities and Barriers in Liquid Metal AM

Additive manufacturing (AM) of liquid metal cooling manifolds has made significant strides in recent years, yet faces several technical and material challenges. Current capabilities allow for the fabrication of complex cooling geometries that would be impossible through traditional manufacturing methods. Liquid metal AM systems can now achieve resolution down to 50-100 microns with certain alloys, enabling intricate internal cooling channels and optimized thermal management designs.

The primary liquid metals utilized in AM cooling manifold production include gallium-based alloys (GaInSn), aluminum alloys, and specialized copper alloys. These materials offer excellent thermal conductivity properties essential for effective heat dissipation. Modern AM systems can process these materials at temperatures ranging from 30°C for gallium-based alloys to over 1000°C for higher-melting-point metals, with build volumes typically reaching 250mm × 250mm × 300mm in commercial systems.

Despite these capabilities, significant barriers persist in the widespread adoption of liquid metal AM for cooling manifolds. Material constraints represent a primary challenge, as many high-performance cooling alloys exhibit poor printability characteristics. Oxidation during the printing process remains problematic, particularly for reactive metals like aluminum, requiring specialized atmospheric controls that increase system complexity and cost.

Surface finish quality presents another substantial barrier, with as-printed components often requiring extensive post-processing to achieve the smooth internal channels necessary for optimal fluid dynamics. Current surface roughness values typically range from Ra 15-25μm before post-processing, whereas cooling efficiency often requires Ra values below 5μm for critical applications.

Dimensional accuracy and repeatability continue to challenge manufacturers, with typical tolerances of ±0.2mm still insufficient for high-precision cooling applications that may require tolerances of ±0.05mm or better. This limitation necessitates hybrid manufacturing approaches combining AM with traditional machining, increasing production complexity and cost.

Process monitoring and quality control systems remain underdeveloped for liquid metal AM, with limited in-situ monitoring capabilities to detect defects such as porosity or incomplete fusion that can critically impact cooling performance. Current defect rates in complex cooling geometries can reach 5-15% depending on design complexity, significantly higher than traditional manufacturing methods.

Cost factors also present barriers to adoption, with liquid metal AM systems typically requiring investments of $500,000-$2,000,000, plus specialized facility requirements and trained operators. Material costs for specialized AM-compatible alloys can be 3-10 times higher than conventional materials, further limiting economic viability for many applications.

The primary liquid metals utilized in AM cooling manifold production include gallium-based alloys (GaInSn), aluminum alloys, and specialized copper alloys. These materials offer excellent thermal conductivity properties essential for effective heat dissipation. Modern AM systems can process these materials at temperatures ranging from 30°C for gallium-based alloys to over 1000°C for higher-melting-point metals, with build volumes typically reaching 250mm × 250mm × 300mm in commercial systems.

Despite these capabilities, significant barriers persist in the widespread adoption of liquid metal AM for cooling manifolds. Material constraints represent a primary challenge, as many high-performance cooling alloys exhibit poor printability characteristics. Oxidation during the printing process remains problematic, particularly for reactive metals like aluminum, requiring specialized atmospheric controls that increase system complexity and cost.

Surface finish quality presents another substantial barrier, with as-printed components often requiring extensive post-processing to achieve the smooth internal channels necessary for optimal fluid dynamics. Current surface roughness values typically range from Ra 15-25μm before post-processing, whereas cooling efficiency often requires Ra values below 5μm for critical applications.

Dimensional accuracy and repeatability continue to challenge manufacturers, with typical tolerances of ±0.2mm still insufficient for high-precision cooling applications that may require tolerances of ±0.05mm or better. This limitation necessitates hybrid manufacturing approaches combining AM with traditional machining, increasing production complexity and cost.

Process monitoring and quality control systems remain underdeveloped for liquid metal AM, with limited in-situ monitoring capabilities to detect defects such as porosity or incomplete fusion that can critically impact cooling performance. Current defect rates in complex cooling geometries can reach 5-15% depending on design complexity, significantly higher than traditional manufacturing methods.

Cost factors also present barriers to adoption, with liquid metal AM systems typically requiring investments of $500,000-$2,000,000, plus specialized facility requirements and trained operators. Material costs for specialized AM-compatible alloys can be 3-10 times higher than conventional materials, further limiting economic viability for many applications.

