Gallium-Based Liquid Metal TIMs: Properties, Risks And Mitigations

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Metal TIMs Evolution and Objectives

Thermal Interface Materials (TIMs) have evolved significantly over the past decades, transitioning from conventional materials like thermal greases and pads to more advanced solutions. Liquid metal TIMs, particularly gallium-based formulations, represent one of the most significant advancements in this evolution. Initially developed for specialized applications in the early 2000s, these materials have gained substantial attention in the past decade due to their exceptional thermal conductivity properties that far exceed traditional TIMs.

The historical progression of liquid metal TIMs began with mercury-based solutions, which were eventually phased out due to toxicity concerns. The shift to gallium-based alloys, particularly those incorporating indium and tin (such as Galinstan), marked a critical turning point in the development of safer liquid metal alternatives. These materials maintain the beneficial properties of liquid metals while mitigating many of the health risks associated with mercury.

From 2010 onwards, commercial applications of gallium-based liquid metal TIMs began to emerge, primarily in high-performance computing and specialized thermal management systems. The technology has since expanded into broader markets, including consumer electronics, where thermal management requirements continue to intensify with increasing power densities and miniaturization trends.

The fundamental objective of developing gallium-based liquid metal TIMs is to address the thermal bottleneck in modern electronic systems. As semiconductor devices continue to increase in power density while decreasing in size, the efficient dissipation of heat has become a critical limiting factor in performance and reliability. Traditional TIMs with thermal conductivities in the range of 1-10 W/mK are increasingly inadequate for these demanding applications.

Gallium-based liquid metal TIMs, with thermal conductivities typically ranging from 20-80 W/mK, aim to provide a step-change improvement in thermal management capabilities. The primary technical objectives include achieving consistent thermal performance over extended operational lifetimes, ensuring compatibility with a wide range of substrate materials, and developing formulations that mitigate the inherent risks associated with liquid metals, such as electrical conductivity and corrosivity.

Looking forward, the evolution of gallium-based liquid metal TIMs is expected to focus on several key areas: development of non-corrosive formulations, creation of application methods suitable for mass production, enhancement of long-term stability, and reduction in manufacturing costs. These objectives align with the broader industry trend toward more efficient thermal management solutions that can support the continued advancement of high-performance electronic systems across multiple sectors.

The historical progression of liquid metal TIMs began with mercury-based solutions, which were eventually phased out due to toxicity concerns. The shift to gallium-based alloys, particularly those incorporating indium and tin (such as Galinstan), marked a critical turning point in the development of safer liquid metal alternatives. These materials maintain the beneficial properties of liquid metals while mitigating many of the health risks associated with mercury.

From 2010 onwards, commercial applications of gallium-based liquid metal TIMs began to emerge, primarily in high-performance computing and specialized thermal management systems. The technology has since expanded into broader markets, including consumer electronics, where thermal management requirements continue to intensify with increasing power densities and miniaturization trends.

The fundamental objective of developing gallium-based liquid metal TIMs is to address the thermal bottleneck in modern electronic systems. As semiconductor devices continue to increase in power density while decreasing in size, the efficient dissipation of heat has become a critical limiting factor in performance and reliability. Traditional TIMs with thermal conductivities in the range of 1-10 W/mK are increasingly inadequate for these demanding applications.

Gallium-based liquid metal TIMs, with thermal conductivities typically ranging from 20-80 W/mK, aim to provide a step-change improvement in thermal management capabilities. The primary technical objectives include achieving consistent thermal performance over extended operational lifetimes, ensuring compatibility with a wide range of substrate materials, and developing formulations that mitigate the inherent risks associated with liquid metals, such as electrical conductivity and corrosivity.

Looking forward, the evolution of gallium-based liquid metal TIMs is expected to focus on several key areas: development of non-corrosive formulations, creation of application methods suitable for mass production, enhancement of long-term stability, and reduction in manufacturing costs. These objectives align with the broader industry trend toward more efficient thermal management solutions that can support the continued advancement of high-performance electronic systems across multiple sectors.

Market Analysis for Advanced Thermal Interface Materials

The global thermal interface materials (TIM) market is experiencing robust growth, driven primarily by increasing thermal management demands in electronics, automotive, and industrial applications. The market was valued at approximately $2.7 billion in 2022 and is projected to reach $4.5 billion by 2028, representing a compound annual growth rate (CAGR) of 8.9%. This growth trajectory is particularly significant for advanced TIMs like gallium-based liquid metals, which are positioned to capture premium segments of this expanding market.

Gallium-based liquid metal TIMs represent a high-performance segment within the broader TIM market, currently accounting for about 3% of the total market value but growing at nearly twice the rate of conventional materials. This accelerated adoption is primarily driven by high-performance computing, gaming systems, and data center applications where thermal management requirements exceed the capabilities of traditional solutions.

The demand for gallium-based liquid metal TIMs is geographically concentrated, with North America and East Asia representing the largest markets. North America accounts for approximately 38% of global consumption, driven by data center expansion and high-performance computing applications. East Asia follows at 35%, with significant demand from consumer electronics manufacturing and emerging gaming hardware production.