Existing Approaches for AM Cooling Manifold Production

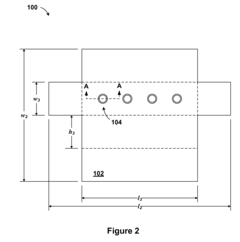

01 Liquid metal cooling manifold designs for electronic components

Liquid metal cooling manifolds are designed specifically for electronic components to efficiently dissipate heat. These designs incorporate channels and passages that allow liquid metal coolants to flow through and around heat-generating components. The manifolds are typically constructed from materials compatible with liquid metals and are engineered to maximize thermal transfer while minimizing space requirements. These systems are particularly effective for high-performance computing applications where traditional cooling methods are insufficient.- Liquid metal cooling manifold designs for electronic components: Liquid metal cooling manifolds are designed specifically for electronic components to efficiently dissipate heat. These designs incorporate channels and pathways that allow liquid metal coolants to flow directly over or near heat-generating components. The manifolds are often integrated into electronic assemblies such as processors, power modules, or server systems, providing superior thermal conductivity compared to traditional cooling methods. These designs may include specialized inlet and outlet configurations to optimize coolant flow and heat transfer efficiency.

- Materials and composition of liquid metal coolants: Various materials and compositions are used in liquid metal cooling systems to enhance thermal performance. These include gallium-based alloys, indium-tin mixtures, and other metal alloys with low melting points that remain liquid at operating temperatures. The composition of these coolants is engineered to maximize thermal conductivity while minimizing issues such as corrosion, oxidation, and material compatibility. Some formulations include additives that improve wetting properties or reduce surface tension to enhance contact with cooling surfaces.

- Flow control and distribution systems in liquid metal cooling manifolds: Advanced flow control and distribution systems are implemented in liquid metal cooling manifolds to ensure optimal thermal management. These systems include pumps, valves, and pressure regulators that control the flow rate and distribution of liquid metal coolant throughout the cooling circuit. The design focuses on maintaining uniform temperature across components, preventing hotspots, and adapting to varying thermal loads. Some systems incorporate sensors and feedback mechanisms to dynamically adjust coolant flow based on real-time temperature monitoring.

- Integration of liquid metal cooling manifolds with power electronics: Liquid metal cooling manifolds are specifically designed for integration with power electronics to manage high heat loads. These cooling systems are engineered to handle the thermal challenges of high-power density components such as inverters, converters, and power modules. The manifolds are often directly bonded or attached to semiconductor devices to minimize thermal resistance. Some designs incorporate multiple cooling layers or 3D structures to maximize cooling efficiency while maintaining electrical isolation where required.

- Manufacturing techniques for liquid metal cooling manifolds: Specialized manufacturing techniques are employed to produce liquid metal cooling manifolds with precise dimensions and surface characteristics. These include advanced machining, additive manufacturing, micro-channel fabrication, and bonding processes that create complex internal geometries for optimal coolant flow. Surface treatments may be applied to enhance wettability and prevent corrosion or erosion from liquid metal contact. Some manufacturing methods focus on creating seamless connections and hermetic sealing to prevent coolant leakage, which is particularly critical with liquid metal coolants.

02 Integration of liquid metal cooling in power generation systems

Liquid metal cooling manifolds are utilized in power generation systems to manage high thermal loads. These cooling systems incorporate specialized manifolds that distribute liquid metal coolants throughout critical components of power generators, turbines, and engines. The liquid metal's superior thermal conductivity allows for more efficient heat transfer compared to conventional coolants, resulting in improved system performance and longevity. These cooling systems are designed to withstand extreme operating conditions while maintaining optimal temperature control.Expand Specific Solutions03 Advanced manufacturing techniques for liquid metal cooling manifolds

Innovative manufacturing techniques are employed to produce complex liquid metal cooling manifolds with precise internal geometries. These methods include additive manufacturing, precision casting, and advanced machining processes that enable the creation of optimized flow paths and heat exchange surfaces. The manufacturing techniques focus on producing manifolds with minimal joints and seams to prevent leakage of liquid metal coolants. These processes also allow for the integration of sensors and monitoring systems within the cooling manifold structure.Expand Specific Solutions04 Materials compatible with liquid metal coolants for manifold construction

Specialized materials are developed for constructing liquid metal cooling manifolds that can withstand the corrosive properties of liquid metals such as gallium, indium, and their alloys. These materials include refractory metals, ceramics, and specially treated alloys that resist chemical attack and maintain structural integrity at high temperatures. The selection of appropriate materials is crucial for preventing degradation of the cooling system and ensuring long-term reliability. Coatings and surface treatments are also applied to enhance compatibility and improve thermal performance.Expand Specific Solutions05 Control systems for liquid metal cooling manifolds

Sophisticated control systems are implemented to regulate the flow and temperature of liquid metal coolants within cooling manifolds. These systems incorporate pressure sensors, temperature monitors, and flow regulators to maintain optimal cooling performance under varying thermal loads. Advanced algorithms adjust coolant flow rates and distribution patterns to respond to changing cooling demands. The control systems also include safety features to detect and mitigate potential issues such as blockages or leaks, ensuring reliable operation of the liquid metal cooling system.Expand Specific Solutions

Industry Leaders in Liquid Metal AM Manufacturing

Additive manufacturing of liquid metal cooling manifolds is currently in an early growth phase, with the market expanding due to increasing demand for efficient thermal management solutions in high-performance applications. The global market size is projected to grow significantly as industries adopt advanced cooling technologies. From a technological maturity perspective, companies like Siemens Energy, IBM, and Boeing are leading commercial implementation, while research institutions such as Harbin Institute of Technology and Shanghai Jiao Tong University are advancing fundamental capabilities. Divergent Technologies and GEFERTEC have developed specialized processes for liquid metal applications, while established manufacturers like Air Liquide and Toshiba are integrating these technologies into broader manufacturing ecosystems. The field is characterized by a mix of specialized startups and large industrial players collaborating to overcome technical challenges in material properties and process control.

Siemens AG

Technical Solution: Siemens has pioneered a comprehensive approach to additively manufactured liquid metal cooling manifolds, particularly for power generation applications. Their technology utilizes selective laser melting (SLM) with specialized aluminum and copper alloys to create highly optimized cooling geometries. Siemens' process incorporates computational fluid dynamics (CFD) simulation to design intricate internal channel structures that maximize cooling efficiency while minimizing pressure drop. Their manufacturing process includes proprietary parameter sets for different metal powders that ensure consistent material properties and minimal porosity. Siemens has implemented this technology in gas turbine components, achieving cooling efficiency improvements of up to 40% compared to conventional designs. The company has also developed specialized quality control protocols including CT scanning and flow testing to verify the performance of each manufactured cooling manifold. Their integrated design-to-manufacturing workflow enables rapid iteration and optimization of cooling designs based on operational data.

Strengths: Highly optimized cooling performance through advanced simulation and design; established quality control processes; proven implementation in industrial power generation equipment. Weaknesses: High initial investment costs; limited material selection compared to conventional manufacturing; challenges in scaling production for larger components.

GM Global Technology Operations LLC

Technical Solution: GM has developed a proprietary additive manufacturing process for liquid metal cooling manifolds specifically tailored for electric vehicle battery thermal management systems. Their approach utilizes direct metal laser sintering (DMLS) with aluminum alloys containing enhanced thermal conductivity additives. GM's technology focuses on creating ultra-compact cooling manifolds with optimized flow distribution to ensure uniform temperature across battery modules. Their manufacturing process incorporates in-situ monitoring to detect and correct defects during the build process, ensuring consistent quality and performance. GM has implemented specialized post-processing techniques including chemical etching and mechanical polishing to reduce internal surface roughness, which improves flow characteristics and reduces pressure drop by approximately 35% compared to as-built surfaces. The company has successfully deployed this technology in their latest generation of electric vehicles, achieving more uniform battery temperatures (within ±3°C across the pack) and enabling faster charging capabilities while extending battery life.

Strengths: Optimized for EV battery cooling applications; enables more compact and efficient thermal management systems; supports faster charging capabilities through improved thermal management. Weaknesses: Currently limited to specific vehicle platforms; higher production costs compared to conventional manifolds; requires specialized quality control processes.

Critical Patents in Liquid Metal AM Cooling Systems

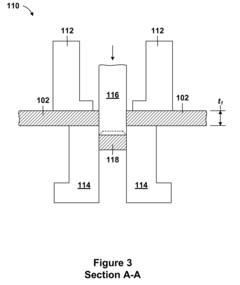

ACTIVE COOLING TECHNIQUE FOR ADDITIVE MANUFACTURING

PatentActiveBR102018015314A2

Innovation

- An active cooling technique involving continuous quasi-immersion of the preform in a liquid cooling fluid during construction, controlling heat dissipation through the liquid cooling fluid's level and temperature equilibrium with the preform, ensuring direct contact with all layers except the deposition region.