Industry verticals show distinct adoption patterns for these advanced materials. The computing sector currently represents the largest application segment (42%), followed by telecommunications (23%), automotive electronics (18%), and industrial applications (12%). The remaining 5% is distributed across various niche applications including aerospace and medical devices.

Price sensitivity varies significantly across these segments. High-performance computing and gaming applications demonstrate lower price elasticity, with customers willing to pay premium prices for superior thermal performance. In contrast, consumer electronics manufacturers show greater price sensitivity, creating market pressure for cost-optimized formulations that maintain essential performance characteristics.

The competitive landscape for gallium-based liquid metal TIMs remains relatively concentrated, with five manufacturers controlling approximately 70% of global production capacity. This concentration has implications for pricing power and supply chain resilience, particularly as demand continues to grow. Market forecasts indicate potential supply constraints by 2025 if production capacity expansion does not keep pace with projected demand growth.

Customer adoption barriers include concerns about long-term reliability, potential electrical conductivity risks, and application complexity. These factors have limited penetration in certain risk-averse sectors such as automotive and medical devices, despite the clear thermal performance advantages these materials offer.

Gallium-based liquid metal TIMs represent a high-performance segment within the broader TIM market, currently accounting for about 3% of the total market value but growing at nearly twice the rate of conventional materials. This accelerated adoption is primarily driven by high-performance computing, gaming systems, and data center applications where thermal management requirements exceed the capabilities of traditional solutions.

The demand for gallium-based liquid metal TIMs is geographically concentrated, with North America and East Asia representing the largest markets. North America accounts for approximately 38% of global consumption, driven by data center expansion and high-performance computing applications. East Asia follows at 35%, with significant demand from consumer electronics manufacturing and emerging gaming hardware production.

Industry verticals show distinct adoption patterns for these advanced materials. The computing sector currently represents the largest application segment (42%), followed by telecommunications (23%), automotive electronics (18%), and industrial applications (12%). The remaining 5% is distributed across various niche applications including aerospace and medical devices.

Price sensitivity varies significantly across these segments. High-performance computing and gaming applications demonstrate lower price elasticity, with customers willing to pay premium prices for superior thermal performance. In contrast, consumer electronics manufacturers show greater price sensitivity, creating market pressure for cost-optimized formulations that maintain essential performance characteristics.

The competitive landscape for gallium-based liquid metal TIMs remains relatively concentrated, with five manufacturers controlling approximately 70% of global production capacity. This concentration has implications for pricing power and supply chain resilience, particularly as demand continues to grow. Market forecasts indicate potential supply constraints by 2025 if production capacity expansion does not keep pace with projected demand growth.

Customer adoption barriers include concerns about long-term reliability, potential electrical conductivity risks, and application complexity. These factors have limited penetration in certain risk-averse sectors such as automotive and medical devices, despite the clear thermal performance advantages these materials offer.

Gallium-Based Liquid Metal TIMs: Current Status and Challenges

Gallium-based liquid metal thermal interface materials (TIMs) have emerged as promising alternatives to conventional thermal management solutions due to their exceptional thermal conductivity and conformability. Currently, these materials demonstrate thermal conductivity values ranging from 20-40 W/m·K, significantly outperforming traditional thermal greases and pads that typically achieve only 3-10 W/m·K. This superior performance has positioned gallium-based TIMs as potential game-changers for high-performance computing, power electronics, and aerospace applications.

Despite their promising properties, several critical challenges impede widespread commercial adoption. The most significant concern is gallium's inherent corrosivity toward aluminum and certain other metals. When in contact with aluminum, gallium rapidly penetrates grain boundaries, causing catastrophic structural degradation through liquid metal embrittlement (LME). This phenomenon has been documented extensively in laboratory settings, with complete structural failure occurring within hours of contact in some cases.

Another substantial challenge is the tendency of gallium-based alloys to oxidize rapidly when exposed to air. Surface oxidation creates a passivation layer that, while providing some protection against further oxidation, can compromise thermal performance and complicate application processes. The oxide skin formation alters the rheological properties of these materials, potentially reducing their effectiveness as TIMs over extended operational periods.

Manufacturing integration presents additional hurdles. Current application methods for gallium-based TIMs lack standardization and often require specialized equipment or techniques to ensure uniform distribution and optimal thermal contact. The high surface tension of these materials can lead to inconsistent coverage, creating thermal hotspots that undermine overall cooling efficiency.

Long-term reliability remains inadequately characterized, with limited data available on performance degradation under thermal cycling, mechanical stress, and environmental exposure. Preliminary studies indicate potential issues with pump-out effects and migration during thermal cycling, raising concerns about maintenance requirements and system longevity.

From a global perspective, research and development efforts are concentrated primarily in North America, East Asia, and Europe. Chinese institutions have published extensively on novel gallium alloy formulations, while American and European entities focus more on integration technologies and mitigation strategies for corrosion issues. This geographical distribution of expertise has created distinct approaches to addressing the fundamental challenges of gallium-based TIMs.

Cost considerations further complicate adoption, as gallium's market price has experienced significant volatility in recent years. Current production methods for high-purity gallium suitable for TIM applications remain relatively expensive compared to conventional thermal interface materials, creating economic barriers to widespread implementation.