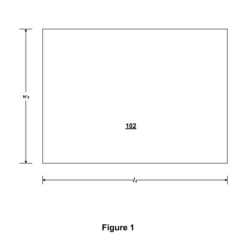

Manifold for a liquid cooling system

PatentInactiveUS20160354833A1

Innovation

- A method involving forming a threaded hole extrusion in a sheet metal flat pattern before folding and welding it into a manifold, using techniques like punching and extrusion to create a watertight connection that eliminates metal shavings and reduces manufacturing time and cost.

Thermal Performance Benchmarking Methodologies

Establishing standardized thermal performance benchmarking methodologies is critical for evaluating the effectiveness of liquid metal cooling manifolds produced through additive manufacturing processes. These methodologies must account for the unique geometric complexities and material properties that AM techniques enable, while providing reliable comparative data against conventional cooling solutions.

The primary thermal performance metrics for liquid metal cooling manifolds include heat transfer coefficient, thermal resistance, pressure drop, coolant flow rate, and temperature uniformity across the cooled surface. These metrics must be measured under controlled conditions that simulate real-world operational environments, including varying heat loads and ambient temperatures.

Experimental setups for benchmarking typically involve thermal test beds equipped with precision temperature sensors, flow meters, pressure transducers, and heat flux sensors. Infrared thermography provides valuable non-contact temperature distribution data across manifold surfaces, while embedded thermocouples offer precise point measurements at critical locations. For comprehensive evaluation, both steady-state and transient thermal response characteristics should be documented.

Computational fluid dynamics (CFD) simulations complement physical testing by providing detailed insights into flow patterns, pressure distributions, and thermal gradients within complex internal geometries that may be inaccessible to direct measurement. However, simulation results must be validated against experimental data to ensure accuracy, particularly for novel AM-produced geometries with potentially unique surface roughness characteristics.

Standardized test protocols should specify heat load ranges, coolant properties, flow rates, inlet temperatures, and ambient conditions. The ASTM G175 standard for thermal performance testing of liquid cooling systems provides a foundation, though modifications are often necessary to address the specific characteristics of AM-produced liquid metal manifolds.

Comparative analysis should evaluate AM-produced manifolds against traditional manufacturing methods using identical testing conditions. Performance metrics should be normalized by relevant parameters such as volume, weight, or power consumption to enable fair comparison across different design approaches. Additionally, long-term performance stability testing is essential to evaluate potential degradation mechanisms such as corrosion, erosion, or clogging that may affect thermal performance over time.

Uncertainty analysis must be incorporated into all benchmarking methodologies, accounting for measurement errors, environmental variations, and manufacturing tolerances. This statistical approach ensures that performance improvements attributed to AM techniques are genuinely significant rather than artifacts of measurement variability.

The primary thermal performance metrics for liquid metal cooling manifolds include heat transfer coefficient, thermal resistance, pressure drop, coolant flow rate, and temperature uniformity across the cooled surface. These metrics must be measured under controlled conditions that simulate real-world operational environments, including varying heat loads and ambient temperatures.

Experimental setups for benchmarking typically involve thermal test beds equipped with precision temperature sensors, flow meters, pressure transducers, and heat flux sensors. Infrared thermography provides valuable non-contact temperature distribution data across manifold surfaces, while embedded thermocouples offer precise point measurements at critical locations. For comprehensive evaluation, both steady-state and transient thermal response characteristics should be documented.

Computational fluid dynamics (CFD) simulations complement physical testing by providing detailed insights into flow patterns, pressure distributions, and thermal gradients within complex internal geometries that may be inaccessible to direct measurement. However, simulation results must be validated against experimental data to ensure accuracy, particularly for novel AM-produced geometries with potentially unique surface roughness characteristics.

Standardized test protocols should specify heat load ranges, coolant properties, flow rates, inlet temperatures, and ambient conditions. The ASTM G175 standard for thermal performance testing of liquid cooling systems provides a foundation, though modifications are often necessary to address the specific characteristics of AM-produced liquid metal manifolds.

Comparative analysis should evaluate AM-produced manifolds against traditional manufacturing methods using identical testing conditions. Performance metrics should be normalized by relevant parameters such as volume, weight, or power consumption to enable fair comparison across different design approaches. Additionally, long-term performance stability testing is essential to evaluate potential degradation mechanisms such as corrosion, erosion, or clogging that may affect thermal performance over time.

Uncertainty analysis must be incorporated into all benchmarking methodologies, accounting for measurement errors, environmental variations, and manufacturing tolerances. This statistical approach ensures that performance improvements attributed to AM techniques are genuinely significant rather than artifacts of measurement variability.

Material Compatibility and Sustainability Considerations

Material compatibility represents a critical consideration in the development of liquid metal cooling manifolds through additive manufacturing processes. The interaction between liquid metals (typically gallium-based alloys such as Galinstan or eutectic gallium-indium) and container materials presents significant engineering challenges. These liquid metals exhibit corrosive behavior toward many conventional metals, particularly aluminum and copper, which are ironically the most thermally conductive and commonly used in cooling applications. The corrosion mechanism involves liquid metal embrittlement and dissolution of the container material, leading to structural degradation and potential system failure.

Recent research has focused on identifying compatible materials that can withstand prolonged contact with liquid metals. Nickel-based alloys, stainless steel variants (particularly 316L), and certain ceramics have demonstrated promising resistance to liquid metal corrosion. Surface treatment technologies, including specialized coatings like tungsten carbide or silicon nitride, have also emerged as effective strategies for enhancing compatibility between liquid metals and container materials.

From a sustainability perspective, additive manufacturing of liquid metal cooling manifolds offers several environmental advantages compared to traditional manufacturing methods. The process significantly reduces material waste through precise deposition of only the required material, contrasting sharply with subtractive manufacturing techniques that can waste up to 90% of raw materials. Additionally, the ability to produce complex geometries in a single process eliminates the need for multiple manufacturing steps and joining operations, reducing energy consumption and associated carbon emissions.

Life cycle assessment studies indicate that the environmental footprint of additively manufactured cooling systems can be 30-45% lower than conventionally manufactured alternatives when considering the entire product lifecycle. This advantage stems primarily from material efficiency, extended product lifespan due to optimized designs, and reduced transportation requirements through localized manufacturing capabilities.

The recyclability of materials used in these systems presents both challenges and opportunities. While many metal powders used in additive manufacturing can be reclaimed and reused, the complex multi-material nature of cooling manifolds may complicate end-of-life processing. Research into design-for-disassembly approaches and material separation technologies is ongoing to address these challenges and further enhance the sustainability profile of these advanced cooling solutions.

Regulatory frameworks governing the use of liquid metals in cooling applications continue to evolve, with particular attention to potential environmental impacts from leakage or improper disposal. Manufacturers must navigate these regulations while developing systems that balance performance requirements with environmental responsibility and long-term sustainability objectives.

Recent research has focused on identifying compatible materials that can withstand prolonged contact with liquid metals. Nickel-based alloys, stainless steel variants (particularly 316L), and certain ceramics have demonstrated promising resistance to liquid metal corrosion. Surface treatment technologies, including specialized coatings like tungsten carbide or silicon nitride, have also emerged as effective strategies for enhancing compatibility between liquid metals and container materials.

From a sustainability perspective, additive manufacturing of liquid metal cooling manifolds offers several environmental advantages compared to traditional manufacturing methods. The process significantly reduces material waste through precise deposition of only the required material, contrasting sharply with subtractive manufacturing techniques that can waste up to 90% of raw materials. Additionally, the ability to produce complex geometries in a single process eliminates the need for multiple manufacturing steps and joining operations, reducing energy consumption and associated carbon emissions.

Life cycle assessment studies indicate that the environmental footprint of additively manufactured cooling systems can be 30-45% lower than conventionally manufactured alternatives when considering the entire product lifecycle. This advantage stems primarily from material efficiency, extended product lifespan due to optimized designs, and reduced transportation requirements through localized manufacturing capabilities.

The recyclability of materials used in these systems presents both challenges and opportunities. While many metal powders used in additive manufacturing can be reclaimed and reused, the complex multi-material nature of cooling manifolds may complicate end-of-life processing. Research into design-for-disassembly approaches and material separation technologies is ongoing to address these challenges and further enhance the sustainability profile of these advanced cooling solutions.

Regulatory frameworks governing the use of liquid metals in cooling applications continue to evolve, with particular attention to potential environmental impacts from leakage or improper disposal. Manufacturers must navigate these regulations while developing systems that balance performance requirements with environmental responsibility and long-term sustainability objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!