Despite their promising properties, several critical challenges impede widespread commercial adoption. The most significant concern is gallium's inherent corrosivity toward aluminum and certain other metals. When in contact with aluminum, gallium rapidly penetrates grain boundaries, causing catastrophic structural degradation through liquid metal embrittlement (LME). This phenomenon has been documented extensively in laboratory settings, with complete structural failure occurring within hours of contact in some cases.

Another substantial challenge is the tendency of gallium-based alloys to oxidize rapidly when exposed to air. Surface oxidation creates a passivation layer that, while providing some protection against further oxidation, can compromise thermal performance and complicate application processes. The oxide skin formation alters the rheological properties of these materials, potentially reducing their effectiveness as TIMs over extended operational periods.

Manufacturing integration presents additional hurdles. Current application methods for gallium-based TIMs lack standardization and often require specialized equipment or techniques to ensure uniform distribution and optimal thermal contact. The high surface tension of these materials can lead to inconsistent coverage, creating thermal hotspots that undermine overall cooling efficiency.

Long-term reliability remains inadequately characterized, with limited data available on performance degradation under thermal cycling, mechanical stress, and environmental exposure. Preliminary studies indicate potential issues with pump-out effects and migration during thermal cycling, raising concerns about maintenance requirements and system longevity.

From a global perspective, research and development efforts are concentrated primarily in North America, East Asia, and Europe. Chinese institutions have published extensively on novel gallium alloy formulations, while American and European entities focus more on integration technologies and mitigation strategies for corrosion issues. This geographical distribution of expertise has created distinct approaches to addressing the fundamental challenges of gallium-based TIMs.

Cost considerations further complicate adoption, as gallium's market price has experienced significant volatility in recent years. Current production methods for high-purity gallium suitable for TIM applications remain relatively expensive compared to conventional thermal interface materials, creating economic barriers to widespread implementation.

Current Gallium-Based TIM Solutions and Implementation Methods

01 Thermal properties of gallium-based liquid metal TIMs

Gallium-based liquid metal thermal interface materials (TIMs) exhibit exceptional thermal conductivity, significantly higher than conventional thermal greases or pastes. These materials maintain their liquid state at room temperature, allowing them to conform perfectly to surface irregularities and eliminate air gaps between heat sources and heat sinks. The high thermal conductivity combined with excellent wetting properties enables efficient heat dissipation in electronic devices, making them particularly valuable for high-performance computing applications and power electronics where thermal management is critical.- Thermal properties and conductivity of gallium-based liquid metal TIMs: Gallium-based liquid metal thermal interface materials (TIMs) exhibit exceptional thermal conductivity, significantly higher than conventional thermal greases or pastes. These materials maintain their liquid state at room temperature, allowing them to conform perfectly to surface irregularities and eliminate air gaps between heat sources and heat sinks. The high thermal conductivity combined with excellent wetting properties enables efficient heat transfer in electronic devices, particularly in high-power applications where thermal management is critical.

- Oxidation and corrosion risks of gallium-based liquid metals: A significant challenge with gallium-based liquid metal TIMs is their tendency to oxidize when exposed to air, forming a thin oxide layer that can affect performance. More concerning is their corrosive nature toward certain metals, particularly aluminum, which can lead to structural degradation of components. This corrosive behavior occurs through liquid metal embrittlement and galvanic corrosion mechanisms, potentially compromising the integrity of electronic packages and heat sinks over time. Protective coatings and compatible material selection are necessary to mitigate these risks.

- Composition and formulation innovations for improved stability: Recent advancements in gallium-based liquid metal TIMs focus on modified compositions to address inherent limitations. By alloying gallium with metals like indium, tin, and zinc in specific ratios, researchers have developed formulations with optimized melting points, wettability, and reduced corrosivity. Some innovations incorporate nano-additives or surface-active agents to improve stability and prevent metal separation. These modified formulations maintain the high thermal conductivity benefits while reducing risks associated with traditional gallium alloys.

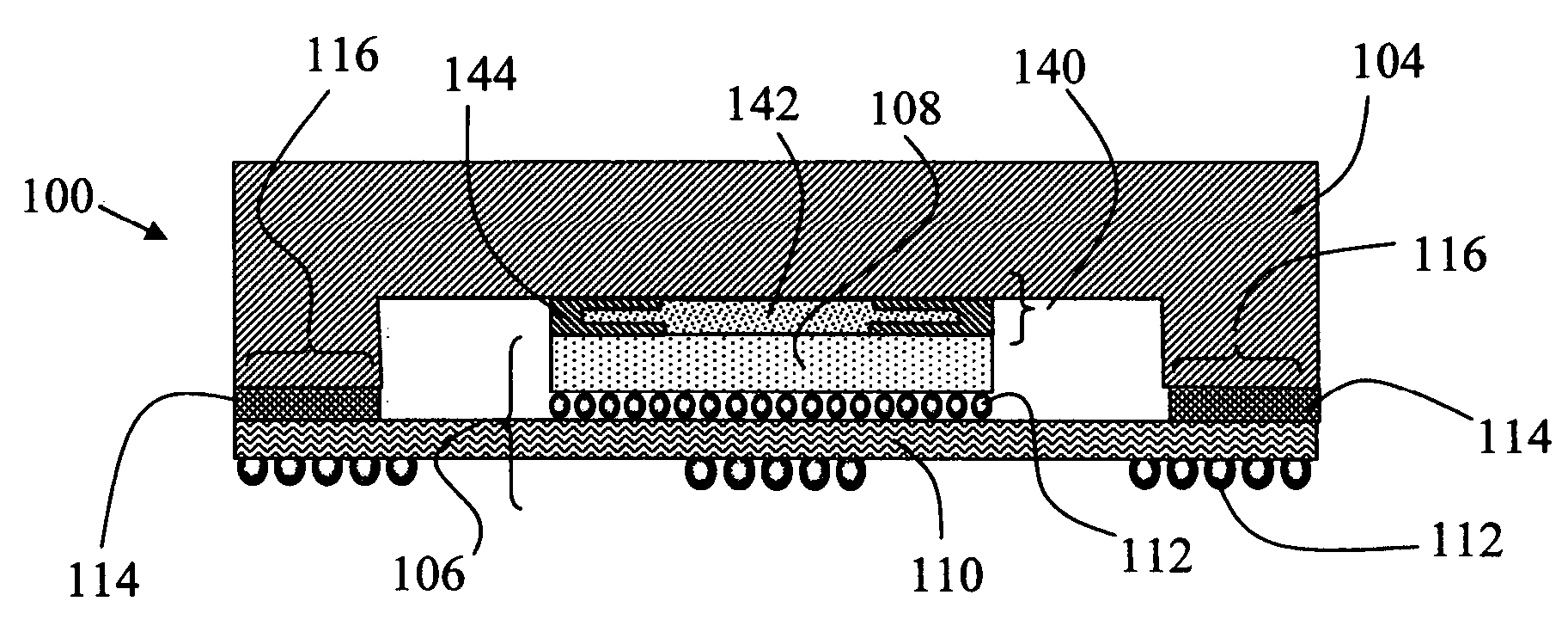

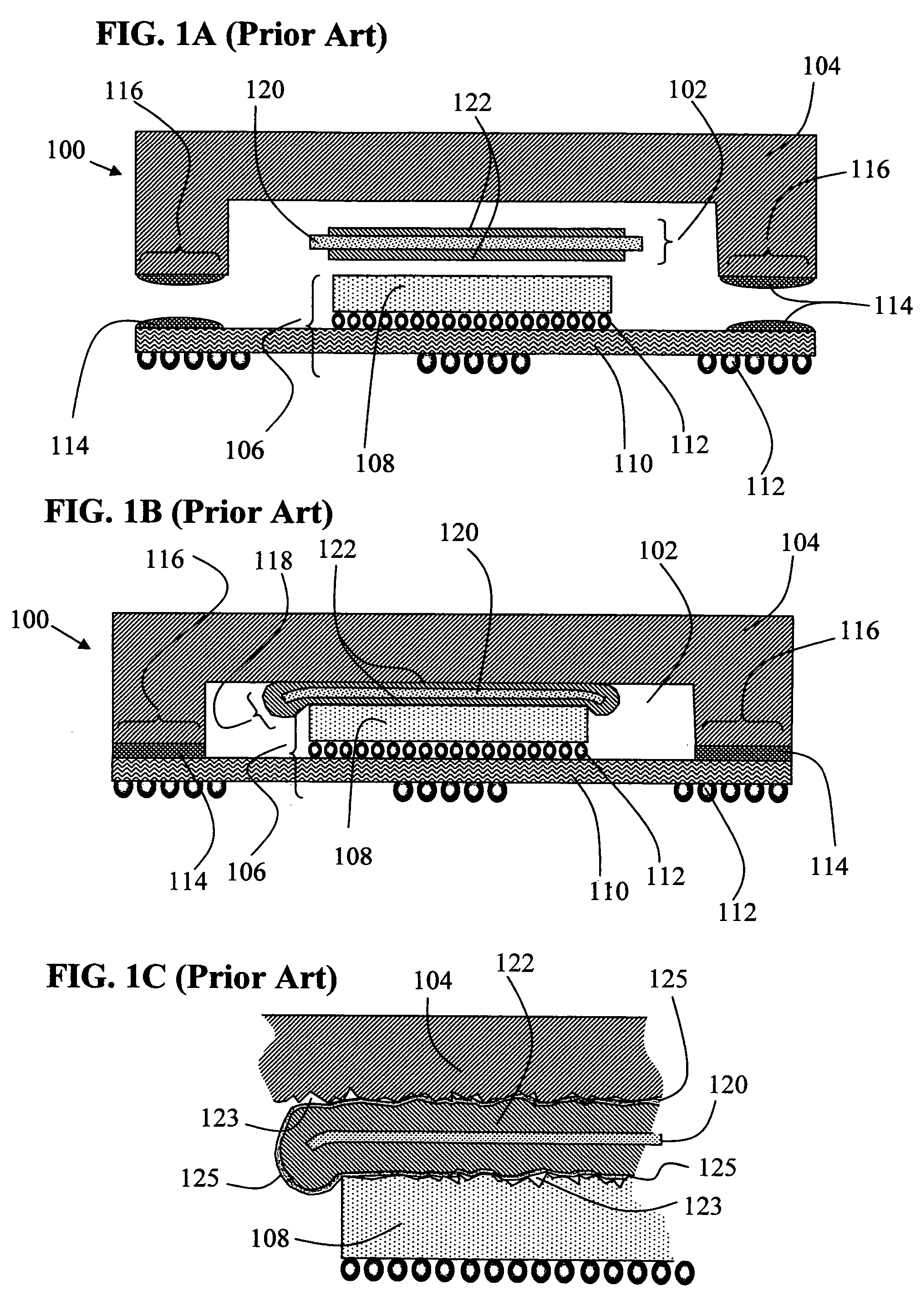

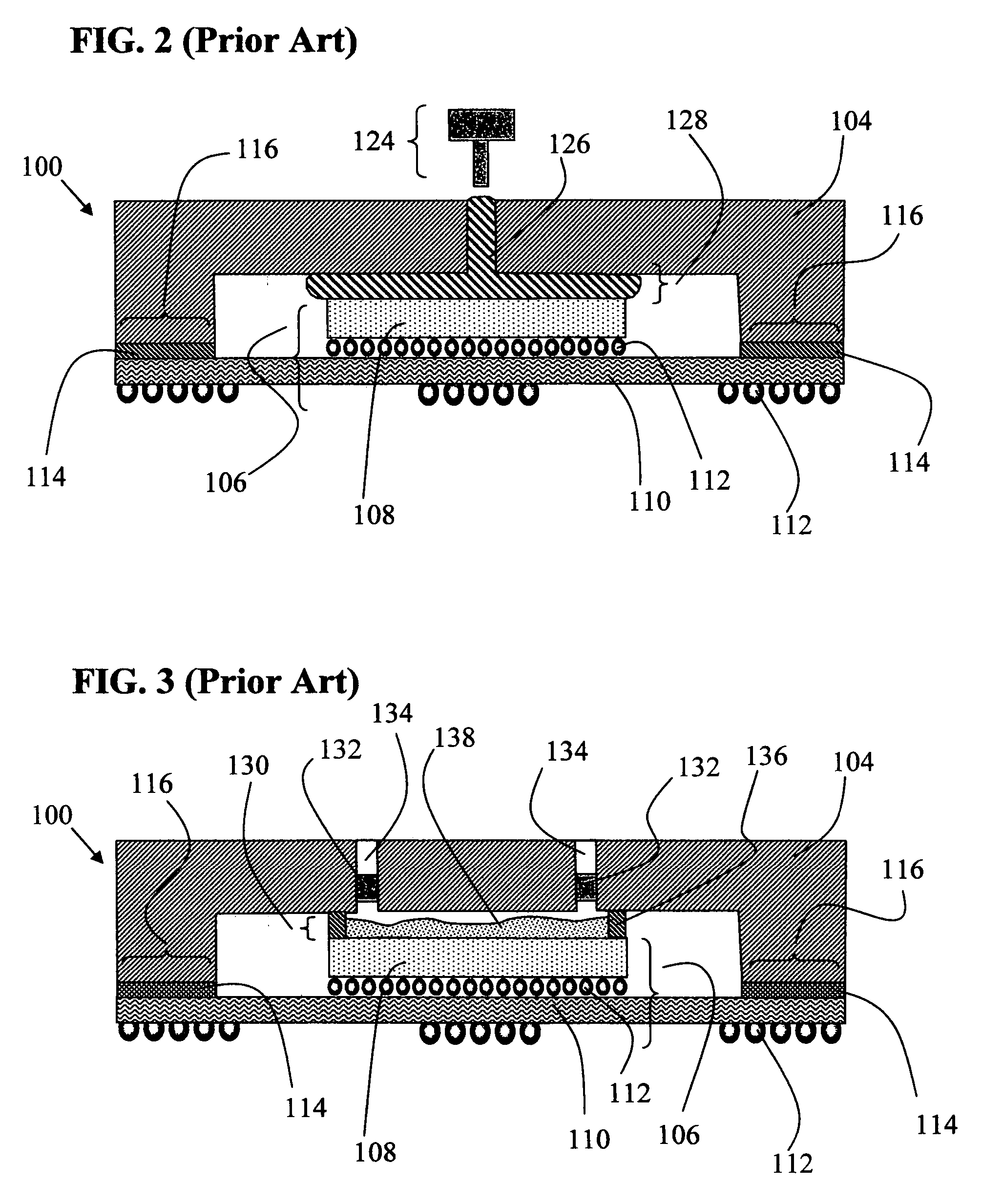

- Application methods and containment strategies: Specialized application and containment techniques have been developed to safely deploy gallium-based liquid metal TIMs. These include encapsulation systems that prevent leakage and migration, which could otherwise cause electrical shorts in electronic components. Vacuum application methods help eliminate air bubbles that would reduce thermal performance. Some patents describe reusable application tools and dispensing systems designed to control the precise amount of material applied while minimizing exposure to air and preventing contamination. Proper containment is essential for long-term reliability in electronic devices.

- Environmental and safety considerations: Gallium-based liquid metal TIMs present several environmental and safety challenges that must be addressed. While gallium itself has low toxicity compared to mercury, these materials can still pose risks if improperly handled or disposed of. Some formulations contain more hazardous elements that require special handling protocols. Patents describe environmentally friendly compositions with reduced toxic components and manufacturing processes designed to minimize waste. Safety considerations include preventing skin contact, as these materials can stain and potentially irritate skin, and implementing proper cleanup procedures for spills to prevent equipment damage.

02 Oxidation and corrosion risks of gallium-based liquid metals

A significant challenge with gallium-based liquid metal TIMs is their tendency to oxidize when exposed to air, forming a thin oxide layer that can affect performance. More concerning is their corrosive nature toward certain metals, particularly aluminum, which can lead to structural degradation of components. The gallium can penetrate grain boundaries in aluminum, causing embrittlement and eventual failure. This corrosive behavior necessitates careful material selection for adjacent components and often requires protective coatings or barrier layers when implementing these TIMs in electronic assemblies.Expand Specific Solutions03 Composition and formulation innovations

Recent innovations in gallium-based liquid metal TIMs focus on optimizing compositions to enhance performance while mitigating risks. These formulations typically include gallium as the base metal, alloyed with indium, tin, or zinc to adjust properties such as melting point, viscosity, and surface tension. Some formulations incorporate additives to improve wetting behavior, reduce oxidation, or enhance thermal conductivity. Nanoparticle additions, such as silver or copper particles, are being explored to further boost thermal performance while maintaining the flowability advantages of liquid metals.Expand Specific Solutions04 Application methods and containment strategies

Specialized application and containment methods have been developed to address the challenges of working with gallium-based liquid metals. These include encapsulation techniques using polymers or metal barriers to prevent leakage and contact with incompatible materials. Various dispensing methods ensure precise application in the correct quantity and location. Some approaches involve pre-applied TIMs in sealed packages that rupture upon installation, while others use frame-like structures to contain the liquid metal within the thermal interface area. These containment strategies are crucial for preventing electrical shorts and protecting surrounding components from potential corrosion.Expand Specific Solutions05 Long-term reliability and environmental considerations

The long-term reliability of gallium-based liquid metal TIMs presents both advantages and concerns. While these materials resist pump-out effects common with traditional thermal greases, they may experience performance degradation over time due to oxidation or migration. Environmental cycling can affect their behavior, particularly in applications with significant temperature fluctuations. From an environmental perspective, while gallium itself has low toxicity compared to mercury or lead, proper handling and disposal protocols are necessary. Research continues on recyclability methods and environmental impact assessment of these materials throughout their lifecycle.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Liquid Metal TIMs

The Gallium-Based Liquid Metal TIMs market is in its growth phase, with increasing adoption in high-performance thermal management applications. The global market is expanding rapidly, driven by demands for efficient cooling solutions in electronics and computing. Intel, TSMC, and Indium Corporation are leading commercial development, while research institutions like ITRI and Technical Institute of Physics & Chemistry CAS are advancing fundamental technologies. Chinese companies such as Yunnan Jingchuang and Ningbo Xinruiqingke are emerging as significant players. The technology is approaching maturity for specific applications but still faces challenges in corrosion control and long-term reliability that companies like LG Chem and Dow Silicones are addressing through innovative formulations and encapsulation techniques.

Intel Corp.

Technical Solution: Intel has developed advanced gallium-based liquid metal thermal interface materials (TIMs) to address thermal management challenges in high-performance computing systems. Their solution incorporates a proprietary gallium-indium-tin alloy (Galinstan) formulation with enhanced wetting properties and controlled oxidation characteristics. Intel's approach includes a protective barrier coating technology that prevents direct contact between the liquid metal and aluminum or copper components, mitigating the risk of corrosion and amalgamation. The company has implemented a multi-layer TIM structure where the liquid metal is encapsulated within a polymer matrix, allowing for thermal conductivity exceeding 80 W/m·K while maintaining long-term reliability. Intel's research has demonstrated that their gallium-based TIMs can reduce thermal resistance by up to 40% compared to traditional thermal greases, enabling more efficient heat dissipation from next-generation processors with increasing power densities.

Strengths: Superior thermal conductivity compared to conventional TIMs, allowing for more efficient cooling of high-performance processors. The encapsulation technology effectively addresses corrosion concerns while maintaining excellent thermal performance. Weaknesses: Higher manufacturing complexity and cost compared to traditional thermal solutions. Potential reliability concerns in extreme temperature cycling environments due to the liquid nature of the material.

Yunnan Jingchuang Liquid Metal Thermal Control Technology R & D Co., Ltd.

Technical Solution: Yunnan Jingchuang has pioneered a comprehensive gallium-based liquid metal TIM solution specifically engineered for high-power electronics cooling applications. Their proprietary technology features a gallium-indium-tin-zinc quaternary alloy system with optimized surface tension and thermal conductivity exceeding 73 W/m·K. The company has developed an innovative surface treatment process that creates a nanoscale oxide layer on the liquid metal droplets, effectively controlling viscosity while maintaining excellent thermal properties. Their solution incorporates anti-corrosion additives that form protective films on metal surfaces, significantly reducing the galvanic corrosion typically associated with gallium-based liquid metals. Yunnan Jingchuang has also developed specialized application methods including vacuum-assisted deposition and precision dispensing technologies that ensure uniform coverage and minimal air entrapment. Field testing has demonstrated that their liquid metal TIMs can reduce junction temperatures by up to 15°C compared to conventional thermal greases in high-power computing applications.

Strengths: Exceptional thermal performance with conductivity values significantly higher than traditional TIMs. The proprietary surface treatment technology effectively addresses wetting and viscosity challenges. Their anti-corrosion additives provide a practical solution to one of the major limitations of gallium-based TIMs. Weaknesses: Limited long-term reliability data in diverse operating environments. The specialized application process requires precise control and may be challenging to implement in mass production environments.

Key Patents and Research on Corrosion Mitigation Techniques

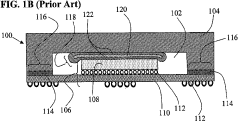

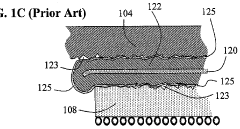

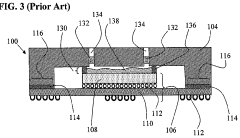

Liquid metal thermal interface material system

PatentInactiveUS20060118925A1

Innovation

- A metal thermal interface system that incorporates a metallic seal member with a metallic interface composition, including oxygen gettering elements and corrosion inhibitors, which flows and fills surface asperities to create a hermetic seal, reducing thermal impedance and preventing migration, while using moisture desiccants and encapsulants to enhance stability and reliability.

Liquid metal thermal interface material system

PatentWO2009100374A1

Innovation

- A metallic thermal interface system that uses a liquid metal alloy with oxygen gettering elements and a design featuring a metallic seal member that flows and fills surface asperities, incorporates vents to expel entrapped air, and includes a diaphragm layer to accommodate excess material, ensuring a hermetic and thin interface for efficient heat transfer.

Environmental and Safety Considerations for Liquid Metal TIMs

The environmental and safety considerations for gallium-based liquid metal TIMs require careful attention as these materials become more prevalent in thermal management applications. Gallium and its alloys present unique challenges that must be addressed to ensure safe handling, application, and disposal throughout their lifecycle.

Gallium-based liquid metals pose potential environmental concerns due to their chemical reactivity. When improperly disposed of, these materials can contaminate soil and water systems, potentially affecting aquatic ecosystems. The metal's ability to amalgamate with other metals raises concerns about its interaction with environmental metallic infrastructure and natural systems. Current research indicates that while gallium itself has relatively low toxicity compared to mercury, its environmental persistence and long-term ecological effects remain under investigation.

Workplace safety protocols for handling liquid metal TIMs must address several risk factors. Direct skin contact with gallium alloys can cause irritation and potential metal absorption through the skin. Proper personal protective equipment, including impermeable gloves, lab coats, and eye protection, is essential for personnel working with these materials. Additionally, the potential for gallium to embrittle certain metals necessitates careful material selection for storage containers and application tools.

The corrosive nature of gallium-based liquid metals presents significant challenges for electronic component integrity. When in contact with aluminum, gallium rapidly penetrates grain boundaries, causing structural degradation. This reaction can compromise the integrity of aluminum heat sinks and other components, potentially leading to catastrophic failures in electronic systems. Protective barriers and compatible material selection are critical mitigation strategies.

Regulatory frameworks governing liquid metal TIMs continue to evolve as their usage expands. Current regulations primarily focus on transportation safety, workplace exposure limits, and waste disposal protocols. Companies implementing these materials must stay informed about regional variations in regulatory requirements and emerging standards as scientific understanding of these materials advances.

Sustainable end-of-life management for gallium-based TIMs represents an emerging challenge. Recovery and recycling processes for gallium from electronic waste are technically feasible but not yet widely implemented. The development of efficient recycling methodologies could significantly reduce the environmental footprint of these materials while recovering valuable gallium resources, aligning with circular economy principles and addressing supply chain vulnerabilities for this critical metal.

Gallium-based liquid metals pose potential environmental concerns due to their chemical reactivity. When improperly disposed of, these materials can contaminate soil and water systems, potentially affecting aquatic ecosystems. The metal's ability to amalgamate with other metals raises concerns about its interaction with environmental metallic infrastructure and natural systems. Current research indicates that while gallium itself has relatively low toxicity compared to mercury, its environmental persistence and long-term ecological effects remain under investigation.

Workplace safety protocols for handling liquid metal TIMs must address several risk factors. Direct skin contact with gallium alloys can cause irritation and potential metal absorption through the skin. Proper personal protective equipment, including impermeable gloves, lab coats, and eye protection, is essential for personnel working with these materials. Additionally, the potential for gallium to embrittle certain metals necessitates careful material selection for storage containers and application tools.

The corrosive nature of gallium-based liquid metals presents significant challenges for electronic component integrity. When in contact with aluminum, gallium rapidly penetrates grain boundaries, causing structural degradation. This reaction can compromise the integrity of aluminum heat sinks and other components, potentially leading to catastrophic failures in electronic systems. Protective barriers and compatible material selection are critical mitigation strategies.

Regulatory frameworks governing liquid metal TIMs continue to evolve as their usage expands. Current regulations primarily focus on transportation safety, workplace exposure limits, and waste disposal protocols. Companies implementing these materials must stay informed about regional variations in regulatory requirements and emerging standards as scientific understanding of these materials advances.

Sustainable end-of-life management for gallium-based TIMs represents an emerging challenge. Recovery and recycling processes for gallium from electronic waste are technically feasible but not yet widely implemented. The development of efficient recycling methodologies could significantly reduce the environmental footprint of these materials while recovering valuable gallium resources, aligning with circular economy principles and addressing supply chain vulnerabilities for this critical metal.

Reliability Testing and Performance Validation Methodologies

Reliability testing and performance validation of Gallium-based liquid metal TIMs require comprehensive methodologies to ensure their effectiveness and safety in real-world applications. Standard thermal performance testing typically includes thermal resistance measurements under various operating conditions, utilizing techniques such as laser flash analysis, steady-state heat flow methods, and transient thermal impedance testing. These methods provide critical data on thermal conductivity, interface resistance, and heat dissipation capabilities across different temperature ranges and pressure conditions.

Long-term reliability testing protocols must address the unique challenges posed by liquid metal TIMs, particularly their potential for migration and corrosion. Thermal cycling tests, ranging from -40°C to 150°C for 1,000+ cycles, are essential to evaluate performance stability under thermal stress conditions that simulate accelerated aging. High-temperature storage tests at 125°C for extended periods (1,000+ hours) help assess material degradation and potential chemical reactions with contact surfaces.

Power cycling tests that simulate actual device operation conditions provide insights into the TIM's behavior under realistic workloads. These tests typically involve rapid temperature changes and are conducted for several thousand cycles to evaluate fatigue resistance and long-term stability. Humidity and environmental stress testing (85°C/85% RH) are particularly important for gallium-based TIMs to assess their behavior in moisture-rich environments.

Mechanical reliability testing includes vibration and shock testing according to industry standards such as JEDEC JESD22-B103 and MIL-STD-810, which are critical for applications in automotive, aerospace, and portable electronics. Pump-out and dry-out tests evaluate the TIM's resistance to material migration under thermal and mechanical stress, a particular concern for gallium-based liquid metals.

Corrosion testing methodologies must be specifically adapted for gallium-based TIMs, including galvanic corrosion tests with various substrate materials, particularly aluminum. Accelerated corrosion testing using salt spray exposure (ASTM B117) and electrochemical impedance spectroscopy provide quantitative data on corrosion rates and mechanisms.

Performance validation should include comparative benchmarking against conventional TIMs using standardized test vehicles and reference designs. This allows for direct comparison of thermal resistance, reliability, and application-specific performance metrics. Advanced imaging techniques such as X-ray microscopy and scanning acoustic microscopy enable non-destructive evaluation of the TIM layer integrity and potential material migration over time, providing valuable insights into failure mechanisms and performance degradation pathways.

Long-term reliability testing protocols must address the unique challenges posed by liquid metal TIMs, particularly their potential for migration and corrosion. Thermal cycling tests, ranging from -40°C to 150°C for 1,000+ cycles, are essential to evaluate performance stability under thermal stress conditions that simulate accelerated aging. High-temperature storage tests at 125°C for extended periods (1,000+ hours) help assess material degradation and potential chemical reactions with contact surfaces.

Power cycling tests that simulate actual device operation conditions provide insights into the TIM's behavior under realistic workloads. These tests typically involve rapid temperature changes and are conducted for several thousand cycles to evaluate fatigue resistance and long-term stability. Humidity and environmental stress testing (85°C/85% RH) are particularly important for gallium-based TIMs to assess their behavior in moisture-rich environments.

Mechanical reliability testing includes vibration and shock testing according to industry standards such as JEDEC JESD22-B103 and MIL-STD-810, which are critical for applications in automotive, aerospace, and portable electronics. Pump-out and dry-out tests evaluate the TIM's resistance to material migration under thermal and mechanical stress, a particular concern for gallium-based liquid metals.

Corrosion testing methodologies must be specifically adapted for gallium-based TIMs, including galvanic corrosion tests with various substrate materials, particularly aluminum. Accelerated corrosion testing using salt spray exposure (ASTM B117) and electrochemical impedance spectroscopy provide quantitative data on corrosion rates and mechanisms.

Performance validation should include comparative benchmarking against conventional TIMs using standardized test vehicles and reference designs. This allows for direct comparison of thermal resistance, reliability, and application-specific performance metrics. Advanced imaging techniques such as X-ray microscopy and scanning acoustic microscopy enable non-destructive evaluation of the TIM layer integrity and potential material migration over time, providing valuable insights into failure mechanisms and performance degradation pathways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!